Chapt5 - Theory of Sedimentation PDF

Chapt5 - Theory of Sedimentation PDF

Uploaded by

Ngoni MukukuCopyright:

Available Formats

Chapt5 - Theory of Sedimentation PDF

Chapt5 - Theory of Sedimentation PDF

Uploaded by

Ngoni MukukuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Chapt5 - Theory of Sedimentation PDF

Chapt5 - Theory of Sedimentation PDF

Uploaded by

Ngoni MukukuCopyright:

Available Formats

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-1

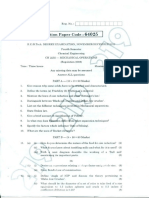

Chapter 5 THEORY OF SEDIMENTATION

Downward movement of small suspended particles by gravity. Sedimentation is classified upon the characteristics and concentration of suspended materials: discrete particles flocculent dilute suspension

Discrete particles (Type 1) Particle whose size, shape and specific gravity do not change with time i.e. noninteractive settling of particles from a dilute suspension. Examples are grit and sand, and their mass is constant. Flocculant particles (Type 2) Particles which agglomerate (coalesce/flocculate) during settling i.e. no constant characteristics. Their mass varies during the process of settling and an increase in mass causes a faster rate of settlement.

Depth

Flocculent particle path

Discrete particle path

Time Fig. 1: Settling paths of discrete and flocculent particles Dilute suspension Concentration of particles is not sufficient to cause significant displacement of water as they settle. 1

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-2

Hindered particles Or called zonal settlement, the particles interact and the concentration of particles is high. Settlement is slow because as particles move down (large in numbers), water is displaced upwards hindering downward settlement.

Theory of sedimentation

Discrete particles Discrete particles will accelerate until a limiting terminal velocity is reached when placed in a liquid of lower density. Gravitational force=frictional drag force

Gravity force = Fg = ( s w )gV

(1)

Where:

s w

V

=density of particle =density of fluid =volume of particle

Fdrag

Fg

Fig. 2: A settling particle in water Fdrag = Cd AC Where: Cd Ac vs =Newtons drag coefficient =cross-sectional area of particle perpendicular to the direction of motion -settling velocity of particle 2

Chapter 5 Theory of Sedimentation

vs2 2

(2)

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-3

The coefficient of drag varies with shape and the regime of flow which is defined by the Reynolds number, Re: For laminar flow, Re1 1<Re103 Re>103

Cd = Cd =

Cd

24 Re 24 3 + + 0.34 Re Re

=0.4 or

Transitional flow, Turbulent flow, and Where;

Re =

v s w d

Re =

v s d

=shape factor =diameter of particle

At equilibrium; Therefore;

Fg = Fdrag

2

( s w )gV = Cd Ac w vs

vs = 2 gV ( s w ) C d Ac w

Particles are assumed spherical and for perfect spheres, the shape factor, =1. The shape factor accounts for irregularities of particles.

V =

d 3

6

Or

4 d V = 3 2

A=

d 2

4

4 gd ( s w ) 3C d w

Hence

vs =

(Newtons law

Or

vs =

4 gd (S s 1) 3Cd

Specific gravity 3

Ss =

s w

Chapter 5

Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-4

Therefore for laminar flow:

gd 2 ( s w ) 18

vs =

gd 2 (S s 1) 18 vs =

(Stokes Law)

Or Where;

vs =

gd 2 (S s S w ) 18

Ss Sw

=specific gravity of particle =specific gravity of liquid

To use the above equations for nonspherical particle, the diameter d must be the diameter of equivalent spherical particle. The volume of the equivalent spherical particle:

Vsphere

4 d 2 = = d non spher 3 2

d = 1.24 0.33 d non sphere

Estiamte values for the shape factors (Sincero, 1996) are in Table 1: Table 1; Estimated values of shape factors shape factor ( ) 0.64 0.77 0.86 1.0

Materila Angular sand Sharp sand Worn sand Perfect sphere

In water treatment flow is usually laminar and transitional, but the sphericity is not always 1, i.e. particles not always spherical. The effects of irregular shape are not pronounced in low settling velocities. This suite most sedimentation processes because they are designed to remove small particles which settle slowly.

Kinematic vis cos ity, =

absolute vis cos ity , mass density,

Therefore dynamic viscosity,

Example 1 Determine the terminal settling velocity for a sand particle with an average diameter of 0.5mm and a density of 2600kg/m3 settling in water at 20oC. 4

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-5

Solution: 1 Determine the terminal settling velocity using Stokes Law:

Check the Reynolds number and assuming =0.85 for sand.

NR 3

=93.2

Because the Reynolds number is greater than 1, then it should be computed 24 3 from the equation: C d = + + 0.34 Re Re

5

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-6

Example 2 Determine the terminal settling velocity of a discrete spherical particle having a diameter of 0.6mm and specific gravity of 2.65. T=22oC.

6

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-7

Example 3 Determine the terminal settling velocity of a discrete worn sand particle having a measured diameter of 0.6mm and specific gravity 2.65. T=22oC. Solution

7

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-8

SETTLING IN AN IDEAL SETTLING BASIN FOR TYPE 1 PARTICLES

An ideal horizontal settling zone is free from inlet and outlet disturbance, in which particles settle freely at terminal settling velocities in quiescent conditions without any disturbances and flocculation is absent (Fig. 3). The particles are distributed uniformly In the design of sedimentation basins, the usual procedure is to select a particle with a terminal velocity vs and to design the basin so that all the particles that have a terminal velocity equal to or greater than vs will be removed.

Q = Av s

Where: A vs =surface area of sedimentation basin =settling velocity or surface loading, m3/m2.day ( v s =

(1)

Q ) A

Inlet zone Particle trajectory h Settling zone vp vs

vp

Outlet zone

Fig. 3 Type I settling in a horizontal basin 8

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-9

Design velocity for a continuous flow sedimentation:

vs =

depth det ention time

H T

The length of basin and the time a unit of water spend in the basin (detention time) should be such that all particles with velocity vs will settle at the bottom of basin, but adjustments must be made for:

effects of inlet and outlet turbulence short circuiting sludge storage

Particles with velocity less than vs will not be removed during the detention time, but some particles with velocity less than vs which enter the tank at distance from the bottom not greater than H will be removed e.g. at h. Assuming that particles of various sizes are uniformly distributed on the entire depth H, at inlet, then particles with settling velocity vp less than vs will be removed in the ratio:

Xr =

Where:

vp vs

Xr =fraction of particle with settling velocity vp that are removed

i.e. particle with settling velocity vp less than vs which enter the tank at a distance from the bottom not greater than H that are removed. To determine the efficiency of removal for a given settling time, t it is necessary to consider the entire range of settling velocities present in the tank. Determination of settling velocities

sieve analysis and hydrometer test combined with Stokes Law:

vs =

g (S s 1)d 2 18

settling column

Settling column analysis 9

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-10

a settling column 2 to 3m deep, and diameter at least 100x largest particle size to prevent wall effects is used (Fig. 4). the initial suspended solid concentration of the suspension is noted, Co in mg/l sample is placed in a jar and mixed completely to ensure uniform distribution of particles. suspension is allowed to settle quiescently samples are drawn at time intervals at a point h (one point) discrete settling particles, the depth of sampling will not affect the resultant distribution curves h of the settling velocities: vi = ti all particle with velocity vp>vs will pass the sampling point and settle, and particles remaining must have settling velocity less than vs (vp<vs). However, there us a partial removal of some particles with velocity vp<vs and will be removed in the ratio:

vs the procedure is repeated for time intervals t2, t3; t4; t5..tn, and these values of settling velocities are plotted against mass fraction remaining to give the settling velocity characteristic distribution curve for the suspension (Fig. 5).

vp<vs

Xr =

vp

Sampling point h

vp>vs

Fig. 4 Column analysis for discrete particles

10

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-11

1.0

Proportion of particles with less than stated settling velocity

1-Xs Xs

Removed particles

Xp

Suspension settling velocity distribution curve for the mass fraction remaining

vp

vs

Settling velocities

Fig. 5: Settling velocity distribution curve for the mass fraction remaining xs vp The total removal is given as: R = (1 x s ) + dx v 0 s Where; Xs =particles with vp=vs 1=Xs =fraction of particles with vpvs removed

xs

v

0

vp

s

dx =fraction of particles with vp<vs removed

Example Determine the total removal efficiency given the following data:

settling analysis results Table 2 column is 1.6m deep surface loading is 30m/day Co=200mg/l

Table 2 Time, min Conc, Ci, mg/l Solution 11

Chapter 5 Theory of Sedimentation

0 200

40 175

80 170

120 160

160 155

200 110

240 80

280 35

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-12

1.

Compute mass fraction remaining and corresponding velocities (Table 3)

Table 3 Time (min) Mass fraction remaining, C xi = i Co h vs = , t m/min vs (m/min) 40 0.88 80 0.85 120 0.8 160 0.78 200 0.55 240 0.4 280 0.175

0.04

0.02

0.013

0.01

0.008

0.0067

0.0007

4x10-2

2x10-2

1.3x10-2

1x10-2

0.8x10-2

0.67x10-2

0.07x10-2

12

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-13

13

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-14

TYPE II SETTLING (FLOCCULENT PARTICLES)

Flocculation particles are in dilute suspension settling is a result of inter-particle collisions density of particles change because flocculating particles are continually changing in size, shape and settling velocities due to the above factors, Stokes law cannot be applies

Analysis of settlement for Type 2 particles analysis performed in column at least 300mm in diameter depth equal to the proposed sedimentation tank samples are withdrawn at regular time intervals from multiple ports or different sampling heights and analysed to determine the reduction in suspended solids the % removal is plotted as a numerical value against the depth and time the concentrations obtained are used to compute mass fraction removal instead of he mass fraction remaining from the plot removal at various times, the theoretical efficiency is predicted and a theoretical surface loading is established the design surface loading should be 1/3 of that suggested by the settling tests (theoretical), to get similar solids removal results to those obtained from a settling column

Cij xij = 1 C 0 100 ,

Where: xij Co Cij

=mass fraction is % that is removed at the ith depth at jth time interval =initial solid concentration =concentration at ith depth and jth depth time interval

the values Cij and time are plotted to give isoremoval lines (Fig. 6), lines with the same concentration the slope at any point on any given isoremoval line is the instantaneous velocity of the fraction of particles represented by the line 14

Theory of Sedimentation

Chapter 5

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-15

velocity becomes greater at greater depth (the slope of the isoremoval lines becomes steeper), a common characteristic of flocculating suspensions, reflecting and increase in particle size and settling velocity because of continued collision and aggregation with other particles.

The % removal is given as:

% removal =

Where: h R1 h

h R + Rn +1 h1 R1 + R2 h2 R2 + R3 + ..... + n n + h 2 h 2 h 2

=column height =see diagram =see diagram

Example Determine the overall removal efficiency of the sedimentation tank and surface loading given the following g data:

initial solid concentration of sample Co =200mg/l results of column analysis of flocculating suspension (Table 4) height of sedimentation tank =2.4m detention time =1 hr 20min

Table 4

Table 5 15

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-16

Solution

Cij (Table 5) xij = 1 C 100 0 plot iso-concentration lines (isoremoval lines), Fig. 6 plot vertical line at t =1 hr 20 mins (80 mins, i.e. retention time) from the graph at 80 mins, about 45% of the solids reach the floor i.e. 100% removed determine h Overall removal, R

compute

16

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-17

Fig. 6 Plot of the iso-concentration curves

Overal % removal =

0.5 45 + 50 0.6 50 + 60 0.3 60 + 70 0.5 70 + 80 0.3 80 + 90 + + + + 2.4 2 2.4 2 2.4 2 2.4 2 2.4 2

0.4 90 + 100 = 73.76% 2.4 2

Surface loading

Q m 3 / day Area(L B ), m 2

volume of tan k Q

Detention time,

t=

80 =

Area heigh Area 2.4 = Q Q

17

Chapter 5 Theory of Sedimentation

cmutsvangwa: Water Quality & Treatment, Dept of Civil & Water Eng.

10/10/2006

5-18

80 min Area = 2.4m Q

Surface loading

Q 2.4 = = 0.03m / min = 43.2m / day = 43.2m 3 / m 2 .day area 80

Adjustment for full scale

SL =

43.2 = 28.8m / day 28.8m 3 / m 2 .day 1.5

The surface loading for continuous flow tank should be 1/3 of that suggested by the settling column tests to get similar solids removal results to those obtained from a settling column. The optimum removal efficiency can be obtained by trying several detention times and then computing the surface loadings. The one which gives the maximum removal efficiency will be the one corresponding the maximum optimum surface loading. References

18

Chapter 5 Theory of Sedimentation

You might also like

- Shear Box TestDocument24 pagesShear Box TestDira Azman88% (8)

- 01 Teach Yourself Complete Afrikaans (2010)Document370 pages01 Teach Yourself Complete Afrikaans (2010)Ngoni Mukuku100% (10)

- Sample Project PlanDocument21 pagesSample Project PlanNgoni MukukuNo ratings yet

- Choke Valve DatasheetDocument1 pageChoke Valve DatasheetMuhammad Rizqi Siregar100% (1)

- KJM4120 Ch3 Defect EquilibriaDocument31 pagesKJM4120 Ch3 Defect EquilibriaMohamed Elsherif100% (1)

- SedimentationDocument16 pagesSedimentationAbriti PantaNo ratings yet

- Chapter 4Document13 pagesChapter 4selambante shiferawNo ratings yet

- SEDIMENTATION PresentationDocument45 pagesSEDIMENTATION PresentationShai Sta CatalinaNo ratings yet

- SedimentationDocument26 pagesSedimentationDavid Charles Meissner100% (1)

- Rms Polytechnic: Prepared By: Priyanka PatelDocument35 pagesRms Polytechnic: Prepared By: Priyanka PatelBhaumik ParmarNo ratings yet

- 6.0 SedimentationDocument43 pages6.0 Sedimentationmythili100% (1)

- SedimentationDocument41 pagesSedimentationGailNo ratings yet

- CrystallizationDocument13 pagesCrystallizationnilay100% (1)

- 3M3 Drag On A Sphere F18!08!2007Document9 pages3M3 Drag On A Sphere F18!08!2007Valentin MoldovanNo ratings yet

- Concept of Settling PDFDocument25 pagesConcept of Settling PDFkasara sreetejNo ratings yet

- SedimentationDocument6 pagesSedimentationgnino2No ratings yet

- Centrifugal Separation Processess: Prepared by Engr. Sandra Enn BahintingDocument31 pagesCentrifugal Separation Processess: Prepared by Engr. Sandra Enn BahintingSandra Enn BahintingNo ratings yet

- Coal Cleaning by Dense Medium Processes H.J. Ruff InprominDocument12 pagesCoal Cleaning by Dense Medium Processes H.J. Ruff InprominTsakalakis G. KonstantinosNo ratings yet

- SedimentationDocument38 pagesSedimentationMilind BhaskarNo ratings yet

- Filtration: Filtration May Be Defined As The Separation of Solid From A Fluid by Means of A PorousDocument33 pagesFiltration: Filtration May Be Defined As The Separation of Solid From A Fluid by Means of A PorousMutia Anissa MarsyaNo ratings yet

- Flotation - Release AnalysisDocument35 pagesFlotation - Release AnalysiswitkerzNo ratings yet

- Extraction and Leaching PPT Notes PDFDocument15 pagesExtraction and Leaching PPT Notes PDFJeaz JeazeNo ratings yet

- SedimentationDocument3 pagesSedimentationEldee BalolongNo ratings yet

- CHEE 220 Lecture Settling & Sedimentation 2021Document39 pagesCHEE 220 Lecture Settling & Sedimentation 2021BASEKI JANI100% (1)

- SedimentationDocument76 pagesSedimentationKhalid Rehman100% (2)

- Final ThesisDocument53 pagesFinal Thesislaconic700100% (1)

- Feedwell Technology & Feed Dilution Systems: Improved Thickener PerformanceDocument4 pagesFeedwell Technology & Feed Dilution Systems: Improved Thickener PerformanceJeromeNo ratings yet

- Fluid Mechanics: Dr. Kamel Mohamed GuedriDocument28 pagesFluid Mechanics: Dr. Kamel Mohamed GuedriAd Man GeTigNo ratings yet

- Pre-Lab ReportDocument6 pagesPre-Lab ReportTintin Brusola SalenNo ratings yet

- Chapter 4four Mechanical Micro-Processes in A FluidDocument43 pagesChapter 4four Mechanical Micro-Processes in A Fluidabdisahurisa24100% (1)

- Principle of SedimentationDocument13 pagesPrinciple of SedimentationKataiTaiNo ratings yet

- Leaching TheoryDocument12 pagesLeaching TheoryJérôme Kyabu0% (1)

- Che 516 Rate-Controlling StepDocument35 pagesChe 516 Rate-Controlling StepDaniel OmolewaNo ratings yet

- Sedimentation: Engr. Nadeem Karim BhattiDocument23 pagesSedimentation: Engr. Nadeem Karim BhattiEngr Sarang Khan100% (1)

- Filtration FinalDocument42 pagesFiltration FinalUsha gowdaNo ratings yet

- A Parametric Study of Froth Stability and Its EffectDocument19 pagesA Parametric Study of Froth Stability and Its EffectJuan OlivaresNo ratings yet

- Thickeners: It Pays To Talk To A SpecialistDocument8 pagesThickeners: It Pays To Talk To A SpecialistKumardasNsNo ratings yet

- KineticsOverview 2Document47 pagesKineticsOverview 2Rara JaveeeNo ratings yet

- Sedimentation ReportDocument36 pagesSedimentation Reportmsherwin017100% (1)

- Fluidization 180402101141Document13 pagesFluidization 180402101141suraj nakumNo ratings yet

- Settling Velocities of Particulate Systems, 6 Kynch Sedimentation ProcessesDocument20 pagesSettling Velocities of Particulate Systems, 6 Kynch Sedimentation ProcessesChristy Alexandra Solano GavelánNo ratings yet

- Sewage Treatment: Chapter Two: Characteristics of Wastewater by Roman ADocument54 pagesSewage Treatment: Chapter Two: Characteristics of Wastewater by Roman Amarshet berhanNo ratings yet

- Settling and SedimentationDocument28 pagesSettling and SedimentationPratiksha GoreNo ratings yet

- CHE572 Chapter 2 Particle Size Characterization PDFDocument18 pagesCHE572 Chapter 2 Particle Size Characterization PDFMuhd FahmiNo ratings yet

- Crystallization Lecture 15Document25 pagesCrystallization Lecture 15Syed Zawar Shah100% (1)

- Flow Through Porous MediaDocument20 pagesFlow Through Porous MediaOmarNo ratings yet

- Mechanical Operations PDFDocument50 pagesMechanical Operations PDFAyush DubeyNo ratings yet

- Lecture 3: Exercise On Measurement of QuantitiesDocument3 pagesLecture 3: Exercise On Measurement of Quantitiesjr_satishNo ratings yet

- Particle Size AnalysisDocument15 pagesParticle Size AnalysissampathkumarNo ratings yet

- Lecture 1425072667Document35 pagesLecture 1425072667Mahesh Babu TalupulaNo ratings yet

- FiltrationDocument23 pagesFiltrationNeha PatelNo ratings yet

- Sedimentation Unit Experimental ManualDocument17 pagesSedimentation Unit Experimental ManualShoaib PathanNo ratings yet

- Chapter One - Mecanical Unit OperationDocument17 pagesChapter One - Mecanical Unit OperationBizuayehu GeroNo ratings yet

- CHE505 ChapterOne Part2 HIM PDFDocument81 pagesCHE505 ChapterOne Part2 HIM PDFShammil AshmanNo ratings yet

- Lecture 6 - CrystallizationDocument29 pagesLecture 6 - CrystallizationRA Memije33% (3)

- CoagulationDocument51 pagesCoagulationKhalid Rehman100% (1)

- Leaching 1 2Document32 pagesLeaching 1 2hartatiprasetyoNo ratings yet

- Report On The Water Treatment Process-MonaDocument9 pagesReport On The Water Treatment Process-MonaBrandeice BarrettNo ratings yet

- 4 FlotationDocument27 pages4 FlotationAnonymous c8tyA5XlNo ratings yet

- SedimentationDocument8 pagesSedimentationnoelNo ratings yet

- Conservation Laws of Fluid Motion: 2.1 Governing Equations of Fluid Flow and Heat TransferDocument16 pagesConservation Laws of Fluid Motion: 2.1 Governing Equations of Fluid Flow and Heat TransferkantscribdNo ratings yet

- Settling DWDocument13 pagesSettling DWLenin MaldonadoNo ratings yet

- !32303037Document16 pages!32303037Luis Benitez100% (1)

- Envirenmental EngineeringDocument87 pagesEnvirenmental Engineering4919404No ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Use of DiscreteDocument8 pagesUse of DiscreteamancivilNo ratings yet

- General Strategies For Global BrandsDocument10 pagesGeneral Strategies For Global BrandsSteffen KurniawanNo ratings yet

- 1effect of Fly AshDocument2 pages1effect of Fly AshNgoni MukukuNo ratings yet

- IPMZ Higher Dip Assignment Booklet April 2013Document15 pagesIPMZ Higher Dip Assignment Booklet April 2013Ngoni MukukuNo ratings yet

- Chapter 3 Double Entry BookkeepingDocument16 pagesChapter 3 Double Entry BookkeepingNgoni Mukuku100% (2)

- Chapter 4 Accruals and PrepaymentsDocument12 pagesChapter 4 Accruals and PrepaymentsNgoni Mukuku100% (2)

- Externality AssignmentDocument8 pagesExternality AssignmentNgoni MukukuNo ratings yet

- Brave Brands AccountingDocument6 pagesBrave Brands AccountingNgoni MukukuNo ratings yet

- Chapter 2 Accounting Concepts and Principles PDFDocument12 pagesChapter 2 Accounting Concepts and Principles PDFAnonymous F9lLWExNNo ratings yet

- By Doug Batchelor Gift of Tongues by Hal Steenson: An Amazing FactDocument11 pagesBy Doug Batchelor Gift of Tongues by Hal Steenson: An Amazing FactNgoni MukukuNo ratings yet

- By Doug Batchelor Gift of Tongues by Hal Steenson: An Amazing FactDocument11 pagesBy Doug Batchelor Gift of Tongues by Hal Steenson: An Amazing FactNgoni MukukuNo ratings yet

- Marketing Mix 1 4psDocument21 pagesMarketing Mix 1 4psNgoni MukukuNo ratings yet

- Developing A Global Marketing Vision Through Marketing ResearchDocument3 pagesDeveloping A Global Marketing Vision Through Marketing ResearchNgoni MukukuNo ratings yet

- Agricultural PoliciesDocument8 pagesAgricultural PoliciesNgoni MukukuNo ratings yet

- Scope and Challenge of International MarketingDocument6 pagesScope and Challenge of International MarketingNgoni MukukuNo ratings yet

- Famous Honda BusinessDocument20 pagesFamous Honda BusinessNgoni MukukuNo ratings yet

- The Entrepreneurial ProcessDocument13 pagesThe Entrepreneurial ProcessNgoni Mukuku100% (1)

- Commodity MarketingDocument21 pagesCommodity MarketingNgoni MukukuNo ratings yet

- Chapter 1 Basic PrinciplesDocument13 pagesChapter 1 Basic PrinciplesNgoni MukukuNo ratings yet

- Chapter 9 Agribusiness ConsolidationDocument3 pagesChapter 9 Agribusiness ConsolidationNgoni MukukuNo ratings yet

- Asignacion Inqu #2Document3 pagesAsignacion Inqu #2Ruben Jair CiezaNo ratings yet

- HA-YS310 Basic Seminar PL ENG 170126 (MHa) PDFDocument36 pagesHA-YS310 Basic Seminar PL ENG 170126 (MHa) PDFEduardo Expósito EspinosaNo ratings yet

- Compre 3 Problem Set No. 1Document8 pagesCompre 3 Problem Set No. 1Jhundel Factor PajarillagaNo ratings yet

- Chapter 5 - Section A - Mathcad Solutions: 5.2 Let The Symbols Q and Work Represent Rates in Kj/s. Then by Eq. (5.8)Document21 pagesChapter 5 - Section A - Mathcad Solutions: 5.2 Let The Symbols Q and Work Represent Rates in Kj/s. Then by Eq. (5.8)light2618No ratings yet

- Department of Mechanical Engineering, IIT Bombay ME 202 End Sem Exam (Spring 2021)Document5 pagesDepartment of Mechanical Engineering, IIT Bombay ME 202 End Sem Exam (Spring 2021)Bitthal ParidaNo ratings yet

- 9 Science NcertSolutions Chapter 10 ExercisesDocument11 pages9 Science NcertSolutions Chapter 10 ExercisesPujitha PotnuruNo ratings yet

- Faculty of Architecture Question Bank: ClimatologyDocument3 pagesFaculty of Architecture Question Bank: ClimatologyVinoth Kumar100% (3)

- Castellated GirderDocument14 pagesCastellated Girderpriyesh jainNo ratings yet

- Unit 10 - Week 7: Solution Thermodynamics: Assignment 7Document4 pagesUnit 10 - Week 7: Solution Thermodynamics: Assignment 7Ashish SinghNo ratings yet

- Lecture 6 RefrigerationDocument65 pagesLecture 6 RefrigerationRamon Gerald AsiloNo ratings yet

- A Step-by-Step Approach To Pump Selection Pumps & SystemsDocument6 pagesA Step-by-Step Approach To Pump Selection Pumps & SystemsABRAHAM ESTRADANo ratings yet

- Sahmani 2019Document15 pagesSahmani 2019Nahid SalmanNo ratings yet

- History SeismologyDocument1 pageHistory SeismologyRadu GanciuNo ratings yet

- Chap 09 T1 Matric Worksheet ChemistryDocument1 pageChap 09 T1 Matric Worksheet ChemistryMuhammad Asim RazaNo ratings yet

- Week 1Document14 pagesWeek 1Mohammed AlryaniNo ratings yet

- 0 - Pengantar Reaktor KimiaDocument16 pages0 - Pengantar Reaktor KimiaMuktafa AkmalNo ratings yet

- Study of Mechanical Properties of Bones and Mechanics of Bone FractureDocument8 pagesStudy of Mechanical Properties of Bones and Mechanics of Bone FracturerifkizidnyNo ratings yet

- ADV Refrigeration System Using FlashchamberDocument40 pagesADV Refrigeration System Using FlashchamberAwesm RishuNo ratings yet

- Fundamental of Mechanical Engineering & Mechatronics MCQsDocument36 pagesFundamental of Mechanical Engineering & Mechatronics MCQsAshish VermaNo ratings yet

- Technical Data: 150x100 CNJA 5 30Document5 pagesTechnical Data: 150x100 CNJA 5 30سمير البسيونىNo ratings yet

- ICSDC 2017 Paper 712Document7 pagesICSDC 2017 Paper 712Jose Joaquin Lozano RadaNo ratings yet

- AISI 1005 Steel: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument2 pagesAISI 1005 Steel: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelIsrael BenavidesNo ratings yet

- DiStillation PDFDocument152 pagesDiStillation PDFMeredith VillareteNo ratings yet

- Engineering Solutions: Kolmetz Handbook of Process Equipment Design Cooling Tower Selection, Sizing and TroubleshootingDocument27 pagesEngineering Solutions: Kolmetz Handbook of Process Equipment Design Cooling Tower Selection, Sizing and Troubleshootingthexp0werNo ratings yet

- Lumped Heat Capacity AnalysisDocument7 pagesLumped Heat Capacity AnalysisSaumyajit MajumderNo ratings yet

- Homework Problem Set 4 Solutions: Chemistry 360 Dr. Jean M. StandardDocument10 pagesHomework Problem Set 4 Solutions: Chemistry 360 Dr. Jean M. Standardisaac wekesaNo ratings yet

- AP Chem Ch. 5 Study Sheet 6: Identify The Choice That Best Completes The Statement or Answers The QuestionDocument3 pagesAP Chem Ch. 5 Study Sheet 6: Identify The Choice That Best Completes The Statement or Answers The QuestionKarm VeerNo ratings yet