Manual For SP1 7890-0166 and G3445B Opt 524

Manual For SP1 7890-0166 and G3445B Opt 524

Uploaded by

Nam Phạm VănCopyright:

Available Formats

Manual For SP1 7890-0166 and G3445B Opt 524

Manual For SP1 7890-0166 and G3445B Opt 524

Uploaded by

Nam Phạm VănOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Manual For SP1 7890-0166 and G3445B Opt 524

Manual For SP1 7890-0166 and G3445B Opt 524

Uploaded by

Nam Phạm VănCopyright:

Available Formats

Refinery Gas Analyzer for

Sour Gas samples up to

C6+

Specials and Solutions Group

For use with G3445 Option 524 and G3440 SP1 7890-0166

This manual only contains information specific to the special parts or

application ordered. Customers should first become familiar with the

Gas Chromatograph, ChemStation software or Mass Spectrometer by

using the documentation supplied with these products.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 2 of 24 Date Printed: 18 June 2015

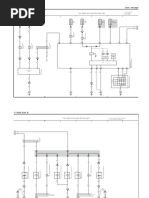

General information

This GC is configured to analyze refinery gas containing high concentrations of hydrogen sulfide.

The analyzer is a four valve system using 1/8 inch packed columns with early back-flush of the C6+

components. A typical plumbing diagram is shown below. The GC has two channels, one dedicated

to hydrogen analysis and the other for permanent gases and hydrocarbons. Fig. 1 shows a

configuration with two pneumatics control modules (PCM) acting as flow sources. The instrument

can also be configured with a packed inlet (PPI) and a pneumatics control module (PCM) or two

packed inlets, although there is no technical advantage on doing so.

FLOW

Valve System

INJECTION VALVE COMPARTMENT

Date :

Order No :

S/N :

Item :

DETECTOR

OVEN LEFT SIDE

SOURCE PORT BLOCK 2 BLOCK 1

4/802/869 1/805/869

Col 5 Col 2

Back Aux

Ch 2 7 6 5 7 6 5

Side

8 4 8 4

PCM C OUT

9 3 9 3

Ch 1 SAMPLE

10

1

2 SAMPLE 10

1

2

IN

Back Inl Col 1

LOOP Back

TCD

(220)

Front Inl

Front

TCD

(220)

Col 4 Col 3

Front Aux 4 4

3 3

Ch 2 5 5

6 2 6

PCM A 1 1

2

Ch 1

3/702/868 2/702/868

Options SP1 options Remarks

2x220,2x309,2x503,2x702,754,802,805, 7890-0166

2x868,2x869

Fig. 1

The columns used in this analyzer are as follows. All are 1/8 inch nickel tubing.

Column #1 2Ft 20% Sebaconitrile column in nickel

Column #2 30Ft 20% Sebaconitrile column in nickel

Column #3 6Ft HayeSep Q 80/100 in nickel

Column #4 10Ft Molecular Sieve 13X in nickel

Column #5 4Ft Molecular Sieve 13X in nickel

All valves are in Hastelloy C for corrosion resistance requirements.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 3 of 24 Date Printed: 18 June 2015

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 4 of 24 Date Printed: 18 June 2015

Analysis Sequence

Permanent Gases and Hydrocarbons Channel

The diagrams below show the sequence of the analysis. The order of the columns is as follows:

30 ft Sebaconitrile 2ft Sebaconitrile HayeSep Q Mole Sieve 13X TCD

1. Injection and first minute of the run.

C5-C1,CO2,CO,N2 O2 C 6+

Note that the sample is injected onto the short Sebaconitrile column.

2. Backflush and reverse flow of the short Sebaconitrile.

C5-C2,CO2,CO,C1 N2 O2 C6+

C6 and heavier compounds come out early in the chromatogram as one peak.

3. Transfer of light compounds to the Mole Sieve column. Heavier compounds distribute along

the first two columns

C5-C3,CO2 C2 's H2S CO C1 N2 O2

Heavier compounds distribute along the first two columns

4. Start transfer hydrogen sulfide and ethane / ethylene into the HayeSep Q column. Light

compounds move further down into the MolSieve column.

C5 's C4 's C3 's CO2 C2 C2= H2S CO C1 N2 O2

Light compounds move further down into the MolSieve column.

5. Trapping of the light compounds in the MolSieve column. Hydrogen sulfide and C2

hydrocarbons elute form the Sebaconitrile columns into the HayeSep Q column.

C5 's C4 's C3 's CO2 C2 C2= H2S CO C1 N2 O2

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 5 of 24 Date Printed: 18 June 2015

Hydrogen sulfide and C2 hydrocarbons elute form the Sebaconitrile columns into the HayeSep Q

column.

6. Trapping of the ethane / ethylene compounds and hydrogen sulfide in the HayeSep Q

column.

C5 's C4 's C3 's C2 C2= H2S CO C1 N2 O2 CO2

Start eluting carbon dioxide and hydrocarbons heavier than C2 into the TCD

7. Continue eluting hydrocarbons from propane to pentanes from the Sebaconitrile columns into

the TCD.

C2 C2= H2S CO C1 N2 O2 C5

8. Start eluting hydrogen sulfide and ethane / ethylene from the HayeSep Q column into the

TCD.

C2 C2= CO C1 N2 O2 H 2S

9. Finish eluting ethane from the HayeSep Q column into the TCD.

CO C1 N2 O2 C2

10. Release and elution of the light compounds from the MolSieve column into the TCD.

N2

CO C1 O2

11. End of the elution of light compounds from the MolSieve column and of the chromatography.

CO

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 6 of 24 Date Printed: 18 June 2015

Installation.

Supply carrier and detector support gases to the GC. Connect helium to PCM A and front TCD.

Connect nitrogen to PCM C and back TCD and power up the GC.

If this is the only factory tested method, then the checkout method set up for the instrument will be

stored in “Method # 9” GC memory position”. Load the GC method pressing [LOAD] [METHOD] [9]

in the GC keyboard or enter the parameters by means of the GC keyboard. Allow the system to

stabilize. If an Agilent ChemStation is being used – bring it up and establish communication with the

GC. Do not resolve the “default” method loaded by ChemStation the first time. Instead “get” the GC

configuration using the “Instrument Configuration” option under the “Instrument” menu. Double click

in the “Agilent 7890A” module in the right side of the screen under “Selected Modules”. The tab

labeled “Connection” has a “Get GC Configuration” button that must be pressed. Close the “GC

Configuration” screen. Following this, go to the “Instrument” menu again and select “Upload method

from Agilent 7890A“ menu option or if the ChemStation is rev. C.01.02 or higher, then go to "Edit

Agilent 7890A Parameters" under the "Instrument" menu view and press the button labeled “Upload

from Instrument” at the bottom of the screen. Verify that the parameters coincide with the ones listed

in this manual or supplied documentation.

Load the method 78900166.M supplied on the CD-ROM disk. Resolve the method if necessary and

save it into the computer’s hard drive.

NOTE: Some conditions might not appear exactly as described here, specially the valve timing due

to column variability between the original design and your current instrument. Check the “Procedure

for a New Setup” section in case of doubt.

=====================================================================

Agilent 7890A

=====================================================================

Oven

Equilibration Time 1 min

Max Temperature 150 degrees C

Slow Fan Disabled

Oven Program On

60 °C for 41 min

Run Time 41 min

Column #1

Agilent RGA column set

150 °C: Packed

In: PCM A-1 He

Out: Front Detector TCD

Flow Program On

28 mL/min for 0 min

Run Time 41 min

Column #2

Agilent G3591-82012 4 ft. MolSieve 13X

150 °C: Packed

In: PCM C-1 N2

Out: Back Detector TCD

Flow Program On

28 mL/min for 0 min

Run Time 41 min

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 7 of 24 Date Printed: 18 June 2015

Front Detector TCD

Heater On 250 °C

Reference Flow On 40 mL/min

Makeup Flow On 2 mL/min

Const Col + Makeup Off

Negative Polarity Off

Filament On

Back Detector TCD

Heater On 250 °C

Reference Flow On 40 mL/min

Makeup Flow On 2 mL/min

Const Col + Makeup Off

Negative Polarity On

Filament On

Valve 1

Other Off

Valve 2

Other Off

Valve 3

Other Off

Valve 4

Other Off

PCM A-1 He: Supplies Column 1

PCM A-2 N2

***Excluded from Affecting GC's Readiness State***

Pressure Program Off

32.225 psi for 0 min

Run Time 41 min

PCM C-1 N2: Supplies Column 2

PCM C-2 N2

***Excluded from Affecting GC's Readiness State***

Pressure Program Off

10 psi for 0 min

Run Time 41 min

Valve Box

Heater On 100 °C

Signals

Signal #1: Front Signal Save On

10 Hz

Signal #2: Back Signal Save On

10 Hz

Run Time Events

Time (min) Event Position Setpoint

0.01 Valve Valve 2 On

0.01 Valve Valve 3 On

0.04 Valve Valve 4 On

0.05 Valve Valve 1 On

0.60 Valve Valve 4 Off

2.00 Valve Valve 1 Off

5.05 Valve Valve 3 Off

6.05 Valve Valve 2 Off

7.05 Valve Valve 3 On

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 8 of 24 Date Printed: 18 June 2015

7.20 Valve Valve 2 On

25.1 Valve Valve 2 Off

34.7 Valve Valve 3 Off

Procedure for a New Setup

This procedure will have to be carried out on a new GC or if new columns are installed or the

present columns are re-conditioned. If new columns are being installed, or present columns need to

be conditioned, condition columns as indicated in the Appendix A

Set up of needle valves

1. Ensure that you have the following conditions set up. Also ensure that you have about 120 psi as

the supply pressure for helium for the front inlet.

Oven Temp 60 C

Column flow 28 ml/min (Typically driven by PCM A)

Valve 1 OFF

Valve 2 OFF

Valve 3 OFF.

2. Monitor the head pressure of the columns by looking at the ‘Actual’ pressure for the main

channel of the Pneumatics Control Module or PCM A-1 (or the corresponding flow supply for the

permanent gases and hydrocarbons channel). When this is steady, note the value.

3. Turn Valve 3 ON by using the GC keyboard.

4. Adjust the needle valve associated with Valve 3 to give the same head-pressure noted in step 2

+/- 0.5 psi. The system may take some time to react to changes, be patient.

5. When this has been done, turn Valve 2 ON by using the GC keyboard.

6. Adjust the needle valve associated with Valve 2 to give the same head-pressure noted in step 2

+/- 0.5 psi. The system may take some time to react to changes, be patient.

Setting the backflush time for valve 4

1. Connect up a cylinder of Refinery Gas Sample, P/N 5080-8755, to the sample inlet line.

2. Clear the run table and then add the following

Valve 2 ON time 0.01

Valve 3 ON time 0.01

Valve 4 ON time 0.04.

3. Save the method as 78900166.M. Flush the sample loop with the gas mixture. Start the method.

As soon as the hydrogen peak has eluted, note the time and manually turn Valve 4 OFF by

means of the GC keyboard. Stop the run. The chromatogram should be similar to Fig. 2 below.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 9 of 24 Date Printed: 18 June 2015

Fig. 2

4. Enter into the run time table

Valve 4 OFF Backflush time noted.

Set backflush time for V1

5. Add the following to the run time table. Note that Valve 1 should turn ON after valve 4 to prevent

helium from diffusing into the sample loop of V4 and influencing the hydrogen analysis. Valve 2

and Valve 3 remain in ON position as in step 2 for this part of the procedure.

Valve 1 ON time 0.05

Valve 1 OFF time 1.70 minutes.

6. Flush the sample loop with the gas mixture and start the method. The chromatogram that you

get should be similar to that in Fig. 3 shown below.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 10 of 24 Date Printed: 18 June 2015

Fig. 3

7. When the run has finished, integrate the runs and make a note of the area of the trans-2-butene

peak and the area of the n-pentane peak.

8. An Excel spreadsheet will help in the task of setting up the valve 1 backflush timing. If Excel is

not available, make up a table shown in Fig. 4 below. The ratio column is the value of the trans-

2-butene peak area divided by the n-pentane peak area. The %Change column is the (change in

ratio/previous ratio) x 100 or ((previous ratio - current ratio)/previous ratio) x 100. Note: this

%Change calculation is valid upon the second run on this experiment.

9. Repeat the above run with Valve1 OFF time changing from 1.80 to 2.20 in 0.1 minute

increments. Note the areas of the trans-2-butene peak and the n-pentane peak for each new run

as you go.

10. Fill out the cells in the Excel spreadsheet you created. You only need to add the areas for the

trans-2-butene peak and the n-pentane peak.

11. When all of the data has been entered, note in the last column (%Change) the first cell from the

top where the number is less than 1%. Note the switch time. In the example below this would be

2.0 minutes. This means that the change of n-pentane peak area is no longer affected by the

backflush time of the valve (this is, is not being backflushed itself), but only by small area

changes found on both peaks run over run. Therefore, the whole n-pentane peak is clearing the

pre-column into the analytical column and into the detector.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 11 of 24 Date Printed: 18 June 2015

Fig. 4

12. Enter this time as the V1 OFF time in the events table of the method.

Set valve timings for V2 and V3

13. Load up the data file that holds the data for the switch time you have selected in the previous

steps. Note the following times in the chromatogram as shown in Fig. 5 below.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 12 of 24 Date Printed: 18 June 2015

Fig. 5

14. Define the following events:

-Time A = tick mark time for first peak – 0.5 minutes

Enter into the run time table

Valve 3 OFF Time A.

Valve 3 ON Time A +2 minutes

-Time B = this is the start tick mark time for the ethylene/ethane peak – 0.2 minutes

Enter into the run time table

Valve 2 OFF Time B

-Time C = this is the start tick mark time for the CO2 peak – 0.2 minutes.

Enter into the run time table

Valve 2 ON Time C

-Time D = this is the stop tick mark time for the n-pentane peak + 0.5 minutes

Enter into the run time table

Valve 2 OFF Time D.

Verify that the following entries are still present in the run time table

Valve 2 ON Time 0.01

Valve 3 ON Time 0.01

15. Save the method. Flush the sample loop with the gas mixture and start the method. The

chromatogram that you get should be similar to that in Fig. 6 shown below.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 13 of 24 Date Printed: 18 June 2015

Fig. 6

IMPORTANT: When the run has finished, manually turn Valve 3 OFF and allow the peaks to

elute from the MolSieve column as they were captured in the previous run and never released

16. Based in the resulting chromatogram from the previous step, define the following additional

events:

-Time E = this is the stop tick mark time for the Ethane peak + 0.5 minutes

Enter into the run time table

Valve 3 OFF Time E

17. Save the method once more. Flush the sample loop with the gas mixture again and start the

method. The chromatogram that you get should be similar to that in Fig. 7 shown below (for both

channels).

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 14 of 24 Date Printed: 18 June 2015

Fig. 7

It is possible to present the chromatographic results merged into one window by superposing the

signals. With the latest ChemStation revisions and GC firmware is also possible to switch detector

signals after the elution of the hydrogen peak in the back TCD to the rest of the components of the

sample in the front TCD. Zeroing the signals and freezing the values between the signal switch

further contributes positively to the overall aspect of the chromatographic result.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 15 of 24 Date Printed: 18 June 2015

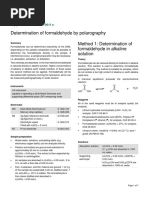

About hydrogen sulfide (H2S)

It is expected in this analyzer to determine the presence of hydrogen sulfide (H2S) in the samples or

standards. Agilent Technologies does not provide this compound in the Refinery Gas Sample, P/N

5080-8755 due to its reactive nature and limited shelf life. However, each instrument is ready and

tested for the presence of hydrogen sulfide in the analysis. The H2S peak is visible after the n-

pentane peak (right after Time D set in step 14 of this guide) and before the ethylene peak (not

present in the example chromatogram). A standard with a small amount of hydrogen sulfide is

shown below in Fig. 8.

Fig. 8

The tailing observed in the H2S peak is most likely due to the highly polar nature of this compound

and its strong tendency to reversibly interact with various materials, including stationary phases of

the analytical columns.

Calibration

Connect up a calibration gas to the GC, purge the sample loop with the calibration gas and allow the

pressure in the loop to come down to atmospheric pressure before starting the run. At the end of the

run, calibrate the GC.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 16 of 24 Date Printed: 18 June 2015

Tips on running the analyzer.

Sample introduction

To get reproducible results, do NOT start the GC when sample is flowing through the sample loop.

Always fill the loop and wait for about 15 seconds for the pressure in the sample loop to equilibrate

to atmospheric pressure before starting the run.

To run the GC as an analyzer automatically proceed as follows.

As stated above, it is not recommended to have flow through the sample loop when injecting the

sample into the GC. You will need a way to control the sample gas. One way is to use an external

solenoid valve controlled by the GC. The pressure of the sample to the valve should be in the 5 to

10 psi range (35 to 70 Kilopascals). The valve should be an ON/OFF type of valve. If you wish to

control this directly from the GC it should operate at 24 Volts DC and with a power rating of no more

than 1.8 watts.

Agilent cable P/N G1530-60590

Connect to

EVENT socket

White Black

Sample vent line

7890 GC

Sample in 24 V Solenoid

at 5-10 psi valve 1.8 W

The 7890 has the possibility to control 8 valves. Four of these, Valve 1 to Valve 4 are ‘internal’

valves and are used to control the valves installed on top of your instrument. The other 4 valve

controls are available at the rear of the GC through the EVENT socket. Valve 5 and Valve 6 are 24

Volt outputs (1.8 watts). Valve 7 and Valve 8 are contact closures. As shown on the diagram, the

solenoid valve would be controlled by the Valve 6 command.

To start the GC automatically, one Valve MUST be defined as a “Gas Sampling valve”. See

appendix B for information on how to configure valves.

The picture below shows a screen shot of the valve configuration screen where:

V1 to V3 are the switching valves used for the analysis

V5 is the “dummy” gas sample valve

V6 is used for the solenoid valve

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 17 of 24 Date Printed: 18 June 2015

The sample can be controlled by entering Valve 6 ON, waiting about 15 seconds, then entering

Valve 6 OFF. Wait 10 seconds for the pressure in the sample loop to come down to ambient

pressure, and then press START run or start the method from the Chemstation.

A macro is supplied that will do this automatically. On the 7890 you must have ChemStation Rev

B.03.02 or higher. Copy the macro file valve6.mac from the CD disk into the CORE directory of the

chemstation (usually c:\chem32\core). To get this macro to run automatically from the chemstation,

go into the ‘Method and Run Control’ view and click the ‘Method’ menu item and then the resulting

‘Run Time Checklist’ menu. The following will appear.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 18 of 24 Date Printed: 18 June 2015

Click the ‘Pre-Run Command/Macro’ check box and enter the name of the macro, Valve6, into the

box as shown. Then press ‘OK’. A program listing of this macro is given in appendix C.

The GC, with the Agilent Chemstation, can be run in four different modes. These are (a) single

analysis, (b) a batch run, (c) continuous analysis and (d) timed analysis. All modes assume that you

have set up a valve to control the sample loading and a valve is configured as a Gas Sampling

Valve.

Single Run

From the chemstation just click the ‘Run method’ item in the ‘Run Control’ menu of the ‘Method and

Run Control’ screen.

Batch Run

This would be used for running a set number of runs one after the other. You will need to set up a

simple sequence. First, set up the sequence table which is accessed from the Sequence Menu in

the Method and Run Control screen.

Enter a Enter number of runs Enter ‘Sample’ for

value here you want here sample type

When this has been done, load up the Sequence Parameters screen as shown below which is also

accessed from the Sequence Menu. To make it easier to find your files it is suggested that you click

the Prefix/Counter radio button and enter a Prefix for your files and set the counter. You may also

set up a sub directory in which your files are stored.

To start the sequence, click the ‘Run Sequence’ item in the ‘Run Control’ menu.

Please note that if you have finished a sequence and wish to repeat it, the old data files will

be over written. Either change the subdirectory, the prefix or the starting position for the

counter.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 19 of 24 Date Printed: 18 June 2015

Continuous Run.

The easiest way is an extension of the Batch run method. You can set up a maximum number of 99

for the inj/location entry. If you need more than 99 runs, you enter a new line which also has 99 runs.

You can have 999 lines in the sequence table. This will give you 98,901 runs. For a 30 minute

analysis time, this is enough for 5 years!

Timed Analysis

This when you want to automatically make a run every hour, for example.

First set up the Sample Information screen.

Set to Prefix/Counter

Set Prefix and where the counter starts

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 20 of 24 Date Printed: 18 June 2015

Set the Prefix /Counter button and then enter the Prefix for your files and where the counter should

start from.

Now start up the Chemstation Scheduler which you can access form the ‘View’ menu in the ‘method

and Run Control’ screen.

Set this to your instrument!!!!

Make sure that you have set the scheduler to your instrument. Enter the date and time that you wish

to start a run. For the command enter ‘runmethod’. For the ‘Mode’ enter ‘DoDaily’. Set the next entry

to be one hour later, for example. If you wish to run every hour, you will need 24 entries in the table.

The system will run as follows. If we take the first entry in the table above, the GC will inject the

sample at 15.00 hours on 9th March 2008. When it has finished, it will automatically add an entry

into the table for 15.00 on the 10th March 2008. This happens when you choose ‘DoDaily’ as the

mode.

When you have finished adding your entries, save by clicking the ‘disk’ icon and then minimize the

scheduler. The scheduler must be running for the entries to be executed.

The scheduler table can only hold 200 lines. If you are automatically adding lines, this can soon fill

up. You will need to go into the scheduler and remove any lines that have been executed. These will

be the lines that are ‘grayed’ out.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 21 of 24 Date Printed: 18 June 2015

Appendix A

Conditioning the columns.

Molecular Sieve 13 X column 10 Foot column

This column should be removed from the GC and installed into a similar GC oven which does not

have valves installed on the top and does not have any other columns installed in the oven.

If a second GC oven is not available, remove all other columns from the oven, remove the valve box

top so that the valves are exposed to atmospheric temperature and turn off the heat to the zones

that heat the valves.

Condition at 350°C for 8 hours with helium gas at 30-40ml/min.

HayeSep Q

You will also need to remove the other columns, but this can be conditioned in this GC. If the GC

has a packed inlet, connect one end of the column to the packed inlet and allow the other end to

hang free. If the GC does not have a packed inlet, remove the Sebaconitrile columns and connect

the HayeSep Q column to the line going to port 6 of Valve 1 or “Column 2 In” connection. Make sure

the Valve 1 remains in OFF position over the length of the conditioning process.

Condition at 225°C for 4 hours with helium gas at 30-40ml/min

Sebaconitrile columns

These columns can be conditioned in the oven with the other columns installed. However, ensure

that Valve 2 and Valve 3 are on the ON position.

Condition at 90°C for 4 hours with helium gas at 30-40ml/min.

Molecular Sieve 13 X column 4 Foot column

This column should be removed from the GC and installed into a similar GC oven which does not

have valves installed on the top and does not have any other columns installed in the oven.

If a second GC oven is not available, remove all other columns from the oven, remove the valve box

top so that the valves are exposed to atmospheric temperature and turn off the heat to the zones

that heat the valves.

Condition at 350°C for 8 hours with nitrogen or argon gas at 30-40ml/min.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 22 of 24 Date Printed: 18 June 2015

Appendix B

Configuring valves on the 7890.

Valves can be configured into the 7890 several ways, with some confusion. The choices are as

follows:

Gas Sampling

Switching

Other

MultiPosition

Not Installed.

Multiposition.

Used to configure a valve as a stream selection valve. Only ONE valve on the GC may be

configured as a multiposition valve.

Not Installed

Used to uninstall a valve.

Other

Used to define something that is not actually a valve. For example the valve control could be used

to switch a relay which controls some other piece of equipment. This still acts as a valve control for

all intents and purposes.

Switching

Used to control a valve. Valve can be controlled from the run table or from the keyboard. Turning

the valve on has no effect on the GC status (see Gas Sampling). Valve will NOT turn to its original

position at the end of the run. To do this you will need a Run Table entry.

If you have a valve hardware configured as a gas sampling valve but configured in the 7890 as a

switching valve, you cannot start the run remotely from the GC ChemStation.

Gas Sampling

Now this is where the confusion starts. If a valve is configured as a Gas Sampling valve, the

following will happen.

The GC can be started remotely from the GC ChemStation providing the injection source has

been set to "GC Valve".

An automatic sequence can be set up.

The valve will return to the OFF position at the end of the run.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 23 of 24 Date Printed: 18 June 2015

If you press "START" on the GC, the GC program will start but the Gas Sampling valve will NOT

inject the sample.

If Valve 1 is configured as a Gas Sampling valve and from the GC keyboard you enter Valve 1

ON, you will inject the sample AND start a GC run. This can be a nuisance if you are trouble

shooting, as all events in the Run Table will also execute.

The switch on time of the Gas Sample Valve will NOT appear in the Run Time Table.

You cannot stagger injection times if you have two or more valves injecting samples.

So what is the best way to set up?

The 7890 has eight valve control functions. It is rare that all are used up. Normally valves 1 to 4 are

used to actually control valves on the GC. This leaves valve controls 5 to 8 free. So configure all of

the valves in your valve system as switching valves and configure one of the unused positions as a

Gas Sampling Valve. This will give the following advantages.

You can control the GC remotely from the GC ChemStation.

You can set up a sequence.

If you press "START" on the GC, the GC will start AND your sample will be injected.

If you enter "Valve 1 ON", valve 1 will switch on but the GC will NOT start a run.

All switching times will appear in the Run Table.

You can stagger injection times.

G3445 Option 524 and G3440 SP1 7890-0166 Printed Copies

Rev. A are Uncontrolled

Agilent Technologies, Inc. Page 24 of 24 Date Printed: 18 June 2015

You might also like

- ASTM D2330-20 Methylene Blue Active SutancesDocument8 pagesASTM D2330-20 Methylene Blue Active SutancesAna OchoaNo ratings yet

- Solution Manual For Digital Systems Design Using Verilog 1st Edition by RothDocument16 pagesSolution Manual For Digital Systems Design Using Verilog 1st Edition by Rotha19397263929% (7)

- QMM-2011 - GC-2010Pro SMDocument79 pagesQMM-2011 - GC-2010Pro SMAtongo George AtiahNo ratings yet

- Product Catalogue For David BrownDocument12 pagesProduct Catalogue For David BrownIzdiharBinRosland0% (1)

- Si 0290 PetrobookDocument150 pagesSi 0290 PetrobooklynxxNo ratings yet

- NatGas 1Document2 pagesNatGas 1Mierza SaputraNo ratings yet

- Manual For SP1Document19 pagesManual For SP1Mai Huong Bui ThiNo ratings yet

- Thermp Scientific - Operating Manual Focus GCDocument188 pagesThermp Scientific - Operating Manual Focus GCEmanuelNo ratings yet

- TRACE1300 1310 SparePartsGuide PDFDocument130 pagesTRACE1300 1310 SparePartsGuide PDFYogendra ReddyNo ratings yet

- Agilent 1290 Infinity II LC: Specification CompendiumDocument38 pagesAgilent 1290 Infinity II LC: Specification CompendiumAmarpreet Singh MalhanNo ratings yet

- Minimum Ventilation Rates in Breathing ZoneDocument3 pagesMinimum Ventilation Rates in Breathing ZonezampacaanasNo ratings yet

- Astm d1945 1996Document17 pagesAstm d1945 1996Brenda Rojas CardozoNo ratings yet

- Hydrogen Content of Gases by Gas ChromatographyDocument3 pagesHydrogen Content of Gases by Gas ChromatographyDavin100% (1)

- G2887-90030 040373 SimdisDocument28 pagesG2887-90030 040373 Simdishung22vietNo ratings yet

- Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosDocument5 pagesDetermination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosBryan PariNo ratings yet

- User Manual BR501554 Rev3 PDFDocument369 pagesUser Manual BR501554 Rev3 PDFBetsy Suri Ramos PachecoNo ratings yet

- Combustion IC PDFDocument12 pagesCombustion IC PDFKhanza26No ratings yet

- GC Troubleshooting Guide 1680649001Document167 pagesGC Troubleshooting Guide 1680649001Pedro AraripeNo ratings yet

- Trace MS Hardware Manual Rev BDocument153 pagesTrace MS Hardware Manual Rev BGC powerNo ratings yet

- Etia00 51710322 e StromboliDocument32 pagesEtia00 51710322 e StrombolimaidenjukaNo ratings yet

- Sop GC6890 MS5973Document11 pagesSop GC6890 MS5973Felipe AndrinoNo ratings yet

- Operating Manual: Ac Oxytracer Analyzer On 7890 GCDocument49 pagesOperating Manual: Ac Oxytracer Analyzer On 7890 GCstemman95No ratings yet

- ELSDDocument78 pagesELSDTanya HiltzNo ratings yet

- Convenient Functions of GC-2014: Gas ChromatographyDocument2 pagesConvenient Functions of GC-2014: Gas ChromatographyShashank ChoudharyNo ratings yet

- User Manual: Shimadzu Advanced Flow Technology Detector Switching SoftwareDocument17 pagesUser Manual: Shimadzu Advanced Flow Technology Detector Switching SoftwareHarold GamaNo ratings yet

- WSRelease NotesDocument17 pagesWSRelease Notesmouth aldibesNo ratings yet

- MANUAL Controls-Shimadzu-Lc10 20systemsDocument79 pagesMANUAL Controls-Shimadzu-Lc10 20systemsdqrocha_ifamNo ratings yet

- TRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFDocument94 pagesTRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFInt PueNo ratings yet

- Oilpac eDocument85 pagesOilpac eAri CleciusNo ratings yet

- WMI SimDis DCS 2.3.3 Quick StartDocument16 pagesWMI SimDis DCS 2.3.3 Quick StartDavid GrudoskiNo ratings yet

- Determination of Total Sulfur by PFPDDocument85 pagesDetermination of Total Sulfur by PFPDTrinh Đình VũNo ratings yet

- Aoac 982.12 17 EdiçaõDocument3 pagesAoac 982.12 17 EdiçaõTiago Antonio Marmentini lopesNo ratings yet

- Shimadzu Gcmssolution: Gas Chromatograph Mass Spectrometer Data System Administration ManualDocument60 pagesShimadzu Gcmssolution: Gas Chromatograph Mass Spectrometer Data System Administration ManualdiegoNo ratings yet

- P007 Clarity IntroductionDocument29 pagesP007 Clarity IntroductionGregorio Antonio Valero VerdeNo ratings yet

- AN205WA0620L Simdist A4Document4 pagesAN205WA0620L Simdist A4MiguelNo ratings yet

- Quick Guide To Using The Agilent 1100 HPLC - Manju SharmaDocument2 pagesQuick Guide To Using The Agilent 1100 HPLC - Manju SharmamaulanaNo ratings yet

- Dani - An156 - RgaDocument6 pagesDani - An156 - RgaandreililioanceaNo ratings yet

- G1701-90112 GCMS Software InstallationDocument65 pagesG1701-90112 GCMS Software InstallationAlaa BassyounyNo ratings yet

- GC Getting Started Guide: 223-60220A Jul. 2010Document50 pagesGC Getting Started Guide: 223-60220A Jul. 2010Jeevan JalliNo ratings yet

- 5991-1059EN LC - SupplycatalogoDocument235 pages5991-1059EN LC - SupplycatalogomagdamayalagNo ratings yet

- Biodiesel 2015Document2 pagesBiodiesel 2015ClydeA.SardoncilloNo ratings yet

- 60-065483 - Rev C - Dionex ICS-5000 Plus, ICS-6000 Dual Pump and Single Pump Preventive Maintenance ProcedureDocument15 pages60-065483 - Rev C - Dionex ICS-5000 Plus, ICS-6000 Dual Pump and Single Pump Preventive Maintenance ProcedureWilmer AriasNo ratings yet

- Valves: An Introduction To GC ValvesDocument27 pagesValves: An Introduction To GC Valvesharsh421100% (1)

- GC Varian 3800Document18 pagesGC Varian 3800nomispipouNo ratings yet

- Guia para CromatografiaDocument98 pagesGuia para Cromatografiasaidvaret100% (1)

- Manuel Utilisateur ACTIVA AnDocument145 pagesManuel Utilisateur ACTIVA AnVanessa MoragaNo ratings yet

- Gta Analytical Methods 0848Document226 pagesGta Analytical Methods 0848milossmile100% (1)

- Seafast For Nexion IcpmsDocument2 pagesSeafast For Nexion Icpmsta quang khanhNo ratings yet

- Usermanual GC Operation 8890 g3540 90014 en AgilentDocument276 pagesUsermanual GC Operation 8890 g3540 90014 en AgilentmohamedNo ratings yet

- Kti Agilent 3000 Manual v1.8Document10 pagesKti Agilent 3000 Manual v1.8Zakir BashaNo ratings yet

- Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MSDocument36 pagesIntroduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MS Introduction To Shimadzu GC/MSLAGNo ratings yet

- Btu Analysis Using A Gas ChromatographDocument5 pagesBtu Analysis Using A Gas Chromatographlutfi awnNo ratings yet

- Application Report DMA 80 Evo Coal USREV061019Document4 pagesApplication Report DMA 80 Evo Coal USREV061019Roni GustiwaNo ratings yet

- Principle, Methodology and Application of Gas Chromatography (GC)Document31 pagesPrinciple, Methodology and Application of Gas Chromatography (GC)syuhadahNo ratings yet

- PAL User Manual Installation and Operation Combi Pal / Pal LHX Pal Combi-Xt / Pal LHX-XTDocument127 pagesPAL User Manual Installation and Operation Combi Pal / Pal LHX Pal Combi-Xt / Pal LHX-XTEliotNo ratings yet

- Manual For SP1 7890-0552 PDFDocument30 pagesManual For SP1 7890-0552 PDFvzimak2355No ratings yet

- Turn Signal and Hazard Warning Light (LHD)Document2 pagesTurn Signal and Hazard Warning Light (LHD)BASILIO JARA HUERTANo ratings yet

- 11 Hilux (Cont. Next Page) : Turn Signal and Hazard Warning Light ClockDocument2 pages11 Hilux (Cont. Next Page) : Turn Signal and Hazard Warning Light ClockautocomtrucksNo ratings yet

- 11 Hilux (Cont. Next Page) : Turn Signal and Hazard Warning Light ClockDocument2 pages11 Hilux (Cont. Next Page) : Turn Signal and Hazard Warning Light ClockautocomtrucksNo ratings yet

- 11 Hilux (Cont. Next Page) : Turn Signal and Hazard Warning Light ClockDocument2 pages11 Hilux (Cont. Next Page) : Turn Signal and Hazard Warning Light ClockautocomtrucksNo ratings yet

- Samsung Confidential Samsung Confidential: SM-T555 (TAB) - LTE - REV0.6Document10 pagesSamsung Confidential Samsung Confidential: SM-T555 (TAB) - LTE - REV0.6CyberBotas ReparacionesNo ratings yet

- HP - Probook.4510s.4520s.wistron.s Intel.H9265 4.48.4GK06.041.Rev .SD .Schematics 2Document61 pagesHP - Probook.4510s.4520s.wistron.s Intel.H9265 4.48.4GK06.041.Rev .SD .Schematics 2tapmesajNo ratings yet

- Iso 6332 1988Document8 pagesIso 6332 1988Jim FrenkenNo ratings yet

- S-231 IC Application Note No.: Title: Nitrite, Nitrate and Phosphate in Sea Water From A Shrimp FarmDocument2 pagesS-231 IC Application Note No.: Title: Nitrite, Nitrate and Phosphate in Sea Water From A Shrimp FarmNam Phạm VănNo ratings yet

- Senleaf O2 LumitrodeDocument23 pagesSenleaf O2 LumitrodeNam Phạm VănNo ratings yet

- Experiment Estimation of Formaldehyde: StructureDocument4 pagesExperiment Estimation of Formaldehyde: StructureNam Phạm VănNo ratings yet

- Determination of Paraformaldehyde Reactivity and Its Relationship To PRF Resin GelationDocument6 pagesDetermination of Paraformaldehyde Reactivity and Its Relationship To PRF Resin GelationNam Phạm VănNo ratings yet

- N-Methyldiethanolamine and Piperazine in Scrubber Solution: IC Application Note C-171Document2 pagesN-Methyldiethanolamine and Piperazine in Scrubber Solution: IC Application Note C-171Nam Phạm VănNo ratings yet

- TCVN7764-3 2007 905802Document132 pagesTCVN7764-3 2007 905802Nam Phạm VănNo ratings yet

- O-40 IC Application Note No.: Title: Borate in SeawaterDocument1 pageO-40 IC Application Note No.: Title: Borate in SeawaterNam Phạm VănNo ratings yet

- Determination of Formaldehyde by Polarography Method 1: Determination of Formaldehyde in Alkaline SolutionDocument7 pagesDetermination of Formaldehyde by Polarography Method 1: Determination of Formaldehyde in Alkaline SolutionNam Phạm VănNo ratings yet

- Curing Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodDocument13 pagesCuring Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodNam Phạm VănNo ratings yet

- Us 4977237Document4 pagesUs 4977237Nam Phạm VănNo ratings yet

- Boron by ICP AESDocument10 pagesBoron by ICP AESNam Phạm Văn100% (1)

- Precise Phosphate Measurement With The Yellow Method : Summary of The Study: The Investigation Has ShownDocument2 pagesPrecise Phosphate Measurement With The Yellow Method : Summary of The Study: The Investigation Has ShownNam Phạm VănNo ratings yet

- Urea Formaldehyde and Alkylated Urea For PDFDocument11 pagesUrea Formaldehyde and Alkylated Urea For PDFNam Phạm VănNo ratings yet

- Weekly U-See-U-Act / Walkabout FindingsDocument3 pagesWeekly U-See-U-Act / Walkabout Findingssiti_noh_4No ratings yet

- API 5L - Summary PDFDocument3 pagesAPI 5L - Summary PDFEason Ng0% (1)

- Application of SurveyingDocument21 pagesApplication of SurveyingAmila Madhushan100% (3)

- AERO Lab PhotosDocument6 pagesAERO Lab PhotosLiNuNo ratings yet

- Uponor Push 23b Shunt Med Wilo Pumpe MANDocument20 pagesUponor Push 23b Shunt Med Wilo Pumpe MANschritte1No ratings yet

- Catalogo TownleyDocument12 pagesCatalogo TownleyVladimir SepulvedaNo ratings yet

- PD 997Document3 pagesPD 997badsaintzNo ratings yet

- Design of Pile FoundationsDocument186 pagesDesign of Pile FoundationsLavinia DamianNo ratings yet

- Tech Note 791 - Galaxy Alarms Are Not Displayed in An Alarm ClientDocument12 pagesTech Note 791 - Galaxy Alarms Are Not Displayed in An Alarm ClientJoão Baptista André SabiomactetoNo ratings yet

- Enterprise Architecture1Document46 pagesEnterprise Architecture1Prasun Roy ChowdhuryNo ratings yet

- Ferromanganese: Standard Specification ForDocument3 pagesFerromanganese: Standard Specification ForPEPENo ratings yet

- Hinton 1998Document4 pagesHinton 1998Jéssica GonçalvesNo ratings yet

- Bharath Institute of Higher Education & Research: (BEEE) Model QuestionsDocument3 pagesBharath Institute of Higher Education & Research: (BEEE) Model QuestionsShaik Abdul RehmanNo ratings yet

- Ebt 338 Dipping ProcessDocument33 pagesEbt 338 Dipping Processdarsyanaa100% (1)

- Zokop Eh81 - ENGDocument5 pagesZokop Eh81 - ENGluismontoy.pNo ratings yet

- Me Lab AldouseDocument3 pagesMe Lab AldouseE.G Boy GudaNo ratings yet

- HYDRO 2012 Rev 1.5Document21 pagesHYDRO 2012 Rev 1.5FolpoNo ratings yet

- Steering Axle: RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)Document22 pagesSteering Axle: RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)stefan corjuc100% (2)

- Cummins China 4BTA3.9 G2Document5 pagesCummins China 4BTA3.9 G2joshua surbakti100% (1)

- Uk Mod 24 Ui - Jul 15Document2 pagesUk Mod 24 Ui - Jul 15yogihardNo ratings yet

- 02 Kaselowch2Document22 pages02 Kaselowch2JCMMPROJECTNo ratings yet

- Bush Btv17 Goodmans Gtv371vcrDocument37 pagesBush Btv17 Goodmans Gtv371vcrangusmecoatupNo ratings yet

- FINALDocument24 pagesFINALJewel higuitNo ratings yet

- Palm IslandDocument12 pagesPalm IslandDon Francis100% (1)

- KFleck Audio Mastering Complete ThesisDocument287 pagesKFleck Audio Mastering Complete Thesisrard111No ratings yet

- Plastic Solvent WeldingDocument5 pagesPlastic Solvent Weldingdavid_graves_okstateNo ratings yet

- Handbook of Semiconductor Wafer Cleaning TechnologyDocument11 pagesHandbook of Semiconductor Wafer Cleaning Technologynothing4free0% (1)