DIN 2076 vs. ASTM A 877

DIN 2076 vs. ASTM A 877

Uploaded by

tobypadfieldCopyright:

Available Formats

DIN 2076 vs. ASTM A 877

DIN 2076 vs. ASTM A 877

Uploaded by

tobypadfieldOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DIN 2076 vs. ASTM A 877

DIN 2076 vs. ASTM A 877

Uploaded by

tobypadfieldCopyright:

Available Formats

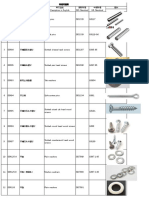

DIN 2076 Patented, cold-drawn carbon steel (material spec DIN 17223 Part 1) Generally used for high

static stress, low dynamic stress applications

ASTM A 877 93 Oil-tempered, Cr-Si alloy steel Valve spring quality, suitable for high dynamic stresses at moderately elevated temperatures No defects allowed within 1% of outer diameter (hot-acid etch) Decarburization must be < 25 m (measured from outer diameter) Stringent requirements for inclusion levels (ASTM E 45)

No real requirements for surface defects No real requirement for decarburization limit No real requirement for inclusion levels

KEY POINTS Both materials have similar requirements for tensile strength, but microstructure (oil-tempered alloy steel vs. patented, cold-drawn carbon steel) differences result in better load loss for Cr-Si, especially at 150 C. The additional requirements for surface defects, decarburization, and inclusion levels make the Cr-Si Valve Spring Quality wire substantially better for fatigue applications.

You might also like

- Human Physiology: An Integrated Approach (7th Edition) : Visit The Link Below To Download The Full Version of This BookDocument23 pagesHuman Physiology: An Integrated Approach (7th Edition) : Visit The Link Below To Download The Full Version of This Bookileanecordlexk627100% (8)

- Spares Parts Cannibalisation ProcedureDocument3 pagesSpares Parts Cannibalisation ProcedureThang Nguyen Hung100% (1)

- 螺丝代号对照表Document38 pages螺丝代号对照表里差No ratings yet

- Joint Affidavit of Undertaking PCO MH DENRDocument2 pagesJoint Affidavit of Undertaking PCO MH DENRGio Trieste100% (5)

- Din 2577Document2 pagesDin 2577zaharievNo ratings yet

- 2814 01jan08t51626Document20 pages2814 01jan08t51626Philip_8300% (1)

- ISO 12128 Lubrication Holes, Grooves and Pockets - Dimensions, Types, Designation and Their Application To Bearing BushesDocument10 pagesISO 12128 Lubrication Holes, Grooves and Pockets - Dimensions, Types, Designation and Their Application To Bearing BushesJuan DuenasNo ratings yet

- Confidential InformationDocument1 pageConfidential InformationJose HansonNo ratings yet

- Marriage Fail Point BookDocument113 pagesMarriage Fail Point BookOlga Altman de Bencosme100% (1)

- En 10029Document5 pagesEn 10029PHAMTOAINo ratings yet

- Din 2393-2Document0 pagesDin 2393-2Yalavarthi ChandrasekharNo ratings yet

- Fittings Din11852 Din11850Document14 pagesFittings Din11852 Din11850dingobk1No ratings yet

- Din 2616 PDFDocument2 pagesDin 2616 PDFTahresNo ratings yet

- 25CrMo4 (EN 10083 3)Document2 pages25CrMo4 (EN 10083 3)mohsen_267No ratings yet

- Article - Tolerances To BS en 10061 For Hot Rolled Hexagon Stainless Steel BarsDocument4 pagesArticle - Tolerances To BS en 10061 For Hot Rolled Hexagon Stainless Steel BarsExcel Hydro Pneumatics (INDIA) EHPINo ratings yet

- DIN ArruelasDocument35 pagesDIN ArruelasSigurbjörnBárðarsonNo ratings yet

- Din 562Document5 pagesDin 562Santosh IngaleNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- Din 2605 PDFDocument3 pagesDin 2605 PDFPedro Montes MarinNo ratings yet

- BS en 1057 Tube Sizes - Crane Copper TubeDocument2 pagesBS en 1057 Tube Sizes - Crane Copper TubestarykltNo ratings yet

- Disc SpringDocument2 pagesDisc SpringParth AuradkarNo ratings yet

- Parallel Pin Din 6325-2.5X12 PDFDocument1 pageParallel Pin Din 6325-2.5X12 PDFFer VFNo ratings yet

- Din 522 Tol. ArruelasDocument1 pageDin 522 Tol. ArruelasBruno ParoliniNo ratings yet

- 140 E Requirements For Approved EUR PalletsDocument4 pages140 E Requirements For Approved EUR PalletsSaša AritonovićNo ratings yet

- Table According To DIN 7985Document4 pagesTable According To DIN 7985SidharthaNo ratings yet

- Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeDocument0 pagesDin 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeAdrian MarinNo ratings yet

- EN 10025: 2004 Is The New European Standard For Structural SteelDocument6 pagesEN 10025: 2004 Is The New European Standard For Structural Steelvimalkumar_trjNo ratings yet

- Din 3357-4-1981Document5 pagesDin 3357-4-1981олегNo ratings yet

- Iso 4762 1997Document9 pagesIso 4762 1997Emir AkçayNo ratings yet

- Iso 228 1 2000Document9 pagesIso 228 1 2000Ulvi NebiyevNo ratings yet

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDocument4 pagesISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkNo ratings yet

- @@@ BS en 1057 Tube Sizes - Crane Copper TubeDocument2 pages@@@ BS en 1057 Tube Sizes - Crane Copper TubestarykltNo ratings yet

- Din 434Document1 pageDin 434RaduZapciroiuNo ratings yet

- Din 319Document3 pagesDin 319Horváth VivienNo ratings yet

- Abrazadera DIN 3567Document2 pagesAbrazadera DIN 3567Marisol EstradaNo ratings yet

- Din 1480 2005Document6 pagesDin 1480 2005PacoNo ratings yet

- Hexagonal Nuts6330Document1 pageHexagonal Nuts6330Augusto VincensiNo ratings yet

- Fabory Fasteners ASTM StudboltDocument13 pagesFabory Fasteners ASTM StudboltJohan ConradieNo ratings yet

- European Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarsDocument13 pagesEuropean Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarspraveenNo ratings yet

- Din 5401 PDFDocument12 pagesDin 5401 PDFLuciano FontesNo ratings yet

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranNo ratings yet

- An Overview of DIN - Deutsches Institut Für Normung - Valve StandardsDocument3 pagesAn Overview of DIN - Deutsches Institut Für Normung - Valve Standardslwwwl2No ratings yet

- TR ThreadsDocument4 pagesTR ThreadsBalasa Constantin MihaiNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Fittings - DIN 2616: VL Code 731Document2 pagesFittings - DIN 2616: VL Code 731RatheeshNo ratings yet

- DIN-975 Threaded RodsDocument1 pageDIN-975 Threaded RodsVictor MacoveiNo ratings yet

- DOZNA - 6000 KN - DIN-6319 PDFDocument4 pagesDOZNA - 6000 KN - DIN-6319 PDFzoranmiskovicNo ratings yet

- Toaz - Info Iso 8062-3-2007 Casting Tolerancepdf PRDocument1 pageToaz - Info Iso 8062-3-2007 Casting Tolerancepdf PRdineshramya190% (1)

- Din 950Document5 pagesDin 950Dule JovanovicNo ratings yet

- List of DIN Standards - 2006-04-20 PDFDocument4 pagesList of DIN Standards - 2006-04-20 PDFSerggie TabanaoNo ratings yet

- Din125 WasherDocument2 pagesDin125 WasherHieu TranvanNo ratings yet

- SN756 2005-02 eDocument4 pagesSN756 2005-02 eChristopher Lloyd100% (1)

- Specification For Plain Washers With Outside Diameter 3 × Inside DiameterDocument2 pagesSpecification For Plain Washers With Outside Diameter 3 × Inside DiameterArogya Raju PudhotaNo ratings yet

- Tower Bolts - Specification: Indian StandardDocument12 pagesTower Bolts - Specification: Indian StandardRamesh MankaniNo ratings yet

- Section Q: Splined Hubs, Drive KitsDocument8 pagesSection Q: Splined Hubs, Drive KitshaggNo ratings yet

- Screw, IsO 14583, PAN, Metric, TorxDocument1 pageScrew, IsO 14583, PAN, Metric, TorxDerekNo ratings yet

- Part List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)Document4 pagesPart List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)restu yanuar salamNo ratings yet

- DIN EN 14399 10 System HRC. Bolt and Nut Assemblies With CalDocument23 pagesDIN EN 14399 10 System HRC. Bolt and Nut Assemblies With CalNiranjan KumarNo ratings yet

- Din 2616 PDFDocument2 pagesDin 2616 PDFALEKSANDARNo ratings yet

- Din 2393-2 PDFDocument5 pagesDin 2393-2 PDFKarthikeyan NNo ratings yet

- NTPC 7th June Chetal SirDocument25 pagesNTPC 7th June Chetal Siraksit2102No ratings yet

- 20230505055345-Dicrest Plus E82c 04 2023Document5 pages20230505055345-Dicrest Plus E82c 04 2023RobertNo ratings yet

- Advances in Welding For Sanitary DesignsDocument34 pagesAdvances in Welding For Sanitary Designskart_rlNo ratings yet

- Codes For Vessels/Heat ExchangersDocument23 pagesCodes For Vessels/Heat ExchangersChiheb KaanicheNo ratings yet

- 02 The Healthy Mind Platter USDocument25 pages02 The Healthy Mind Platter USFitri NihNo ratings yet

- Metro Rail and The CityDocument12 pagesMetro Rail and The Citypavel1989tNo ratings yet

- Research ProjectDocument54 pagesResearch Projectyusufgarba2002No ratings yet

- Oxalate (C2O4) Is - 2 and Water Is Neutral The Overall Charge of The Molecule Is - 1, Therefore, CR Must Be +3 To Balance The Equation.:)Document2 pagesOxalate (C2O4) Is - 2 and Water Is Neutral The Overall Charge of The Molecule Is - 1, Therefore, CR Must Be +3 To Balance The Equation.:)Roberto PichardoNo ratings yet

- Dramatic Play: To Help Support Dramatic Play at Home Try Some of The Following StrategiesDocument2 pagesDramatic Play: To Help Support Dramatic Play at Home Try Some of The Following StrategiesShawna PassmoreNo ratings yet

- Typhoon Yolanda: An Analysis On The Impact of Natural Disasters and Effectiveness of Disaster ManagementDocument7 pagesTyphoon Yolanda: An Analysis On The Impact of Natural Disasters and Effectiveness of Disaster ManagementAl TheaNo ratings yet

- Counter Flow CoolerDocument37 pagesCounter Flow Coolerahmed hegazyNo ratings yet

- DCI Yearbook 2011 PDFDocument256 pagesDCI Yearbook 2011 PDFGaetan DufourNo ratings yet

- Coconut Climbing MachineDocument2 pagesCoconut Climbing MachineVon A. Damirez100% (1)

- Pubmed Ncbi NLM Nih Gov 16964366Document2 pagesPubmed Ncbi NLM Nih Gov 16964366Rezer JohnNo ratings yet

- RBI LAS Thurs 4 29 2021Document2 pagesRBI LAS Thurs 4 29 2021Cris Jay AnguloNo ratings yet

- 2 Organ SystemsDocument5 pages2 Organ SystemsBeaNo ratings yet

- CaveDocument6 pagesCaveKatrina MangaringNo ratings yet

- Air PollutionDocument18 pagesAir PollutionKimjinNo ratings yet

- Coins of Bangladesh 1971-2010Document42 pagesCoins of Bangladesh 1971-2010Ovi Nafisa Zabeen OviNo ratings yet

- A Comparative Study of Ola and Uber Customers in Delhi Post Covid New New 22Document10 pagesA Comparative Study of Ola and Uber Customers in Delhi Post Covid New New 22trivikram SahuNo ratings yet

- ELEC3130: Electric Machines and Power Systems 5.1 Induction Machines IDocument23 pagesELEC3130: Electric Machines and Power Systems 5.1 Induction Machines Isaif thuraonNo ratings yet

- G.R. No. 178741Document1 pageG.R. No. 178741Jefferson BagadiongNo ratings yet

- Performance ApprisalDocument63 pagesPerformance ApprisalravikumarreddytNo ratings yet

- Yyhh 8890Document9 pagesYyhh 8890HailuNo ratings yet

- Seizure Disorders: PathophysiologyDocument12 pagesSeizure Disorders: PathophysiologyjhcacbszkjcnNo ratings yet

- Francis Abaigar-Cot-English-4-Main-IdeaDocument11 pagesFrancis Abaigar-Cot-English-4-Main-IdeaFrancis AbaigarNo ratings yet

- Tiffany Chin CVDocument4 pagesTiffany Chin CVapi-455548272No ratings yet

- Empisal EOL4D Overlocker Manual 1 PDFDocument62 pagesEmpisal EOL4D Overlocker Manual 1 PDFWal Fler100% (1)

- The Analysis and Forecasting COVID-19 Cases in The United States Using Bayesian Structural Time Series ModelsDocument16 pagesThe Analysis and Forecasting COVID-19 Cases in The United States Using Bayesian Structural Time Series ModelsClaudyaNo ratings yet