Form 7-2 Operational Checklist: Aerobic Treatment Unit (ATU)

Form 7-2 Operational Checklist: Aerobic Treatment Unit (ATU)

Uploaded by

Saravanan RasayaCopyright:

Available Formats

Form 7-2 Operational Checklist: Aerobic Treatment Unit (ATU)

Form 7-2 Operational Checklist: Aerobic Treatment Unit (ATU)

Uploaded by

Saravanan RasayaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Form 7-2 Operational Checklist: Aerobic Treatment Unit (ATU)

Form 7-2 Operational Checklist: Aerobic Treatment Unit (ATU)

Uploaded by

Saravanan RasayaCopyright:

Available Formats

Form 7-2 Operational Checklist: Aerobic treatment unit (ATU)

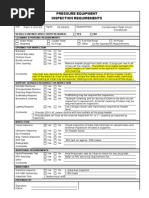

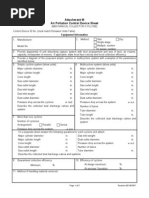

Service provided on: Date: Service provided by: Company: Date of last service: Date of last inspection: !" Time: Reference #: Employee: By: You Other: NOTES

+"

0"

6"

<"

@"

A"

Type of #T$: Suspended%&ro'th #ttached%&ro'th Se(uencin& batch reactor Combination attached)suspended%&ro'th Rotatin& biolo&ical contactor Other: a" *anufacturer: *odel #: Conditions at the #T$ a" Evaluate presence of odor 'ithin !, ft of perimeter of system: -one *ild Stron& Chemical Sour b" Source of odor. if present: c" /as foam)residue observed outside the unit" Yes -o #T$ access a" 1ocated at &rade" Yes -o b" 2f 3-o4. ho' deep is tan5 buried" c" Risers on tan5" Yes -o d" Evidence of infiltration in the risers" Yes -o e" 1ids securely fastened" Yes -o f" 1ids in operable condition" Yes -o 7entin&)#ir supply a" #ir supply method: #spirator #erator Compressor Blo'er 8ree air 9&o to 6"&: b" Operation: Continuous Timed 9On: min. Off: min: c" #ir supply unit operatin& properly" Yes -o d" ;ressure at air supply unit: psi e" #ir flo' at air supply unit: cfm f" #ir filter)screen: Cleaned Replaced &" 7entin& appears operable" Yes -o #eration chamber a" *i=in& in aeration chamber" Yes -o b" DO in aeration chamber: m&)1 c" p> in aeration chamber: d" Temperature in aeration chamber: e" Settlability test: Settled ?. 8loatin& ? in min f" Biomass color in the aeration chamber: Bro'n Blac5 &" Slud&e pumpin& recommended" Yes -o #dditional tas5s for attached%&ro'th: media evaluation a" ;lu&&in&" Yes -o b" 8loatin&" Yes -o c" *edia 'ashed" Yes -o 2f 'ashed. indicate method used: #ir /ater d" *edia replaced" Yes -o Clarification chamber a" Scum layer" Yes -o 2f yes. thic5ness: in b" Clear Bone depth belo' outlet: in c" Effluent screen)tertiary filter cleaned" -"#" Yes -o

+"

#cceptable $nacceptable

0"

#cceptable $nacceptable

6"

#cceptable $nacceptable

<"

#cceptable $nacceptable

@"

#cceptable $nacceptable

A"

#cceptable $nacceptable

Reference #: DO in clarifier: m&)1 p> in clarifier: Temperature in clarifier: Effluent odor after passin& throu&h unit: -one *ild Stron& h" Effluent color after passin& throu&h unit: Clear Bro'n Blac5 i" Effluent turbidity: -T$ C" Slud&e return operatin&: ;assive #ctive a" 2f active. pump 'as chec5ed manually" -"#" Yes -o b" 2f active. pump operatin& properly" -"#" Yes -o D" Control ;anel: -"#" a" Controls operatin& properly" Yes -o b" 2s enclosure 'aterti&ht" Yes -o c" #larm test s'itch operatin& properly" Yes -o d" #t time of inspection. control s'itch 'as set to: -"#" E>and)*anualF E#utoF e" 2f auto. settin&: Time On: 9min: Time Off: 9min: !," #larm9s:: -"#" a" Types: #ir pressure >i&h 'ater Remote b" #larms operatin&" Yes -o c" #larm readin&s: Readin& Readin& Difference -"#" 9present: 9last: i" ET* hours ii" #larm Counter Events 9-C: Elapsed time in alarm status: 9;TR: % 91TR: G Time 9hours: -umber of alarm events: 9;#CR: % 91#CR: G Events 9number: d" Battery bac5up char&ed" -"#" Yes -o e" Telemetry operable" -"#" Yes -o !!" *anufacturer4s re(uired maintenance performed" Yes -o (If Yes, attach Manufacturers Inspection form to this report, if supplied) !+" 1ab samples collected for monitorin&" Yes -o Types of analysis: d" e" f" &"

C"

#cceptable $nacceptable #cceptable $nacceptable

D"

!,"

#cceptable $nacceptable

ET*: elapsed time meter 1#CR: last alarm counter readin& 1TR: last time readin& -C: number of cycles ;#CR: present alarm counter readin& ;TR: present time readin&

You might also like

- Goods Received Note - FormDocument1 pageGoods Received Note - FormSaravanan Rasaya70% (10)

- Audit Checklist - Blasting Painting1Document6 pagesAudit Checklist - Blasting Painting1Angel Angeleye100% (4)

- API 570 Exam 574 QuizDocument3 pagesAPI 570 Exam 574 Quizessnelson100% (2)

- Audit Check List - Investment Casting FoundryDocument15 pagesAudit Check List - Investment Casting FoundryManivannanMudhaliarNo ratings yet

- Checklist For Renewal of Registration As Safety and Health Officer (Sho)Document3 pagesChecklist For Renewal of Registration As Safety and Health Officer (Sho)Saravanan Rasaya100% (1)

- Lecture Notes Green TechnologyDocument34 pagesLecture Notes Green Technologytoyyiying88% (8)

- Form 5-1 Operational Checklist: Holding Tank (HT) : NotesDocument1 pageForm 5-1 Operational Checklist: Holding Tank (HT) : NotesSaravanan RasayaNo ratings yet

- Form 7-1 Operational Checklist: Media Filter (MF) : NotesDocument2 pagesForm 7-1 Operational Checklist: Media Filter (MF) : NotesSaravanan RasayaNo ratings yet

- Form 5-2 Operational Checklist: Septic, Trash and Processing Tanks (STPT)Document2 pagesForm 5-2 Operational Checklist: Septic, Trash and Processing Tanks (STPT)Saravanan RasayaNo ratings yet

- Form 6-2 Operational Checklist: Pump: Demand-Dosed System (PDD) (Including Siphons)Document2 pagesForm 6-2 Operational Checklist: Pump: Demand-Dosed System (PDD) (Including Siphons)Saravanan RasayaNo ratings yet

- Bechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery ProjectDocument22 pagesBechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery Projectravi00098No ratings yet

- Blast Furnace: Standard Operating Procedures For Top FiringDocument7 pagesBlast Furnace: Standard Operating Procedures For Top FiringNishant BandaruNo ratings yet

- Standard ChecklistscorrectedDocument51 pagesStandard Checklistscorrectedmohan_krishna372No ratings yet

- BFP Oil FlushingDocument19 pagesBFP Oil FlushingParthiban KarunaNo ratings yet

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetDocument4 pagesKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsNo ratings yet

- Pid Controllers in Bestune: Standard Independent Pid ControllerDocument7 pagesPid Controllers in Bestune: Standard Independent Pid ControllerCristian ArciniegaNo ratings yet

- Pneumatic Test ProcedureDocument12 pagesPneumatic Test ProcedurePower Power100% (4)

- Magnetic Particle Testing (ISP-MT-ASME V)Document9 pagesMagnetic Particle Testing (ISP-MT-ASME V)Prabhakar KattulaNo ratings yet

- Kimo Kigaz 300 Combustion Gas Analyzer DatasheetDocument5 pagesKimo Kigaz 300 Combustion Gas Analyzer DatasheetayannathompsoneqsNo ratings yet

- OHSAS Pre-Course ExerciseDocument4 pagesOHSAS Pre-Course ExercisekLARA DIVINONo ratings yet

- Type of Survey: Initial/ Annual/Intermediate/Renewal/Change of FlagDocument8 pagesType of Survey: Initial/ Annual/Intermediate/Renewal/Change of FlagBhupender RamchandaniNo ratings yet

- Form 10.1. Installation Checklist Media FiltersDocument4 pagesForm 10.1. Installation Checklist Media FiltersSaravanan RasayaNo ratings yet

- Static Eqipment Itp and FormDocument9 pagesStatic Eqipment Itp and FormaamirapiNo ratings yet

- Barring GearDocument30 pagesBarring GearJeffrey MuellerNo ratings yet

- API 570 Final Exam Close Book Questions 23Document10 pagesAPI 570 Final Exam Close Book Questions 23Ravindra S. Jivani100% (1)

- Name of The Master: - : MV "Dutch Spear" PibrDocument12 pagesName of The Master: - : MV "Dutch Spear" PibrPaschos DimitriosNo ratings yet

- Pneumatic Test - NT2 CCPP Project (Final)Document12 pagesPneumatic Test - NT2 CCPP Project (Final)Huynh Thanh TamNo ratings yet

- Daily Toolpusher InspectionDocument1 pageDaily Toolpusher Inspectionjinyuan74No ratings yet

- Temp en 02 - Hoist R1Document7 pagesTemp en 02 - Hoist R1hbookNo ratings yet

- API 570 Questions 12Document5 pagesAPI 570 Questions 12Ravindra S. JivaniNo ratings yet

- SW Horizontal AbovegroundDocument3 pagesSW Horizontal AbovegroundMohammed EljammalNo ratings yet

- Turn Over Notes For Third OfficerDocument6 pagesTurn Over Notes For Third OfficerMariaAnthessaGalay100% (4)

- SOP 829 - 032 Check-Reset KEMS, CrownomaticDocument2 pagesSOP 829 - 032 Check-Reset KEMS, CrownomaticAnonymous XbmoAFtINo ratings yet

- Data Sheet BDocument22 pagesData Sheet BtceterexNo ratings yet

- Sop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Document10 pagesSop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Iksan Adityo MulyoNo ratings yet

- API 570 Bench Mark Quiz (1-55)Document56 pagesAPI 570 Bench Mark Quiz (1-55)Christopher Randolph100% (5)

- Checklist For Site WorksDocument18 pagesChecklist For Site WorkskhajaimadNo ratings yet

- HotTap Safety ProcedureDocument6 pagesHotTap Safety ProcedureMeghan Smith100% (1)

- Pressure Equipment Inspection Requirements: Train-2 Unit-92 02-E9201 Condensate Flash Drum CondenserDocument2 pagesPressure Equipment Inspection Requirements: Train-2 Unit-92 02-E9201 Condensate Flash Drum CondenserSiva KumarNo ratings yet

- Volt::Ch: Voltech Engineers Pvt. LTDDocument32 pagesVolt::Ch: Voltech Engineers Pvt. LTDstalin63100% (1)

- Pressure Equipment Inspection Requirements: Train-3 Unit-82 03-S8203A Sea Water FilterDocument1 pagePressure Equipment Inspection Requirements: Train-3 Unit-82 03-S8203A Sea Water FilterSiva KumarNo ratings yet

- Ut Gas Pipe Line Written ProcedureDocument5 pagesUt Gas Pipe Line Written Procedureramaprasad_32100% (1)

- QC Doc 304 (Nde Procedure)Document8 pagesQC Doc 304 (Nde Procedure)gaehdd1No ratings yet

- Energy Conversion Lab Manual NewDocument50 pagesEnergy Conversion Lab Manual NewRavi TejNo ratings yet

- 50 Short Questions For MerchandisersDocument8 pages50 Short Questions For MerchandisersSîronamHin MonirNo ratings yet

- Pipeline Hydrotest PlanDocument16 pagesPipeline Hydrotest PlanSunday Paul0% (1)

- 2230 - Mechanical Collector CDS - RevDocument3 pages2230 - Mechanical Collector CDS - RevnatsmdNo ratings yet

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Document4 pagesCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)nike_y2k85% (13)

- Bridon Service Procedures SP - 45Document5 pagesBridon Service Procedures SP - 45Khawaja Arslan AhmedNo ratings yet

- Form 10.3. Installation Checklist Aerobic Treatment UnitDocument4 pagesForm 10.3. Installation Checklist Aerobic Treatment UnitSaravanan RasayaNo ratings yet

- Pressure Equipment Inspection Requirements: Train3 - Unit 08 03-E0801 Nitrogen Column ReboilerDocument1 pagePressure Equipment Inspection Requirements: Train3 - Unit 08 03-E0801 Nitrogen Column ReboilerSiva KumarNo ratings yet

- Pressure Equipment Inspection Requirements: 03-V0301A Molecular Sieve BedDocument1 pagePressure Equipment Inspection Requirements: 03-V0301A Molecular Sieve BedSiva KumarNo ratings yet

- Api 510 QB A-FDocument54 pagesApi 510 QB A-FRanaweera Ariyamanjula100% (1)

- Job Order Cost System: Richmond-Lady-Boat-Show-Price PDFDocument33 pagesJob Order Cost System: Richmond-Lady-Boat-Show-Price PDFLadyromancerWattpadNo ratings yet

- Forming Service Center Maintenance Report Electric & AutomationDocument8 pagesForming Service Center Maintenance Report Electric & AutomationMochamad Zain NurzamanNo ratings yet

- Api 510 Preparatory: Points To Recall - Day 6Document2 pagesApi 510 Preparatory: Points To Recall - Day 6Ranaweera AriyamanjulaNo ratings yet

- U-Stamp QapDocument6 pagesU-Stamp Qapchonubobby100% (1)

- Ek 2001 March 95 Me KG 4 Sr. No.3Document3 pagesEk 2001 March 95 Me KG 4 Sr. No.3Bhupender RamchandaniNo ratings yet

- API 570 Questions 07Document20 pagesAPI 570 Questions 07Ravindra S. Jivani100% (1)

- Pressure Equipment Inspection Requirements: Train2 - Unit 07 03-E0707 Debutanizer CondenserDocument1 pagePressure Equipment Inspection Requirements: Train2 - Unit 07 03-E0707 Debutanizer CondenserSiva KumarNo ratings yet

- 105 Transformer Installation Instructions enDocument3 pages105 Transformer Installation Instructions enSujit AdhyaNo ratings yet

- Stories from the Road 7: An Automotive Case Studies SeriesFrom EverandStories from the Road 7: An Automotive Case Studies SeriesNo ratings yet

- Holiday Shutdown ChecklistDocument5 pagesHoliday Shutdown ChecklistSaravanan RasayaNo ratings yet

- GC3 Marking SheetsDocument2 pagesGC3 Marking SheetsSaravanan RasayaNo ratings yet

- Safety Memo 003Document2 pagesSafety Memo 003Saravanan RasayaNo ratings yet

- Reference Electrical JDDocument3 pagesReference Electrical JDSaravanan RasayaNo ratings yet

- MPR Job Search Ebook 2015 WCDocument29 pagesMPR Job Search Ebook 2015 WCSaravanan RasayaNo ratings yet

- Laws of Malaysia: Occupational Safety and Health Act 1994 (Act 514)Document2 pagesLaws of Malaysia: Occupational Safety and Health Act 1994 (Act 514)Saravanan RasayaNo ratings yet

- Action Item - 7 Pillar Audit Mar 06Document8 pagesAction Item - 7 Pillar Audit Mar 06Saravanan RasayaNo ratings yet

- Joe's Enterprises For Fast Food, Inc. Is A Small Food Service Company Incorporated inDocument6 pagesJoe's Enterprises For Fast Food, Inc. Is A Small Food Service Company Incorporated inSaravanan RasayaNo ratings yet

- Interface Global Education Authorised Centre by Asia UniversityDocument1 pageInterface Global Education Authorised Centre by Asia UniversitySaravanan RasayaNo ratings yet

- Cash Flow Management: Business Finance SolutionsDocument21 pagesCash Flow Management: Business Finance SolutionsSaravanan RasayaNo ratings yet

- WWTP HazopDocument12 pagesWWTP HazopMarco MazzucatoNo ratings yet

- 2q 2012 Ir Pack Final ExpDocument23 pages2q 2012 Ir Pack Final ExpSaravanan RasayaNo ratings yet

- 8 Firms Get 2,600 MHZ SpectrumDocument1 page8 Firms Get 2,600 MHZ SpectrumSaravanan RasayaNo ratings yet

- ARTC ApplicantGuidelinesDocument25 pagesARTC ApplicantGuidelinesSaravanan RasayaNo ratings yet

- 2q 2012 Ir Pack Final ExpDocument23 pages2q 2012 Ir Pack Final ExpSaravanan RasayaNo ratings yet

- Signing SummaryDocument1 pageSigning SummarySaravanan RasayaNo ratings yet

- Chapter I III Water HyacinthDocument78 pagesChapter I III Water Hyacinthdatuben guiomsNo ratings yet

- Environmental Chemistry NotesDocument8 pagesEnvironmental Chemistry NotesTauqeer AhmadNo ratings yet

- Simapro Database Manual: Methods LibraryDocument74 pagesSimapro Database Manual: Methods LibraryAdhe MartiyaNo ratings yet

- Bright Business Opportunity in Innovative Solar Technology: Solar Powered Cold StorageDocument1 pageBright Business Opportunity in Innovative Solar Technology: Solar Powered Cold StoragePradeep SinglaNo ratings yet

- Documentation Ombu Spain Norman FosterDocument14 pagesDocumentation Ombu Spain Norman FosterAousten AAtenNo ratings yet

- Determination of Biochemical Oxygen DemandDocument12 pagesDetermination of Biochemical Oxygen DemandIbrahim DewaliNo ratings yet

- Green Buildings in IndiaDocument3 pagesGreen Buildings in IndiaSriram KumaranNo ratings yet

- MBR Process Design Calculations - US UnitsDocument26 pagesMBR Process Design Calculations - US Unitsmuhammad naseemNo ratings yet

- Advantages and Disadvantages of BiomassDocument2 pagesAdvantages and Disadvantages of BiomassAnil KumarNo ratings yet

- HUI Service CatalogDocument12 pagesHUI Service CatalogSaefuddin SaefuddinNo ratings yet

- SIP Sustainable Drainage SolutionDocument5 pagesSIP Sustainable Drainage SolutionElyNo ratings yet

- Online Pumped StorageDocument2 pagesOnline Pumped StorageABHINAV SAURAVNo ratings yet

- CPT S-1 Renovasi Clading Gedung Kementerian BUMNDocument9 pagesCPT S-1 Renovasi Clading Gedung Kementerian BUMNUsep SNo ratings yet

- NERC Standard of Capacity Factor Steam Power Plant 100mw - Penelusuran GoogleDocument2 pagesNERC Standard of Capacity Factor Steam Power Plant 100mw - Penelusuran GoogleAlif Nur FirdausNo ratings yet

- Calculation ETPDocument9 pagesCalculation ETPashok815350% (4)

- My TestDocument17 pagesMy Testamanda mayorgaNo ratings yet

- Wastewater Treatment Plant Design - Lecture 3 - Water and Wastewater ConsumptionDocument25 pagesWastewater Treatment Plant Design - Lecture 3 - Water and Wastewater ConsumptionAQ UANo ratings yet

- Hydraulic Calculation For 18+430Document16 pagesHydraulic Calculation For 18+430designbridgeeng geo groupNo ratings yet

- Misr Spinning & Weaving Co. (Mehalla Kubra) : Industrial Waste Water Treatment PlantDocument29 pagesMisr Spinning & Weaving Co. (Mehalla Kubra) : Industrial Waste Water Treatment PlantmohamedqadiNo ratings yet

- Hydrological & Hydraulic Models ComparisionDocument6 pagesHydrological & Hydraulic Models ComparisionFiraol OromoNo ratings yet

- Pollution EviromentDocument2 pagesPollution EviromentHạnh Đoàn Công NữNo ratings yet

- Envi - Research Study For Revision IntroDocument7 pagesEnvi - Research Study For Revision IntropotatokingNo ratings yet

- Chapter 1Document18 pagesChapter 1Jarul ZahariNo ratings yet

- En8591 - Municipal Solid Waste ManagementDocument16 pagesEn8591 - Municipal Solid Waste ManagementASHA BALASUBRAMANIAMNo ratings yet

- Elective QuizDocument2 pagesElective QuizClaudine MedalladaNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNo ratings yet

- I. Organics (Bod, Cod, Toc, O&G) : Understanding Laboratory Wastewater TestsDocument8 pagesI. Organics (Bod, Cod, Toc, O&G) : Understanding Laboratory Wastewater Testsurie666No ratings yet

- Veolia WAVE Magazine - North America Issue - With LinksDocument48 pagesVeolia WAVE Magazine - North America Issue - With LinksManjunath GangadharNo ratings yet

- Unit Ii Ee IiDocument75 pagesUnit Ii Ee IiPIERO SEBASTIAN MENDOZA TIMANANo ratings yet