Saes-L-108, 10112010

Saes-L-108, 10112010

Uploaded by

Sathishkumar DhamodaranCopyright:

Available Formats

Saes-L-108, 10112010

Saes-L-108, 10112010

Uploaded by

Sathishkumar DhamodaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saes-L-108, 10112010

Saes-L-108, 10112010

Uploaded by

Sathishkumar DhamodaranCopyright:

Available Formats

Engineering Standard

SAES-L-108

11 October 2010

S e l e c t i o n o f Va l v e s

Document Responsibility: Valves Standards Committee

Saudi Aramco DeskTop Standards

Table of Contents

1

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

General........................................................... 4

General Design Limitations............................ 6

Specific Valve Type Limitations...................... 8

Specific Service Limitations.......................... 10

Materials Limitations..................................... 12

Materials Appendix............................................. 14

Previous Issue: 21 March 2010 Next Planned Update: 11 October 2015

Revised paragraphs are indicated in the right margin

Primary contact: Shiha, Saad Mohammed on 966-3-8760163

CopyrightSaudi Aramco 2010. All rights reserved.

Page 1 of 1

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

Selection of Valves

Scope

1.1

This Standard covers limitations on the selection of all valves normally

classified under Saudi Aramco Materials System (SAMS) Class 04. This will

normally include ball, butterfly, check, choke, diaphragm, gate, globe, needle,

and plug valves used for on-off, for manual control service or for prevention of

reverse flow, as appropriate.

1.2

Specifically excluded from the scope are:

1.3

SAES-L-108

a)

Control, safety-relief, relief, surge relief, solenoid, pilot and other valves

classified under SAMS Class 34.

b)

Applications involving flues and chimneys, air conditioning and

ventilation ducts.

c)

Drilling and wellhead valves classified under SAMS Class 45.

Where applicable, this Standard supplements the requirements of ASME B31,

Code for Pressure Piping.

Conflicts and Deviations

2.1

Any conflicts between this standard and other applicable Saudi Aramco

Engineering Standards (SAESs), Materials System Specifications (SAMSSs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this standard in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

References

The selection of material and equipment, and the design, construction, maintenance, and

repair of equipment and facilities covered by this standard shall comply with the latest

edition of the references below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a

Mandatory Saudi Aramco Engineering

Requirement

Page 2 of 2

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Saudi Aramco Engineering Standards

SAES-B-017

Fire Water System Design

SAES-L-102

Regulated Vendor List for Valves

SAES-L-110

Limitations on Pipe Joints and Components

SAES-L-133

Corrosion Protection Requirements for

Pipelines/Piping

SAES-L-136

Pipe Selection and Restriction

Saudi Aramco Materials System Specifications

04-SAMSS-001

Gate Valves

04-SAMSS-002

Globe Valves

04-SAMSS-003

Additional Requirements for Low Temperature

Valves

04-SAMSS-005

Swing Check Valves

04-SAMSS-035

General Requirements for Valves

04-SAMSS-041

Expanding Plug Valve

04-SAMSS-042

4-Way Diverter Valves

04-SAMSS-048

Valve Inspection and Testing Requirements

04-SAMSS-049

Inspection & Testing Requirements for

API SPEC 6A 10,000 psi Valves

04-SAMSS-050

Thru-conduit Gate Valves

04-SAMSS-051

API SPED 6D Ball Valves

04-SAMSS-052

API SPEC 6A Ball Valves

09-SAMSS-080

Shop-Applied Baked Internal Coatings

09-SAMSS-091

Qualification Requirements for Shop-Applied

Internal FBE Coatings

Saudi Aramco Form and Data Sheet

6233-1-ENG

3.2

Valve Data Sheet

Industry Codes and Standards

American National Standards Institute/Fluid Controls Institute

ANSI/FCI 70.2

Control Valve Seat Leakage

Page 3 of 3

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

American Petroleum Institute

API SPEC 6A

Specification for Wellhead and Christmas Tree

Equipment

API SPEC 6D

Specification for Pipeline Valves

API SPEC 6FA

Specification for Fire Test for Valves

API STD 598

Valve Inspection and Testing

API STD 602

Compact Steel Gate Valves - Flanged, Threaded,

Welding, and Extended-Body Ends

API STD 607

Fire Test for Soft Seated Quarter-Turn Valves

API STD 609

Butterfly Valves, Lug-Type and Wafer-Type

American Society of Mechanical Engineers

ASME B16.5

Steel Pipe Flanges and Flanged Fittings

ASME B16.34

Valves - Flanged, Threaded, and Welding End

ASME B31

Code for Pressure Piping

British Standards Institution

BS 6755

Testing of Valves

Manufacturers Standardization Society of the Valve and Fittings Industry, Inc.

MSS SP-45

Bypass and Drain Connection Standard

National Association of Corrosion Engineers/International Standardization

Organization

NACE MR0175/ISO 15156 Petroleum and Natural Gas Industries

Materials for Use in H2S Containing

Environments in Oil and Gas Production

4

General

4.1

Valves shall be purchased from approved manufacturers listed in SAES-L-102.

Approval of purchase from manufacturers not listed in this document shall be

strictly governed by the provisions provided therein.

4.2

The selection of valves shall normally be limited to the materials, types and

sizes that are listed in SAMS Class 04 unless no suitable valve is listed.

Page 4 of 4

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

4.3

Whenever applicable, the relevant Saudi Aramco Materials System

Specifications (SAMSS's) listed in Section 3 of this Standard shall be included

in all requisitions.

4.4

At times it is necessary to purchase a valve that is generally similar to that

covered by an SAMSS but differing from it in some specific design,

construction, materials or performance characteristics. In such cases, the

SAMSS shall be included in the purchase requisition in addition to the required

modifications provided that these modifications are in accordance with all other

Mandatory Saudi Aramco Engineering Requirements.

4.5

All valve requisitions, except those for API SPEC 6A 10000 psi valves 2-1/16

inch and larger, shall reference 04-SAMSS-035, General Requirements for

Valves, and 04-SAMSS-048, Valve Inspection & Testing Requirements.

4.6

Form 6233-1-ENG, Valve Data Sheet, shall be filled out and attached to every

non-SAMS class 04 valve purchase requisition.

4.7

Field Tests

4.7.1

Testing location shall be specified by proponent.

4.7.2

If requested by the proponent, all new valves designated for isolation

service (as specified by the Proponent) shall be subjected to a high

pressure hydrostatic seat test prior to installation in the line.

4.7.3

A low pressure pneumatic seat test at 35 kPa (5 psig) shall be

substituted for the high pressure hydrostatic seat test for flare system

valves.

4.7.4

Buttweld and socketweld end valves in nominal pipe size (NPS) 2

inches and smaller are exempt from the above field testing

requirements.

4.7.5

Test procedures, pressures, durations, and leakage acceptance criteria

shall be equal to those that the valves were originally purchased to. All

resilient (soft) seated isolation valves shall have zero leakage.

4.8

The use of ANSI FCI 70.2 to specify seat leakage criteria is not permitted

without the specific approval of the Chairman of the Valves Standards

Committee.

4.9

Trim material includes the stem, the body and closure seating surfaces,

bushings, pins, springs, guides, and any other small parts in contact with the

service fluid.

Page 5 of 5

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

General Design Limitations

5.1

5.2

5.3

Bonnet/Cover

5.1.1

Pressure seal bonnet valves shall be used only in steam or other clean

non-corrosive services. They are permitted in other services only if the

body has been inlayed in the bonnet sealing area with an 18-8 material

or higher alloy suitable for the service.

5.1.2

Bonnets retained by split rings and sealed by means of an O-ring or a

seal-welded membrane shall only be used after approval by the

Chairman of the Valves Standards Committee.

5.1.3

The use of welded bonnet valves in hydrocarbon services shall be

limited to NPS 4 inch and smaller provided it is approved by the

Manager of the responsible operating department.

5.1.4

Screwed bonnet and screwed body valves shall not be used in any

hydrocarbon or hazardous material services unless the bonnets and

body end connections are tack welded to the body or provided with

locking pin.

5.1.5

Straight-thru union body check valves shall be used only in portions of

piping systems where pipe unions are permissible.

5.1.6

Union bonnet valves shall not be used in any hydrocarbon or hazardous

material services.

End Connections

5.2.1

The requirements of SAES-L-110 are applicable to all valves.

5.2.2

Integral flanged valve bodies with tapped bolt holes shall not be used

except with specific approval of the Proponent and the Chairman of the

Valves Standards Committee. These requirements do not apply to lug

type valves.

5.2.3

If requested by the proponent, critical valves, welding end valves, and

others that cannot be removed from the line without serious difficulty

(e.g., in restrained pipelines), NPS 8 inch and larger, shall be of a type

that is repairable in the line (top-entry) provided it is specifically

approved by the Chairman of the Valves Standards Committee.

Ratings

5.3.1

Valves utilizing soft seats do not necessarily follow ASME B16.5 or

Page 6 of 6

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

other industry standard pressure/temperature relationships at

temperatures above 38C. The specific Vendor's literature shall be

consulted when the pressure-temperature ratings for higher

temperatures have not been specified by the relevant SAMSS or the

Purchase Order.

5.3.2

5.4

In hydrocarbon services, the minimum body rating of threaded and

socketweld end NPS 2 inch and smaller valves shall be equivalent to

API STD 602 Class 800.

Sizes

Valves shall be subject to the same size limitations specified for pipe in

SAES-L-136.

5.5

Stem Packing

Isolation valves NPS 3 inch and larger in hydrocarbon services shall not be

provided with pure polymer/elastomer stem packing or stem seals unless the

valves have been qualified as fire-safe, except as permitted by an approved

SAMSS.

5.6

5.7

Actuators

5.6.1

The need for power actuation of all valves NPS 12 inch and larger in

all pressure classes shall be reviewed with the responsible operating

organization.

5.6.2

Chainwheel operation shall not be provided for emergency isolation

valves or valves having a threaded body connection.

Installation

5.7.1

Gate valves with back-seats shall not be installed with their stems

below the horizontal except in the following cases: (a) clean services,

(b) when they function as isolation valves in pressure relief and flare

system piping, and (c) when in utility or other similar non-critical

services (firewater is considered to be critical service).

Note: Critical / non-critical valves shall be specified by proponent and

specifically approved by the Chairman of the Valves Standards

Committee.

5.7.2

Seal welding

5.7.2.1

All threaded connections on valve bodies and associated

piping shall be seal welded.

Page 7 of 7

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Exceptions:

Exceptions are those connections that are frequently

disassembled (such as vent and drain plugs) and those

that are adjacent to elements that contain small moving

parts (such as injection fittings and body relief valves).

5.7.2.2

5.8

Seal welding shall follow the general requirements of

SAES-L-110.

Coating

The body of steel gate valve shall not be internally coated unless the wedge is

rubber-lined.

Specific Valve Type Limitations

6.1

Ball Valves

Lever operated ball valves shall be equipped with a handwheel or self-locking

handle to prevent accidental operation.

6.2

Butterfly Valves

6.2.1

Concentric butterfly valves, such as the API STD 609 Category A type

(typically with internal rubber linings), are permitted only in nonhydrocarbon applications.

6.2.2

The use of high performance butterfly valves in hydrocarbon service

shall be limited to a maximum rating of Class 900. Minimum

requirements in hydrocarbon service are as follows:

a)

Valves shall be designed in accordance with API STD 609

Category B valves with offset-seat type construction.

b)

Valves shall be qualified fire-safe to either API SPEC 6FA,

API STD 607, or BS 6755 Part 2, except in applications where

other components of the system are not designed to be firesafe

such as Single-Point-Mooring (SPM) systems.

c)

The body shall be of the lug-type design with tapped bolt holes,

unless the (double) flanged type has been specified. Use of the

wafer-type body is not permitted.

d)

Valves shall be full-rated. In systems where the normal operating

pressure is 103 kPa (15 psig) or less, the valve may be specified

Page 8 of 8

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

with half-rated trim (approximately 50% of the full-rated

pressure).

e)

6.3

Valves shall be bi-directional, although they may have a

"preferred" direction. Valves shall be installed in the "preferred"

direction indicated on the valve.

Check Valves

6.3.1

Dual and single plate wafer check and swing check valves shall not be

used in reciprocating pump and compressor suction and discharge

services or similar pulsating services.

6.3.2

A non-slam internal-spring-assisted type check valve shall be installed

at the discharge of pumps and compressors. Other check valve types

shall be specifically approved by the Chairman of the Valves Standards

Committee.

6.3.3

If requested by the proponent, for parallel pump systems with

individual pump discharge piping of NPS 20 inch and larger, a

hydraulic analysis shall be conducted to verify that the selected check

valves have the correct dynamic response to prevent slamming and

limit pressure surge to an acceptable level. The analysis shall include

consideration of the "worst case" operating mode scenario.

6.3.4

For all sizes NPS 4 inch and above, a turbulence-free minimum

distance of 5 pipe diameters upstream and 2 pipe diameters

downstream of every check valve shall be maintained. No pipe fittings

such as elbows, reducers, tees, etc., or flow restricting devices such as

orifices, control valves, etc., shall be installed in these zones unless

specifically approved by the Chairman of the Valves Standards

Committee. Valves in intermittent service and valves in skid-mounted

systems are exempt from these requirements.

6.3.5

Check valves in sizes NPS 3 inch and above shall not be installed in

vertical lines, unless specifically approved by the Chairman of the

Valve Standards Committee. Valves in skid-mounted systems are

exempt from this requirement.

6.3.6

Check valves in hydrocarbon service up to Class 600 shall either have

a lug-type body with tapped bolt holes or a flanged body. In higher

ratings, a flanged body is mandatory. Wafer-type bodies are not

permitted in any hydrocarbon service.

6.3.7

Spring-assisted non-slam piston check valves (also referred to as

nozzle check valves) shall be long-pattern with face-to-face

Page 9 of 9

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

dimensions in accordance with API SPEC 6D. Short-pattern valves

shall not be used without the review and approval of the Chairman of

the Valves Standards Committee.

6.4

Plug Valves (Hydrocarbon service only)

Flanged plug valves in hydrocarbon service shall be of the inverted lubricated

pressure balanced design, except that Class 150 valves NPS 6 inch and smaller

may have a standard plug with springs for balancing the plug.

Specific Service Limitations

7.1

7.2

Low Temperature Services

7.1.1

Valves in services between -45C and -18C shall meet the

requirements of 04-SAMSS-003. If the service is also sour,

compliance with NACE MR0175/ISO 15156 shall be specifically

stated in the purchase requisition.

7.1.2

All valves in services below -45C shall be full austenitic stainless steel

and shall meet the requirements of 04-SAMSS-003, paragraph 6.3.

7.1.3

All valves in service below -100C shall have an extended bonnet.

7.1.4

For LPG or high pressure gases which autorefrigerate, an upstream

gate valve shall be installed in addition to the throttling valve in any

line that discharges to the atmosphere or to a low pressure system.

Underwater Valves

Isolation valves shall be ball type per 04-SAMSS-051 with a minimum rating of

Class 300. The flange face shall be the ring joint type.

7.3

Pressure Relief Valve Piping

Isolation valves in stand-alone pressure relief valve inlet and discharge piping

shall be gate, ball, high performance butterfly (flanged) or plug valves that can

be car-sealed open. A gate valve in this service shall be installed with the stem

in or below the horizontal position. For clean gas service, the valves shall be

soft seated with double block and bleed capability if temperature permits.

7.4

Flare Systems

7.4.1

Isolation valves in flare system piping shall be gate, ball, high

performance butterfly or plug valves.

Page 10 of 10

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

7.4.2

7.5

SAES-L-108

Selection of Valves

A gate valve in this service shall be installed with the stem in or below

the horizontal position.

Emergency Isolation Valves

Emergency isolation valves (EIVs) shall be gate, ball, high performance

butterfly (flanged) or plug valves. Soft seated valves shall be fire safe in

accordance with API STD 607, API SPEC 6FA, or BS 6755 Part 2. Metal

seated valves shall meet the same requirement if they do not have graphite seals

or their standard specified leakage rate exceeds that of API STD 598.

7.6

Firewater Systems

Buried sectionalizing valves in firewater systems shall meet the requirements of

SAES-B-017.

7.7

Drains and Vents

Atmospheric drain and vent valves shall be provided with a plug or blind on the

discharge side.

7.8

Storage Tanks and Vessels

Flangeless valves shall not be used as the first block valve against storage tanks

or vessels containing hazardous materials unless specifically approved by the

Chairman of the Valves Standards Committee.

7.9

7.10

API SPEC 6A 10,000 psi services

7.9.1

Valves shall only be purchased from manufacturers approved in

accordance with SAES-L-102.

7.9.2

Valves shall be tested and inspected in accordance with 04-SAMSS-049.

Scraper Trap Valves

7.10.1

Scraper trap mainline isolation valves shall be full bore thru-conduit

gate or ball valves.

7.10.2

Drain valves shall be inverted pressure balanced lubricated plug valves

with Stellite hardfacing on the plug and body seating surfaces.

7.10.3

Kicker valves and vent valves shall be inverted pressure balanced

lubricated plug valves.

7.10.4

The scraper trap isolation valve and the kicker valve shall have a

minimum trim metallurgy of SS F 51 regardless of service. In

Page 11 of 11

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

addition, the valve seat pockets (applicable to spring loaded seats only)

shall be specified to have an Inconel 625 weld overlay. The

requirements of this paragraph override the materials requirements

listed in the Appendix, unless those are more stringent.

7.11

7.12

Instrumentation root isolation valves

7.11.1

Instrumentation root isolation valves shall be API STD 602 gate

valves. Approval of equivalents shall be referred to the Chairman of

the Valves Standards Committee.

7.11.2

Modular valve assemblies consisting of a root isolation valve together

with bleed/vent and other types of valves and instruments are permitted

subject to specific review and approval by the Chairman of the Valves

Standards Committee on a case-by-case basis.

Steam service

Isolation valves, NPS 2 inch and larger, in Class 600 and higher rated systems

shall be parallel slide gate valves equipped with a cavity pressure relief system.

Other gate type shall be specifically approved by the Chairman of the Valves

Standards Committee.

7.13

Blowdown Valves

Blowdown valves in gas pipelines shall be plug valves.

7.14

Bypass/equalization valves

Mainline bypass/equalization valves in gas service shall be inverted pressure

balanced lubricated plug valves.

Materials Limitations

8.1

Valves with bodies of cast iron, ductile iron, or low melting point alloys (such as

brass or bronze) shall not be used in hydrocarbon services.

8.2

Valves with steel bodies shall be used in the following cases:

8.3

a)

The first valve on all tanks and other vessels if failure could create a

personnel or fire hazard or result in a large monetary loss.

b)

In hazardous areas where it is essential that the valve not fail in a fire.

Minimum material requirements are specified in the attached Materials

Appendix, except as modified above. Refer to paragraph 4.3 for cases where the

required materials differ from those in the SAMSS.

Page 12 of 12

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

8.4

11 October 2010

SAES-L-108

Selection of Valves

When austenitic stainless steels are to be seal-welded, welded or overlaid, low

carbon grades shall be specified.

Revision Summary

Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued

with editorial changes to reflect the changes in committee members list.

Page 13 of 13

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Materials Appendix

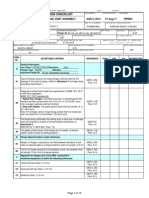

Table I Service and Application Requirements Valve Body and Trim Materials

Environment

Conditions

Conc.(%)

Temp.(C)

Valve Materials

Body

Trim

Remarks

Acid, Hydrochloric

LT 37

5 - 50

PVC

B-2

PVC

B-2

No ferric ions or other

oxidants for B-2

Acid, Hydrofluoric

non-oxidizing

1 - 70

GT 65

5 - 50

5 - 40

M400

PTFE

C-276

PTFE

No glass or glass reinforced

plastics; no titanium,

zirconium or tantalum

Acid, Hydrofluoric

(aerated or oxidizing)

All conc.

to 50

20

20

Acid, Nitric

1 - 70

70 - 99

5 - 50

30 max.

304L (6)

304L

304L

304L

304L is preferred to 316L for

nitric acid

Acid, Phosphoric

1 - 85

5 - 50

316

G-3(X)

316L

G-3(X)

Applies to chloride or fluoride

free grades of phosphoric

acid only

Acid, Sulfuric(8)

or Sulfurous

90 -100+

1 -103

to 60

1 - 100

to 50

to 65

to 65

100

316

20

CPVC

C-276

316L

20

CPVC

C-276

ADIP (AminoDiisopropanol)

20 - 30

5 - 150

CS

316

Air or Nitrogen gas

N/A

0 - 400

CS

BR

410

BR

Ammonia,

Anhydrous (10)

100

0 - 50

CS

410

Carbon Dioxide

dry

wet

100

LT 100

0 - 150

5 - 90

CS

316

410

316

Chlorine,

dry (12)

100

0 - 70

wet (13)

LT 100

0 - 70

CS

M400

PVC

C-276

M400

M400

PVC

C-276

PVC

CPVC

C-276

PVC

CPVC

C-276

Chlorine/Water

1-5

to 50

50 - 80

to 80

No copper alloys allowed

No copper alloys allowed

For castings, Hastelloy C-4

is preferred to C-276

For castings, Hastelloy C-4

is preferred to C-276

(Refer to General and Specific Notes at the end of Table 1)

Page 14 of 14

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table I (Cont'd)

Environment

Crude Oil or

Product (15)

Conditions

Conc.(%)

Temp.(C)

Valve Materials

Body

Trim

N/A

to 220

CS

ENP

to 280

CS

CS

CS

410

316

TC

280 to 340

340 to 500

CrMo5

316

410

316

CS

CS

CS

316(X)

410

316(X)

316

316

Remarks

Up to 10% water cut only

(10 year projected rate)

TEFZEL or PEEK soft seals

and seats shall be specified if

valves will be exposed to

acidizing conditions

Diglycolamine

(DGA) or

Diethanolamine

(DEA)

to 100

to 65

20 - 70

5 - 190

Flare Lines

N/A

to 400

CS

CS

410

316

Freon

100

0 to 70

-100 to 0

CS

316

410

316

Hydrocarbon Gas

including Khuff

Gas (15, 18)

N/A

-18 to 220

- 18 to 280

CS

CS

CS

CS

ENP

410

316

TC

ENP trim not permitted

for wet or sour gas

(Ref: SAES-L-133

para 3.1,3.2,3.3)

Hydrogen (16)

100

0 - 220

CS

CS

316(X)

CrMo22

316(X)

316

ENP

410

316(X)

410

316(X)

316

Same restriction on ENP as

above

220 to 325

325 to 400

Use 316 bodied valves where

304 or 316S.S. pipe is

employed or for throttling

applications

Hypochlorite,

Sodium or Calcium

to 5

5 - 50

PVC

C-276

PVC

C-276

Treat same as chlorine/water

solutions

Light Hydrocarbons

(Butane, Ethane,

Hexane, Methane,

Pentane and

Propane) and

NGL

100

-18 to 220

-18 to 400

CS

CS

CS

CS

LTS

304

316

ENP

410

316

TC

316

304

316

ENP trim not permitted for

wet or sour gas

Lube Oil

100

CS

304

316

410

304

316

-45 to -18

LT -45

5 - 120

(Refer to General and Specific Notes at the end of Table 1)

Page 15 of 15

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table I (Cont'd)

Environment

Conditions Valve Materials

Conc.(%)

Temp.(C)

Body

Naphtha

100

0 - 150

CS

CS

410

316(X)

Sewer, Oily Water

N/A

5 - 50

DI (7)

Br(20)

Sewer,

Storm or

Sanitary

N/A

5 - 50

DI (7)

Br (20)

PVC

Br(20)

Br(20)

PVC

Sodium

Hydroxide

50

5 - 50

20

316(X)

M400

M400 (2)

M400

304L(X)

316

M400

M400

Trim

Remarks

20

5 - 50

5 - 80

80 - 100

D2

316(X)

CS

M400(X)

CS

304L(X)

CS

CS

M400

Steam

100

120 - 400

400 - 480

CS

CRMoll

410

410

Steam

Condensate

100

5 - 120

CS

CS

410

410

Sulfur Dioxide

(Solution)

0.5

C-276

C-276

Solution in deaerated seawater, pH 1.5

Sulfur Molten

100

GT 107

CS

316

Keep dry. Moisture causes

corrosion

N/A

0 - 100

CS

D1 (7)

Br

CS

410

Br

Br

316

Includes deaerated and/or

inhibited sea, raw, well water

Zeolite softened, chilled, and

boiler feed water. pH GT 6,

oxygen LT 25 ppb

N/A

5 - 50

Br (20)

PVC

CS (26)

D1 (7)

Br (20)

CPVC

CS (26)

Br (20)

PVC

316

Br (20)

Br (20)

CPVC

316

50 - 80

Water

Non-corrosive

(oxygen free or

(inhibited)

Potable (Sweet)

50 - 72

Seat rings shall be overlayed

with Stellite. For Class 600

systems and higher, all

seating areas shall be

overlayed

(Refer to General and Specific Notes at the end of Table 1)

Page 16 of 16

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table I (Cont'd)

Environment

Saline

(includes all

untreated sea,

raw, well, and

aquifier waters)

(Aerated, corrosive)

(14, 28, 29)

Soft or Pure

Conditions

Conc.(%)

Temp.(C)

Valve Materials

Body

Trim

N/A

SSS

SSS

Br (20)

SSS

Ti

Br (20)

For sour brine, formation and

disposal water, and other

highly corrosive waters such

as untreated sea water,

Wasia water, upto NPS

4-inch. (21,23)

CS

SSS

CS (24)

CS

DI

Br (20)

316 (27)

Br (20)

For larger sizes, body shall

be internally lined or coated.

(22)

Br (20)

D2

DI (7)

Br (20)

Br (20)

Br (20)

For low pressure utility

service waters (raw water,

well water) which are not as

aggressive.

PVC

304

316

PVC

304

316

Includes Zeolite softened,

distilled or demineralized.

N/A

5 - 80

5 - 500

Remarks

General Notes:

(A)

All valve designs shall incorporate features required to resist galling of mating surfaces by means of necessary hardness

differentials, weld overlays, galling resistant material combinations, etc.

(B)

Trim material includes the stem, the body and closure seating surfaces, bushings, pins, springs, guides, or any small parts

in contact with the service fluid.

(C)

The gate, disc, piston, ball, or plug that provide closure are normally made from the "trim" material in smaller valve sizes

(less than about 6 inches). The closure may be made from material equivalent to the valve body except that the closure

seating surfaces shall be of the material having a corrosion resistance equal to or "better" than the trim.

(D)

See Table IV(a), (b) and (c) for material designations.

(E)

LT means "Less Than", GT means "Greater Than."

(F)

(X) indicates materials for critical applications such as hazardous service, poor accessibility for maintenance, or significant

loss of production in the event of failure.

(G)

Austenitic ("300 Series") stainless steel components that are to be welded or weld overlaid shall be low carbon (.03%

carbon maximum) grades. Low carbon grades may be substituted for regular carbon grades, but not vice versa.

Specific Notes:

(2)

Monel K-500 may be substituted for Monel 400 where additional hardness or strength is required.

(6)

Do not expose stainless-steel trim to HCl acid-cleaning.

(7)

Gray cast iron valve bodies may be substituted for ductile iron. However, ductile iron is preferred.

Page 17 of 17

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table I (Cont'd)

(8)

Sulfuric acid concentrations over 100% ("Oleum") contain free sulfur trioxide.

(10) Inhibited against stress corrosion cracking of steel with minimum 2000 ppm water.

(12) Dry chlorine contains less than 2000 ppm water; do not use with titanium components.

(13) Wet chlorine contains at least 2000 ppm water.

(14) These services are subject to additional considerations such as galvanic compatibility, velocity effects or additional water

chemistry factors. For example, high velocities or low pH may dictate against the use of bronze trim or Ductile Iron (DI)

bodies. Copper alloy bodied valves shall not be used with carbon steel pipe in corrosive water service without the use of

insulating sets.

(15) Materials for valves in wet sour service shall meet the requirements of NACE MR0175/ISO 15156.

NACE MR0175/ISO 15156 defines sour service. See also SAES-L-133.

(16) See Nelson Charts for details concerning the influence of temperature and partial pressure of hydrogen on material

selection.

(18) Body materials for Khuff Gas valves are per API SPEC 6A. Drain valves and valves at low points where water may collect

under stagnant conditions shall have 316 stainless steel "or better" bodies.

(20) Where indicated, the zinc content of wetted copper alloy components shall be 16% or less.

(21) Availability of bronze valves in ratings above Class 150 is limited, and have not yet been tried in Saudi Aramco.

(22) Linings are generally used in butterfly valves, non-lubricated plug valves, and some wedge gate valves. Coatings are used

on ball, check, globe and gate valves, and shall be specified in accordance with 09-SAMSS-080 and 09-SAMSS-091 as

applicable.

(23) Sour brine services may require specification of NACE MR0175/ISO 15156.

(24) Use ductile iron body, if available, for butterfly valves in non-hydrocarbon services.

(26) For potable water service, carbon steel body valves with SS316 trim are allowed in NPS 4-inch and above only. For critical

service, use coated or lined valves.

(27) Type 316 trim is only acceptable when there is a high degree of confidence that occasional oxygen ingress cannot occur

due to startup conditions, pump or valve packing leaks, etc. All trim shall be full SS316.

(28) Carbon steel overlaid with Inconel 625 may be substituted for super austenitic or duplex stainless steels (SSS) provided that

(a) the entire exposed area is overlaid and (b) the fused material has no more than 30% dilution.

(29) Where seawater is chlorinated, residual chlorine should be limited to 2 ppm or less for SSS alloys rated A in Table IV-B, 1

ppm for those rated B, and 0.5 ppm for those rated C. Where residual chlorine exceeds 2 ppm, the Alloy C family of alloys

in Table IV-A should be considered.

Page 18 of 18

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table II Alternate Stem and Spring Materials

The stem and spring alloys listed below may be used in valves having the trim materials

specified in Table I. These alloys usually may be fabricated to the required strength

levels more readily than the general trim materials and their corrosion resistance is

approximately equal to or better than that of the corresponding general trim.

Specified Trim

Alternate

Stem Materials

Stainless Steels

410

6NM

304

316

20

SSS

17-4, A286

17-4, A286

17-4, A286

N50, 718

625

625

17-4, X750, 600

17-4, X750, 600

17-4, X750, 600

718, MP35N, E1g

MP35N, Elg, 625, C-276

MP35N, Elg, 625, C-276

Low Alloy Steels

CrMoll, CrMo22, CrMo5

17-4, 410

17-4, X750

M400, MK500, SSS,

Aluminum Bronze, Nickel

Aluminum Bronze, Silicon

Bronze C69400

625, C-276, MP35N, Elg

MK500, 718, C-276 (1)

625, C-276

MP35N, Elg, C-276, 625, 718

MP35N, Elg, C-276, 625

Copper Alloys

Br

Nickel Base Alloys

M400

G-3

Alternate

Spring Materials (2)

Notes:

(1)

A specialized application for gaseous chlorine service.

(2)

Iron base alloy springs shall not be used in sour service.

Page 19 of 19

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table III Service and Application Requirements - Plastic/Elastomeric Components

M A T E R I A L S (2)

(See Table IV)

(See Notes 7 and 8)

Regarding Flurocarbon Materials)

Environment (1)

O-Rings, Diaphragms &

Resilient Seats (8)

Plastic Parts (7)

Acid, Hydrochloric

EPDM, PTR, IIR, CR

PVC, CPVC, PE, PP

Acid, Hydrofluoric

CSM, PTR

PP, PE, PVDC, CPE

Acid, Nitric

to 100%

to 60%

PTFE/Elastomer PF(3)

Fluorocarbon Elastomer

CPE, PTFE, FEP

CPVC, CPE

Acid, Phosphoric

EPDM, IIR, CR, RN, CSM

PVC, CPVC, PE, PP,

CPE, PVDC

Acid, Sulfuric Oleum

PTFE/Elastomer, PF

Fluorocarbon Plastics

only, except PVDF

Acid, Sulfuric

90%+

LT 60%

CSM

CR, CSM, IIR, EPDM

PVDC, CPE

PVDC, CPE, CPVC

Acid, Sulfurous

Fluorocarbon elastomers

Air

Ammonia (8)

Any within dry temperature and

pressure limits

Any except amine cured FKM, TFE/P

Amines (MEA, DEA, DGA,

ADIP) (8)

VMQ, EPDM, PTR, CSM (amine

cured FKM, TFE/P not suitable)

Carbon Dioxide, Dry

150C

Any within dry temperature limits

and pressure limits

Carbon Dioxide, Wet

90C

Any within temperature/

pressure limits

Chlorine, Dry

Fluorocarbon Elastomers FVMQ (4)

Fluorocarbon Plastics

Chlorine, Wet

Fluorocarbon Elastomers FVMQ

PVC, CPVC

Crude Oil

to 50C

to 200C

Fluorocarbon Elastomers

Fluorocarbon Elastomers

PVC, CPVC, PP, PPS

Fluorocarbon Plastics

NBR, CSM, ECO, TFE/E

(FKM not suitable)

CPVC, Nylon

Freon 11 or 12

Any except Nylon

FEP, PTFE

Page 20 of 20

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table III (Cont'd)

M A T E R I A L S (2)

(See Table IV)

(See Notes 7 and 8)

Regarding Flurocarbon Materials)

Environment (1)

O-Rings, Diaphragms &

Resilient Seats (8)

Plastic Parts (7)

Gas [T LT 121C

(250F)]

Fluorocarbon Elastomers (5)

PVC, CPVC, PPS

Gasoline (9)

FKM,PTR,FVMQ

PVDF,PVDC,CPE

Gasoline, MTBE blend

NBR (min. 40% acrylonitrile)

Fluorocarbon plastics

Hydrogen Sulfide

PTR,CSM,EPDM

PE, PP, PVC, PVDF

Hypochlorite, Ca/Na

Butyl, CSM , CR, ECO

PVC, CPVC, PCDC

Light Hydrocarbons

(Butane, Ethane, Methane,

Pentane, Propane)

PTR, ECO, FKM, FVMQ

Fluorocarbon Plastics, PPS

Naphtha

PTR, ECO, FVMQ

PVDC, CPE

Sewage, Oily

CR, NBR, PTR

PVC, CPVC, PVDC

Sewage, Sanitary

Any

Any

Sodium Hydroxide

Any except FKM and TFE/P

at high conc.

Any except PVDC

Sodium Carbonate (all conc.)

Any

Sodium Sulfite

Any

Polypropylene, RN, PVC,

CPVC

Any

Sulfur, Molten

PTFE/Elastomer, PF

Fluorocarbon Plastics

Sulfur Trioxide Solution 0.5%

Fluorocarbon Elastomers

Sulfamic Acid (to 30%)

EPDM, IIR, CSM, RN

PP, PVC

Water, All Services

Any

Any (6)

Notes:

(1)

Temperatures are 49C or less unless otherwise indicated.

(2)

See Table IV-A, B and C for material designations.

(3)

"/Elastomer" indicates any backup elastomer within the permissible temperature range.

Page 21 of 21

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table III (Cont'd)

(4)

Do not use diaphragm valves in dry chlorine service.

(5)

Viton shall be peroxide cured Grade GF, GLC or equal where amine inhibitor is employed.

(6)

For water services, use PVC up to 50C. Use CPVC in range between 50C and 72C.

(7)

The fluorocarbon plastics PTFE, FEP, ETFE, ECTFE, CTFE, and PVDF are compatible with all of the services listed in

Table III, except that PVDF is not suitable for oleum service. To avoid excessive repetition, these materials are not referred

to in Table III, except for the notation "fluorocarbon plastics" where the above are the only suitable materials for plastic

liners.

(8)

Services not compatible with fluorocarbon elastomers are the exception. These materials are not listed under "O-Rings,

Diaphragms and Resilient Seats," except for services where fluorocarbon elastomers are the only suitable materials for

these components. The term "fluorocarbon elastomers" refers to PF, FKM, TFE/P, or PTFE/E in Table IV-B, but not FVMQ

(Fluoro-silicone Rubber). PF (Kalrez Perfluoroelastomers), and PTFE backed elastomers (PTFE/Elastomer) are suitable for

all services in Table III. FKM (Viton, or Fluorel) and TFE/P (Aflas) are not resistant to concentrated nitric acid (G.T. 60%),

oleum, concentrated caustic, ammonia, many amines (except Viton "GF"), steam, Freon. Peroxide cured FKM (grades GF

or GLC) may be used in amines or ammonia, but not amine cured FKM.

(9)

Nitrile Rubber (NBR) is not suitable for gasoline or sour fluids.

Page 22 of 22

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table IVA Metallic Material Designations

Alloy Designation

Description

UNS No.

17-4

17-4 PH Stainless Steel

S17400

20

Alloy 20

N08020

304

AISI 304 Stainless Steel

S30400

304L

AISI 304L Stainless Steel

S30403

316

AISI 316 Stainless Steel

S31600

316L

AISI 316L Stainless Steel

S31603

410

AISI 410 Stainless Steel

S41000

4140

AISI 4140 Steel

G41400

600

Inconel 600

N06600

625

Inconel 625

N06625

6NM

13 Cr-4Ni Stainless Steel (Grade CA6NM) (4)

J91540

718

Inconel 718

N07718

800

Inconel 800

NO8800

825

Inconel 825

N08825

A286

Precipitation - Hardening Stainless Steel

S66286

B-2

Hastelloy B-2

N10665

Br

Bronze (See Note 1 and Table IV-B)

C-276

Hastelloy C-276

N10276

CI

Gray Cast Iron

CS

Carbon Steel

CrMoll

1-1/4 Cr 1/2 Mo Steel

J11872

CrMo22

2-1/4 Cr 1 Mo Steel

J21890

CrMo5

5 Cr-1/2 Mo Steel

J42045

D2

Ductile Ni Resist

F43000

DI

Ductile Iron

Page 23 of 23

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table - IVA (Cont'd)

Alloy Designation

Description

UNS No.

Elg

Elgiloy

R30003

ENP

Electroless Nickel Plating

G-3

Hastelloy G-3

N06985

LTS

Carbon Steel for Low Temperature Applications (2)

M400

Monel 400

N04400

MK500

Monel K-500

N05500

MP35N

MP35N

R30035

N50

Nitronic 50

S20910

NiRe

Ni Resist Type 1

F41000

NiRe2

Ni Resist Type 2

F41002

SSS

Special Stainless Steels

(See Table IV-B)

St12

Alloy 12 (Stellite No. 12)

R30012

St6

Alloy 6 (Stellite No. 6)

R30006

TC

Tungsten Carbide

Ti

Titanium (Unalloyed)

X750

Inconel X750

N07750

Notes:

(1)

Copper alloys shall have 16% or less zinc when used in corrosive aqueous service.

(2)

Reference: 04-SAMSS-003.

(3)

CA6NM Stainless Steel may be substituted for Type CA15 (AISI 410) for cast valve components.

Page 24 of 24

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table IVB Special Stainless Steels and Copper Base Alloys

Alloy

Designation

SSS

Generic, Popular,

or Trade Name

Form

UNS No.

Spec or Grade

(A)

(A)

(A)

(A)

(B)

(B)

(B)

(C)

(B)

(B)

(B)

(A)

Wrought

Wrought

Wrought

Cast

Wrought

Wrought

Cast

Cast

Cast

Cast

Cast

Cast

S32550

S32750

S32760

J93380

A240

A276, 182

A276, 182

S31803

J92205

J93370

A182-F51

A890-4A

A743, A890

DIN 9.4462

A890-2A

A890-3A

A890-5A

(A)

(A)

(A)

(A)

(A)

(B)

(B)

(B)

(B)

Wrought

Wrought

Wrought

Wrought

Cast

Wrought

Wrought

Wrought

Cast

N08366

Aluminum Bronze

Aluminum Bronze

Aluminum Bronze

Valve Bronze

Ounce Metal

Copper-Silicon Alloy

Copper-Silicon Alloy

Copper Alloy

Cast

Wrought

Wrought

Cast

Cast

Wrought

Wrought

Cast

All

C60600

All

C92200

C83600

C65100

C65500

C84400

Duplex Stainless (1)

Ferralium

SAF 2507

Zeron 100

Zeron 100

Zeron 25

SAF 2205

SAF 2205

CD4MCu

CD4MCu

Escoloy

Escoloy

Alloy 958

SSS

J93404

Superaustenitic

AL-6XN

25-6Mo

1925HMO

254 SMO

254 SMO

Nitronic 50

904L, 2RK65

JS-700

IN872, HV-93

BR

J93345

N08926

S31254

S20910

N08904

N08700

B675, B690

B475, B649

A240, A479

A182, A312

A351 CKMCuN

A479-XM19

B625, B649

B672, B599

A743-CN3M

Copper Alloys

B148 (2)

B169

B150

B61

B62

B98

B98

B584

Notes:

(1)

SSS alloy rankings for pitting and crevice corrosion resistance are shown in parentheses next to the name, (A) being best.

SSS alloys for seawater or sour brine service must be those ranked (A).

(2)

ASTM B148 components for seawater service shall receive a temper anneal heat treatment per ASTM B601 Condition "TB".

Page 25 of 25

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table IVC Plastics and Elastomers

Material

Designation

Generic or Trade Names

Polymer

PVC

PVC

Polyvinyl Chloride

CPVC

Chlorinated PVC

Chlorinated Polyvinyl Chloride

PE

Polyethylene

Polyethylene

PP

Polypropylene

Polypropylene

PVDF

Kynar

Polyvinylidene-Fluoride

PLASTICS

FEP

Fluorinated Ethylene-Propylene

ETFE

Tefzel

Ethylene-Tefrafluoro Ethylene

ECTFE

Halar

Ethylene-Chlorotrifluoro-Ethylene

CTFE

Kel-f

Chlorotrifluoro-Ethylene

PTFE

Teflon

Poly-Tetrafluoro-Ethylene

Nylon

Polyamide

PVDC

Saran

Polyvinylidene Chloride

CPE

Penton

Chlorinated Polyether

PPS

Ryton

Polyphenylene Sulfide

RN

Natural Rubber

Poly-Isoprene

CR

Neoprene or Chloroprene

Poly-Chloroprene

EPDM

Nordel, Epcar

Ethylene-Propylene

IIR

Butyl Rubber GR-1

Isobutylene Isoprene

NBR

Buna-N, Nitrile Rubber, GR-N

Butadiene-Acrylonitrile

SBR

Buna-S, GR-S

Styrene-Butadiene

CSM

Hypalon

Chlorosulfonated Polyethylene

PTR

Polysulfide Rubber

Dichlorile-Polysulfide

ELASTOMERS

Page 26 of 26

Document Responsibility: Valves Standards Committee

Issue Date: 11 October 2010

Next Planned Update: 11 October 2015

SAES-L-108

Selection of Valves

Table - IVC (Cont'd)

Material

Designation

Generic or Trade Names

Polymer

ELASTOMERS (Cont'd)

ECO

Epichlorohydrin Rubber

Epichlorohydrin

EU

Adiprene

Polyester/Urethane

AU

Adiprene Vulcollan

Polyester/Urethane

VMQ

Silicone Rubber

Organic Silicone

FVMQ(1)*

Fluorosilicone Rubber

Fluorinated Organic Silicone

FLUOROCARBON-ELASTOMERS

PF

Perfluoroelastomer

FKM

Fluorel, Viton

Vinylidene Fluoride-Hexafluoropropylene

TFE/P

Aflas

Tetrafluoroethylene-Propylene

PTFE/Elastomer

PTFE with any elastomer backing

Poly-tetrafuoro-ethylene/Elastomer

Note:

*

FVMQ is NOT categorized as a fluorocarbon elastomer.

Page 27 of 27

You might also like

- 04-SAMSS-035 ARAMCO General Reuirement For ValvesDocument18 pages04-SAMSS-035 ARAMCO General Reuirement For ValvesAhmed100% (4)

- Saes L 132Document38 pagesSaes L 132BM TECH100% (1)

- 02 Samss 005 PDFDocument16 pages02 Samss 005 PDFayubqc.gusatNo ratings yet

- 117-Gemstone IdentificationDocument17 pages117-Gemstone Identificationms_pmNo ratings yet

- Saep 122Document18 pagesSaep 122Handa Bin AdiNo ratings yet

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDocument8 pagesSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- SAIC-L-2014 Rev. 5Document10 pagesSAIC-L-2014 Rev. 5Jagadeesh PuppalaNo ratings yet

- 20 Samss 001Document9 pages20 Samss 001asimazami690% (1)

- 04 Samss 055Document42 pages04 Samss 055nadeem shaikh100% (1)

- SAEP-352 - Welding Procedures Review and Approval PDFDocument14 pagesSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637No ratings yet

- 04-SAMSS-048 Valve Inspection and Testing RequirementsDocument8 pages04-SAMSS-048 Valve Inspection and Testing RequirementsHAYKEL79100% (1)

- 04 Samss 058 PDFDocument5 pages04 Samss 058 PDFbalajiNo ratings yet

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDocument17 pagesOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranNo ratings yet

- 04 Samss 048Document11 pages04 Samss 048Sami100% (1)

- 04 SAMSS 005 Check ValvesDocument9 pages04 SAMSS 005 Check ValvesShino UlahannanNo ratings yet

- 04 Samss 041Document6 pages04 Samss 041Moustafa BayoumiNo ratings yet

- 04-Samss-35 ValvesDocument28 pages04-Samss-35 ValvesNabeel AKNo ratings yet

- Saep 380 PDFDocument10 pagesSaep 380 PDFbassamNo ratings yet

- 01 Samss 029Document15 pages01 Samss 029Cherukunnon Jubu100% (1)

- SAIC-A-2007 Rev 3Document12 pagesSAIC-A-2007 Rev 3imrankhan22No ratings yet

- Saes L 100Document13 pagesSaes L 100Honesto Bautista100% (3)

- Saes L 136Document8 pagesSaes L 136kartik_harwani4387100% (1)

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- 34 Samss 711 PDFDocument26 pages34 Samss 711 PDFFlorin Daniel AnghelNo ratings yet

- 01 Samss 010 PDFDocument11 pages01 Samss 010 PDFAnonymous ZxJZoU0% (1)

- SAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARDocument6 pagesSAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARZahidRafique100% (1)

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Saep 301Document12 pagesSaep 301Demac Saud50% (2)

- 34 Samss 112Document14 pages34 Samss 112naruto256No ratings yet

- 02-Samss-005 2014Document16 pages02-Samss-005 2014My SinuNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010aamirtec301No ratings yet

- Saes A 202 - PDF - Search Engine Indexing - Specification (Technical Standard) PDFDocument41 pagesSaes A 202 - PDF - Search Engine Indexing - Specification (Technical Standard) PDFAhmed Essam El-DinNo ratings yet

- Saep 35Document6 pagesSaep 35hendraox3996No ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saep 323Document8 pagesSaep 323brecht1980100% (1)

- Procurement QC SupervisorDocument2 pagesProcurement QC SupervisorWalid Megahed100% (1)

- Saep 206 PDFDocument7 pagesSaep 206 PDFRami ElloumiNo ratings yet

- Saep 119Document11 pagesSaep 119Demac SaudNo ratings yet

- SAEP-379 Quality Issues Notification 2-MAR-2016Document4 pagesSAEP-379 Quality Issues Notification 2-MAR-2016asiqna100% (1)

- Saep 324Document8 pagesSaep 324brecht1980100% (4)

- Saep 322Document18 pagesSaep 322brecht1980100% (1)

- 2019 Saes W 016Document18 pages2019 Saes W 016smdriyazbashaNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh50% (2)

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Document4 pages1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- Saic A 2013Document6 pagesSaic A 2013jerinNo ratings yet

- Saic L 2015Document8 pagesSaic L 2015Engr IrfanNo ratings yet

- Saep 119Document12 pagesSaep 119brecht1980No ratings yet

- Saep 1630Document10 pagesSaep 1630faisalqr100% (1)

- SAIC-A-2003 Rev 0Document3 pagesSAIC-A-2003 Rev 0bluelions_19No ratings yet

- Saep 1161Document51 pagesSaep 1161Anonymous 4IpmN7OnNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- 04 Samss 056Document8 pages04 Samss 056shadow.luNo ratings yet

- 04-SAMSS-053 - Nov. 28, 2013Document8 pages04-SAMSS-053 - Nov. 28, 2013LainhatanhNo ratings yet

- General Requirements For ValvesDocument16 pagesGeneral Requirements For ValvesKrishna Prasad R100% (2)

- 34 Samss 612Document8 pages34 Samss 612naruto256No ratings yet

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285No ratings yet

- 04-SAMSS-048Document8 pages04-SAMSS-048yasser awadallhNo ratings yet

- Saes-L-108 (2016)Document29 pagesSaes-L-108 (2016)PraveenNo ratings yet

- 04 Samss 005Document9 pages04 Samss 005YOUSUF KHANNo ratings yet

- AVK Group of CompaniesDocument4 pagesAVK Group of CompaniesSathishkumar DhamodaranNo ratings yet

- Flyer ERIplus Edition01!09!03-2015 enDocument2 pagesFlyer ERIplus Edition01!09!03-2015 enSathishkumar DhamodaranNo ratings yet

- Service ReportDocument3 pagesService ReportSathishkumar DhamodaranNo ratings yet

- Kat A 1331wafer Cerex300 W Wasser en 03 12Document6 pagesKat A 1331wafer Cerex300 W Wasser en 03 12Sathishkumar DhamodaranNo ratings yet

- Printable Salary CertificateDocument1 pagePrintable Salary CertificateSathishkumar DhamodaranNo ratings yet

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Document6 pagesKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranNo ratings yet

- KAT B 5512 HYsec Edition2 en 12 10Document16 pagesKAT B 5512 HYsec Edition2 en 12 10Sathishkumar DhamodaranNo ratings yet

- AVK Couplings Adaptors PDFDocument16 pagesAVK Couplings Adaptors PDFSathishkumar DhamodaranNo ratings yet

- KAT-1352 - Cerex M300-F PDFDocument3 pagesKAT-1352 - Cerex M300-F PDFSathishkumar DhamodaranNo ratings yet

- Butterfly ValveDocument5 pagesButterfly ValveSathishkumar DhamodaranNo ratings yet

- Kat-A 1321 Ekn-Awwa 6-3 10-12 enDocument3 pagesKat-A 1321 Ekn-Awwa 6-3 10-12 enSathishkumar DhamodaranNo ratings yet

- Kat-A 1013 Beta200-Baio en 07-11Document7 pagesKat-A 1013 Beta200-Baio en 07-11Sathishkumar DhamodaranNo ratings yet

- KAT-A 1310 EKN-M300 Edition1 02-01-2017 ENDocument7 pagesKAT-A 1310 EKN-M300 Edition1 02-01-2017 ENwinston11No ratings yet

- Flyer Air-Valves Edition02!20!04-2016 en 01Document12 pagesFlyer Air-Valves Edition02!20!04-2016 en 01Sathishkumar DhamodaranNo ratings yet

- Kat-A 1030 Bs Ekoplus-Bs en 07-11Document4 pagesKat-A 1030 Bs Ekoplus-Bs en 07-11Sathishkumar DhamodaranNo ratings yet

- GA Industries Product Line BrochureDocument8 pagesGA Industries Product Line BrochureSathishkumar DhamodaranNo ratings yet

- KAT B 1913 - Spring Loaded Air Valve - Edition1 - en - 01 10Document11 pagesKAT B 1913 - Spring Loaded Air Valve - Edition1 - en - 01 10Sathishkumar DhamodaranNo ratings yet

- Flyer EROXplus Edition2!10!03-2015 enDocument2 pagesFlyer EROXplus Edition2!10!03-2015 enSathishkumar DhamodaranNo ratings yet

- Flyer ERIplus Edition01!09!03-2015 enDocument2 pagesFlyer ERIplus Edition01!09!03-2015 enSathishkumar DhamodaranNo ratings yet

- Flyer Non Return Valves Edition06!11!05 2016 enDocument12 pagesFlyer Non Return Valves Edition06!11!05 2016 enSathishkumar DhamodaranNo ratings yet

- KAT-A 1130-IL KOS-Internal Edition7 31.07.2018 enDocument4 pagesKAT-A 1130-IL KOS-Internal Edition7 31.07.2018 enSathishkumar DhamodaranNo ratings yet

- IMSDesign 2018Document1 pageIMSDesign 2018Sathishkumar DhamodaranNo ratings yet

- Flyer Butterfly-Valves Edition03 15-05-2016 EN 01 PDFDocument8 pagesFlyer Butterfly-Valves Edition03 15-05-2016 EN 01 PDFSathishkumar DhamodaranNo ratings yet

- Butterfly ValveDocument5 pagesButterfly ValveSathishkumar DhamodaranNo ratings yet

- Gate Valve - Metal SeatedDocument6 pagesGate Valve - Metal SeatedSathishkumar DhamodaranNo ratings yet

- KAT A 1331 W Wafer CEREX300 W Stainless Steel Water Edition10 17.12.2018 enDocument3 pagesKAT A 1331 W Wafer CEREX300 W Stainless Steel Water Edition10 17.12.2018 enSathishkumar DhamodaranNo ratings yet

- Facts About WaterDocument1 pageFacts About WaterSathishkumar DhamodaranNo ratings yet

- Introduction To Skin Effect Heat Tracing SystemDocument22 pagesIntroduction To Skin Effect Heat Tracing Systemvivek bevara100% (1)

- Extrusion Processing Guide: ABS - Acrylonitrile-Butadiene-StyreneDocument5 pagesExtrusion Processing Guide: ABS - Acrylonitrile-Butadiene-StyreneMalwadkar P.B.0% (1)

- DM-M-4-5-2-06-TDS Orgacyl NMP1313-V01Document3 pagesDM-M-4-5-2-06-TDS Orgacyl NMP1313-V01d_vikram86No ratings yet

- Entropy ChangeDocument13 pagesEntropy ChangeAhmedAmer1No ratings yet

- Prorox wm970 en - inDocument1 pageProrox wm970 en - inDannis AnantoNo ratings yet

- Cal LCDocument1 pageCal LCNasr Eldin AlyNo ratings yet

- Index Catalogue English 2019Document18 pagesIndex Catalogue English 2019api-513440808No ratings yet

- Calcium Phosphate Apatites With Variable Ca/P Atomic Ratio I. Synthesis, Characterisation and Thermal Stability of PowdersDocument8 pagesCalcium Phosphate Apatites With Variable Ca/P Atomic Ratio I. Synthesis, Characterisation and Thermal Stability of PowdersMaximimilianoNo ratings yet

- EME-301 Material Science Engineering PDFDocument3 pagesEME-301 Material Science Engineering PDFPartha Pratim PalNo ratings yet

- Seminar ReportDocument8 pagesSeminar ReportLaxman HosamaniNo ratings yet

- Specific Gravity and Weight of MaterialDocument11 pagesSpecific Gravity and Weight of MaterialPeejay OllabracNo ratings yet

- ITS Labtest DHAKADocument6 pagesITS Labtest DHAKAMuaiena Khatun RunaNo ratings yet

- K Walker PHD FinalDocument145 pagesK Walker PHD FinalLeandro González De CeccoNo ratings yet

- CB Continental CatalogueDocument69 pagesCB Continental CatalogueAina Likuntati100% (1)

- Cooper 1985Document4 pagesCooper 1985mr.snorhaarNo ratings yet

- HW7 Solutions ENGS 33Document8 pagesHW7 Solutions ENGS 33Brayan LozanoNo ratings yet

- Basic Tech 2023 Third Term ExamsDocument4 pagesBasic Tech 2023 Third Term ExamsOlusolaNo ratings yet

- Chapter 7 Transverse ShearDocument7 pagesChapter 7 Transverse ShearSumaya MahmoodNo ratings yet

- Sorensen Paper OCDocument6 pagesSorensen Paper OCChristopher TanjungNo ratings yet

- Nitrogen in SteelsDocument5 pagesNitrogen in SteelsAnca ElenaNo ratings yet

- Method Statement - Drainage & SewerageDocument8 pagesMethod Statement - Drainage & Seweragedanes hereNo ratings yet

- Archi LouversDocument54 pagesArchi LouversArnab GoswamiNo ratings yet

- Indian Chemical Industry MRPDocument60 pagesIndian Chemical Industry MRPNamit Dehariya100% (1)

- Pipeline Activity PDFDocument45 pagesPipeline Activity PDFdndudc100% (1)

- Marine Boilers 25Document99 pagesMarine Boilers 25Anjaana PrashantNo ratings yet

- What Is Slagging and Fouling in Boilers - Thermodyne Engineering SystemsDocument3 pagesWhat Is Slagging and Fouling in Boilers - Thermodyne Engineering Systemskumar100% (2)

- 04-11-01 Phosphoric Acid - Quantitative MethodDocument2 pages04-11-01 Phosphoric Acid - Quantitative MethodMuhammad Farhan HidayatNo ratings yet

- New Acrylic Polyols For Low-VOC Coatings: Order Reprints No CommentsDocument6 pagesNew Acrylic Polyols For Low-VOC Coatings: Order Reprints No CommentsRANJITHNo ratings yet

- BCS-CRM 113 Mar2014Document3 pagesBCS-CRM 113 Mar2014Ishmael WoolooNo ratings yet