CHAPTER 4 TIMBER/WOOD Wood Structure The trunk consist of a series of concentric rings covered by a layer of bark.

. Each ring represents one year of tree growth and is called annual ring. Function of the trunk to convey a solution (sap) to the leaves to support the tree at such height to ensure a sufficiency of air and light. The older wood is known as heartwood and usually darker in color, drier and harder than the living layer (sapwood). Sapwood has lower natural decay resistance & accepts preservatives more readily than the heartwood.

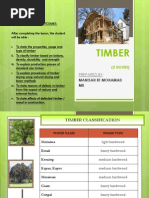

Species of Timber There are more than 2500 species of timber in Malaysia. Malaysia timber are grouped botanically into hardwoods and softwoods. These names can be confusing since some softwoods are actually harder than some hardwoods. And conversely some hardwoods are softer than some softwoods.

�HARD WOODS Have 3 groups based on density & durability heavy, medium and light hardwoods. Sometimes referred to as pored wood - presence of large cell (vessels) which perform the function of conduction. Used for flooring, architectural wood work, interior woodwork, and paneling available from lumberyards and building supply dealers. Most hardwood lumber and dimensions stock are remanufactured into furniture, flooring, pallets, containers and blocking available directly from the manufacturer, through wholesalers and brokers, and from some retail yards SOFT WOODS Referred to as non-pored wood. The cells provide conduction & mechanical support occur principally in the spring wood Used for general construction and structural purposes. Softwoods are available directly from the sawmill, wholesale and retail yards, or lumber brokers. Softwood lumber and plywood are used in construction for forms, scaffolding, framing, flooring and others. Softwoods may also appear in the form of doors and other millwork, in addition to some rough products such as timber and round posts Strength Classes The strength is defined primarily by bending strength. The strength class therefore will contain both different grades and different species. A given species may appear in more than one strength class, depending upon its grade. For Malaysia timber, the strength class will be based on the moisture content and in this case the moisture content more than 19% are taken as consideration.

FRIM has divided the stress of timber into three grades and they are selected grade, standard grade, and common grade. Based on the strength, FRIM had divided the strength into 4 group naming A, B, C and D.

�Factors Affecting Strength of Timber Density The higher the density, the higher the mechanical properties. Young tree very low density and reduced stresses are used for such material The weight of timber is reduced by drying and most strength properties are substantially increased Moisture Content Moisture content of wood is defined as the weight of water in wood expressed as a fraction, usually a percentage, of the weight of oven dry wood. Can be determine by the oven-dry method or by the electricmoisture-meter method Weight, shrinkage, strength, and other properties depend upon the moisture content of wood. In trees, moisture content can range from about 30% to more than 200% of the weight of wood substance. In softwoods, the moisture content of sapwood is usually greater than that of heartwood. In hardwoods, the difference in moisture content between heartwood and sapwood depends on the species. Variability of moisture content exist even within individual boards cut from the same tree. The mechanical properties of wood are considerably influenced by moisture content. Timber need equilibrium moisture content. Equilibrium moisture content is defined as that moisture content at which the wood is neither gaining nor losing moisture; an equilibrium condition has been reached. The moisture content of wood below the fiber saturation point is a function of both relative humidity and temperature of the surrounding air.

Temperature With increasing temperature, the strength of timber decreases. A permanent loss of strength may result if wood is held at a high temperature for a long period. Grain Structure Grain structure determines the permissible and modulus of elasticity.

The tensile strength of timber varies with grain direction. Max. strength if parallel to the grain Min. strength if perpendicular to the grain.

�Position in Tree In softwoods, the wood from near the butt of the tree is usually somewhat denser, stronger and harder than that from near the top of the tree and in the early years of a trees life the wood often tends to become stronger with increasing distance from the pitch. Conditions of Growth Environmental factors affecting tree growth, such as height above sea-level, temperature, rainfall, type of soil and spacing between trees. Defects Knots o o Reduce the strength of the timber but appreciably affect the stiffness of timber. Knots are when the section of the tree branches have been cut with the board either cross section @ longitudinal sections.

Decay o Seriously decayed wood has a very little strength and is particularly low in toughness o Thus timber showing decay should not be used for purposes where strength required o Decay is caused by fungi rather than by bacteria. Insects, borer and marine organism o Termites and the larvae or certain beetles can cause wood destruction, where they exist o Termites are normally found in warmer climates and wood beetles in regions or conditions of high humidity o Attack by marine organism may seriously reduce the strength of timber piles and other timber in contact with salt water or even water of low salinity. Shake, split and checks o These defects are unsightly and reduce the resistance to other stresses. Shakes are lengthwise separations in the wood occurring between annual rings. Split are lengthwise separations of wood caused by handling. Checks are lengthwise separations in the wood, occurring across the annual ring.

�Wood as a structural material

Wood Based Product 1. Plywood Is defined by BS6100 as a term which includes core plywood such as block board and lamin board, is a based panel product consisting of an assembly of plies bonded together, some or all of which are wood, in which all plies are made of veneers oriented with their plane parallel to the surface of the panel. Plywood is a versatile product that can combine attractive surface appearance with superior performance under hazardous conditions whilst retaining comparatively high strength/weight properties Heavy Construction Works Timber piles, bridges, etc 2. Glue laminated timber Refers to structural and non-structural members formed by gluing together boards in such a manner that grain directions in all boards are substantially parallel by the use of arrange of adhesive to: o Increase strength o Improve functional properties o Enhance permissible stresses This depends on: o laminated form of construction, o available of suitable adhesives, o the geometry of the built-up forms.

STRUCTURAL USAGE OF TIMBER:

Marine Structure

Medium/Light Construction Works Roof trusses, rooms partitions, floors, walls, formwork, etc.

Wharves, plies, cofferdam, etc

Characteristic of Structural Timber Density Shrinkage Warping Strength Durability

�Preservation of Timber Preservation treatments Are most commonly designed to introduce materials that will render the wood toxic or repellent and this prevent the growth of fungi and insects. Coal tar creosote Produced by the distillation of bituminous coal and is known as creosote oil. It is permanent owing to its insolubility, and it is highly toxic to both fungi, insects and marine worms. Provided that the creosote oil is deeply and evenly introduced into wood in sufficient quantity, there is an assurance of good protection form borers, termites, decay and marine organisms. Tar Oil Are distilled from coal and wood tar. They do not leach out when used externally, even in water and do not corrode metals. Having high viscosity and often use for the surface treatment or poles either alone or in combination with oil or bitumen. This is applied as a surface dressing and considered to be a poor preservative. Petroleum Oil Refined or residual petroleum oil is considered not to be very effective as petroleum have insufficient toxicity towards fungi to prevent decay. It is expensive, highly inflammable during use and strong smelling. Suitable for brushing or cold dipping, resistance to leaching and non-corrosion. Water-borne Preservatives (Inorganic-Copper, chromium & arsenic salts) Advantages: o Ease of handling o Clean paintable surfaces produced

o Odourless o Non-flammable o Cheaper to buy and to transport This salt combines with other toxic radicals to ensure resistance to fungi and insects but give little protection against weathering. Boric Acid or Borax Boron compound give immunity to veneer and sawn timber against weathering. Advantages: o Cleanliness in use o Permanence in dry timber o Freedom from any known danger to health o Do not stain or colour the wood Method of Treating Timber i. Pressure process: Pressure greater than the atmospheric are employed, the actual pressure depends on the species, preservative and treatment to be given. ii. Non-pressure processes: A. The hot and cold bath treatment. Placed in a tank of hot preservative and heated there for some hours. At the end of the heating period, the timber removed to a separate tank containing cold preservative or left down in the same tank. B. Steeping/soaking in water soluble preservative. This method consist of immersing the dry timber in a tank of preservative, removing, draining and allowing to dry. Duration normally 2 weeks and usually done with preservative of the aqueous solution type.

�Characteristics of Structure Timber Density The density of wood in the green condition is much more variations in moisture content. The value quoted are average densities at 19% moisture content. It is not possible to give on accurate estimate of the weight of nominally green timber as used in a structure because of the unknown drying factors involved and variability of moisture content in the green state. As a general rule, light timbers dry faster than dense timbers and small sections faster than heavy sections, and it can be estimated as such that an increase in weight caused by moisture by adding 0.5% of the given weight for every 1% increase in moisture content. Shrinkage It is important that in all structures made from green timber the possible effect of shrinkage should be recognized, particular attention being paid to joints. Collapse, which is excessive shrinkage resulting from actual collapse of the wood cells, may also occur in some species. This increases the apparent shrinkage and varies according the drying and other conditions. The amount of shrinkage is proportional to the amount of water removed. Shrinkage is not equal in all directions. The greatest shrinkage is in the direction of annual rings, while the least is along the length of the board. Tendency of Warp Warping is a condition in which the flat, plane surface has been distorted in some manner. Types of warp are crook (edgewise deviation), bow (flat deviation), cup (cross deviation) and twist. Warping depends on the way in which the piece is cut from the log (the smaller the size, the greater the tendency to

warp), the defects present, the magnitude of internal stresses in the tree from which the timber is cut. In general, straight-gained timbers with a low shrinkage warp least where as characteristically cross-grained timbers, although remaining straight in large sizes, warp badly in small sizes.

Strength Timber used for structural purposes are usually classified according: o modulus of rapture, o modulus of elasticity, o crushing strength parallel to grain, o shear strength. Timber is much stronger in compression parallel to the grain than in compression perpendicular to it because wood fibers resist compressive loads by giving lateral support to another Timber is also stronger in tension parallel to grain. Timber is very strong in shear perpendicular to the grain. Timber is strong in bending. Bending loads creates compressive stresses in the upper proportion of a beam, tensile stresses in the lower portion, and longitudinal stresses at the neutral axis.

� Durability Is referred to the natural resistance of the wood to fungal decay and termites. It is also noted that if timber are kept thoroughly dry and protected from attack by termites, will last indefinitely. Durability is expressed by one five classes based upon the average life of a 50 mm section of heartwood in ground contact. The classes used are: o very durable (>25 years), o durable (15-25 years), o moderately durable (10-15 years), o non-durable (5-10 years), o perishable (<5 years)