LS2 - Variation in Refrigeration Coefficient of Performance at Various Operating Conditions

Uploaded by

Faez FeakryLS2 - Variation in Refrigeration Coefficient of Performance at Various Operating Conditions

Uploaded by

Faez FeakryThermofluids Lab-MEC 554/ LS 2/ Rev.

02-20012

UNIVERSITI TEKNOLOGI MARA

FACULTY OF MECHANICAL ENGINEERING

________________________________________________________________________

Program

:

Bachelor Of Engineering (Hons) Mechanical

Course

:

Thermalfluids Lab

Code

:

MEC 554

________________________________________________________________________

LAB SHEET NO:

HEATING, VENTILATION & AIR CONDITIONING LABORATORY SHEET (HVAC)

TITLE : Variation In Refrigeration Coefficient Of Performance At Various Operating

Conditions.

1. INTRODUCTION

Refrigeration is used widely in various applications from industrial to domestic situations, mainly for

the storage and transport of perishable foodstuffs and chemical substances. It has the prime

function to remove heat from a low temperature region, and it can also be applied as a heat pump

for supplying heat to a region of high temperature.

2. OBJECTIVE

To investigate the variation of Coefficient of Performance (COPR) of a vapor compression

refrigeration system at different cooling load.

3. THEORY

A refrigeration cycle works to lower and maintain the temperature of a controlled space by heat

transfer from a low to a high temperature region.

High Temperature Reservoir, TH

QH

.

Wnet

QL

Low Temperature Reservoir, TL

Refrigeration duty is another term for the cooling effect of the refrigeration system, which is the rate

of heat being removed from the low temperature region with specified evaporation and

condensation temperatures. The unit for duty measurements is in Watts (for 1 ton of

refrigeration = 3517W).

Thermofluids Lab-MEC 554/ LS 2/ Rev. 02-20012

3.1

The Vapor Compression Cycle

Ideal refrigeration systems follows the theoretical Reversed Carnot Cycle process. In

practical refrigerators, compression and expansion of a gas and vapor mixture presents

practical problems in the compressor and expander. Therefore, in practical refrigeration,

compression usually takes place in the superheated condition and a throttling process is

substituted for the isentropic expansion.

Thermofluids Lab-MEC 554/ LS 2/ Rev. 02-20012

The cycle :

12

23

34

41

Condensation of the high pressure vapour during which heat is transferred to the

high temperature region.

Adiabatic throttling of the condensed vapour from the condensing to the

evaporating pressure.

Evaporation of the low pressure liquid during which heat is absorbed from the low

temperature source.

Isentropic compression of the vapour, from the evaporating to the condensing

pressures.

Energy Transfers Analysis

Compressor

q4-1 = h4 h1 + w4-1

If compression is adiabatic, q4-1 = 0, and w4-1 = h1 h4 = wcomp

Power requirement, P = (h1 h4), where is the flow rate of working fluid per unit time.

Condenser

q1-2 = h2 h1 + w

w = 0, therefore q1-2 = h2 h1 and rate of heat rejection Q1-2 = ( h2 h1 )

Expansion Valve

q2-3 = h3 h2 + w

w = 0, therefore q 2-3 = h2 h3 and process is assumed adiabatic q 0

therefore h2 = h3

Evaporator

q34 = h4 h3 + w

w = 0 therefore q34 = h4 h3 and rate of heat absorbed Q34 = ( h4 h3 )

Coefficient of Perfomance, COPref:

COPref =

q3 4

h4 h3

=

w

h1 h4

Thermofluids Lab-MEC 554/ LS 2/ Rev. 02-20012

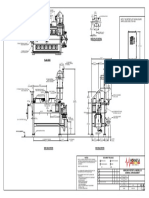

5. EQUIPMENT

TH Series Computer Linked Refrigeration Unit (Edibon).

6. PROCEDURES

6a) Condenser-water and evaporator-water

a. Select water as a heat source by opening valves AVS-4 and AVS-5.Then click START

b. Adjust the water flow rate at the condenser to 5 L/m and 3 L/m at the evaporator

(evaporator load).

c. Then click COMPRESSOR

d. When the system is stabilized, start recording the data by click START SAVING

e. Set the sampling rate at 120 second per sample.

f. Record the data for six minutes (3 samples @ 360 second). STOP SAVING

g. Then increase evaporator load to 5 L/m and repeat step (c) to step (f).

6b) Condenser-water and evaporator-air

a. Select air as a heat source by opening valves AVS-3 and AVS-5.Then click START

b. Adjust the water flow rate at the condenser to 5 L/m and adjust the air flow of the

evaporator until 50% of the maximal flow (evaporator load).

c. Then click COMPRESSOR

d. When the system is stabilized, start recording the data by click START SAVING

e. Set the sampling rate at 120 second per sample.

f. Record the data for six minutes (3 samples @ 360 second). STOP SAVING

g. Then increase evaporator load to 100% and repeat step (c) to step (f).

6c) Condenser-air and evaporator-air

a. Select air as a heat source by opening valves AVS-3 and AVS-6. Then click START

b. Adjust the air flow of the condenser to maximum flow (100%) and 50% of the maximal

flow at the evaporator (evaporator load).

c. Then click COMPRESSOR

d. When the system is stabilized, start recording the data by click START SAVING

e. Set the sampling rate at 120 second per sample.

f. Record the data for six minutes (3 samples @ 360 second). STOP SAVING

g. Then increase evaporator load to 100% and repeat step (c) to step (f).

6d) Condenser-air and evaporator-water

a. Select water as a heat source by opening valves AVS-4 and AVS-6.Then click START

b. Adjust the air flow of the condenser to maximum flow (100%) and adjust the water flow

rate at the evaporator to 3 L/m (evaporator load).

c. Then click COMPRESSOR

d. When the system is stabilized, start recording the data by click START SAVING

e. Set the sampling rate at 120 second per sample.

f. Record the data for six minutes (3 samples @ 360 second). STOP SAVING

g. Then increase evaporator load to 5 L/m and repeat step (c) to step (f).

7. DATA AND RESULTS

7.1

By using data obtained from the experiments, show sample calculations of the parameters

below and complete the results summary table.

(a)

Refrigerant mass flow rate (kg/s),

(b)

Evaporator cooling load , Qevap

(c)

Coefficient of performance, COPref

(d)

Average COPref

Thermofluids Lab-MEC 554/ LS 2/ Rev. 02-20012

Data Summary table

240

360

240

360

Cond - Water

Evap - Water

Cond - Water

Evap - Air

SC-2 = 5 L/m

Cond - Air

Evap - Air

Fan power at condenser = 100%

Cond - Air

Evap - Water

Fan power at condenser = 100%

120

SC-2 = 5 L/m

120

Time (s)

360

SC-3 = 5 L/m

240

120

SC-3 = 3 L/m

360

120

Fan power at

evap. = 100%

240

Fan power at

evap. = 50%

360

Fan power at

evap. = 100%

240

Fan power at

evap. = 50%

360

SC-3 = 5 L/m

240

SC-3 = 3 L/m

360

120

Evaporator

heat load

240

120

Condenser

cooling load

360

120

a

Working fluid

Exp #

240

120

SW-1

(W)

SC-1

(L/h)

SP-2

(bar)

SP-1

(bar)

ST-4

(oC)

ST-3

(oC)

ST-2

(oC)

Thermofluids Lab-MEC 554/ LS 2/ Rev. 02-20012

Results Summary table

Time (s)

Exp #

Vref

(m3/s)

v2 (table)

(m3/kg)

mref (kg/s)

= Vref/v2

h3 (kJ/kg)

h4 (kJ/kg)

Qevap (kW)

= mref (h4 h 3)

120

240

360

Average COP

a

120

240

360

Average COP

120

240

360

Average COP

b

120

240

360

Average COP

120

240

360

Average COP

c

120

240

360

Average COP

120

240

360

Average COP

d

120

240

360

Average COP

COP =

Qevap/ (SW1/1000)

Thermofluids Lab-MEC 554/ LS 2/ Rev. 02-20012

8. DISCUSSIONS

a.

What is the effect on the COPref as the load is increased? Why?

b.

What is the effect of cooling medium on the average refrigeration COP? Why?

c.

What do you understand by the term load? Give examples of actual loads in refrigeration

practice in a domestic fridge, in a room, and in a factory.

d.

Conclusion of the experiment.

You might also like

- Mec 2405 - Thermodynamics (Refrigeration Report)No ratings yetMec 2405 - Thermodynamics (Refrigeration Report)15 pages

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Thermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of Air69% (13)Thermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of Air9 pages

- Copeland Refrigeration Manual - Part 4 - System Design100% (3)Copeland Refrigeration Manual - Part 4 - System Design98 pages

- Program: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554No ratings yetProgram: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 5547 pages

- Universiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553No ratings yetUniversiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE5533 pages

- Theory and Introduction Multi Pump Test RigNo ratings yetTheory and Introduction Multi Pump Test Rig6 pages

- Measurement of The Drag Coefficients of Spherical ParticlesNo ratings yetMeasurement of The Drag Coefficients of Spherical Particles10 pages

- Property Measurement-Pvt: Abstract - The Experiment Was Carried Out ToNo ratings yetProperty Measurement-Pvt: Abstract - The Experiment Was Carried Out To6 pages

- Experiment 4 - Level Measurement & CalibrationNo ratings yetExperiment 4 - Level Measurement & Calibration12 pages

- CDB 3082 Chemical Engineering Lab Iv: - Flame PropagationNo ratings yetCDB 3082 Chemical Engineering Lab Iv: - Flame Propagation8 pages

- CHE486 - EXPERIMENT 10 (Marcet Boiler) UiTMNo ratings yetCHE486 - EXPERIMENT 10 (Marcet Boiler) UiTM6 pages

- CLB20703 Chemical Engineering Thermodynamics Experiment 1: Refrigeration CycleNo ratings yetCLB20703 Chemical Engineering Thermodynamics Experiment 1: Refrigeration Cycle7 pages

- S-Lab Manual Exp 3 - Air Flow Process ControlNo ratings yetS-Lab Manual Exp 3 - Air Flow Process Control12 pages

- Fdocuments - in 51634963 Orifice Discharge Lab ReportNo ratings yetFdocuments - in 51634963 Orifice Discharge Lab Report2 pages

- Ex. No.3. Experiment On Performance of Flat Plate Collector - Thermosyphonic Mode Solar Water HeaterNo ratings yetEx. No.3. Experiment On Performance of Flat Plate Collector - Thermosyphonic Mode Solar Water Heater3 pages

- Exp - 4 - Pulsed Column Liquid - Liquid Extraction0% (3)Exp - 4 - Pulsed Column Liquid - Liquid Extraction14 pages

- Experiment 2 - Forced Draft Cooling TowerNo ratings yetExperiment 2 - Forced Draft Cooling Tower14 pages

- Brief Depressurization Exp 2 Intro and Result and CalculationNo ratings yetBrief Depressurization Exp 2 Intro and Result and Calculation2 pages

- Conclusion, Recoomendation, Reffenrence, Lab 2, CHE 485No ratings yetConclusion, Recoomendation, Reffenrence, Lab 2, CHE 4852 pages

- Application of Internship Placement For Engineering StudentNo ratings yetApplication of Internship Placement For Engineering Student1 page

- Universiti Teknologi Mara (Uitm) Shah AlamNo ratings yetUniversiti Teknologi Mara (Uitm) Shah Alam1 page

- Topic 1: Introduction To Control System and Mathematical ReviewNo ratings yetTopic 1: Introduction To Control System and Mathematical Review43 pages

- Mem575 Industrial Management Course Outline PM IsmailNo ratings yetMem575 Industrial Management Course Outline PM Ismail8 pages

- Mem575 Industrial Management Course Outline PM IsmailNo ratings yetMem575 Industrial Management Course Outline PM Ismail8 pages

- 10.0 References: Micro-And Nano-Metrology". Meas. Sci. Technol. 17, 504-509No ratings yet10.0 References: Micro-And Nano-Metrology". Meas. Sci. Technol. 17, 504-5091 page

- 5.0 Method of Approach Sand and Mold PreparationNo ratings yet5.0 Method of Approach Sand and Mold Preparation6 pages

- Results and Data Analysis: 2 Cups of Pallets Cup + Pallets 0.116 KGNo ratings yetResults and Data Analysis: 2 Cups of Pallets Cup + Pallets 0.116 KG2 pages

- KTA - TB-HV-DWG-0001.REV.2 HVAC Equipment For Office Building - DWG PDFNo ratings yetKTA - TB-HV-DWG-0001.REV.2 HVAC Equipment For Office Building - DWG PDF9 pages

- Design and Development of A Peltier Cooler For Real Life ApplicationsNo ratings yetDesign and Development of A Peltier Cooler For Real Life Applications12 pages

- Mechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)No ratings yetMechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)3 pages

- Part PFH Optional Requirements For Feedwater Heater (When Located WithinNo ratings yetPart PFH Optional Requirements For Feedwater Heater (When Located Within1 page

- Lennox Mini Split Air Conditioner Heat Pump Error CodesNo ratings yetLennox Mini Split Air Conditioner Heat Pump Error Codes3 pages

- 20 Reznor Udsa-Udsbd Pliant Ci 06.11.20 enNo ratings yet20 Reznor Udsa-Udsbd Pliant Ci 06.11.20 en8 pages

- Catalog: Blower Coil Air Handler Models BCHD and BCVDNo ratings yetCatalog: Blower Coil Air Handler Models BCHD and BCVD104 pages

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second Edition

- Thermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of AirThermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of Air

- Copeland Refrigeration Manual - Part 4 - System DesignCopeland Refrigeration Manual - Part 4 - System Design

- Program: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554Program: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554

- Universiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553Universiti Teknologi Mara Mid-Term Assessment: Confidential EH/MAY 2021/CHE553

- Measurement of The Drag Coefficients of Spherical ParticlesMeasurement of The Drag Coefficients of Spherical Particles

- Property Measurement-Pvt: Abstract - The Experiment Was Carried Out ToProperty Measurement-Pvt: Abstract - The Experiment Was Carried Out To

- CDB 3082 Chemical Engineering Lab Iv: - Flame PropagationCDB 3082 Chemical Engineering Lab Iv: - Flame Propagation

- CLB20703 Chemical Engineering Thermodynamics Experiment 1: Refrigeration CycleCLB20703 Chemical Engineering Thermodynamics Experiment 1: Refrigeration Cycle

- Fdocuments - in 51634963 Orifice Discharge Lab ReportFdocuments - in 51634963 Orifice Discharge Lab Report

- Ex. No.3. Experiment On Performance of Flat Plate Collector - Thermosyphonic Mode Solar Water HeaterEx. No.3. Experiment On Performance of Flat Plate Collector - Thermosyphonic Mode Solar Water Heater

- Exp - 4 - Pulsed Column Liquid - Liquid ExtractionExp - 4 - Pulsed Column Liquid - Liquid Extraction

- Brief Depressurization Exp 2 Intro and Result and CalculationBrief Depressurization Exp 2 Intro and Result and Calculation

- Conclusion, Recoomendation, Reffenrence, Lab 2, CHE 485Conclusion, Recoomendation, Reffenrence, Lab 2, CHE 485

- Application of Internship Placement For Engineering StudentApplication of Internship Placement For Engineering Student

- Topic 1: Introduction To Control System and Mathematical ReviewTopic 1: Introduction To Control System and Mathematical Review

- Mem575 Industrial Management Course Outline PM IsmailMem575 Industrial Management Course Outline PM Ismail

- Mem575 Industrial Management Course Outline PM IsmailMem575 Industrial Management Course Outline PM Ismail

- 10.0 References: Micro-And Nano-Metrology". Meas. Sci. Technol. 17, 504-50910.0 References: Micro-And Nano-Metrology". Meas. Sci. Technol. 17, 504-509

- Results and Data Analysis: 2 Cups of Pallets Cup + Pallets 0.116 KGResults and Data Analysis: 2 Cups of Pallets Cup + Pallets 0.116 KG

- KTA - TB-HV-DWG-0001.REV.2 HVAC Equipment For Office Building - DWG PDFKTA - TB-HV-DWG-0001.REV.2 HVAC Equipment For Office Building - DWG PDF

- Design and Development of A Peltier Cooler For Real Life ApplicationsDesign and Development of A Peltier Cooler For Real Life Applications

- Mechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)Mechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)

- Part PFH Optional Requirements For Feedwater Heater (When Located WithinPart PFH Optional Requirements For Feedwater Heater (When Located Within

- Lennox Mini Split Air Conditioner Heat Pump Error CodesLennox Mini Split Air Conditioner Heat Pump Error Codes

- Catalog: Blower Coil Air Handler Models BCHD and BCVDCatalog: Blower Coil Air Handler Models BCHD and BCVD