HT24LC02: CMOS 2K 2-Wire Serial EEPROM

HT24LC02: CMOS 2K 2-Wire Serial EEPROM

Uploaded by

vetchboyCopyright:

Available Formats

HT24LC02: CMOS 2K 2-Wire Serial EEPROM

HT24LC02: CMOS 2K 2-Wire Serial EEPROM

Uploaded by

vetchboyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

HT24LC02: CMOS 2K 2-Wire Serial EEPROM

HT24LC02: CMOS 2K 2-Wire Serial EEPROM

Uploaded by

vetchboyCopyright:

Available Formats

HT24LC02

CMOS 2K 2-Wire Serial EEPROM

Features

· Operating voltage: 2.2V~5.5V · Partial page write allowed

· Low power consumption · 8-byte Page write modes

- Operation: 5mA max. · Write operation with built-in timer

- Standby: 5mA max. · Hardware controlled write protection

· Internal organization: 256´8 · 40-year data retention

· 2-wire serial interface · 106 erase/write cycles per word

· Write cycle time: 5ms max. · Commerical temperature range (0°C to +70°C)

· Automatic erase-before-write operation · 8-pin DIP/SOP/TSSOP package

General Description

The HT24LC02 is a 2K-bit serial read/write non-volatile low power and low voltage operation are essential. Up

memory device using the CMOS floating gate process. to eight HT24LC02 devices may be connected to the

Its 2048 bits of memory are organized into 256 words same 2-wire bus. The HT24LC02 is guaranteed for 1M

and each word is 8 bits. The device is optimized for use erase/write cycles and 40-year data retention.

in many industrial and commercial applications where

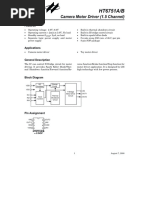

Block Diagram Pin Assignment

A 0 1 8 V C C

S C L I/O H V P u m p A 1 2 7 W P

C o n tro l

S D A A 2 3 6 S C L

L o g ic

V S S 4 5 S D A

X

D E E P R O M H T 2 4 L C 0 2

M e m o ry E A rra y 8 D IP -A /S O P -A /T S S O P -A

W P C o n tro l C

L o g ic

P a g e B u f

Y D E C

A d d re s s

A 0 ~ A 2 S e n s e A M P

C o u n te r

R /W C o n tro l

V C C

V S S

Pin Description

Pin Name I/O Description

A0~A2 I Address inputs

SDA I/O Serial data inputs/output

SCL I Serial clock data input

WP I Write protect

VSS ¾ Negative power supply, ground

VCC ¾ Positive power supply

Rev. 1.10 1 November 5, 2002

HT24LC02

Absolute Maximum Ratings

Operating Temperature (Commercial)..........................................................................................................0°C to 70°C

Storage Temperature.............................................................................................................................-50°C to 125 °C

Applied VCC Voltage with Respect to VSS ................................................................................................-0.3V to 6.0V

Applied Voltage on any Pin with Respect to VSS ..............................................................................-0.3V to VCC+0.3V

Note: These are stress ratings only. Stresses exceeding the range specified under ²Absolute Maximum Ratings² may

cause substantial damage to the device. Functional operation of this device at other conditions beyond those

listed in the specification is not implied and prolonged exposure to extreme conditions may affect device reliabil-

ity.

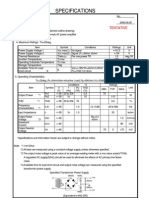

D.C. Characteristics Ta=0°C to 70°C

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VCC Conditions

VCC Operating Voltage ¾ ¾ 2.2 ¾ 5.5 V

ICC1 Operating Current 5V Read at 100kHz ¾ ¾ 2 mA

ICC2 Operating Current 5V Write at 100kHz ¾ ¾ 5 mA

VIL Input Low Voltage ¾ ¾ -1 ¾ 0.3VCC V

VIH Input High Voltage ¾ ¾ 0.7VCC ¾ VCC+0.5 V

VOL Output Low Voltage 2.4V IOL=2.1mA ¾ ¾ 0.4 V

ILI Input Leakage Current 5V VIN=0 or VCC ¾ ¾ 1 mA

ILO Output Leakage Current 5V VOUT=0 or VCC ¾ ¾ 1 mA

ISTB1 Standby Current 5V VIN=0 or VCC ¾ ¾ 5 mA

ISTB2 Standby Current 2.4V VIN=0 or VCC ¾ ¾ 4 mA

CIN Input Capacitance (See Note) ¾ f=1MHz 25°C ¾ ¾ 6 pF

COUT Output Capacitance (See Note) ¾ f=1MHz 25°C ¾ ¾ 8 pF

Note: These parameters are periodically sampled but not 100% tested

Rev. 1.10 2 November 5, 2002

HT24LC02

A.C. Characteristics Ta=0°C to 70°C

Standard Mode* VCC=5V±10%

Symbol Parameter Remark Unit

Min. Max. Min. Max.

fSK Clock Frequency ¾ ¾ 100 ¾ 400 kHz

tHIGH Clock High Time ¾ 4000 ¾ 600 ¾ ns

tLOW Clock Low Time ¾ 4700 ¾ 1200 ¾ ns

tr SDA and SCL Rise Time Note ¾ 1000 ¾ 300 ns

tf SDA and SCL Fall Time Note ¾ 300 ¾ 300 ns

After this period the

tHD:STA START Condition Hold Time first clock pulse is 4000 ¾ 600 ¾ ns

generated

Only relevant for

tSU:STA START Condition Setup Time repeated START 4000 ¾ 600 ¾ ns

condition

tHD:DAT Data Input Hold Time ¾ 0 ¾ 0 ¾ ns

tSU:DAT Data Input Setup Time ¾ 200 ¾ 100 ¾ ns

tSU:STO STOP Condition Setup Time ¾ 4000 ¾ 600 ¾ ns

tAA Output Valid from Clock ¾ ¾ 3500 ¾ 900 ns

Time in which the bus

must be free before a

tBUF Bus Free Time 4700 ¾ 1200 ¾ ns

new transmission can

start

Input Filter Time Constant Noise suppression

tSP ¾ 100 ¾ 50 ns

(SDA and SCL Pins) time

tWR Write Cycle Time ¾ ¾ 5 ¾ 5 ms

Note: These parameters are periodically sampled but not 100% tested

* The standard mode means VCC=2.2V to 5.5V

For relative timing, refer to timing diagrams

Rev. 1.10 3 November 5, 2002

HT24LC02

Functional Description

· Serial clock (SCL) · Acknowledge

The SCL input is used for positive edge clock data into All addresses and data words are serially transmitted

each EEPROM device and negative edge clock data to and from the EEPROM in 8-bit words. The

out of each device. EEPROM sends a zero to acknowledge that it has re-

ceived each word. This happens during the ninth clock

· Serial data (SDA)

cycle.

The SDA pin is bidirectional for serial data transfer.

The pin is open-drain driven and may be wired-OR

D a ta a llo w e d

with any number of other open-drain or open collector to c h a n g e

devices. S D A

· A0, A1, A2

The A2, A1 and A0 pins are device address inputs that S C L

are hard wired for the HT24LC02. As many as eight S ta rt A d d re s s o r S to p

2K devices may be addressed on a single bus system c o n d itio n a c k n o w le d g e c o n d itio n

v a lid

(the device addressing is discussed in detail under the

Device Addressing section).

Device addressing

· Write protect (WP)

The 2K EEPROM devices all require an 8-bit device ad-

The HT24LC02 has a write protect pin that provides

dress word following a start condition to enable the chip

hardware data protection. The write protect pin allows

for a read or write operation. The device address word

normal read/write operations when connected to the

consist of a mandatory one, zero sequence for the first

VSS. When the write protect pin is connected to Vcc,

four most significant bits (refer to the diagram showing

the write protection feature is enabled and operates

the Device Address). This is common to all the

as shown in the following table.

EEPROM device.

WP Pin

Protect Array The next three bits are the A2, A1 and A0 device ad-

Status

dress bits for the 2K EEPROM. These three bits must

At VCC Full Array (2K) compare to their corresponding hard-wired input pins.

At VSS Normal Read/Write Operations The 8th bit of device address is the read/write operation

select bit. A read operation is initiated if this bit is high

Memory organization and a write operation is initiated if this bit is low.

· HT24LC02, 2K Serial EEPROM If the comparison of the device address succeed the

Internally organized with 256 8-bit words, the 2K re- EEPROM will output a zero at ACK bit. If not, the chip will

quires an 8-bit data word address for random word ad- return to a standby state.

dressing.

1 0 1 0 A 2 A 1 A 0 R /W

Device operations

D e v ic e A d d r e s s

· Clock and data transition

Data transfer may be initiated only when the bus is not

Write operations

busy. During data transfer, the data line must remain

stable whenever the clock line is high. Changes in · Byte write

data line while the clock line is high will be interpreted A write operation requires an 8-bit data word address

as a START or STOP condition. following the device address word and acknowledg-

ment. Upon receipt of this address, the EEPROM will

· Start condition

again respond with a zero and then clock in the first

A high-to-low transition of SDA with SCL high is a start

8-bit data word. After receiving the 8-bit data word, the

condition which must precede any other command

EEPROM will output a zero and the addressing de-

(refer to Start and Stop Definition Timing diagram).

vice, such as a microcontroller, must terminate the

· Stop condition write sequence with a stop condition. At this time the

A low-to-high transition of SDA with SCL high is a stop EEPROM enters an internally-timed write cycle to the

condition. After a read sequence, the stop command non-volatile memory. All inputs are disabled during

will place the EEPROM in a standby power mode (re- this write cycle and EEPROM will not respond until the

fer to Start and Stop Definition Timing Diagram). write is completed (refer to Byte write timing).

Rev. 1.10 4 November 5, 2002

HT24LC02

· Page write

S e n d W r ite C o m m a n d

The 2K EEPROM is capable of an 8-byte page write.

A page write is initiated the same as byte write, but the

S e n d S to p C o n d itio n

microcontroller does not send a stop condition after to In itia te W r ite C y c le

the first data word is clocked in. Instead, after the

EEPROM acknowledges the receipt of the first data

S e n d S ta rt

word, the microcontroller can transmit up to seven

more data words. The EEPROM will respond with a

z e ro a f t e r e a c h d a t a w or d r e c ei ve d . T h e S e n d C o tr o ll B y te

w ith R /W = 0

microcontroller must terminate the page write se-

quence with a stop condition.

The data word address lower three (2K) bits are inter-

(A C K = 0 )? N o

nally incremented following the receipt of each data

word. The higher data word address bits are not incre-

mented, retaining the memory page row location (re- Y e s

fer to Page write timing). N e x t O p e r a tio n

· Acknowledge polling

Acknowledge polling flow

Since the device will not acknowledge during a write

· Read operations

cycle, this can be used to determine when the cycle is

complete (this feature can be used to maximize bus Read operations are initiated the same way as write

throughput). Once the stop condition for a write com- operations with the exception that the read/write se-

mand has been issued from the master, the device ini- lect bit in the device address word is set to one. There

tiates the internally timed write cycle. ACK polling can are three read operations: current address read, ran-

be initiated immediately. This involves the master dom address read and sequential read.

sending a start condition followed by the control byte · Current address read

for a write command (R/W=0). If the device is still busy The internal data word address counter maintains the

with the write cycle, then no ACK will be returned. If last address accessed during the last read or write op-

the cycle is completed, then the device will return the eration, incremented by one. This address stays valid

ACK and the master can then proceed with the next between operations as long as the chip power is main-

read or write command. tained. The address roll over during read from the last

byte of the last memory page to the first byte of the first

· Write protect

page. The address roll over during write from the last

The HT24LC02 can be used as a serial ROM when byte of the current page to the first byte of the same

the WP pin is connected to VCC. Programming will be page. Once the device address with the read/write se-

in h ib i t ed and t he ent i r e m em or y w i l l b e lect bit set to one is clocked in and acknowledged by

write-protected. the EEPROM, the current address data word is seri-

B y te w r ite tim in g

D e v ic e a d d r e s s W o rd a d d re s s D A T A

S D A S A 2 A 1 A 0 P

S ta rt R /W A C K A C K

A C K

S to p

P a g e w r ite tim in g

D e v ic e a d d r e s s W o rd a d d re s s D A T A n D A T A n + 1 D A T A n + x

S D A S P

S ta rt A C K A C K A C K A C K

S to p

C u r r e n t r e a d tim in g

D e v ic e a d d r e s s D A T A

S to p

S D A S A 2 A 1 A 0 P

S ta rt A C K N o A C K

Rev. 1.10 5 November 5, 2002

HT24LC02

ally clocked out. The microcontroller does not respond · Sequential read

with an input zero but generates a following stop con- Sequential reads are initiated by either a current ad-

dition (refer to Current read timing). dress read or a random address read. After the

· Random read microcontroller receives a data word, it responds with an

A random read requires a dummy byte write sequence acknowledgment. As long as the EEPROM receives an

to load in the data word address which is then clocked acknowledgment, it will continue to increment the data

in and acknowledged by the EEPROM. The word address and serially clock out sequential data

microcontroller must then generate another start con- words. When the memory address limit is reached, the

dition. The microcontroller now initiates a current ad- data word address will roll over and the sequential read

dress read by sending a device address with the continues. The sequential read operation is terminated

read/write select bit high. The EEPROM acknowl- when the microcontroller does not respond with a zero

edges the device address and serially clocks out the but generates a following stop condition.

data word. The microcontroller does not respond with

a zero but does generates a following stop condition

(refer to Random read timing).

R a n d o m r e a d tim in g

D e v ic e a d d r e s s W o rd a d d re s s D e v ic e a d d r e s s D A T A

S to p

S D A S A 2 A 1 A 0 S P

A C K A C K A C K N o A C K

S ta rt S ta rt

S e q u e n tia l r e a d tim in g

D e v ic e a d d r e s s D A T A n D A T A n + 1 D A T A n + x

S D A S P

S ta rt A C K A C K A C K

S to p

Timing Diagrams

tf tr tH IG H

tL O W

S C L

tS U :S T A tH D :S T A tS U :D A T tS U :S T O

tH D :D A T

S D A tS P

tB U F

tA A

S D A

V a lid V a lid

O U T

S C L

S D A 8 th b it A C K

W o rd n tW R

S to p S ta rt

C o n d itio n C o n d itio n

Note: The write cycle time tWR is the time from a valid stop condition of a write sequence to the end of the valid start

condition of sequential command.

Rev. 1.10 6 November 5, 2002

HT24LC02

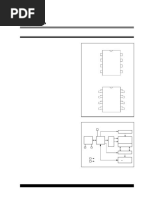

Package Information

8-pin DIP (300mil) outline dimensions

8 5

B

1 4

D

= I

E G

Dimensions in mil

Symbol

Min. Nom. Max.

A 355 ¾ 375

B 240 ¾ 260

C 125 ¾ 135

D 125 ¾ 145

E 16 ¾ 20

F 50 ¾ 70

G ¾ 100 ¾

H 295 ¾ 315

I 335 ¾ 375

a 0° ¾ 15°

Rev. 1.10 7 November 5, 2002

HT24LC02

8-pin SOP (150mil) outline dimensions

8 5

A B

1 4

C '

G

D H

E F =

Dimensions in mil

Symbol

Min. Nom. Max.

A 228 ¾ 244

B 149 ¾ 157

C 14 ¾ 20

C¢ 189 ¾ 197

D 53 ¾ 69

E ¾ 50 ¾

F 4 ¾ 10

G 22 ¾ 28

H 4 ¾ 12

a 0° ¾ 10°

Rev. 1.10 8 November 5, 2002

HT24LC02

8-pin TSSOP outline dimensions

8 5

E 1

1 4

E

D

L

A A 2

C G

e B A 1 L 1

R 0 .1 0 y

(4 C O R N E R S )

Dimensions in mm

Symbol

Min. Nom. Max.

A 1.05 ¾ 1.20

A1 0.05 ¾ 0.15

A2 0.95 ¾ 1.05

B ¾ 0.25 ¾

C 0.11 ¾ 0.15

D 2.90 ¾ 3.10

E 6.20 ¾ 6.60

E1 4.30 ¾ 4.50

e ¾ 0.65 ¾

L 0.50 ¾ 0.70

L1 0.90 ¾ 1.10

y ¾ ¾ 0.10

q 0° ¾ 8°

Rev. 1.10 9 November 5, 2002

HT24LC02

Product Tape and Reel Specifications

Reel dimensions

D

T 2

A B C

T 1

SOP 8N

Symbol Description Dimensions in mm

A Reel Outer Diameter 330±1.0

B Reel Inner Diameter 62±1.5

13.0+0.5

C Spindle Hole Diameter

-0.2

D Key Slit Width 2.0±0.15

12.8+0.3

T1 Space Between Flange

-0.2

T2 Reel Thickness 18.2±0.2

TSSOP 8L

Symbol Description Dimensions in mm

A Reel Outer Diameter 330±1.0

B Reel Inner Diameter 62±1.5

13.0+0.5

C Spindle Hole Diameter

-0.2

D Key Slit Width 2.0±0.5

12.8+0.3

T1 Space Between Flange

-0.2

T2 Reel Thickness 18.2±0.2

Rev. 1.10 10 November 5, 2002

HT24LC02

Carrier tape dimensions

P 0 P 1

D t

F

W

B 0

C

D 1 P

K 0

A 0

SOP 8N

Symbol Description Dimensions in mm

12.0+0.3

W Carrier Tape Width

-0.1

P Cavity Pitch 8.0±0.1

E Perforation Position 1.75±0.1

F Cavity to Perforation (Width Direction) 5.5±0.1

D Perforation Diameter 1.55±0.1

D1 Cavity Hole Diameter 1.5+0.25

P0 Perforation Pitch 4.0±0.1

P1 Cavity to Perforation (Length Direction) 2.0±0.1

A0 Cavity Length 6.4±0.1

B0 Cavity Width 5.20±0.1

K0 Cavity Depth 2.1±0.1

t Carrier Tape Thickness 0.3±0.05

C Cover Tape Width 9.3

TSSOP 8L

Symbol Description Dimensions in mm

12.0+0.3

W Carrier Tape Width

-0.1

P Cavity Pitch 8.0±0.1

E Perforation Position 1.75±0.1

F Cavity to Perforation (Width Direction) 5.5±0.5

D Perforation Diameter 1.5+0.1

D1 Cavity Hole Diameter 1.5+0.1

P0 Perforation Pitch 4.0±0.1

P1 Cavity to Perforation (Length Direction) 2.0±0.1

A0 Cavity Length 7.0±0.1

B0 Cavity Width 3.6±0.1

K0 Cavity Depth 1.6±0.1

t Carrier Tape Thickness 0.3±0.013

C Cover Tape Width 9.3

Rev. 1.10 11 November 5, 2002

HT24LC02

Holtek Semiconductor Inc. (Headquarters)

No.3, Creation Rd. II, Science-based Industrial Park, Hsinchu, Taiwan

Tel: 886-3-563-1999

Fax: 886-3-563-1189

http://www.holtek.com.tw

Holtek Semiconductor Inc. (Sales Office)

11F, No.576, Sec.7 Chung Hsiao E. Rd., Taipei, Taiwan

Tel: 886-2-2782-9635

Fax: 886-2-2782-9636

Fax: 886-2-2782-7128 (International sales hotline)

Holtek Semiconductor (Shanghai) Inc.

7th Floor, Building 2, No.889, Yi Shan Rd., Shanghai, China

Tel: 021-6485-5560

Fax: 021-6485-0313

http://www.holtek.com.cn

Holtek Semiconductor (Hong Kong) Ltd.

RM.711, Tower 2, Cheung Sha Wan Plaza, 833 Cheung Sha Wan Rd., Kowloon, Hong Kong

Tel: 852-2-745-8288

Fax: 852-2-742-8657

Holmate Semiconductor, Inc.

48531 Warm Springs Boulevard, Suite 413, Fremont, CA 94539

Tel: 510-252-9880

Fax: 510-252-9885

http://www.holmate.com

Copyright Ó 2002 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek as-

sumes no responsibility arising from the use of the specifications described. The applications mentioned herein are used

solely for the purpose of illustration and Holtek makes no warranty or representation that such applications will be suitable

without further modification, nor recommends the use of its products for application that may present a risk to human life

due to malfunction or otherwise. Holtek reserves the right to alter its products without prior notification. For the most

up-to-date information, please visit our web site at http://www.holtek.com.tw.

Rev. 1.10 12 November 5, 2002

You might also like

- P-H Agua PDFDocument1 pageP-H Agua PDFSarah B. LopesNo ratings yet

- Vox VT-Cheat SheetDocument1 pageVox VT-Cheat Sheetstereomati3751No ratings yet

- Plumbing Services: NBC-2016-PART-9Document3 pagesPlumbing Services: NBC-2016-PART-9Rohan Kulkarni100% (2)

- Hydril MSP 29-500 ManualDocument26 pagesHydril MSP 29-500 ManualTitanBOP100% (1)

- Monthly Averages of Air Temperatures (In Celsius) and Amount of Rainfall in Lake Taal From 2000 - 2011Document33 pagesMonthly Averages of Air Temperatures (In Celsius) and Amount of Rainfall in Lake Taal From 2000 - 2011Brian PaguiaNo ratings yet

- HT24LC02: CMOS 2K 2-Wire Serial EEPROMDocument12 pagesHT24LC02: CMOS 2K 2-Wire Serial EEPROMhcarcaroNo ratings yet

- HT24LC02: 2K 2-Wire CMOS Serial EEPROMDocument8 pagesHT24LC02: 2K 2-Wire CMOS Serial EEPROMvetchboyNo ratings yet

- 24 LC 04Document8 pages24 LC 04mjankebnuNo ratings yet

- Drive MotorDocument5 pagesDrive MotorHenrique Flávio Sucupira PaivaNo ratings yet

- 74VHC244 Octal Buffer/Line Driver With 3-STATE Outputs: General Description FeaturesDocument8 pages74VHC244 Octal Buffer/Line Driver With 3-STATE Outputs: General Description FeaturesrzvNo ratings yet

- 24LC01BI_PDocument12 pages24LC01BI_PNilantha GeethapriyaNo ratings yet

- 24C01SCDocument12 pages24C01SCaprilila5555No ratings yet

- 74VHC04 HEX InverterDocument8 pages74VHC04 HEX InverterDiem NguyenducNo ratings yet

- 24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesDocument12 pages24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesarminNo ratings yet

- 24C1 Memoria Eeprom SankeyDocument11 pages24C1 Memoria Eeprom Sankeyjavier venturaNo ratings yet

- 279170Document34 pages279170Roli MixNo ratings yet

- 24C32Document12 pages24C32SilviuCocoloșNo ratings yet

- 24C256Document14 pages24C256Việt Thảo TrầnNo ratings yet

- VHC32Document7 pagesVHC32quangNo ratings yet

- Atmel 4 Wire Serial EepromsDocument13 pagesAtmel 4 Wire Serial Eeproms轮摇No ratings yet

- Atmel 24c02 PDFDocument30 pagesAtmel 24c02 PDFMAX GNo ratings yet

- 74VHC541 Octal Buffer/Line Driver With 3-STATE Outputs: General DescriptionDocument7 pages74VHC541 Octal Buffer/Line Driver With 3-STATE Outputs: General Descriptionprdp_666No ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument32 pages24AA02/24LC02B: 2KI C Serial EEPROMhanifNo ratings yet

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package Typesinsomnium86No ratings yet

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDocument34 pages24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaNo ratings yet

- dp8570aDocument28 pagesdp8570aDaniel Enrique Zamora SifredoNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pages24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezNo ratings yet

- 1K 5.0V I C™ Serial EEPROM: Features: DescriptionDocument36 pages1K 5.0V I C™ Serial EEPROM: Features: DescriptionDanna PerezNo ratings yet

- 74ACT04Document7 pages74ACT04movilsoft00No ratings yet

- Triple Schmitt Inverter: Order CodesDocument7 pagesTriple Schmitt Inverter: Order CodeselieNo ratings yet

- M48Z02 M48Z12: 16 Kbit (2Kb X 8) ZEROPOWER SramDocument12 pagesM48Z02 M48Z12: 16 Kbit (2Kb X 8) ZEROPOWER SramUzair SajidNo ratings yet

- 2-Wire Serial EEPROM Smart Card Module: FeaturesDocument12 pages2-Wire Serial EEPROM Smart Card Module: FeaturesMaikol DominguezNo ratings yet

- I C-Compatible Serial E Prom: General DescriptionDocument20 pagesI C-Compatible Serial E Prom: General Descriptionsajjad_pirzadaNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFNicoli LourençoNo ratings yet

- A. Atmel ProductsDocument16 pagesA. Atmel ProductsJuan Jose MendozaNo ratings yet

- 2-Wire Serial EEPROM: FeaturesDocument21 pages2-Wire Serial EEPROM: Featuresuwbg.ycion44No ratings yet

- 25AA128 25LC128 128K SPI Bus Serial EEPROM 2000183-3443116Document36 pages25AA128 25LC128 128K SPI Bus Serial EEPROM 2000183-3443116Alf CelNo ratings yet

- 24aa515, 24LC515, 24FC515Document20 pages24aa515, 24LC515, 24FC515dorudNo ratings yet

- 24l1026i Memoria EEPROM 1024kDocument28 pages24l1026i Memoria EEPROM 1024kMarta_d_eNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument24 pages24AA02/24LC02B: 2KI C Serial EEPROMMayk OzNo ratings yet

- Write Protect Pin For Hardware Data ProtectionDocument16 pagesWrite Protect Pin For Hardware Data Protectionisc44242100% (2)

- At 25080Document21 pagesAt 25080sabNo ratings yet

- 74ac14 Hex Schmitt InverterDocument9 pages74ac14 Hex Schmitt Invertermarcel.mazziNo ratings yet

- 2-Wire Serial Eeprom: FeaturesDocument10 pages2-Wire Serial Eeprom: FeaturesPablo Diego Cecere CasadoNo ratings yet

- 2-Wire Serial Eeprom: FeaturesDocument11 pages2-Wire Serial Eeprom: FeaturesRomel Ranin CalangNo ratings yet

- 24FC1025 EepromDocument28 pages24FC1025 EepromAnirudh ReddyNo ratings yet

- DTM0660 Data SheetDocument10 pagesDTM0660 Data SheetJuan Francisco Pozo AcostaNo ratings yet

- 16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangesDocument22 pages16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangeshcarcaroNo ratings yet

- 2-Wire Serial Eeprom: FeaturesDocument20 pages2-Wire Serial Eeprom: FeaturesAgustin AndrokaitesNo ratings yet

- M54HC132 M74HC132: Quad 2-Input Schmitt Nand GateDocument9 pagesM54HC132 M74HC132: Quad 2-Input Schmitt Nand GatenooorNo ratings yet

- SPI Serial Eeproms: FeaturesDocument15 pagesSPI Serial Eeproms: FeaturesMarcus SilvaNo ratings yet

- BCD To DECIMAL DecoderDocument10 pagesBCD To DECIMAL DecoderMr Miracle100% (1)

- FM24C02A-FudanDocument19 pagesFM24C02A-FudanJohnsan DrummerNo ratings yet

- M54HCT00 M74HCT00: Quad 2-Input Nand GateDocument9 pagesM54HCT00 M74HCT00: Quad 2-Input Nand GateStuxnetNo ratings yet

- 24C64 - EepromDocument20 pages24C64 - Eepromropay61705No ratings yet

- At25f512a 844895Document19 pagesAt25f512a 844895mirage0706No ratings yet

- Two-Wire Serial EEPROM 2K: Wuhan Eshine Technology Co., LTDDocument20 pagesTwo-Wire Serial EEPROM 2K: Wuhan Eshine Technology Co., LTDgrufNo ratings yet

- 24C02BN Su18Document26 pages24C02BN Su18Dwp BhaskaranNo ratings yet

- AT24C16BDocument20 pagesAT24C16Blucio perezNo ratings yet

- 24LC04B PDFDocument22 pages24LC04B PDFEddy RosarioNo ratings yet

- 74ac541 TristateDocument9 pages74ac541 TristateershadsaabNo ratings yet

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDocument29 pages24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanNo ratings yet

- 2-Wire Serial Eeproms: FeaturesDocument16 pages2-Wire Serial Eeproms: FeaturesTuan Pham AnhNo ratings yet

- Audio Tda8510j Spec enDocument16 pagesAudio Tda8510j Spec envetchboyNo ratings yet

- 2 X 3 W Dual/Quad Power Amplifier For Car Radio: ProtectionsDocument10 pages2 X 3 W Dual/Quad Power Amplifier For Car Radio: ProtectionsJosé VidalNo ratings yet

- CD-R/RW Playback Shock Proof CDP Chipset Specification: (Full Digit LCD Model)Document16 pagesCD-R/RW Playback Shock Proof CDP Chipset Specification: (Full Digit LCD Model)vetchboyNo ratings yet

- Dual Btl/Quad Power Amplifier For Car Radio: ProtectionsDocument14 pagesDual Btl/Quad Power Amplifier For Car Radio: ProtectionsvetchboyNo ratings yet

- 120V - 100W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyDocument13 pages120V - 100W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyvetchboyNo ratings yet

- TDA7384A: 4 X 35W Quad Bridge Car Radio AmplifierDocument9 pagesTDA7384A: 4 X 35W Quad Bridge Car Radio AmplifierGerardo Moreno RenteriaNo ratings yet

- Tda 7296Document14 pagesTda 7296Mayra GonzálezNo ratings yet

- Digital Controlled Stereo Audio Processor With Loudness: DescriptionDocument14 pagesDigital Controlled Stereo Audio Processor With Loudness: DescriptionvetchboyNo ratings yet

- 4 X 18W Bridge Car Radio Amplifier: Protections: DescriptionDocument10 pages4 X 18W Bridge Car Radio Amplifier: Protections: DescriptionvetchboyNo ratings yet

- Tda7294 PDFDocument16 pagesTda7294 PDFRoger NunesNo ratings yet

- Tda 7265 2 x25 WDocument12 pagesTda 7265 2 x25 WJavier CanaviriNo ratings yet

- TA2041 Four Channel Class-T Digital Audio Amplifier Using Digital Power Processing (DPP) TechnologyDocument18 pagesTA2041 Four Channel Class-T Digital Audio Amplifier Using Digital Power Processing (DPP) TechnologyvetchboyNo ratings yet

- 30W Bridge Car Radio Amplifier: DescriptionDocument10 pages30W Bridge Car Radio Amplifier: DescriptionvetchboyNo ratings yet

- 10W Car Radio Audio Amplifier: DescriptionDocument11 pages10W Car Radio Audio Amplifier: DescriptionvetchboyNo ratings yet

- STK442 110Document4 pagesSTK442 110Ivan AsimovNo ratings yet

- TDA 2822M CircuitoDocument11 pagesTDA 2822M CircuitoDATA24No ratings yet

- Audio Tas5100a Spec enDocument15 pagesAudio Tas5100a Spec envetchboyNo ratings yet

- pt2388 (v1Document18 pagespt2388 (v1vetchboy0% (1)

- Description: Angus Electronics Company LimitedDocument9 pagesDescription: Angus Electronics Company LimitedvetchboyNo ratings yet

- Description: Angus Electronics Company LimitedDocument13 pagesDescription: Angus Electronics Company LimitedvetchboyNo ratings yet

- 2-Channel Preamplifier For Car Stereo: Package Dimensions FeaturesDocument7 pages2-Channel Preamplifier For Car Stereo: Package Dimensions FeaturesvetchboyNo ratings yet

- Angus Electronics Company Limited: PT2323 DescriptionDocument18 pagesAngus Electronics Company Limited: PT2323 DescriptionvetchboyNo ratings yet

- 2-Channel Preamplifier For Car Stereo: Package Dimensions FeaturesDocument7 pages2-Channel Preamplifier For Car Stereo: Package Dimensions FeaturesvetchboyNo ratings yet

- LM124/224/324/324A/ SA534/LM2902: Low Power Quad Op AmpsDocument12 pagesLM124/224/324/324A/ SA534/LM2902: Low Power Quad Op AmpsvetchboyNo ratings yet

- Angus Electronics Company Limited: PreliminaryDocument18 pagesAngus Electronics Company Limited: PreliminaryvetchboyNo ratings yet

- Dual Operational Amplifiers: Technical DataDocument4 pagesDual Operational Amplifiers: Technical DatavetchboyNo ratings yet

- Features: Stereo 330mW Audio Power Amp With ShutdownDocument9 pagesFeatures: Stereo 330mW Audio Power Amp With ShutdownvetchboyNo ratings yet

- T Series VRLA Battery PDFDocument4 pagesT Series VRLA Battery PDFsistemsem30No ratings yet

- SustainabilityDocument37 pagesSustainabilityMarcin OsieckiNo ratings yet

- OCW - Control Systems - I (EE 503) - AY 2016-17 - 2017-18 PDFDocument100 pagesOCW - Control Systems - I (EE 503) - AY 2016-17 - 2017-18 PDFCiczmockingbird TsvkAdm100% (1)

- Instituto Alemão de Normalização-Din 10149-2Document15 pagesInstituto Alemão de Normalização-Din 10149-2Helder VieiraNo ratings yet

- Permit Issued in Dec 2015: Job Number Permit Type Property AddressDocument180 pagesPermit Issued in Dec 2015: Job Number Permit Type Property AddressBrian PetranoNo ratings yet

- Service Manual: RefrigeratorDocument18 pagesService Manual: RefrigeratorLeonardo Alejandro OrdoñezNo ratings yet

- Design of Oneway SlabsDocument5 pagesDesign of Oneway SlabsOsama TamariNo ratings yet

- Makerfabs Company DescriptionDocument16 pagesMakerfabs Company Descriptionhe fangNo ratings yet

- User Manual: 6 SeriesDocument60 pagesUser Manual: 6 Seriesnavaron64No ratings yet

- EurokinDocument14 pagesEurokinapitbhuNo ratings yet

- Name - Navneet Kumar Class - XI - (A) Roll NO - 20 Teacher Name - Gajendar SharmaDocument18 pagesName - Navneet Kumar Class - XI - (A) Roll NO - 20 Teacher Name - Gajendar SharmaJunaid AhmedNo ratings yet

- Remote HackingDocument2 pagesRemote Hackingberthol8942No ratings yet

- Exam 1 Sp23Document11 pagesExam 1 Sp23Mike TederNo ratings yet

- ResumeDocument2 pagesResumeManoharNo ratings yet

- Propaq: MD Service ManualDocument100 pagesPropaq: MD Service ManualFelix CobianNo ratings yet

- Process Specification Heat Exchanger CpeccDocument2 pagesProcess Specification Heat Exchanger CpeccroyNo ratings yet

- Operating Instructions: STAR LIFTKET - Electric Chain HoistsDocument40 pagesOperating Instructions: STAR LIFTKET - Electric Chain HoistsMuhammad Lathieful HaqNo ratings yet

- Case Study: Powercrete and CablecemDocument2 pagesCase Study: Powercrete and CablecemAnonymous N13JdnNo ratings yet

- Sany SCC1800A 180tonDocument68 pagesSany SCC1800A 180tonNunoNo ratings yet

- R0 Quotation AC - Hotel HarbertDocument4 pagesR0 Quotation AC - Hotel HarbertTrinevi SalindehoNo ratings yet

- Anemometer - Anemoscope - Instruction ManualDocument10 pagesAnemometer - Anemoscope - Instruction Manualrecep.orucogluNo ratings yet

- Database Systems (SET11101) : TasksDocument5 pagesDatabase Systems (SET11101) : TasksNajeeb ZulfiqarNo ratings yet

- Ma Pa Ua EuDocument1 pageMa Pa Ua EuBeldimanaftobingNo ratings yet

- AC7102 - 5 Rev. F - CleanDocument12 pagesAC7102 - 5 Rev. F - Cleanradimkov75No ratings yet

- Aksa Product Line Catalogue (50hz) (2022)Document40 pagesAksa Product Line Catalogue (50hz) (2022)محمد الخاتمNo ratings yet