Tensile Stress-Strain Relationship For Ferro Cement Structures

Tensile Stress-Strain Relationship For Ferro Cement Structures

Uploaded by

Sulaiman Mohsin AbdulAzizCopyright:

Available Formats

Tensile Stress-Strain Relationship For Ferro Cement Structures

Tensile Stress-Strain Relationship For Ferro Cement Structures

Uploaded by

Sulaiman Mohsin AbdulAzizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Tensile Stress-Strain Relationship For Ferro Cement Structures

Tensile Stress-Strain Relationship For Ferro Cement Structures

Uploaded by

Sulaiman Mohsin AbdulAzizCopyright:

Available Formats

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

27

Tensile Stress-Strain Relationship For Ferro cement Structures

Azad A. Mohammed and Dunyazad K. Assi

E-mail : azadkadr@yahoo.com E-mail dunya3s@yahoo.com

College of Engineering , University of Sulaimani

Abstract

Tests on fibrocement discs were carried out to measure tensile stress- strain relationship

including testing wide ranges of matrix strength. Equations were proposed for

calculating tensile strength based on the present test results and other results in the

literature. A trilinear idealized model was proposed for calculating tensile stress strain

response of Ferro cement. The model was found to be accurate especially for higher

strength Ferro cement. Later an analysis was carried out for calculating the load-

deflection relationship of Ferro cement beams based on moment curvature

relationship and bending theory of elastic beam. The analysis which based on the

proposed tensile model was found to be accurate for Ferro cement beams and slab strips

provided that the span / depth ratio less than 22.

KEYWARDS: Analysis, Beam, Elastic, Ferro cement, Flexure, Plastic, Slab, Strain,

Tensile Stress

-

.

/ /

.

. -

. -

.

.

-

/ 22 .

Received: 9 1 - 2010 Accepted: 15 6 - 2011

Al-Rafidain Engineering Vol.20 No. 2 March 2012

28

1- Introduction

Ferro cement is considered as one of the nonconvential types of reinforced concrete

usually known by its thin section and high tensile strength to weight ratio. Application of

Ferro cement in which the section subjects to uniaxial tension can be seen in the case of silos,

liquid retaining tanks, pipes, etc. Although the invention of Ferro cement turned back to the

period of middle of the nineteenth century , researches for understanding mechanical and

structural properties begin at the early 1970s. Nowadays the basic properties of Ferro cement

were well understood and equations for design were proposed, that basically depend on the

knowledge obtained from tests carried out during the last forty years.

ACI Committee 549

[ 1 ]

prepared a state-of -the- art report to be a guidance for practical

applications of Ferro cement. According to ACI 549 recommendations the role of Ferro

cement mortar on tensile strength is neglected and the tensile strength is calculated from the

load carried by the wire meshes divided by the sectional area. It should be noted that this

recommendation is based on the results of tests carried out during the period from 1971 to

1977 [3, 5, 7] for Ferro cement sections made from a cement mortar of medium strength.

Such recommendation is acceptable for calculating tensile strength of Ferro cement section

made from normal strength mortar and greatly underestimates the tensile strength of high

strength mortar Ferro cement. This is because the tensile strength of plain matrix alone is

high and may be considerably greater than that calculated from the recommendations of ACI

549. For example, for a Ferro cement section of 25.4 mm thickness reinforced with five

layers of wire mesh of 0.6 mm diameter, 12 mm spacing, and 412 MPa yield stress, the

tensile stress will be 1.91 MPa. If the compressive strength of matrix be 80 MPa and cracking

tensile stress is calculated from the relationship given by Shah and Balaguru

[ 8 ]

the result

which becomes 4.91 MPa. Therefore , one can found that the ultimate tensile stress calculated

from ACI 549 recommendation is only 39% of the cracking stress. The later ratio is quite

small and can be considered not reviewed. Therefore developing equations for predicting

ultimate tensile stress of Ferro cement made of mortar of high strength is necessary. The aim

of the present research is to provide an alternative equation for calculating tensile strength of

Ferro cement applicable for wide range of matrix strength based on tensile stress tests and

regression analysis. In the present study an attempt was made to develop a model for

calculating tensile stress strain relationship depending on the idealized trilinear response.

Later, an analysis was introduced for calculating the complete load deflection relationship

of Ferro cement beams or slab strips based on derivation of moment- curvature relationship

and results of elastic beam theory. The predictions of analysis were compared with the

flexural test data carried out on ferrocement from literature to test the accuracy of the

analysis.

2- Experimental Work

Ordinary Portland cement ( Type I ) was used for casting disc and compression specimens.

Medium graded clean river sand passed by 100% on 2.36 mm sieve was used. For high

strength mixes a high range water reducer (super plasticizer) of Gellunum type which is

commercially available was used. Welded galvanized steel wire mesh fabric of 0.6 mm

diameter and 12 mm spacing between wires and of 458 MPa yield stress was used as

reinforcement. Details of mixes and arrangement of reinforcement in each tensile test

specimen can be found in Table 1. The tensile test specimens were discs of 152 mm and 25

mm thickness. Such type of specimens were cast inside the standard cylinders after putting

wooden spacers to cancel a height of about 275 mm and to leave only 25 mm for thickness

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

29

of the specimen. Figure ( 1 ) shows the mould used and the arrangement of Ferro cement wire

mesh at casting period. All specimens were cured in the potable water at about 25

o

C for the

period of 28 days and then left to dry in the laboratory for another 14 days before testing. For

measuring the strain a foil of electrical strain gage was paste to the concrete surface in the

direction of wire meshes but perpendicular to the direction of applied load . Figure 2 shows

the specimen after testing which illustrates the position of strain gage . Disc specimens were

tested in a manner similar to that of Brazilian split cylinder test by applying a load of a rate

equal to 5 kN/min. Using the following relationship given in the textbooks of concrete

technology, the tensile stress can be calculated as follows

LD

P

ftu

t

2

=

In which f

tu

is the splitting tensile stress, P is the failure load, L is the length of specimen, and

D is the diameter of specimen.

Figure ( 1 ) : The mould used for casting disc specimens and wire mesh layer arrangement .

3-Test Results and Regression Analysis

Test results of compressive strength and tensile strength are shown in Table ( 1 ). Tensile

stress strain relationship for the disc specimens are shown in Figures ( 3 ) to ( 13 ). It is

shown that the slope of the curves ( or stiffness ) is high for the initial portion and the slope

is reduced with increasing in stress. The curve in general become horizontal in the later stage

which is considered to be a plastic stage. Three different stages are clearly observed in the

most of the tensile stress strain relationships. Such observation is not new and observed by

others like Shah and Baluguru

[ 8 ]

and Baluguru et al

[ 2 ]

. Figure ( 14 ) shows the variation of

tensile strength with the wire mesh layers, indicating the positive role of reinforcement ratio

on the tensile strength. Figure ( 15 ) illustrates the effect of mortar strength on the tensile

strength. It is clearly shown that both of the reinforcement ratio and matrix strength affect the

tensile strength of Ferro cement. Based on such results the tensile strength of Ferro cement

can be represented by the superposition of the matrix strength and the stress carried by the

wire mesh layers in the following relationship

ts tm tu f f f + = --------------------------------------------------------------------------------------- (1)

Figure ( 1 ) : The mould used for casting

disc specimens and wire mesh layer

arrangement .

Figure ( 2 ) : View of a disc specimen

after testing.

Al-Rafidain Engineering Vol.20 No. 2 March 2012

30

where f

tu

is the tensile strength of Ferro cement, f

tm

is the tensile strength of the matrix, and f

ts

is the tensile stress carried by the wire mesh. The tensile strength of matrix is the cracking

stress and can be calculated from the expression given by Oluokun

[ 6 ]

, as follows:

7 . 0

) ( 2 . 0 c tm f f ' = ------------------------------------------------------------------------------------- (2)

Later the value of f

ts

is calculated from the result of subtracting f

tm

from f

tu

obtained from

test results. In order to obtain the dependent variable ( f

ts

) a regression analysis was carried

out. The independent variable is the reinforcement index ( yR Rf V ). The two variables are

combined in the following linear equation

f

ts

= + ( yR Rf V ) ---------------------------------------------------------------------------- (3)

Statistical regression analysis based on least square method was carried out using the 14 data

points and the values of constants and was found to be 0.56 and 0.72, respectively.

Hence the final form of the tensile strength equation is as follows

56 . 0 72 . 0 ) ( 2 . 0

7 . 0

+ + ' = yR R c tu f V f f -------------------------------------------------------------- (4)

The above equation has a correlation coefficient equal to 0.81, mean value ( test / theoretical

) equal to 0.99 and standard deviation equal to 17%. Figure ( 16 ) shows the relationship

between the calculated and test tensile strength of Ferro cement. It is shown that there is a

fairly good agreement between the two values.

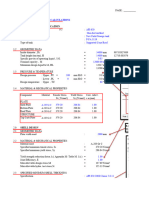

Table ( 1 ) Detail of specimens and test results

Mix

w/c

Ratio

No. of

Layers

Ultimate

Load

( kN)

Tensile

Strength

( MPa)

Maximum

Vertical

Displacement

( mm )

Cube

Compressive

Strength

( N/mm

2

)

Cylinder

Compressive

Strength

(MPa)**

1:3

1:3

0.64

0.64

3

3

21.6

19.2

3.23

2.87

-

1.90

24.86

24.88

19.89

19.90

1:3

1:3

0.64

0.64

6

6

19.84

20.94

2.97

3.13

3.50

1.90

-

-

-

-

1:2.5

1:2.5

0.60

0.60

3

3

22.14

15.47

3.31

2.31

3.25

1.00

22.83

32.25

18.26

25.80

1:2.5 0.60 6 24.02 3.59 3.37 27.54 22.03

1:2

1:2

0.53

0.53

3

3

24.59

16.78

3.68

2.51

3.20

2.60

26.85

30.99

21.48

24.79

1:2

1:2

0.45

0.45

6

6

25.70

32.59

3.84

4.87

2.87

-

34.12

34.63

27.30

27.70

1:1 0.43 3 26.20 3.92 1.84 51.36 41.09

1:1

1:1

0.34*

0.34*

3

6

32.11

36.0

4.80

5.39

1.51

1.72

64.80

58.31

51.84

46.65

* With 0.6% superplastcizer ( Gellunum type )

** Cylinder Compressive Strength = 0.8 x Cube Compressive Strength

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

31

Figure ( 3 ) Tensile Stress - Strain Relationship of Ferrocement ( mix

1:3 , three layers of wire mesh )

0

0.5

1

1.5

2

2.5

3

3.5

0 100 200 300 400 500 600 700 800

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Test

Calculated

Figure ( 4 ) Tensile Stress - Strain Relationship of Ferrocement ( Mix

1:3 , Six Layers of Wire Mesh)

0

0.5

1

1.5

2

2.5

3

3.5

4

0 50 100 150 200 250 300 350

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Test

Calculated

Figure ( 7 ) Tensile Stress - Strain Relationshipof Ferrocement ( Mix

1:2.5,Six Layers of Wire Mesh )

0

0.5

1

1.5

2

2.5

3

3.5

4

0 50 100 150 200 250 300 350 400 450

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Calculated

Figure ( 8 ) Tensile Stress - Strain Relationship of Ferrocement ( Mix

1:2 , Three Layers of Wire Mesh )

0

0.5

1

1.5

2

2.5

3

3.5

4

0 50 100 150 200 250 300 350

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Calculated

Al-Rafidain Engineering Vol.20 No. 2 March 2012

32

4- Tensile Stress Strain Model

The proposed model for the tensile stress strain relationship is based on experimental data

obtained from present test results. The relationship is based on three portions : elastic, elastic-

plastic and plastic portion . Elastic stage terminates at cracking of the matrix and plastic stage

begins at a value of stress equal to ultimate tensile stress and the other stage locates between

Figure ( 9 ) Tensile Stress - Strai Relationship of Ferrocement ( Mix

1:2,Three Layers of Wire Mesh )

0

0.5

1

1.5

2

2.5

3

3.5

0 50 100 150 200 250 300 350

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Calculated

Figure ( 10 ) Tensile Stress - Strain Relationship of Ferrocement ( Mix

1:2 , Six Layers of Wire Mesh)

0

1

2

3

4

5

6

0 50 100 150 200 250 300 350 400

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Test

Calculated

Figure ( 13 ) Tensile Stress - Strai Relationship of Ferrocement ( Mix

1:1H , Six Layers of Wire Mesh )

0

1

2

3

4

5

6

0 50 100 150 200 250

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Calculated

Figure ( 14 ) Relationship Between Tensile Strength of Ferrocement

and Number of Layers of Wire Mesh

0

1

2

3

4

5

6

0 1 2 3 4 5 6 7

Layers of Wire Mesh

T

e

n

s

i

l

e

S

t

r

e

n

g

t

h

(

M

P

a

)

Figure ( 11 ) Tensile Stress - Strain Relationship of Ferrocement ( Mix

1: 1 , Three Layers of Wire Mesh )

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

0 50 100 150 200 250

Tensile Strain ( Microns )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Calculated

Figure ( 12 ) Tensile Stress - Strain Relationship of Ferrocement ( Mix

1:1H , Three Layers of Wire Mesh )

0

1

2

3

4

5

6

0 50 100 150 200 250 300

Tensile Strain ( MIcrons )

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

P

a

)

Test

Calculated

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

33

the mentioned stages. Figure (17) shows the idealized form of the tensile stress strain

relationship.

The cracking strain is calculated for elastic Ferro cement material as follows:

c

tm

tm

E

f

= c ------------------------------------------------------------------------------------------- (5)

where E

c

is the elastic modulus of the composite given by

[ 8 ]

) 1 ( n V E E R m c + = ------------------------------------------------------------------------------------ (6)

E

m

is the elastic modulus of the matrix, can be calculated from the equation given be ACI

Code as follows

4730 = m E

'

fc ------------------------------------------------------------------------------- (7)

and n is the ratio of elastic modulus of reinforcement to that of matrix ( E

R

/E

m

), and V

R

is

the ratio of reinforcement in the section given by

bh

A

V

sf

R = ------------------------------------------------------------------------------------------ (8)

where A

sf

is the area of the reinforcement in the section and bh is the cross sectional area .

The last variable needs to be assessed for constructing the tensile stress strain relationship is

the strain corresponding to the ultimate stress

tu

. For this purpose an approximation is made

utilizing the trend of the cracking zone of the actual tensile stress strain relationship. With

increasing stress the stiffness is reduced due to cracking and here it is assumed that the ratio

of the slope of the curve for the elastic plastic range, , to that of elastic stage, E

c

, [ Figure (

17 ) ] is equal to the ratio of tensile stress of matrix to the ultimate tensile stress, or

tu

tm

f

f

Ec

=

----------------------------------------------------------------------------------------- (9)

From the shape of the portion the value of

is calculated as follows:

tm tu

tm tu f f

c c

= ------------------------------------------------------------------------------------- (10)

Combining equations ( 9 ) and ( 10 ) leads to the following equation for calculating

tu

2

) ( ) ( 1 [

tm

tu

tm

tu

tm tu

f

f

f

f

+ = c c ] ------------------------------------------------------------------- (11)

Calculated stress- strain versus test tensile stress-strain relationships are shown in Figure ( 3 )

to ( 13) for all specimens.

Al-Rafidain Engineering Vol.20 No. 2 March 2012

34

5- Flexural Analysis of Ferro cement

Having the Proposed idealized tensile model and an idealized compressive stress strain

given by Walraven and Spierenburg

[ 10 ]

shown in Figure ( 18 ), Ferro cement structural

member can be analyzed for moment curvature and load deflection relationships.

Calculation of moment curvature relationship is based on the equilibrium of forces and

compatibility of strains. According to the compressive stress- strain and tensile stress- strain

relationships different cracking stages exist and as a result nonlinear response is obtained.

Hence, the material nonlinearity is included in the present analysis.

5-1 Moment-Curvature Relationship

5-1-1 Elastic Stage

Stress and strain distributions for this stage are shown in Figure ( 19-a ). Depth of the

compression zone c is calculated from equilibrium of compressive and tensile forces acting

on the section, or

C-T = 0 --------------------------------------------------------------------------------------- (12)

It is assumed that the elastic modulus calculated from Eq. ( 6 ) is valid for compression and

tension zone of the section and as a result the depth of compression zone for the elastic stage

is equal to that in tension zone and equal to h/2. For this stage the moment curvature

relationship is given by

)

2

3

2

3

3

(

3

c

h c

h h

bEc

Me + =

|

-------------------------------------------------------------- (13a)

Where b is the width of the section, | is the curvature, h is the depth of the section and c is

the depth of compression zone. Substituting c= h/2 the moment- curvature relationship

becomes

12

3

| bEch

Me = --------------------------------------------------------------------------------- (13b)

This stage is valid until the matrix cracks in which the corresponding curvature becomes

) ( c h

tm

e

=

c

| ------------------------------------------------------------------------------------ (14a)

Substituting c=h/2, the above curvature limit becomes

h

tm

e

c

|

2

= -------------------------------------------------------------------------------------- (14b)

5-1-2 Elastic-Plastic Stage (1)

Stress and strain distributions for this stage are shown in Figure ( 19-b ). For this stage the

depth of compression zone is given by

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

35

) (

]

2

2

) ( )[ ( (

2

2

)

|

| | |

c

+ +

=

Ec

h

h

Ec

tm

Ec h

c --------------------------------- (15)

is the slope of elastic plastic portion of the tensile stress strain relationship given by

Eq.( 10 ) . Moment-curvature relationship for this stage is as follows

] [

3

2

3

] [

3

3

3

3

3

2 2 3

1

|

|

|

c

| |

|

ctm tm

ep

h

Ec

c

h c

h

c

E M c + + + = --------------------------- (16)

This stage is valid until the curvature becomes

) (

1

c h

tu

ep

=

c

| -------------------------------------------------------------------------------------- (17)

5-1-3 Elastic-Plastic Stage ( 2 ):

Stress and strain distributions for this stage are shown in Figure ( 19-c ). Equilibrium of

forces lead to the following value of c for this stage is given by

) (

) ( 2 ) (

2 2 2 2

2

|

c |

c c

+ + + +

=

Ec

h E f Ec

E

f f

c

tu c tu

tm tu tm c

tu tu

------------------------------ (18)

Moment curvature for this stage is given by

) (

2

] [

3

2

3

2 3

2

2

2 3 3

2

3

2 3

2

|

c

c c

|

|

c

|

tu

tm tu

tm

tu

tu c

ep

h

ftu Ec

hc f

c

f

c

E

M + + + + = ------------------- (19)

The terminating point of curvature for this stage is given by

c E

f

c

cu

ep = 2 | --------------------------------------------------------------------------------------- (20)

Figure ( 15 ) Relationship Between Tensile Strength of Ferrocement

and Compressive Strength of Concrete

0

1

2

3

4

5

6

0 10 20 30 40 50 60

Compressive Strength ( MPa )

T

e

n

s

i

l

e

S

t

r

e

n

g

t

h

(

M

P

a

)

Three Layers

Six Layers

Figure( 16 ) Calculated Versus Test Tensile Strength of Ferrocement

0

1

2

3

4

5

6

7

0 1 2 3 4 5 6 7

Test

C

a

l

c

u

l

a

t

e

d

Al-Rafidain Engineering Vol.20 No. 2 March 2012

36

5-1-4 Elastic-Plastic Stage (3):

Stress and strain distributions for this stage are shown in Figure ( 19-d ). For this stage the

value of depth of compression zone c is calculated as follows

tu cu

cu

tm

tm tu

tu

tu

f f

Ec

f Ec

h f

c

+

+ + +

=

| |

c

c c

|

|

c

2 2

] [

2

] [

2

2

2 2

----------------------------------------- (21)

The relationship between moment and curvature is given by

) 22 ( ]

2

2

[

2

] [

3 2

] [

3

] [

2

2

3 3

2 2

3

2

2

2

3

2

3 + + + + + =

|

c

c c

|

| |

c tu

tu

tm tu

c

cu

c

cu

c

tm

tu tu cu ep

h

bf b

E

f b

E

f

E

b

hc bf

c

f f

b

M

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

37

The terminating point for this stage or the collapse occurs when the compressive strain in

concrete reaches 0.0038. The corresponding curvature becomes

c

ep

0038 . 0

3 = | ------------------------------------------------------------------------------------ (23)

5-2 Load-Deflection Relationship

Having the calculated moment-curvature relationship given in the previous section, load-

deflection relationship can be calculated for any type of beams loaded by various type of

loads. For example, for a simply supported beam loaded by two central point load each P/2,

the value of central deflection is given by

) 3 4 (

48

2 2

l a

EI

Pa

= e --------------------------------------------------------------------------- (24)

The load - curvature relationship is given by :

a

EI

P

| 2

= --------------------------------------------------------------------------------------- (25)

Where EI is the value of flexural rigidity which varies with the cracking stages.

5-3 Procedure for Analysis

1- Specify an initial value of curvature.

2- Calculate the depth of compression zone.

3- Check the cracking limit.

4- Calculate the moment.

5- Calculate EI from the moment divided by curvature.

6- Calculate value of the load from Eq.( 25 )

7- Calculate the deflection from Eq. ( 24 ).

8- Repeat the steps 2 to 7 for another curvature increment and other cracking stages until

the complete load- deflection response is obtained .

5-4 Results of Analysis and Role of Span / Depth Ratio

Test results from researches carried out on Ferro cement beams and slab strips [ 4,9,10 ] are

used here to assess the accuracy of the proposed analytical procedure. From the comparison

between test and predicted ultimate load, it is found that the analytical method is accurate for

Ferro cement having wide ranges of compressive strength of mortar and wire mesh ratios but

significantly sensitive to the span / depth ratio of the beam or slab strip. Figure (20) shows the

test and calculated moment curvature relationship for Ferro cement specimens of different

span / depth ratios tested by Mansur

[ 4 ]

. From a comparison between test and calculated

moment curvature relationship it is observed that there is a good agreement between the

two responses. Figure( 21 ) shows the load deflection relationship calculated from the

analytical procedure presented in this study and test results obtained by Walraven and

Spierenburg

[ 10 ]

. It is observed from the figure that the analysis overestimates the load for all

values of deflection. This occurs because the tested specimen has a span / depth ( L/h ) ratio

Al-Rafidain Engineering Vol.20 No. 2 March 2012

38

equal to 35.7 and considered to be thin section. It is suggested

[ 11 ]

that any slab strips having

span / depth ratio larger than 22 considered to be very thin slabs and between 18 and 22

defined as thin slabs. In fact the analysis presented in this paper is not applied to very thin

slabs and its predictions are accurate ( as shown from the comparison with test results ) only

for the case of thick Ferro cement section ( L/h < 18 ) and thin Ferro cement sections ( 18<

L/h < 22 ) because very thin slabs suffer from large deflections and such effect should be

incorporated in the analysis. Figure ( 22 ) shows the variation of the ratio of test to calculated

ultimate load with the span / depth ratio. It is clearly shown that for Ferro cement specimens

having L/h ratio smaller than 22 the prediction is safe and accurate, regardless the wire mesh

ratio and mortar strength. Walraven and Spierenburg

[ 10 ]

in their analytical model on Ferro

cement section assumed a constant value of the strain at which plastic stage commences,

ut

,

equal to 1.2x10

-3

. The authors believe that the value of

ut

given in the present study using

Eq.( 11 ) is better and accurate for use in flexural analysis . Because the proposed value of

ut

depends on the vital parameters of Ferro cement, namely tensile strain of matrix, tensile

strength of matrix and ultimate tensile stress of Ferro cement which found to depend on both

the matrix strength and reinforcement index ( V

R

f

yR

).

6-CONCLUSI ONS

From the present study which contains test data and analytical procedures, the following

conclusions can be drawn

1- Test results on Ferro cement disc specimens indicate that the tensile strength

depends on both matrix strength and wire mesh ratio. An equation was proposed to

calculate the tensile strength of Ferro cement depending on the matrix strength and

reinforcement index ( V

R

f

yR

) [ Eq. ( 4 ) ].

2- Tensile strain at which plastic stage of stress-strain response commences was found

to depend on tensile strain of matrix, tensile strength of matrix and ultimate tensile

stress of Ferro cement [ Eq.( 11 ) ].

3- Flexural analysis was carried out to calculate the load deflection relationship of

Ferro cement beams and slab strips. The predictions of the analysis were compared

with the test data from literature, and was found that the analysis is accurate and

safe for calculating the load-deflection relationship, provided that the span/depth

ratio not more than 22.

Mohammed: Tensile Stress-Strain Relationship For Ferrocement Structures

39

Reference

1- ACI Committee 549 ,( 2001 ) State -of the-Art Report on Ferro cement , in Manual of

Concrete Practice , Part ( 5 ) , Detroit , Michigan

2- Baluguru , Perumalsamy N. , Naaman , Antoine E. , and Shah , S.P. ,( 1977 ) , Analysis

and Behavior of Ferro cement in Flexure , Proceeding , ASCE , V. 103 , No. ST10 ,

pp.1937-1951

3- Johnston , Colin D. , and Mattar , Samir G. , ( 1976 ) , Ferro cement in Tension and

Compression , Proceedings , ASCE , V.102 , ST5 , pp.857-899

4- Mansur , M.A. , ( 1988 ) , Ultimate Strength Design of Ferro cement in Flexure , Journal

of Ferro cement , Vol.18 , No. 4 , pp. 385-395

5- Naaman , Antoine E. , and Shah , Surendra P. ,( 1971 ) , Tensile Tests on Ferro cement

,ACI Journal , Proceedings , V.68 , No.5 , pp. 693-698

6- Oluokun , F.A.( 1991 ) , Prediction of Concrete Tensile Strength from Compressive

Strength : Evaluation of Existing Relations for normal weight concrete ACI Materials

Journal , Vol. 88 , No. 3 , pp. 302-309

Figure ( 21 ) Test and Calculated Load - Deflection Relationship of Ferrocement

[ Test results from Ref.( 10 ) ]

0

0.5

1

1.5

2

2.5

0 10 20 30 40 50 60

Deflection ( mm )

L

o

a

d

(

k

N

)

Test

Calculated

Figure ( 22 ) Vatiation of the Ratio of Test / Calculated Ultimate Load with

Span / Depth Ratio

0

20

40

60

80

100

120

140

160

0 10 20 30 40 50 60 70

Span / Depth Ratio ( L/h )

P

e

r

c

e

n

t

a

g

e

o

f

T

e

s

t

/

C

a

l

c

u

l

a

t

e

d

U

l

t

i

m

a

t

e

L

o

a

d

1

1

1

1

1

3

1 Data from Ref. 4

2 Data friom Ref. 10

3 Data from Ref. 9

2 3

Al-Rafidain Engineering Vol.20 No. 2 March 2012

40

7- Pama , R.P. , Sutharatnachaiyarom , C. and Lee , S. L. ,( 1974 ) , Rigidities and

Strength of Ferro cement , Proceedings , First Australian Conf. on Engineering Materials

, Univ. of New South Wales , Sydney , pp. 287-308

8- Shah , Surendra P. , and Baluguru , P.N. , ( 1984 ) , Ferro cement , New Reinforced

Concrete , R. N. Swamy , Ed. , Surrey Univ. Press , UK , pp. 1-51

9- Shareef , Yaman Sami , ( 2008 ) , Flexural Behavior of Axially Restrained Ferrocement

One-Way Slabs , MSc Thesis , University of Duhok , 110 pp.

10- Walraven , J.C. and Spierenburg , S.E. J. ,( 1985 ) , Behavior of Ferrocement with

Chicken Wire Mesh Reinforcement ,Journal of Ferro cement , Vol. 15 , No. 1 , pp.3-13

11- Welch , Ronald Wayne, ( 1999 ) , Compressive Membrane and Capacity Estimates in

Laterally Edge Restrained Concrete One-Way Slabs , PhD. Thesis , University of Illinois

at Urbana Champaign .

Notation

a shear span

A

sf

area of wire mesh reinforcement

, constants

b width of Ferro cement section

c depth of compression zone

n modular ratio ( E

R

/E

c

)

E

R

elastic modulus of reinforcement

E

c

elastic modulus of Ferro cement material

E

m

elastic modulus of plain matrix

c

compressive strain

t

tensile strain

tm

cracking strain of matrix

tu

tensile strain corresponding to ultimate tensile stress

f

c

compressive stress

f

t

tensile stress

f

tu

tensile strength of Ferro cement

f

tm

tensile strength of the matrix

f

ts

tensile stress carried by wire meshes

f

c

cylinder compressive strength of concrete

f

yR

yield stress of wire reinforcement

h depth of the Ferro cement section

slope of the elastic-plastic portion of the tensile stress-strain relationship

V

R

ratio of the wire mesh reinforcement in the section

M moment in general

curvature in general

The work was carried out at the college of Engineering. University of Sulaimani

You might also like

- Calculus For BeginnersDocument21 pagesCalculus For BeginnersJay LawsonNo ratings yet

- Radiation Scattering in The High Intensity Regime: Madalina Boca Victor Dinu Viorica FlorescuDocument20 pagesRadiation Scattering in The High Intensity Regime: Madalina Boca Victor Dinu Viorica FlorescuDaniel Bogdan Dinca100% (1)

- Determination of Rectangular Stress BlocDocument6 pagesDetermination of Rectangular Stress BlocKorrapati Pratyusha 19PHD0497No ratings yet

- The Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsDocument6 pagesThe Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- OgBayrak - Response Prediction by Plastic Hinge AnalysisDocument6 pagesOgBayrak - Response Prediction by Plastic Hinge AnalysisRui CbNo ratings yet

- Steel Concrete Bonding Connection An Exp PDFDocument12 pagesSteel Concrete Bonding Connection An Exp PDFMuntean FabianNo ratings yet

- Evaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsDocument9 pagesEvaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsJakob FiskerNo ratings yet

- Material Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler SandDocument24 pagesMaterial Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler Sanddisha847No ratings yet

- Strain Compatibility Between HPFRCC and Steel ReinforcementDocument2 pagesStrain Compatibility Between HPFRCC and Steel ReinforcementRachida KrachaiNo ratings yet

- Fatigue Life Assessment of Orthotropic Steel Deck With UHPC PavementDocument7 pagesFatigue Life Assessment of Orthotropic Steel Deck With UHPC PavementGuilherme AlencarNo ratings yet

- Local Bond Stress-Slip Models For Reinforcing Bars and Prestressing Strands in High-Peformance Fiber-Reinforced Cement CompositesDocument23 pagesLocal Bond Stress-Slip Models For Reinforcing Bars and Prestressing Strands in High-Peformance Fiber-Reinforced Cement CompositesSameerNo ratings yet

- Testing and Design of Gravity-Loaded Steel Purlins Restrained by SheetingDocument10 pagesTesting and Design of Gravity-Loaded Steel Purlins Restrained by SheetingamokeNo ratings yet

- Shear Strength of Steel Fiber-Reinforced Lightweight Concrete BeamsDocument7 pagesShear Strength of Steel Fiber-Reinforced Lightweight Concrete Beamsmoraru_gabriel_2No ratings yet

- Bond Between Normal Strength and High-Strength Concrete (HSC) and Reinforcing Bars in Splices in BeamsDocument8 pagesBond Between Normal Strength and High-Strength Concrete (HSC) and Reinforcing Bars in Splices in BeamsAhmad YaniNo ratings yet

- Compressive Stress Strain Relationship of Steel Fibre-Reinforced Concrete at Early AgeDocument14 pagesCompressive Stress Strain Relationship of Steel Fibre-Reinforced Concrete at Early AgesonugaurNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- Steel Fibre Reinforced Concrete (SFRC) For Tunnel Linings - A Technical ApproachDocument7 pagesSteel Fibre Reinforced Concrete (SFRC) For Tunnel Linings - A Technical ApproachMehdi BakhshiNo ratings yet

- Shear Capacity of Reinforced Concrete Columns Strengthened With CFRP SheetDocument6 pagesShear Capacity of Reinforced Concrete Columns Strengthened With CFRP SheetAzhar PLNo ratings yet

- Thesis On Steel Fibre Reinforced ConcreteDocument8 pagesThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- Behaviour and Strength of High Strength Concrete L-Beams Under Combined Shear, Bending and Torsional LoadingDocument17 pagesBehaviour and Strength of High Strength Concrete L-Beams Under Combined Shear, Bending and Torsional LoadingThulasi Raman KowsiganNo ratings yet

- Shear Behavior of MasonryDocument11 pagesShear Behavior of MasonryRazvan IonNo ratings yet

- Appendix E Tensile Strength of Roller Compacted Concrete: EP 1110-2-12 30 Sep 95Document15 pagesAppendix E Tensile Strength of Roller Compacted Concrete: EP 1110-2-12 30 Sep 95nywd806033No ratings yet

- ST060 Anas PaultreDocument10 pagesST060 Anas PaultreRizki Nuursirullah MahibNo ratings yet

- Punching Shear Resistance of SlabDocument8 pagesPunching Shear Resistance of SlablinkgreencoldNo ratings yet

- Prestressed Concrete: A Review: Kaushal ChopraDocument7 pagesPrestressed Concrete: A Review: Kaushal ChopraKaushal ChopraNo ratings yet

- 2017-APFIS Conference - Strengthening Concrete Columns Using NSM CFRP LaminatesDocument4 pages2017-APFIS Conference - Strengthening Concrete Columns Using NSM CFRP LaminatesThanoon AlmarwasyNo ratings yet

- Bae 2016Document12 pagesBae 2016IngénieurCivilNo ratings yet

- Study On The Lap-Splice Behavior of Post-Yield Deformed Steel Bars inDocument9 pagesStudy On The Lap-Splice Behavior of Post-Yield Deformed Steel Bars insmh.pelfberryNo ratings yet

- 2003lam and Teng - Design-Oriented Stress-Strain Model For FRP-confined ConcreteDocument19 pages2003lam and Teng - Design-Oriented Stress-Strain Model For FRP-confined ConcreteFilipe RibeiroNo ratings yet

- Average Stress Strain Relations For ConcDocument10 pagesAverage Stress Strain Relations For ConcKorrapati Pratyusha 19PHD0497No ratings yet

- Design ofDocument12 pagesDesign ofAli AlomyNo ratings yet

- Jurnal 6Document16 pagesJurnal 6Iqra GantengNo ratings yet

- Strain Concentrations in Pipelines With Concrete CoatingDocument7 pagesStrain Concentrations in Pipelines With Concrete CoatingAslan AlpNo ratings yet

- Published 10.1201 - 9780429426506-204 PDFDocument5 pagesPublished 10.1201 - 9780429426506-204 PDFMohammad Ali MahdavipourNo ratings yet

- Bond Behaviour of Structural Lightweight Concrete: January 2018Document10 pagesBond Behaviour of Structural Lightweight Concrete: January 2018SameerKareeeemNo ratings yet

- Design Equation For Punching Shear Capacity of SFRC SlabsDocument8 pagesDesign Equation For Punching Shear Capacity of SFRC SlabsAref AbadelNo ratings yet

- amr.163 167.1251Document7 pagesamr.163 167.1251zana connorNo ratings yet

- Finite Element Study of Concrete-Filled Steel Tubes Using A New Confinement-Sensitive Concrete Compression ModelDocument20 pagesFinite Element Study of Concrete-Filled Steel Tubes Using A New Confinement-Sensitive Concrete Compression ModelSaliNo ratings yet

- A Nonlinear FE Method For The Prediction of Slabs On Grade BehaviourDocument7 pagesA Nonlinear FE Method For The Prediction of Slabs On Grade BehaviourJuan BravoNo ratings yet

- Numero 29 Art 36Document9 pagesNumero 29 Art 36OscarCastilloNavaNo ratings yet

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteDocument8 pagesShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abNo ratings yet

- 2 Paper 1734Document12 pages2 Paper 1734innovativeequationsNo ratings yet

- Lab 4 Manual - Concrete Testing - F15Document18 pagesLab 4 Manual - Concrete Testing - F15kaligleean100% (1)

- Prediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie ModelsDocument4 pagesPrediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie Modelschetan2042No ratings yet

- 1-s2.0-S0958946506002162 - CHOI ET ALDocument12 pages1-s2.0-S0958946506002162 - CHOI ET ALThiagoNo ratings yet

- 1.1. Factors That Influence The BondDocument10 pages1.1. Factors That Influence The BondalfredoNo ratings yet

- Behavior of Bonded and Unbonded Prestressed Normal and High Strength Concrete BeamsDocument13 pagesBehavior of Bonded and Unbonded Prestressed Normal and High Strength Concrete BeamsjasamnajNo ratings yet

- Experimental Study of Steel Fiber Prestressed Concrete Beam For Shear, Bending and TorsionDocument16 pagesExperimental Study of Steel Fiber Prestressed Concrete Beam For Shear, Bending and TorsionChaitali patilNo ratings yet

- Confinement Effects On The Steel-Concrete Bond Strength 2012Document13 pagesConfinement Effects On The Steel-Concrete Bond Strength 2012Saurabh PednekarNo ratings yet

- RC Two-Way Slabs Strengthened With CFRP StripsDocument6 pagesRC Two-Way Slabs Strengthened With CFRP Stripsvishwanath malalanayakeNo ratings yet

- Response of Small Scale Ultra High Performance Fibre Reinforced Concrete Slabs To Blast LoadingDocument9 pagesResponse of Small Scale Ultra High Performance Fibre Reinforced Concrete Slabs To Blast LoadingAdityaNo ratings yet

- Materials: Shear Behavior Models of Steel Fiber Reinforced Concrete Beams Modifying Softened Truss Model ApproachesDocument21 pagesMaterials: Shear Behavior Models of Steel Fiber Reinforced Concrete Beams Modifying Softened Truss Model Approachesmoraru_gabriel_2No ratings yet

- Experimental Study of Bond-Slip Performance of Corroded Reinforced Concrete Under Cyclic LoadingDocument10 pagesExperimental Study of Bond-Slip Performance of Corroded Reinforced Concrete Under Cyclic Loadingofreneo_joshua4437No ratings yet

- Nonlinear Analysis of Concrete Beams Strengthened With FRP PlateDocument5 pagesNonlinear Analysis of Concrete Beams Strengthened With FRP PlateKorrapati Pratyusha 19PHD0497No ratings yet

- 4 Lam2003Document38 pages4 Lam2003Tú LêNo ratings yet

- Fatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressDocument17 pagesFatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressVicente Bergamini PugliaNo ratings yet

- Aci - 108-M04Document9 pagesAci - 108-M04Denglei TangNo ratings yet

- Thrust Ring - PaperDocument10 pagesThrust Ring - Paperbhathiya01No ratings yet

- Chapter One: 1.1 GeneralDocument1 pageChapter One: 1.1 GeneralSulaiman Mohsin AbdulAzizNo ratings yet

- Structuro W437-Formerly RXDocument2 pagesStructuro W437-Formerly RXSulaiman Mohsin AbdulAziz0% (1)

- Design For Torsion and Shear According To ACI-318-99Document1 pageDesign For Torsion and Shear According To ACI-318-99Sulaiman Mohsin AbdulAzizNo ratings yet

- Curing ConcreteDocument10 pagesCuring ConcreteShariq KhanNo ratings yet

- Calculation of Stresses in Footings Subjected To Uniaxial or Biaxial MomentsDocument6 pagesCalculation of Stresses in Footings Subjected To Uniaxial or Biaxial MomentsSulaiman Mohsin AbdulAziz100% (1)

- About A-PDF WatermarkDocument1 pageAbout A-PDF WatermarkSulaiman Mohsin AbdulAzizNo ratings yet

- Shear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsDocument2 pagesShear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsSulaiman Mohsin AbdulAziz100% (1)

- مسائل في المساحة المستويةDocument39 pagesمسائل في المساحة المستويةabsbond100% (1)

- ETABSDocument5 pagesETABSSulaiman Mohsin AbdulAzizNo ratings yet

- Reinforcement Steel SpecificationsDocument1 pageReinforcement Steel SpecificationsSulaiman Mohsin AbdulAzizNo ratings yet

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Document1 pageDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNo ratings yet

- Decentralized Wastewater Treatment Highlights BrochureDocument20 pagesDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizNo ratings yet

- 129-044 - Boring Big HolesDocument4 pages129-044 - Boring Big HolesSulaiman Mohsin AbdulAzizNo ratings yet

- Influence LinesDocument6 pagesInfluence LinesClorinda Astete ChuquichaicoNo ratings yet

- 39 TransportationDocument7 pages39 Transportationmpe1No ratings yet

- All Sheets ConcreteDocument72 pagesAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- CM A Hollow Core SlabsDocument36 pagesCM A Hollow Core SlabsSulaiman Mohsin AbdulAziz100% (1)

- Hollow Core Sales PresentationDocument29 pagesHollow Core Sales PresentationSulaiman Mohsin AbdulAzizNo ratings yet

- Different CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Document11 pagesDifferent CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Sulaiman Mohsin AbdulAzizNo ratings yet

- RC Hollow Members Confined With FRP Experimental Behavior and Numerical ModelingDocument339 pagesRC Hollow Members Confined With FRP Experimental Behavior and Numerical ModelingSulaiman Mohsin AbdulAziz100% (1)

- HP Series Medium Speed Bowl MillDocument19 pagesHP Series Medium Speed Bowl MillKhaled Chisty50% (2)

- Microelectronic Circuit Design 4th Edition Jaeger Solutions ManualDocument17 pagesMicroelectronic Circuit Design 4th Edition Jaeger Solutions Manualjulieshawwzgcieqfxa100% (11)

- P-V-T Behaviour - 05 - 07 - 2022Document16 pagesP-V-T Behaviour - 05 - 07 - 2022Prince EtornamNo ratings yet

- Comparative Study of Dye Removal by Adsorption Method and Nanocrystalline Tio Thin FilmsDocument11 pagesComparative Study of Dye Removal by Adsorption Method and Nanocrystalline Tio Thin FilmssumitNo ratings yet

- LAS Gen - Chem2 - MELC - 2 3 - Q4 Week 1Document10 pagesLAS Gen - Chem2 - MELC - 2 3 - Q4 Week 1Bjai MedallaNo ratings yet

- Classification of PolymersDocument11 pagesClassification of Polymerssayon.ghosh1001No ratings yet

- Gas Law - DLP 10Document7 pagesGas Law - DLP 10cherrymaeregalario2001No ratings yet

- Conduction of Heat in Solids: 9.1 The Energy Equation For ConductionDocument47 pagesConduction of Heat in Solids: 9.1 The Energy Equation For ConductionSamuel Ayoola AyoolaNo ratings yet

- Structure WATER TANK 6Document30 pagesStructure WATER TANK 6mayur_lanjewarNo ratings yet

- CIV 2109 - Lecture 1 - IntroductionDocument54 pagesCIV 2109 - Lecture 1 - IntroductionAMESHANo ratings yet

- Fixed Bed Adsorption of CO H Mixtures On Activated Carbon: Experiments and ModelingDocument19 pagesFixed Bed Adsorption of CO H Mixtures On Activated Carbon: Experiments and ModelingSaba GheniNo ratings yet

- RCC 2 MarksDocument27 pagesRCC 2 MarksWilliam WhaiteNo ratings yet

- Le Chatelier's Principle (Lecture) - 0Document18 pagesLe Chatelier's Principle (Lecture) - 0salehaupmNo ratings yet

- Photochemistry of Polymers: 5.1 Photopolymerization and Cross-LinkingDocument6 pagesPhotochemistry of Polymers: 5.1 Photopolymerization and Cross-LinkingDanish JamalNo ratings yet

- 04 - Sanjana B - Sem 5 - Elective - Interpretation - Assignment 4Document21 pages04 - Sanjana B - Sem 5 - Elective - Interpretation - Assignment 4Sanjana BhandiwadNo ratings yet

- Common Tablet DefectsDocument2 pagesCommon Tablet DefectsMaiah Dinglasan50% (2)

- 04-Type 4-Con99-Sambungan Rafter Ke Rafter (Posisi Mid)Document80 pages04-Type 4-Con99-Sambungan Rafter Ke Rafter (Posisi Mid)Guntur SuwantoroNo ratings yet

- DLS - Analysis of Cellulose NanocrystalDocument7 pagesDLS - Analysis of Cellulose NanocrystalCassiano PiresNo ratings yet

- Physics ExamDocument323 pagesPhysics ExamEslam Ashraf100% (1)

- What Is A UV-Vis SpectrophotometerDocument5 pagesWhat Is A UV-Vis SpectrophotometerBilal JuttNo ratings yet

- Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument5 pagesAssembly Analysis of Piston, Connecting Rod & Crankshaftbis-2009100% (1)

- Api - 650 2008Document27 pagesApi - 650 2008WinsonLimHuiWahNo ratings yet

- Student - Electron ConfigurationDocument8 pagesStudent - Electron ConfigurationChimamanda NWERRIHNo ratings yet

- Astm A53Document22 pagesAstm A53Cristina ZamoraNo ratings yet

- 9701 w15 Ms 22 PDFDocument7 pages9701 w15 Ms 22 PDFAl BeruniNo ratings yet

- Machine Element II Worksheet 3Document2 pagesMachine Element II Worksheet 3Hanan ShayiboNo ratings yet

- AP Physics B Formula Study SheetDocument5 pagesAP Physics B Formula Study Sheetnanio_7No ratings yet

- Improved Etching Technique For The Determination of Percent MarDocument6 pagesImproved Etching Technique For The Determination of Percent Marpinheiro_pinheiro6780No ratings yet

- RCPT Test ProcedureDocument5 pagesRCPT Test Procedurevempadareddy75% (4)