Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801

Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801

Uploaded by

Ravi ParikhCopyright:

Available Formats

Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801

Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801

Uploaded by

Ravi ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801

Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801

Uploaded by

Ravi ParikhCopyright:

Available Formats

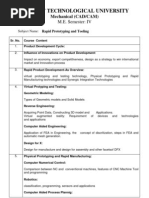

GUJARAT TECHNOLOGICAL UNIVERSITY

MECHANICAL (CAD/CAM) (08)/ MECHANICAL (MACHINE DESIGN) (09)

RAPID PROTOTYPING AND TOOLING

SUBJECT CODE: 2740801

SEMESTER: IV

Type of course: Post Graduate

Prerequisite: Zeal to learn the Subject

Rationale: In present era it is highly essential to be able to prepare final product or its prototypes at the

earliest. This is desirable to ensure that all the expected requirement of product are addressed and if

required, its performance is also assessed from the prototype. Rapid prototyping offers a convenient option

for manufacturing of product or its prototype from the CAD model.

Teaching and Examination Scheme:

Teaching Scheme

L

Credits

C

2#

Examination Marks

Theory Marks

ESE PA (M)

(E)

70

30

Total

Marks

Practical Marks

PA (V)

PA (I)

ESE

OEP

PA

RP

20

10

10

10

150

Content:

Sr.

No.

1

Content

Introduction:

Introduction to Prototyping, Traditional Prototyping Vs. Rapid Prototyping

(RP), Need for time compression in product development, Usage of RP parts,

Generic RP process, Distinction between RP and CNC, other related

technologies, Classification of RP.

CAD Modelling and Data Processing for RP:

CAD model preparation, Data Requirements, Data formats ( STL, SLC,

CLI, RPI, LEAF, IGES, HP/GL, CT, STEP), Data interfacing, Part

orientation and support generation, Support structure design, Model Slicing

and contour data organization, direct and adaptive slicing, Tool path

generation.

RP Systems:

Photopolymerization

Stereolithography (SL), SL resin curing process, SL scan patterns,

Microstereolithography, Applications of Photopolymerization Processes.

Powder Bed Fusion:

Selective laser Sintering (SLS), Powder fusion mechanism and powder

handling, SLS Metal and ceramic part creation, Electron Beam melting

(EBM), Applications of Powder Bed Fusion Processes.

Extrusion-Based RP Systems:

Fused Deposition Modelling (FDM), Principles, Plotting and path control,

Total

Hrs

% Weightage

5%

15%

20

45%

Applications of Extrusion-Based Processes.

3D Printing :

3D printing (3DP), Research achievements in printing deposition,

Technical challenges in printing, Printing process modelling, Applications of

Printing Processes.

Sheet Lamination :

Laminated Object Manufacturing (LOM), Ultrasonic Consolidation (UC),

Gluing, Thermal bonding, LOM and UC applications.

Beam Deposition:

Laser Engineered Net Shaping (LENS), Direct Metal Deposition (DMD),

Processing-structure-properties, relationships, Benefits and drawbacks.

Rapid Tooling:

Conventional Tooling Vs. Rapid Tooling, Classification of Rapid Tooling,

Direct and Indirect Tooling Methods, Soft and Hard Tooling methods.

Reverse Engineering:

Basic concept, Digitization techniques, Model Reconstruction, Data

Processing for Rapid Prototyping, Reverse Engineering (RE) Methodologies

and Techniques, Selection of RE systems, RE software, RE hardware, RE in

product development.

Errors in RP Processes:

Pre-processing, processing, post-processing errors, Part building errors in

SLA, SLS.

RP Applications:

Design, Engineering Analysis and planning applications, Rapid Tooling,

Reverse Engineering, Medical Applications of RP.

10%

15%

5%

5%

Reference Books:

1. Chua C K, Leong K F, Chu S L, Rapid Prototyping: Principles and Applications in Manufacturing,

World Scientific.

2. Gibson D W Rosen, Brent Stucker., Additive Manufacturing Technologies: Rapid Prototyping to

Direct Digital Manufacturing, Springer.

3. Noorani R, Rapid Prototyping: Principles and Applications in Manufacturing, John Wiley & Sons.

4. Hilton P, Jacobs P F, Rapid Tooling: Technologies and Industrial Applications, CRC press.

5. Liou W L, Liou F W, Rapid Prototyping and Engineering applications: A tool box for prototype

development, CRC Press.

6. Kamrani A K, Nasr E A, Rapid Prototyping: Theory and practice, Springer,

Course Outcome:

On completion of this course students will be able to:

1. Understand and use techniques for processing of CAD models for rapid prototyping.

2. Understand and apply fundamentals of rapid prototyping techniques.

3. Use appropriate tooling for rapid prototyping process.

4. Use rapid prototyping techniques for reverse engineering.

List of Tutorials:

1. Review of CAD Modelling Techniques and Introduction to RP

2. Generating STL files from the CAD Models & Working on STL files

3. Processing the CAD data in Catalyst software (Selection of Orientation, Supports generation, Slicing,

Tool path generation)

4. Simulation in Catalyst Software

5. Fabricating the physical part on a RP machine

6. Learning techniques for fabricating an assembly

7. Prepare a CAD model with complex geometry and study effect of slicing parameters on final product

manufactured through RP.

Major Equipment:

1. CAD Tools.

2. Rapid prototyping machine.

3. 3D Printer.

Review Presentation (RP): The concerned faculty member shall provide the list of peer reviewed Journals

and Tier-I and Tier-II Conferences relating to the subject (or relating to the area of thesis for seminar) to the

students in the beginning of the semester. The same list will be uploaded on GTU website during the first

two weeks of the start of the semester. Every student or a group of students shall critically study 2 papers,

integrate the details and make presentation in the last two weeks of the semester. The GTU marks entry

portal will allow entry of marks only after uploading of the best 3 presentations. A unique id number will be

generated only after uploading the presentations. Thereafter the entry of marks will be allowed. The best 3

presentations of each college will be uploaded on GTU website.

You might also like

- Question Bank - Cad Cam CaeDocument12 pagesQuestion Bank - Cad Cam CaePravin DahalkeNo ratings yet

- Rapid PrototypingDocument123 pagesRapid PrototypingSyed irfan100% (2)

- AutoCAD Electrical 2017 for Electrical Control Designers, 8th EditionFrom EverandAutoCAD Electrical 2017 for Electrical Control Designers, 8th EditionRating: 3 out of 5 stars3/5 (1)

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Divyeshkumar MorabiyaNo ratings yet

- Syllabus AMTDocument2 pagesSyllabus AMTSyed Farooq PatilNo ratings yet

- List of Exercises: Computer Integrated Manufacturing & Technology Driven PracticesDocument1 pageList of Exercises: Computer Integrated Manufacturing & Technology Driven Practicesnavneetkpatil8409No ratings yet

- Am SyllabusDocument1 pageAm Syllabusme SrinietNo ratings yet

- Iam SyllabusDocument1 pageIam Syllabusme SrinietNo ratings yet

- Reverse Engineering SyllabusDocument2 pagesReverse Engineering SyllabusAyush SrivastavNo ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiDocument3 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiGeorge CamachoNo ratings yet

- SyllabusDocument3 pagesSyllabusDishank UpadhyayNo ratings yet

- 19ME307 Rapid Product DevelopmentDocument2 pages19ME307 Rapid Product DevelopmentsahilNo ratings yet

- Unit 1 ADMDocument43 pagesUnit 1 ADMCHINTAKINDI VENKATAIAH RAGHUVAMSHINo ratings yet

- Zero Lecture MEC 135Document20 pagesZero Lecture MEC 135Vivek SharmaNo ratings yet

- The Importance of Additive ManufacturingDocument9 pagesThe Importance of Additive ManufacturingraviNo ratings yet

- Rapid PrototypingDocument90 pagesRapid PrototypingShivam TiwariNo ratings yet

- Annexure CD - 01'Document5 pagesAnnexure CD - 01'Arsalan MustafaNo ratings yet

- 279-Article Text-501-1-10-20200623Document9 pages279-Article Text-501-1-10-20200623SURABHI SAINo ratings yet

- Zero LectureDocument23 pagesZero Lecturetemobam569No ratings yet

- CADCAM Course OutlineDocument9 pagesCADCAM Course OutlineJibril JundiNo ratings yet

- Course 12 Additive Manufacturing For Industry 4Document8 pagesCourse 12 Additive Manufacturing For Industry 4Ioan IonescuNo ratings yet

- SyllabusDocument3 pagesSyllabusAnonymous 4h9p1EIQYSNo ratings yet

- 0 Productlifecycle PDFDocument40 pages0 Productlifecycle PDFCharith ReddyNo ratings yet

- Honours Minor Degree Program Syllabus - 6Document25 pagesHonours Minor Degree Program Syllabus - 6Tarini DeshpandeNo ratings yet

- Title of SubjectDocument2 pagesTitle of Subjectloki654321No ratings yet

- RPT SyllabusDocument2 pagesRPT SyllabusSreejith S NairNo ratings yet

- UNIT1,3Document14 pagesUNIT1,3Sagar BatraNo ratings yet

- Rapid PrototypingDocument6 pagesRapid PrototypingVijay KannanNo ratings yet

- BE Mechanical-Mumbai UniversityDocument82 pagesBE Mechanical-Mumbai UniversityJayesh NavareNo ratings yet

- Topic 1: Overview of CAD/CAM SystemsDocument3 pagesTopic 1: Overview of CAD/CAM SystemsKelvin Ting S BNo ratings yet

- Additive Manufacturing Student NotesDocument90 pagesAdditive Manufacturing Student NotesUdayaKumar100% (1)

- VIIIth Semester Scheme and SyllabusDocument21 pagesVIIIth Semester Scheme and SyllabusJitesh DewanganNo ratings yet

- Additive Manufacturing TechniquesDocument1 pageAdditive Manufacturing Techniquesmathewalex18No ratings yet

- Zero LectureMEC136Document25 pagesZero LectureMEC136SudhanshuNo ratings yet

- Course Scheme MEC 5301 KUST 2k24Document2 pagesCourse Scheme MEC 5301 KUST 2k24Hassan IsmailNo ratings yet

- Rapid Pro To Typing and ToolingDocument2 pagesRapid Pro To Typing and Toolingabhay_15865099No ratings yet

- Course Contents: 1.2 Traditional Prototyping VsDocument90 pagesCourse Contents: 1.2 Traditional Prototyping Vsharsh vaghelaNo ratings yet

- Gujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIDocument4 pagesGujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIKrupal VithlaniNo ratings yet

- Additive Manufacturing Additive Manufacturing Technology Additive ManufacturingDocument19 pagesAdditive Manufacturing Additive Manufacturing Technology Additive Manufacturingvarun.119No ratings yet

- Home About Us Manufacturing Courses Photo Gallery Contact Us Result WebmailDocument6 pagesHome About Us Manufacturing Courses Photo Gallery Contact Us Result WebmailudaygwlNo ratings yet

- Professional Engineering Training Institute (P.E.T.I) : SR - No Workshop Workshop Contents Duration Fees Per StudentDocument1 pageProfessional Engineering Training Institute (P.E.T.I) : SR - No Workshop Workshop Contents Duration Fees Per StudentAmit NirmalNo ratings yet

- Syllabus ADMDocument2 pagesSyllabus ADMDevesh KankariyaNo ratings yet

- Additive MFGDocument18 pagesAdditive MFGEmerald InnovatesNo ratings yet

- CSE II - II SyllabusDocument16 pagesCSE II - II SyllabusBabu GiriNo ratings yet

- Rapid Prototyping and ToolingDocument1 pageRapid Prototyping and Toolingroscilla100% (1)

- Engineering Design & Drafting Institute in MumbaiDocument3 pagesEngineering Design & Drafting Institute in MumbaiSuvidya Institute of TechnologyNo ratings yet

- Rapid Prototyping: Department of Mechanical Engineering, The Ohio State UniversityDocument41 pagesRapid Prototyping: Department of Mechanical Engineering, The Ohio State Universityvikram1092No ratings yet

- AMTA UNIT 1 CompleteDocument11 pagesAMTA UNIT 1 CompleteAdula RajasekharNo ratings yet

- Subject OutlineDocument9 pagesSubject OutlineAbdullah NafiNo ratings yet

- The Integration of CAD/CAM and Rapid Prototyping in Product Development: A ReviewDocument8 pagesThe Integration of CAD/CAM and Rapid Prototyping in Product Development: A ReviewWangi Pandan SariNo ratings yet

- Introduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMDocument12 pagesIntroduction To CAM - Pdfud Abdul Majeed - 1 - Introduction To CAMKiranRao BiradarNo ratings yet

- Preface: Freeform Fabrication, Desktop Manufacturing or Layer Manufacturing TechnologiesDocument3 pagesPreface: Freeform Fabrication, Desktop Manufacturing or Layer Manufacturing TechnologiesZaheer AhamedNo ratings yet

- Summary Rapid Prototyping TechnologiesDocument1 pageSummary Rapid Prototyping Technologiesmuhammadmunawir007No ratings yet

- Flow Measurement Appratus: Aim of The ExperimentDocument5 pagesFlow Measurement Appratus: Aim of The ExperimentRavi Parikh100% (1)

- Product Manual EIE - Pipe Friction FM 300Document12 pagesProduct Manual EIE - Pipe Friction FM 300Ravi ParikhNo ratings yet

- Organization's ISO 9001:2015 Certificate: Product Manual EIE - Cavitation ApparatusDocument10 pagesOrganization's ISO 9001:2015 Certificate: Product Manual EIE - Cavitation ApparatusRavi ParikhNo ratings yet

- Operating Instruction Manual Of: Big Notch and Weir APPARATUSDocument9 pagesOperating Instruction Manual Of: Big Notch and Weir APPARATUSRavi ParikhNo ratings yet

- Operating Instruction Manual Of: Orifice and Mouthpiece ApparatusDocument9 pagesOperating Instruction Manual Of: Orifice and Mouthpiece ApparatusRavi ParikhNo ratings yet

- Product Manual EIE - Pitot Tube ApparatusDocument8 pagesProduct Manual EIE - Pitot Tube ApparatusRavi ParikhNo ratings yet

- Pressure Measurement Apparatus: Operating Instruction Manual ofDocument10 pagesPressure Measurement Apparatus: Operating Instruction Manual ofRavi ParikhNo ratings yet

- Cascade Refrigeration Cycle Test RigDocument16 pagesCascade Refrigeration Cycle Test RigRavi Parikh100% (1)

- EIE Instruments PVT LTD: Product Manual TM - 049 - V-Funnel ApparatusDocument11 pagesEIE Instruments PVT LTD: Product Manual TM - 049 - V-Funnel ApparatusRavi ParikhNo ratings yet

- Spinning Drop Video Tensiometer For Measuring Low To Ultra-Low Interfacial TensionsDocument4 pagesSpinning Drop Video Tensiometer For Measuring Low To Ultra-Low Interfacial TensionsRavi ParikhNo ratings yet

- Product Manual EIE - Bernoullis Theorm ApparatusDocument11 pagesProduct Manual EIE - Bernoullis Theorm ApparatusRavi ParikhNo ratings yet

- L-BOX Apparatus PDFDocument11 pagesL-BOX Apparatus PDFRavi ParikhNo ratings yet

- Veego Matic MD PDFDocument38 pagesVeego Matic MD PDFRavi ParikhNo ratings yet

- Smoke Point Apparatus PDFDocument14 pagesSmoke Point Apparatus PDFRavi ParikhNo ratings yet

- Aimil Geotextile Testing PDFDocument10 pagesAimil Geotextile Testing PDFRavi ParikhNo ratings yet

- Water Absorption Test Ceramic TilesDocument11 pagesWater Absorption Test Ceramic TilesRavi ParikhNo ratings yet

- Marsh Cone Funnel For Grout Astm C939 Flow ConeDocument1 pageMarsh Cone Funnel For Grout Astm C939 Flow ConeRavi ParikhNo ratings yet

- Half Cell Potentiometer - PortableDocument2 pagesHalf Cell Potentiometer - PortableRavi ParikhNo ratings yet

- Assembly of Apparatus For Determination of Carbon Dioxide in LimeDocument2 pagesAssembly of Apparatus For Determination of Carbon Dioxide in LimeRavi ParikhNo ratings yet

- To Study Variables Affecting The Performance of Rankine CycleDocument2 pagesTo Study Variables Affecting The Performance of Rankine CycleRavi Parikh100% (1)

- Stiffness-Based QC/QA Testing: Tech BriefDocument4 pagesStiffness-Based QC/QA Testing: Tech BriefRavi ParikhNo ratings yet

- Speed GlassDocument16 pagesSpeed GlassRavi ParikhNo ratings yet

- Embalming Machine With SS Outer CabinetDocument1 pageEmbalming Machine With SS Outer CabinetRavi ParikhNo ratings yet

- Rapid ToolingDocument31 pagesRapid ToolingRavi ParikhNo ratings yet

- Eureka Flow Meter Product CatlogueDocument8 pagesEureka Flow Meter Product CatlogueRavi ParikhNo ratings yet

- Heat EngineDocument12 pagesHeat EngineRavi ParikhNo ratings yet

- Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801Document3 pagesGujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801Ravi ParikhNo ratings yet