A Method To Test The Detectability of GC PFPD For

A Method To Test The Detectability of GC PFPD For

Uploaded by

Marian Si Teofana HasnaCopyright:

Available Formats

A Method To Test The Detectability of GC PFPD For

A Method To Test The Detectability of GC PFPD For

Uploaded by

Marian Si Teofana HasnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

A Method To Test The Detectability of GC PFPD For

A Method To Test The Detectability of GC PFPD For

Uploaded by

Marian Si Teofana HasnaCopyright:

Available Formats

J. Sep. Sci.

2008, 31, 1761 1768

K.-H. Kim

1761

Ki-Hyun Kim

Atmospheric Environment Laboratory, Department of Earth and Environmental Sciences, Sejong University, Seoul, Korea

Original Paper A method to test the detectability of GC/PFPD for an extended concentration range with respect to reduced sulfur compounds

In this study, a possible means to extensively expand the quantifiable range of reduced sulfur compounds (RSC) in air has been investigated by a combined application of GC with pulsed flame photometric detector (PFPD) and a multifunction thermal desorber (TD) system. To comply with the purpose of this study, gaseous RSC standards containing the equimolar concentrations of H2S, CH3SH, DMS, DMDS, and CS2 were prepared at 11 concentration levels (i. e., 10 ppb 10 ppm (over 103 range)). These standards were then used to derive three-point calibrations based on the modified injection through a TD (MITD). If the mean calibration slopes of each concentration level are normalized to that of CH3SH, the relative ordering is found as 0.65 (H2S): 1 (CH3SH): 1.34 (DMS): 2.24 (DMDS). The reproducibility of MITD method, when assessed in terms of relative standard error (RSE) for all calibration slopes, had the most stable pattern for DMDS (5.77%) and the least stable one for H2S (12.8%). The sensitivity of the MITD-based calibration generally improved with an increase in concentration levels of standard gas. Based on our study, the MITD technique is useful to extend quantification of GC/PFPD by allowing RSC detection over a 103 range.

Keywords: Hydrogen sulfide / PFPD / Reduced sulfur compounds (RSC) / Thermal desorber / Received: December 23, 2007; revised: January 29, 2008; accepted: January 30, 2008 DOI 10.1002/jssc.200700682

1 Introduction

It is commonly acknowledged that airborne pollutants are divided into gaseous or particulate phases by their physical nature. If the former phase type is divided further with respect to the potential of sensory recognition, they can be distinguished as either odorous or odorless components. Malodor issues can hence be accounted for by the instantaneous or continuous build-up of offensive components in air. The odorous compounds produced by and released from many types of man-made activities include diverse chemical groups such as aldehydes or reduced sulfur compounds (RSC) [1]. Because these chemicals can pose a nuisance and/or health threats above cerCorrespondence: Dr. Ki-Hyun Kim, Atmospheric Environment Laboratory, Department of Earth and Environmental Sciences, Sejong University, Seoul 143-747, Korea E-mail: khkim@sejong.ac.kr Fax: +82-2-499-2354 Abbreviations: AS, air server; FPD, flame photometric detection; MFC, mass flow controller; MITD, modified injection through a thermal desorber; MS, multistream selector; PFPD, pulsed flame photometric detector; RSC, reduced sulfur compounds; RSE, relative standard error; SR, square root; TD, thermal desorber

tain concentration levels, accurate quantification of their concentration levels is often recognized as the key component to their regulation. Although the analysis of each individual component from the mixture of odorous chemicals involves the employment of multiple analytical set-ups, the operation of such system does not necessarily guarantee the detection of certain components with the fairly low threshold values. Due to several complexities involved in the RSC analysis, there has been a pressing need for the development of methodologies allowing their quantification at various pollution levels [2]. As GC determination of RSC heavily relied on the flame photometric detection (FPD) method in the early stage, a modification of the instrumental set-up has often been implemented to atone for its limited detectability [3, 4]. Technical limitations encountered in the early stage were however resolved to a certain degree by the introduction of more sensitive instrumental systems (e. g., pulsed FPD (PFPD), sulfur chemiluminesence (SCD), etc.). Moreover, improvements in the focusing technique with the aid of thermal desorber (TD) or solid phase microextration (SPME) allowed us to expand the efficiency of the cryofocusing stage with the substitution of an electronic cooling sys-

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jss-journal.com

1762

K.-H. Kim

J. Sep. Sci. 2008, 31, 1761 1768

tem for liquid nitrogen [5 8]. As such, acquisition of RSC at sub-ppb concentration levels has been facilitated not only for grab sampling method [9] but also for an online analysis [10]. Although advances accomplished in the GC-based analysis of RSC are substantial, there are still several restrictions to overcome in the present technologies. Because of the uniqueness of sulfur specific detection systems (e. g., FPD and PFPD), the detectability of such systems generally falls on a narrow quantifiable range [9]. In an effort to investigate the detectability of RSC contained in various environmental samples, we investigated the performance characteristics of the GC/PFPD system for both low concentration samples (e. g., ppb range with the aid of TD [2]) and high concentration samples (e. g., ppm range without a complicated supporting system [11]). As a result, we were able to describe the fundamental properties of the PFPD application for each analytical mode (e. g., the reproducibility, equimolarity of S response, and LODs). In the present study, we report an overview of our new experimental approach, namely the modified injection through a TD (MITD) technique to explore the quantification of RSC over a wide concentration range (i. e., 103) under the unified operation settings of the TD system.

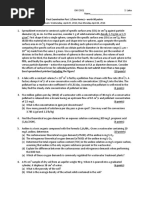

Figure 1. An instrumental set-up for the RSC analysis in the present study: a schematic diagram of a combined set-up for the preconcentration system using an AS and a TD unit.

2 Materials and methods

2.1 Theoretic basis of the MITD method

The MITD technique is a modified approach developed to analyze gaseous samples over an extended concentration range with the aid of the multifunction TD system equipped with air server (AS) unit (UNITY model, Markes International, UK) (Fig. 1). (Here, the term multifunction TD is used, as it is built to facilitate the analysis of volatile compounds collected either by tube sampler or by bag sampler with the aid of a programmable gas flow control system (AS)). Considering that the AS system is built to transfer a sample with large volume (e. g., above a few tens to several hundreds of mililiters) at a given flow rate, its usage is basically limited to the samples of significantly low concentrations (samples with ppb or ppt levels). This is inevitable, unless extra dilution is applied to the concentrated samples. Because of uncertainties in low sample transfers by the mass flow controller (MFC) unit (at significantly low flow rates) or the system contamination during the treatment of concentrated samples, the AS/TD system is not feasible to directly analyze highly concentrated samples (e. g., ppm level) with a small sample volume size. Accordingly, if the analysis of highly concentrated RSC samples is desirable, one needs to employ the system that fits such purpose (e. g., direct injection into the GC injector or into a loop injection system). Although a number of dual instrumental system

Figure 2. Pictures of the MITD technique: (A) the upper two pictures show the connection between Tedlar bag and an outlet of the MS; and (B) the lower two pictures show that the silicone tubing line used for connecting MS and Tedlar bag is used as the temporary injector to receive standard gases loaded in a gas-tight syringe.

had been built with FPD or PFPD to treat RSC samples of different concentration ranges, relatively little is known about a single system to cover a wide concentration range at once [9]. For the purpose of extending the applicability of the PFPD system to cover samples over a wide concentration range, we investigated an MITD technique in which both ambient and polluted samples can be analyzed by the

www.jss-journal.com

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

J. Sep. Sci. 2008, 31, 1761 1768

Gas Chromatography

1763

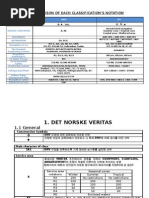

Table 1. A design of experiment for RSC calibration over 103 concentration range; results of computation are given for the absolute quantity of RSC supplied to the TD system by means of MITD technique

Exp no. Concentrationa) STD loading conditionb) Absolute quantity of RSC loaded into TD (ng) CH3SH DMS DMDS CS2 H 2S CH3SH Peak area

ppb

lmol/m3 Volume Quantity H2S (mL) (pmol) 0.42 40 80 160 20 40 80 13.3 28.0 53.3 8 16 32 4 8 16 2 4 8 0.8 1.6 3.2 0.4 0.8 1.6 0.2 0.4 0.8 0.08 0.16 0.32 0.04 0.08 0.16 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 16.6 33.3 66.5 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.19 2.27 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.13 2.27 0.57 1.13 2.27

DMS

DMDS

CS2

10

20

0.83

30

1.2

50

2.1

100

4.2

200

8.3

500

20.8

1 000 41.6

2 000 83.2

10

5 000 208.0

11

10 000 415.9

0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.68 3.20 0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.60 3.20 0.80 1.60 3.20

1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.17 4.13 1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.07 4.14 1.03 2.07 4.14

1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.29 6.27 1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.13 6.27 1.57 3.13 6.27

1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.66 5.06 1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.53 5.06 1.26 2.53 5.06

49 391 156 581 450 725 25 806 226 820 628 864 83 603 195 426 538 914 81 329 236 932 613 997 60 884 171 478 501 417 66 960 196 799 508 711 51 015 148 734 418 506 60 640 190 038 524 178 42 075 120 549 344 699 42 734 124 880 390 635 13 320 213 780 541 257

110 377 300 193 723 448 62 477 412 396 974 996 149 526 351 691 931 145 148 659 418 908 993 324 116 343 313 440 862 283 125 692 354 617 871 313 92 853 259 204 691 164 104 276 325 357 851 720 99 636 277 713 729 541 96 916 282 477 787 940 17 304 355 976 906 061

189 512 445 327 916 003 115 163 518 438 1 177 001 225 138 476 331 1 113 920 240 979 571 180 1 244 813 196 383 465 779 1 144 388 231 454 533 012 1 161 088 166 682 381 322 941 383 175 934 475 460 1 102 230 184 982 441 564 1 018 835 205 461 439 165 1 097 372 40 381 539 141 1 235 904

913 823 1 716 911 3 095 306 444 013 1 581 136 3 377 564 691 801 1 315 745 2 941 429 712 211 1 504 973 3 133 538 586 399 1 256 697 2 841 987 676 122 1 393 882 2 951 146 524 862 1 077 401 2 415 515 603 614 1 325 688 2 808 208 555 638 1 200 920 2 518 763 597 114 1 164 020 2 640 547 137 326 1 428 593 3 023 435

572 335 1 005 099 1 617 443 272 084 840 920 1 866 615 408 319 788 120 1 918 117 425 196 954 264 2 107 891 337 194 774 859 1 955 211 411 278 853 949 1 997 188 312 679 694 420 1 647 537 264 403 747 876 1 854 433 335 853 707 063 1 620 339 358 237 696 755 1 720 353 33 404 757 243 1 909 965

a)

b)

The original concentrations expressed in ppb (v/v) ratio are converted into mol/volume ratio assuming T = 208C and P = 1 atm. While RSC standard gases are supplied into TD system, the back-up N2 gas is delivered from a 10 L Tedlar bag via AS system at constant flow rate of 40 mL/min for a duration of 5 min.

single analytical set-up consisting of AS/TD system. To apply this approach, a back-up (ultrapure) N2 gas filled in a Tedlar bag (instead of sample bag) is initially connected to the multistream selector (MS) unit (Fig. 2). The transfer of the N2 gas into the TD unit proceeds in the same manner as the normal operation conditions of the TD setting, as discussed below. Standard gases, prepared at varying concentration range (Table 1), are then drawn into a gastight syringe and injected into the AS unit via a temporary injection port (refer to the lower part of Fig. 2). This injection port is built to connect the silcosteel tubing line of the AS outlet (MS) and the N2 gas container (Tedlar bag). Because a short piece of silicone tubing is used as a temporary injection port, the syringe needle can penetrate into the inner tubing line of the MS outlet to allow direct delivery of standard gas into the TD unit. By this

modification of the TD loading condition, a variable quantity of samples (e. g., small volume of concentrated samples and large volume of low concentration samples) can be introduced into the TD without extra sample treatment. As such, the AS/TD system can be used to cover samples over a wide concentration range through the application of the MITD method.

2.2 Analysis of RSC standards by MITD method over 103 concentration range

In order to perform a series of calibration experiments based on the proposed MITD approach, the AS/TD system was operated in the following sequence. As a preparation of calibration experiments, the working standard samples were prepared at a total of 11 concentration levels

www.jss-journal.com

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

1764

K.-H. Kim

J. Sep. Sci. 2008, 31, 1761 1768

(10 ppb to 10 ppm: Table 1) by conducting a one-step dilution of the primary standard with an ultrapure N2 gas (99.999% purity with a moisture content of less than 5%). For the purpose of this study, the primary standard containing all four S compounds at an equimolar concentration of 10 ppm (ppm, 10 6) was purchased (Ri Gas, Korea); this original standard gas was prepared gravimetrically using a concentration of 5% (by ISO 6142 method). To initiate MITD-based calibration experiment, a Tedlar bag of a 10 L capacity was filled with ultrapure N2 gas and connected to the inlet of an MS system in the AS unit using 2 cm long silicone tubing (Cole-Parmer, Vernon Hills, US) at 3.2 (id) and 6.4 mm (od) (Fig. 1B). The quantity of RSC required to derive the three-point calibrations (16.6, 33.3, and 66.6 pmol) was then drawn individually by gas-tight syringes with respective capacity. To reduce the possible contamination of the system due to the use of high concentration samples with the glass syringe, several syringes of the identical capacity were prepared and used. Because memory effects were seen occasionally after the injection of standards with the highest concentration (e. g., near 10 ppm standard), syringes were replaced and treated immediately to eliminate the sources of contamination. These standard gases were then injected into the inner wall of the MS tubing line across the silicone connector, while the back-up N2 gas was supplied to the TD unit at a fixed condition (e. g., flow rate of 40 mL/min for a duration of 5 min) (Fig. 1). Because RSC standard gas is transferred directly into the MS tubing line, the sum of gas supply into the TD (e. g., RSC standard plus back-up N2 gas) is controlled at the total volume of 200 mL. Through an application of the MITD method, quantification of RSC was made with the single TD system to cover both small (highly concentrated) and large (diluted) sample volumes, without any kind of transition between different analytical system (or modes). Hence, the performance of the MITD method is clearly distinguished from that of the complicated dual mode set-up for RSC analysis introduced in the previous work (e. g., [9]). The analysis of the RSC samples transferred to the GC/ PFPD system via the TD unit was made under the following conditions. The temperature (T) conditions for the GC system were set as follows: (i) T (initial): 808C for 2 min; (ii) T (ramping): 68C/min rate; and (iii) T (final): 2108C at 2 min. To acquire a good resolution in the GC system between different RSCs, a BP-1 column (60 m60.32 mm id, 5 lm film thickness, SGE) was used at a column flow rate of 1.2 mL/min (at the end of the column for the N2 carrier gas) with each running cycle ending at 20 min intervals. To provide pulsed flames into the combustor (15 mm length and 2 mm id), gases were provided: H2 = 11.5, Air1 (wall gas) = 10, and Air2 (combustor) = 10 mL/min. In addition, to allow a simple comparison of the PFPD responses between different S com-

pounds, integration of their peak areas was made in the linear mode with the square root (SR) function on. The use of this SR function can efficiently help mask the SR response (i. e., due to the conversion of S atoms to an S2 complex) of the detector. Hence, the calibration procedure of the PFPD system can be facilitated, as if one were handling a simple, first-order equation. The fundamental analytical parameters covering the analytical performance of the GC/PFPD system have also been examined. As an indirect means to evaluate the reliability of RSC standard used in this study, we routinely compared its calibration results with those made by a permeation tube (DYNACAL permeation device: VICI Metronics, Poulsbo, USA). A fairly good agreement (e. g., a 5%) was commonly achieved between the two standard types. General information about the QA for our RSC analysis with and without the TD has been described elsewhere [2, 11]. The datasets produced by the GC/PFPD system with the aid of the AS/TD unit showed a reasonably good reliability in terms of relative standard error (RSE); the RSE values quantified from triplicate analyses of identical samples were generally seen between 1 and 5% [2]. The absolute LOD values of the four RSCs, when estimated under the AS/TD operation conditions, generally fell into the range of l10 (CH3SH, DMS, and DMDS) to 30 pg (H2S) [2].

2.3 An instrumental set-up for the RSC analysis

In order to investigate the reliability of the MITD method, the GC system for RSC separation (Model DS 6200, Donam Instruments, Korea) was interfaced with a pulsed flame photometric detector (PFPD model 5380, O.I. Analytical, College Station, Texas, USA). In order to examine the extendibility of RSC analysis with the GC/ PFPD system, a multifunction TD system was operated to selectively cryofocus S compounds contained in working standard gases prepared over a 103 concentration range (refer to Table 1 for the experimental configuration). Basic information concerning the combined application of the GC/PFPD method with the AS/TD system has been described elsewhere [6]. Equipped with an internal vacuum pump and MFC, the AS unit can pull up any type of gas mixtures (standard gas or air samples) stored in various container types (e. g., Tedlar bag (232 Series, SKC, US)) into the TD unit through any channel in the MS. Hence, the supply rate of sample gases into the TD system can be controlled over a desirable flow rate (i. e., between 5 and 100 mL/min) for a variable duration (i. e., between 0.1 and 999.9 min). A built-in cold trap unit of TD (a mixture of silica gel and carbotrap B) then allows for cryofocusing the S gases via electronic cooling by Peltier cooler (PC). As the preconcentration was performed by the PC at 158C, S compounds were desorbed thermally by rapidly heating the

www.jss-journal.com

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

J. Sep. Sci. 2008, 31, 1761 1768

Gas Chromatography

1765

cold trap at 2508C (5 min duration for heating). Finally, the analytical components were detected by the GC/PFPD system for the quantification of the individual S compounds [6]. As shown in Fig. 2A, samples stored in any container type (e. g., Tedlar bag in this study) are pulled by the vacuum pump via MFC unit in the AS and delivered into the (focusing) cold trap unit under the normal TD operation conditions. For the application of the MITD method, sample transfer into TD proceeds only via gas tight syringe, while the delivery of back-up gas is induced simultaneously by the MFC unit (Fig. 2B). It should be noted that the operation of the MFC system can be subject to a large bias, if the flow control for samples departs from its maximum capacity [12]. Thus, there is a potential risk that operation of the AS/TD unit far below its maximum supply rate can yield erroneous information for both sample loading volume and the resulting concentration level of unknown samples.

4 Discussion

In the analysis of gaseous pollutants collected from various environmental settings, one should consider the technical problems arising from unique linearity ranges of different GC detector systems in the case of S (either with a conventional FPD or PFPD). For readers' reference, the linearity of PFPD system for the RSC analysis falls in a fairly narrow range depending on species such as l101 for DMDS, although H2S exhibits a more extended range over l103 [11]. The limited linearity ranges of the S-specific detectors contrasts sharply with those of other detector types such as FID, well known for its extensive linearity coverage (e. g., over 107). Hence, where the analysis of significantly low RSC concentrations is concerned, the use of the TD technique is the most reliable choice by cryofocusing samples of a large volume (e. g., a few tens of milliliters to a few liters). On the other hand, if one has to analyze samples of significantly high concentrations (a few ppm level), direct injection of samples into the GC injector (or loop system) is a primary choice to consider [9]. As a means to overcome the present limitations in the practically recoverable linearity range with the GC/PFPD, the MITD approach was explored against RSC standard samples prepared over a wide concentration range with the aid of a multifunction TD unit. Our efforts were directed, especially toward an assessment of analytical reliability in the measurements of the RSC samples with variable concentration ranges without transition (or modification) between different analytical set-ups. To this end, we designed and treated a series of experiments based on the MITD technique of which applicability was initially tested in the previous study of the RSC recovery rate for the TD system [13]. According to such preliminary study, RSC concentrations determined by direct injection (via GC injector) over a certain concentration range were highly comparable to those tested by the MITD method [13]. In this study, however, the MITD method was tested extensively to cover a wide standard concentration range (over 103) for all the RSCs. The results derived by the MITD method were then used to evaluate its performance according to the experimental design presented in Table 1. Like the case of the present study, there have been many attempts to develop a technique to accurately control sample transfer quantity for GC analysis such as loop injection method [11] or pressure assisted electrokinetic injection (PAEKI: [14, 15]). As the maximum sample volume for the direct loop injection method is determined by the loop size, its application is generally confined to the samples of significantly polluted samples (e. g., near a ppm level [11]). On the other hand, in the case of PAEKI-type approach, it is advantageous in that the control of injectable volume is fairly systematic and automatizable. However, its reliwww.jss-journal.com

3 Results

In this study, the analysis of RSC standard samples was made over a concentration range of 103 (e. g., samples of as low as 10 ppb to the maximum of 10 ppm) by the GC/ PFPD with an application of the MITD technique. The results of RSC calibration made using standard samples of 11 concentration levels are provided in Table 1 with their respective peak area values. Despite significant differences in the concentration levels between different standard types (i. e., 103), all calibrations were designed to fit identical quantities for each RSC at all three calibration points (16.6, 33.3, and 66.5 pmol). For instance, to make three-point calibrations of a 10 ppb standard, 40, 80, and 160 mL of standard samples were drawn by the syringe and introduced into the TD unit for analysis. On the other hand, for the calibration of the standard at the highest concentration level (i. e., 10 ppm), a three-point calibration was made at sample volumes of 40, 80, and 160 lL. Each calibration was then made by directly injecting standard gas drawn by the gas tight syringe into the inner tubing line of the MS unit, while the back up N2 gas contained in a 10 L Tedlar bag was supplied to the TD unit at a constant flow rate of 40 mL/min. Figure 3 shows the calibration results of each RSC made using standard samples of 11 different concentration levels. Here, all calibration results of five RSCs are simultaneously shown for each respective concentration level. A brief inspection of the calibration results indicates that H2S is the most variable, while those of DMDS are the most stable. The results indicate that relative ordering of RSC calibration slopes is maintained consistently across the entire concentration range.

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

1766

K.-H. Kim

J. Sep. Sci. 2008, 31, 1761 1768

Figure 3. Comparison of calibration slope values across different RSCs at a given concentration level. Results are shown for the lower three and upper three concentration ranges of eleven standard prepared for this study. A brief summary of these comparative calibration experiments is provided in Table 2.

ability can also be limited by the problems associated with pressure control, if one needs to transfer significantly small sample volume (e. g, below a few tens or hundreds of microliters). The use of the MITD method, while its operation is supported partially by the manual method, can hence be advantageous from many respects. Most importantly, it allows to control sample volume for the identical TD set-up to range from as little as microliter (for direct GC injection) to several hundred milliliters volume (with a syringe of a large capacity). Figure 3 depicts the RSC calibration results obtained using standards of each individual concentration level. When calibration slopes of the different RSCs are compared at a given concentration level, extremely strong

consistency is seen with the relative ordering of sensitivity: H2S a CH3SH a DMS a DMDS a CS2. To make a meaningful comparison of these calibration data, the absolute slope values of each compound are plotted as a function of standard concentration level (Fig. 4). Hence, when calibration results of each compound derived from the entire concentration range are put together, some common features are found consistently from all calibration experiments across a wide concentration range. Most importantly, the relative ordering of calibration slopes is maintained, as discussed above. It is also interesting to note that absolute calibration slope values do not vary significantly with increasing standard concentrations, although the results obtained at lower concentration

www.jss-journal.com

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

J. Sep. Sci. 2008, 31, 1761 1768

Gas Chromatography

1767

Figure 4. Comparison of calibration slope values as a function of the RSC concentration levels prepared as working standard.

Table 2. A summary of calibration results of RSC in terms of their slope values EXP no. Conc. (ppb) H2S 10 20 30 50 100 200 500 1000 2000 5000 10 000 6198 8573 7439 8619 6897 7143 5789 7263 4757 5310 7459 6859 1240 877 12.78 CH3SH 10 318 13 703 12 950 14 197 12 000 12 366 9 663 11 913 10 228 10 916 12 461 11 883 1 464 1 035 8.71 DMS 13 580 16 774 15 950 18 212 16 331 17 008 13 438 15 845 14 722 15 667 17 353 15 898 1 501 1 061 6.68 Slope CS2 47 884 48 994 42 734 46 532 41 412 43 704 35 327 41 470 37 304 38 606 43 188 42 469 4 304 3 043 7.17 DMDS 25 911 26 965 27 334 30 814 27 787 28 933 23 734 26 271 23 561 24 711 26 299 26 575 2 167 1 532 5.77

Average SD SE RSE(%)

ranges are moderately variable. The results of this comparison thus suggest that the MITD method can be used to expand the range of sample volume from a few microliters to several hundreds of milliliters for TD analysis without a significant matrix effect which might have otherwise suffered from direct GC injection due to the changing sample volume [2]. In Table 2, the basic statistical parameters were computed using all calibration slope values derived using each of all standards analyzed in this study. If the mean calibration slopes are normalized to that of CH3SH, the relative ordering of the former four RSCs is computed as 0.65 (H2S): 1 (CH3SH): 1.34 (DMS): 2.24 (DMDS). The observed relative patterns appear to comply well with those derived through an application of a loop injection system such as 0.63:1:1.65:3 [11]; in our previous study, the photomultiplier tube (PMT) voltage values were reduced arbitrarily with an increase in standard concentrations to overcome the inflection problems of PFPD

(i. e., due to its limited linearity range). It should however be noted that the differences in relative calibration slope values between the light (H2S) and heavy RSC (DMDS) are much narrower in the present study than those observed in our previous one. Because our previous experiments based on loop-injection method were significantly modified to arbitrarily control the RSC response (PMT voltage), calibration yielded less stable patterns over a less extended concentration range of 102. As the calibration experiments in the present study were conducted over an extensive range of concentrations, reproducibility of the MITD method was examined separately at both lower and upper bound concentration ranges. The results of the ancillary experiments confirmed that the calibration patterns derived by the MITD method is highly reproducible with RSE values of less than a few percent. Although an involvement of various chromatographic processes (e. g., cryofocusing) is suggested to introduce an inevitable bias in the GC response (e. g., [16]), the calibration data

www.jss-journal.com

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

1768

K.-H. Kim

J. Sep. Sci. 2008, 31, 1761 1768

obtained by our MITD method appear to be reasonably reliable over a wide concentration range without the system modification. To account for the effect of concentration differences on the reproducibility of the RSC calibration, the calibration slope values derived using all 11 concentration levels were combined together for the derivation of RSE for each RSC (Table 2). The results of this computation show that RSE values (%) change in an ascending order: 5.77 (DMDS), 6.68 (DMS), 7.17 (CS2), 8.71 (CH3SH), and 12.8 (H2S). This, thus, indicates that the calibration of H2S is the least reproducible, while that of DMDS exhibits the most reproducible and stable pattern. The observed pattern of the relative reproducibility test is in fact comparable to those derived on the basis of the thermal desorbing technique [2] or loop injection method [11]. For instance, according to the results of the former study [2], the sensitivity of H2S detection was found to be highly variable so that its calibration slopes increase systematically in relation to the initial standard concentration level (the overall RSE value of H2S calibration slope l20%). However, those of the other RSCs exhibited fairly constant trends with the RSE values ranging from 2.4 to 5.5%. Although the calibration slope value of H2S measured in the present study exhibits the largest variability of all the RSCs, it does not vary systematically with standard concentration levels. In light of all those aspects with the RSC calibration, the results of present study share some similarities and dissimilarities to the previous study. It should however be stated that the calibration results obtained using the MITD method are reasonably stable enough to maintain good reproducibility in a concentration range over 103.

trated samples with sufficiently low sample volume (e. g., a few lL). As such, we were able to acquire relatively constant calibration datasets from samples of an extended concentration range (e. g., 103) in a consistent manner through an application of the MITD method. The results of MITD-based calibration experiments confirm that the reliability of RSC analysis, when assessed in terms of RSE from all calibration slope values of 11 concentration levels, can be reflected at least in part by their molecular weights. It is found that RSE of H2S slope exhibits the least reproducible value of 12.8%, while that of DMDS is at 5.77%. The results of the present MITD analysis also show good agreement in relative calibration properties of RSC with the results of the previous study made by loop-based method in which their calibration trend was estimated over an extended concentration range through the arbitrary adjustment of PMT sensitivity. The results of the present study hence suggest that the use of the MITD method is recommendable for extending the detectable range of the GC/PFPD system as well as the validity of its calibration results by the employment of the TD technique, if gaseous samples of a varying concentration range must be handled. This work was supported by a grant from the Korea Research Foundation (KRF-2005-201-C00045) funded by the Korean government (MOEHRD). The authors declared no conflict of interest.

6 References

[1] Dincer, F., Odabasi, M., Muezzinoglu, A., J. Chromatogr. A 2006, 1122, 222 229. [2] Kim, K.-H., Environ. Sci. Technol. 2005a, 39, 6765 6769. [3] Hayward, T. C., Thurbide, K. B., J. Chromatogr. A 2006, 1105, 66 70. [4] Xiao, Q., Yu, C., Xing, J., Hu, B., J. Chromatogr. A 2006, 1125, 133 137. [5] Harper, M., J. Chromatogr. A 2000, 885, 129 151. [6] Visan, M., Parker, W. J., Water Res. 2004, 38, 3800 3808. [7] Burbank, H. M., Qian, M. C., J. Chromatogr. A 2005, 1066, 149 157. [8] Fang, Y., Qian, M. C., J. Chromatogr. A 2005, 1080, 177 185. [9] Kim, K.-H., Int. J. Environ. Anal. Chem. 2006, 86, 805 817. [10] Kim, K.-H., Im, M.-S., Jeon, E.-C., Koo, Y.-S., Youn, Y.-H., Atmos. Environ. 2007, 41, 3829 3840. [11] Kim, K.-H., Atmos. Environ. 2005b, 39, 2235 2242. [12] Kim, K.-H., Lindberg, S. E., J. Geophys. Res. 1994, 99, 5379 5384. [13] Kim, K.-H., Ju, D. W., Joo, S. W., Talanta 2005, 67, 955 959. [14] Ma, C. Y., McCorkle, D. L., Ding, W., J. Chromatogr. A 1999, 844, 217 224. [15] Feng, Y.-L., Lian, H., Zhu, J., J. Chromatogr. A 2007, 1148, 244 249. [16] Slemr, J., Slemr, F., D'Souza, H., Partridge, R., J. Chromatogr. A 2004, 1061, 75 84.

5 Conclusions

In the present study, we explored a new experimental approach named the MITD to evaluate the performance of GC/PFPD for RSC standards over an extensive concentration range by the normal operation setting of the thermal desorbing system. By transferring the RSC mesurand directly into the tubing line of MS unit in the TD system, we were able to analyze the RSC samples of all concentration levels with a single analytical set-up (i. e., without transition between different analytical modes). Because sample transfers along the TD track can be controlled with an internal MFC unit, the use of the authentic TD system can be optimized by low concentrated samples with sufficient volume (e. g., above a few 100 mL). Hence, the application of the MITD method can offer the versatility of the TD system to cover samples of the varying RSC concentration ranges, especially highly concen-

2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.jss-journal.com

You might also like

- ASTM D2330-20 Methylene Blue Active SutancesDocument8 pagesASTM D2330-20 Methylene Blue Active SutancesAna OchoaNo ratings yet

- Techno Commercial Offer of Water Treatment EMAMI LIMITED COOLING TOWERDocument12 pagesTechno Commercial Offer of Water Treatment EMAMI LIMITED COOLING TOWERsumanta4u100% (1)

- Manual QuickCODultra 07E4317 PDFDocument270 pagesManual QuickCODultra 07E4317 PDFpreciosariyazNo ratings yet

- BR501610 CompassCDS PDA User GuideDocument65 pagesBR501610 CompassCDS PDA User Guidekinnser analyticalsNo ratings yet

- NatGas 1Document2 pagesNatGas 1Mierza SaputraNo ratings yet

- Thermp Scientific - Operating Manual Focus GCDocument188 pagesThermp Scientific - Operating Manual Focus GCEmanuelNo ratings yet

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDocument5 pagesTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaNo ratings yet

- Cerec 3d Preparation Guidelines en PDFDocument10 pagesCerec 3d Preparation Guidelines en PDFMarian Si Teofana HasnaNo ratings yet

- Environmental Engineering Final Exam Part IDocument2 pagesEnvironmental Engineering Final Exam Part IVaasha Ramnarine100% (2)

- Concepts of GCDocument187 pagesConcepts of GCanoiring55No ratings yet

- Convenient Functions of GC-2014: Gas ChromatographyDocument2 pagesConvenient Functions of GC-2014: Gas ChromatographyShashank ChoudharyNo ratings yet

- GC Getting Started Guide: 223-60220A Jul. 2010Document50 pagesGC Getting Started Guide: 223-60220A Jul. 2010Jeevan JalliNo ratings yet

- G2887-90030 040373 SimdisDocument28 pagesG2887-90030 040373 Simdishung22vietNo ratings yet

- A Review - GC Method Development and ValidationDocument7 pagesA Review - GC Method Development and ValidationastroguilleNo ratings yet

- Determination of Total Sulfur by PFPDDocument85 pagesDetermination of Total Sulfur by PFPDTrinh Đình VũNo ratings yet

- User Manual BR501554 Rev3 PDFDocument369 pagesUser Manual BR501554 Rev3 PDFBetsy Suri Ramos PachecoNo ratings yet

- P007 Clarity IntroductionDocument29 pagesP007 Clarity IntroductionGregorio Antonio Valero VerdeNo ratings yet

- Hydrogen Content of Gases by Gas ChromatographyDocument3 pagesHydrogen Content of Gases by Gas ChromatographyDavin100% (1)

- GC PDFDocument27 pagesGC PDFViper ThroughNo ratings yet

- Crude Oil DistillationDocument17 pagesCrude Oil DistillationMelitza Gonzalez100% (2)

- GC TCD SopDocument6 pagesGC TCD Soparfan.irinbestindoNo ratings yet

- Falex 400C Operations Manual Ver. 1.1 (JFTOT)Document49 pagesFalex 400C Operations Manual Ver. 1.1 (JFTOT)ΓΙΩΡΓΟΣ ΓεωNo ratings yet

- Trace Carbonyl Sulfide in Propylene by Gas Chromatography: Standard Test Method ForDocument6 pagesTrace Carbonyl Sulfide in Propylene by Gas Chromatography: Standard Test Method ForahmedNo ratings yet

- Manual For SP1 7890-0166 and G3445B Opt 524Document24 pagesManual For SP1 7890-0166 and G3445B Opt 524Nam Phạm VănNo ratings yet

- Btu Analysis Using A Gas ChromatographDocument5 pagesBtu Analysis Using A Gas Chromatographlutfi awnNo ratings yet

- User Manual: Shimadzu Advanced Flow Technology Detector Switching SoftwareDocument17 pagesUser Manual: Shimadzu Advanced Flow Technology Detector Switching SoftwareHarold GamaNo ratings yet

- Varian 3800 GC: User Guidelines & Standard Operating Procedure For TheDocument31 pagesVarian 3800 GC: User Guidelines & Standard Operating Procedure For TheHUYQUYEN0% (1)

- Operating Manual: Ac Oxytracer Analyzer On 7890 GCDocument49 pagesOperating Manual: Ac Oxytracer Analyzer On 7890 GCstemman95No ratings yet

- Astm d1945 1996Document17 pagesAstm d1945 1996Brenda Rojas CardozoNo ratings yet

- USP Medicines Compendium - Eflornithine Topical Cream - 2013-01-16Document3 pagesUSP Medicines Compendium - Eflornithine Topical Cream - 2013-01-16amin138irNo ratings yet

- LOD LOQ DeterminationDocument2 pagesLOD LOQ Determinationharunsarip0% (1)

- Standard Operating Procedures (Sops) Gc-Ms AnalysesDocument3 pagesStandard Operating Procedures (Sops) Gc-Ms AnalysesmasifaaNo ratings yet

- White Paper On Liquid Hydrocarbon Drop Out in Natural Gas InfrastructureDocument30 pagesWhite Paper On Liquid Hydrocarbon Drop Out in Natural Gas InfrastructureHans MuellerNo ratings yet

- The Impact of PH On HPLC Method Development: Separations at Low PH - Retention and SelectivityDocument6 pagesThe Impact of PH On HPLC Method Development: Separations at Low PH - Retention and SelectivityHikmah AmelianiNo ratings yet

- MA180-005 subPUR-duoPUR User ManualDocument34 pagesMA180-005 subPUR-duoPUR User ManualDiana Putri SofyanNo ratings yet

- GC TroubleshootingDocument43 pagesGC TroubleshootingsalduwikatNo ratings yet

- Method Oia-1677-09 2010Document28 pagesMethod Oia-1677-09 2010sergioalex1430No ratings yet

- Shimadzu GC 2010 Training ManualDocument10 pagesShimadzu GC 2010 Training ManualTatiana Sainara Maia FernandesNo ratings yet

- WMI SimDis DCS 2.3.3 Quick StartDocument16 pagesWMI SimDis DCS 2.3.3 Quick StartDavid GrudoskiNo ratings yet

- D 3465 - 00 Monomero Por CGDocument3 pagesD 3465 - 00 Monomero Por CGsbiasotoNo ratings yet

- Mhra - GLPDocument24 pagesMhra - GLPRambabu komati - QANo ratings yet

- Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MSDocument36 pagesIntroduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MSLAGNo ratings yet

- Trace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDocument12 pagesTrace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDavinNo ratings yet

- Gas ChromatographyDocument75 pagesGas Chromatographyshruti shahNo ratings yet

- Astm D7111 - IcpDocument9 pagesAstm D7111 - IcpMireliz CorillocllaNo ratings yet

- GC Solution Software User Basics: Real Time AnalysisDocument7 pagesGC Solution Software User Basics: Real Time AnalysisZetsu MandaNo ratings yet

- 2.2.19. Amperometric TitrationDocument2 pages2.2.19. Amperometric TitrationRomin PatelNo ratings yet

- Restek ColumnDocument28 pagesRestek ColumnhafisjNo ratings yet

- Wet Gas Sampling in The Upstream Area Rev Brazil - ISO TC193 - SC3 Chairman DocumentDocument13 pagesWet Gas Sampling in The Upstream Area Rev Brazil - ISO TC193 - SC3 Chairman DocumentPhilip A Lawrence EUR Ing , C.Eng. F. Inst M.C.No ratings yet

- Gas Chromotagraphy: B.HemakumarDocument46 pagesGas Chromotagraphy: B.HemakumarAkshayRMishraNo ratings yet

- Gas ChromatographyDocument6 pagesGas ChromatographyPriyank ShahNo ratings yet

- Principle, Methodology and Application of Gas Chromatography (GC)Document31 pagesPrinciple, Methodology and Application of Gas Chromatography (GC)syuhadahNo ratings yet

- Calcipotriol+Betamethasone OintmentDocument50 pagesCalcipotriol+Betamethasone OintmentJai MurugeshNo ratings yet

- G3170-90037 Troubleshooting and Maintenance ManualDocument290 pagesG3170-90037 Troubleshooting and Maintenance ManualDevy Kartika RatnasariNo ratings yet

- Series N ParallelDocument11 pagesSeries N ParallelAliza MyNo ratings yet

- TF6 ReportDocument19 pagesTF6 ReportTing Kee Chuong100% (1)

- Dissolution WHO PresentationDocument64 pagesDissolution WHO PresentationnkszoneNo ratings yet

- Amar Autoclave PDFDocument44 pagesAmar Autoclave PDFdhavaleshNo ratings yet

- Oilpac eDocument85 pagesOilpac eAri CleciusNo ratings yet

- Low Level DioxinDocument4 pagesLow Level DioxinBin HadithonNo ratings yet

- Kim 2006Document6 pagesKim 2006Tri Indah Lestari AnnasNo ratings yet

- GC MSDocument53 pagesGC MSNaresh Kumar Marx50% (2)

- Oral MalodourDocument9 pagesOral MalodourMarian Si Teofana HasnaNo ratings yet

- Effect of Tongue Brushing On Oral Malodor in AdolescentsDocument5 pagesEffect of Tongue Brushing On Oral Malodor in AdolescentsMarian Si Teofana HasnaNo ratings yet

- Self AssesmentDocument6 pagesSelf AssesmentMarian Si Teofana HasnaNo ratings yet

- Assessment of Oral Malodor: A Comparison of The Organoleptic Method With Sulfide MonitoringDocument9 pagesAssessment of Oral Malodor: A Comparison of The Organoleptic Method With Sulfide MonitoringMarian Si Teofana HasnaNo ratings yet

- Banks DIH Field Trip ReportDocument10 pagesBanks DIH Field Trip ReportTakchandra JaikeshanNo ratings yet

- Unit 5: Social Issues and Environmental EducationDocument6 pagesUnit 5: Social Issues and Environmental Education1611 Dmello Myron MosesNo ratings yet

- Environmental EngineerDocument2 pagesEnvironmental EngineerJessica StefflerNo ratings yet

- Chapter 10 SCMDocument15 pagesChapter 10 SCMNhạn Phan Thị BíchNo ratings yet

- Cooltech PresentationDocument12 pagesCooltech PresentationCooltech ApplicationsNo ratings yet

- Who Mono 46 PDFDocument450 pagesWho Mono 46 PDFAlin BAMNo ratings yet

- EVS Question BankDocument8 pagesEVS Question Bankg6614134No ratings yet

- Chemical Engineering Department: A Written Report On Utility Consumption: Power, Water and Bunker FuelDocument10 pagesChemical Engineering Department: A Written Report On Utility Consumption: Power, Water and Bunker FuelMc Jason LaureteNo ratings yet

- Farm Waste ManagementDocument46 pagesFarm Waste ManagementJoseph Vincent BabaNo ratings yet

- Clark County OpinionDocument30 pagesClark County OpinionNorthwest Environmental Defense CenterNo ratings yet

- Liquid Nitrogen VehicleDocument13 pagesLiquid Nitrogen VehicleNishant SharmaNo ratings yet

- 110726 각선급별부호정리 (DnV, BV)Document23 pages110726 각선급별부호정리 (DnV, BV)Dae Hyung ChoNo ratings yet

- BoilersDocument8 pagesBoilerswindreader1No ratings yet

- Role of NgoDocument12 pagesRole of NgoSailaja Sankar SahooNo ratings yet

- Environmental Product DeclarationEPDDocument28 pagesEnvironmental Product DeclarationEPDanamikakahlatihaiNo ratings yet

- Environment ComplianceDocument7 pagesEnvironment ComplianceSarvesh NerurkarNo ratings yet

- Tajudeen Adejare Aderibigbe, Abiola Azeezjimoh, ChijiokeolisahDocument10 pagesTajudeen Adejare Aderibigbe, Abiola Azeezjimoh, ChijiokeolisahIOSRjournalNo ratings yet

- Worksheet On Module 2 Solar Energy and The AtmosphereDocument4 pagesWorksheet On Module 2 Solar Energy and The AtmosphereIC EspinosaNo ratings yet

- Lecture Notes 2aDocument35 pagesLecture Notes 2aLiviu IordacheNo ratings yet

- Oil and Gas IncidentsDocument7 pagesOil and Gas IncidentsAnkit ChauhanNo ratings yet

- Skema Jawapan SOLAF 1 Sains SPM 2011Document9 pagesSkema Jawapan SOLAF 1 Sains SPM 2011Muhd Shahir Salleh100% (1)

- Hood Duct and Stack Design PDFDocument59 pagesHood Duct and Stack Design PDFSanth RaulNo ratings yet

- Sustainable DevelopmentDocument8 pagesSustainable DevelopmentAngel VillalonNo ratings yet

- Hazard Analysis For UtilityDocument4 pagesHazard Analysis For UtilityBoiler ScrubberNo ratings yet

- Hpac - 201301Document69 pagesHpac - 201301Antonio LebrunNo ratings yet

- MGT330 AssignmentDocument16 pagesMGT330 AssignmentArifin Ahmed ZawadNo ratings yet

- ISO 14001 Quality Productivity Society PakistanDocument82 pagesISO 14001 Quality Productivity Society Pakistankashifbutty2k100% (3)

- Construction Waste Management: Hotel Jen, Penang - 26.9.2018 - Baylon ThamDocument45 pagesConstruction Waste Management: Hotel Jen, Penang - 26.9.2018 - Baylon ThamTory LowNo ratings yet