LRFD Pedestrian Bridge Example Rev

Uploaded by

魏学军LRFD Pedestrian Bridge Example Rev

Uploaded by

魏学军AASHTO LRFD Pedestrian Bridge Design Example

Half-Through Truss Bridge with Tubular Members

General

Note(s):

- Use the AASHTO LRFD Guide Specifications for Pedestrian Bridges (Draft - 2008)

- Article 1.2.1: Minimum metal thickness of closed structural tubing members shall be 1/4 inch.

Evaluate the bridge for the following limit states per Article 3.7

Strength I

Strength III

Service I

Fatigue ???

- Article 3.1: Pedestrian bridges shall be designed for a uniform pedestrian loading of not less than 90

psf. Impact is not included in the pedestrian loading.

AASHTO LRFD Guide Specification Pedestrian Bridge Design Example

Half-Through Truss Bridge with Tubular Members

ILLUSTRATIVE EXAMPLE OF KEY PROVISIONS OF GUIDE SPECIFICATIONS

Load and Resistance Factor Design

GENERAL INFORMATION

Specifications Used:

- AASHTO LRFD Bridge Design Specifications, 2008 (AASHTO LRFD)

- AASHTO Standard Specificationsfor Structural Supports for

Highway Signs, Luminaires and Traffic Signals, 2008 (AASHTO Signs)

- LRFD Guide Specifications for Pedestrian Bridges (Specification)

Geometry:

Span = 72 ft.

Deck width, w

deck

= 10 ft.

CL-CL trusses = 10.5 ft.

A500, Gr. B, F

y

= 46 ksi

TRUSS MEMBERS: All Structural Tubing

Top and Bottom Chords:

Section: 6 x 3 x 5/16" structural tubing

A = 4.98 in

2

w = 16.96 plf

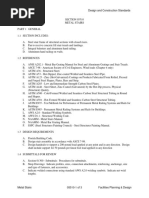

L00 L01 L02 L03 L04 L05 L06

U00 U01 U02 U03 U04 U05 U06

Symm @

C Span

L

12 Panels @ 6'-0" = 72'-0" Span

5

'

-

0

"

10'-6" C C Trusses

5

'

-

0

"

C

C

C

h

o

r

d

s

4

'

-

6

"

L L

10'-0" Deck Width

L

L

Floorbeam

End Posts:

Section: 6 x 3 x 5/16" structural tubing

A = 4.98 in

2

w = 16.96 plf

Vertical Posts:

Section: 5 x 3 x 5/16" structural tubing

A = 4.36 in

2

w = 14.83 plf

I

x

= I

c

= 13.2

in

4

Diagonals:

Section: 4 x 3 x 1/4" structural tubing

A = 3.09 in

2

w = 10.51 plf

FLOORBEAMS:

Section: W8x10

I

x

= I

b

= 30.8

in

4

S

x

= 7.81

in

3

Spacing = 6 ft. at each panel point

DEAD LOAD:

Weight of each truss = 60 plf per truss

Assumed deck loading = 25 psf

Weight of deck & floor system = 25 psf x 10.50 ft. / 2

= 132 plf per truss

Total dead load = 60 plf + 132 plf

= 192 plf Use 200 plf

PEDESTRIAN LIVE LOAD: (Specification, Article 3.1)

MAIN MEMBERS: Trusses

- Use 90 psf without impact.

Live load per truss = pedestrian loading x deck width / 2

= 90 psf x 10.0 ft. / 2

= 450 plf

SECONDARY MEMBERS: Deck, Stringers, Floorbeams

- Use 90 psf without impact.

VEHICLE LOAD: (Specification, Article 3.2)

- Use Table 3.2-1 for Minimum Axle Loads and Spacings.

Use the following vehicle for a clear deck width between 7 ft. and 10 ft.

Front axle = 2 k

Rear axle = 8 k

Axle spacing = 14 ft.

Wheel spacing = 6 ft.

Note:

WIND LOAD: (Specification, Article 3.4)

- Assume 100 mph design wind.

- The design life shall be taken as 50 years for the purpose of calculating the wind loading.

- The deck area may be used to compute design pedestrian live load for all main member components

(truss members). The deck area is the non-zero influence surface for all such components.

- Vehicular access is not prevented by fixed physical methods, therefore, the pedestrian bridge should be

designed for an occassional single maintenance vehicle load.

- The vehicular load shall not be placed in combination with the pedestrian load. Consideration of impact

is not included with this vehicular loading.

- Neglect wind load on the live load vehicle.

For this example, the pedestrian load controls for the truss design; however, the

vehicle load will control for the floor system design.

- Use wind load as specified in the AASHTO Signs , Articles 3.8 and 3.9.

Horizontal Wind Loading

- Apply the design horizontal wind pressure on the truss components.

P

z

= design wind pressure on superstructure using AASHTO Signs, Eq. 3-1 or Table 3-7, psf

= 0.00256K

z

GV

2

I

r

C

d

(AASHTO Signs, Eq. 3-1)

where:

K

z

= height and exposure factor from AASHTO Signs, Eq. C3-1 or Table 3-5

= 1.00 (conservatively taken from Table 3-5 for a height of 32.8 ft.)

G = gust effect factor

= 1.14 (minimum)

V = basic wind velocity

= 100 mph

I

r

= wind importance factor from AASHTO Signs, Table 3-2

= 1.00

C

d

= wind drag coefficient from AASHTO Signs, Table 3-6

= 2.00

P

z

= 58.4 psf

Projected vertical area per linear foot:

Chords: 2 @ 3 in./ 12 x 6 ft. / 6 ft. 0.50 SF/ft.

Verticals: 3 in./ 12 x 4.75 ft. long / 6 ft. 0.20 SF/ft.

Diagonals: 3 in. x 7.81 ft. long / 6 ft. 0.33 SF/ft.

Total per Truss: 1.03 SF/ft.

Deck + Stringers: 10" / 12 0.83 SF/ft.

WS

H

= total horizontal wind on superstructure, plf

= (2 trusses x 1.03 SF/ft. + 0.83 SF/ft.) x 58.4 psf

= 169 plf

Note:

(Alternatively, AASHTO Signs, Table 3-7 may be used

with a C

d

value of 2.0 applied)

The full lateral wind loads must be resisted by the entire superstructure.

Appropriate portions of the design wind loads must also be distributed to the truss

top chord for design lateral forces on the truss verticals.

Vertical Wind Loading

WS

V

=

= P

v

*w

deck

where:

P

v

= vertical wind loading on superstructure, ksf

= 0.020 ksf

w

deck

= total deck width, ft.

= 10.0 ft.

Therefore,

WS

V

= 0.020 ksf x 1000 x 10.00 ft.

= 200 plf

Vertical load on leeward truss = 200 plf x (7.5 ft. + (0.5 in. + 2.5 in.) / 12) / 10.50 ft.

= 147.6 plf

Vertical load on windward truss = 200 plf x (2.5 ft. + (0.5 in. + 2.5 in.) / 12) / 10.50 ft.

= 52.4 plf (uplift)

TOTAL VERTICAL LOADS PER TRUSS: (Specification, Article 3.7)

DEAD LOAD (DC1+DC2): 200 plf

LIVE LOAD (Pedestrian, PL): 450 plf

WIND (Overturning, WS): 148 plf

Load Factors (AASHTO LRFD Table 3.4.1-1)

Limit

State

DC1 & DC2 PL WS

Str I 1.25 1.75 0

Str III 1.25 0 1.40

Ser I 1.00 1.00 0.30

STRENGTH I LIMIT STATE (

DC1+DC2

*(DC1+DC2) +

PL

*PL)

= 1,038 plf

STRENGTH III LIMIT STATE (

DC1+DC2

*(DC1+DC2) +

WS

*WS

V

)

= 457 plf

SERVICE I LIMIT STATE (

DC1+DC2

*(DC1+DC2) +

PL

*PL +

WS

*WS

V

)

= 694 plf

vertical wind load on the full projected area of the superstructure applied at the

windward quarter point, plf

- Apply a vertical pressure of 0.020 ksf over the full deck width concurrently with the horizontal loading.

This loading shall be applied at the windward quarter point of the deck width.

TRUSS MEMBER DESIGN LOADS:

Panel point load from controlling load comb. = 1.038 klf x 6.0 ft. panel = 6.23 k/panel

Maximum Truss Member Axial Loads (from separate truss analysis):

Chord (U05-U06) 134.57 k (compression)

End Post (U00-L00) 34.27 k (compression)

Diagonal (U00-L01) 53.52 k (tension)

Vertical (U01-L01) 28.04 k (compression)

TRUSS TOP CHORD LATERAL SUPPORT: (Specification, Article 7.1)

- Lateral support is provided by a transverse U-frame consisting of the floorbeam and truss verticals.

Compute CL/P

c

for use in the Table.

where:

C = P/A

= 2.917 k/in. (from a separate 2D analysis)

L =

= 72 in.

P

c

=

= 178.9781 k

CL/P

c

= 1.17

n = number of panels

= 12

Therefore,

1/K = 0.688 (Specification, by interpolation of Table 7.1.2-1)

K = 1.45

- Assume the truss verticals are adequate to resist the lateral force per Specification, Article 7.1.1 (Must

verify assumption; see section titled "LATERAL FORCE TO BE RESISTED BY VERTICALS")

unbraced length of the chord in compression (i.e. length between panel

points), in.

desired critical buckling load (i.e. factored compressive force) multiplied by 1.33, k

(Specification, Article 7.1.2)

Determine the design effective length factor, K, for the individual top chord members supported between

the truss verticals using Specification, Table 7.1.2-1.

TOP CHORD COMPRESSIVE RESISTANCE: (AASHTO LRFD, Article 6.9.2)

Check the slenderness ratio against the limiting value.

For main members: KL/r s 120

For bracing members: KL/r s 140

Section: 6 x 3 x 5/16" Structural Tube

A = 4.98 in

2

r

x

= radius of gyration about the x-axis, in.

= 2.06 in.

r

y

= radius of gyration about the y-axis, in.

= 1.18 in.

K = 1.45

L = 72 in.

KL/r

x

= (1.45 x 72 in.) / 2.06 in.

= 50.8 < 120 OK

KL/r

y

= (1.00 x 72 in.) / 1.18 in.

= 61.0 < 120 OK

P

r

= factored resistance of components in compression, k

= |

c

P

n

(AASHTO LRFD, Eq. 6.9.2.1-1)

where:

|

c

= resistance factor for compressive per AASHTO LRFD, Article 6.5.4.2

= 0.9

P

n

= nominal compressive resistance per AASHTO LRFD, Article 6.9.4, k

Determine the nominal compressive resistance, P

n

If s 2.25, then:

P

n

= 0.66

F

y

A

s

(AASHTO LRFD, Eq. 6.9.4.1-1)

If > 2.25, then:

P

n

= (AASHTO LRFD, Eq. 6.9.4.1-2)

y s

0.88F A

= (AASHTO LRFD, Eq. 6.9.4.1-3)

= 0.60

where:

A

s

=

gross cross-sectional area, in

2

= 4.98 in

2

F

y

= specified minimum yield strength, ksi

= 46 ksi

E = modulus of elasticity, ksi

= 29,000 ksi

KL/r

s

= Maximum of KL/r

x

,KL/r

y

= 61

Therefore, the top chord factored resistance is:

P

n

=

0.66

0.60

x 46 ksi x 4.98 in

2

= 178 k

|

c

P

n

= 160 k > P

chord

= 134.57 k OK

LATERAL FORCE TO BE RESISTED BY VERTICALS: (Specification, Article 7.1.1)

H

f

= minimum lateral force, k

= 0.01/K*P

avg

where:

K = 1.45

P

avg

= average design compressive force in adjacent chord members, k

= 134.57 k

Verify limit 0.01 / 1.45 = 0.007 > 0.003 OK

Therefore,

H

f

= 0.01 / 1.45 x 134.57 k

= 0.93 k

Length of vertical = 54.0 in.

Lateral Moment in Vertical due to C = 0.93 k x 54.0 in. = 50.00 k-in.

Apply H

f

as the lateral force at the top of the Truss Verticals. Apply H

f

concurrently with other primary

forces in the Verticals (combined compression plus bending analysis). Include lateral wind forces for

AASHTO LRFD Load Combination Strength III.

2

y

s

F

KL

r E

| |

|

t

\ .

END POSTS: (Specification, Article 7.1.1)

Lateral Force: C = 0.01 x 34.27 k = 0.34 k

Note: All other truss members are analyzed using conventional methods per AASHTO LRFD.

DEFLECTION: (Specification, Article 5)

Maximum pedestrian LL Deflection = 1/500 of the span length = 72.00 ft. x 12 / 500 = 1.73 in.

From Truss Analysis, LL Deflection (w

LL

= 0.450 k/ft) = 1.20 in. < L/500 OK

VIBRATIONS: (Specification, Article 6)

Vertical Direction

f = 0.18*SQRT(g / A

DL

)

where:

g = acceleration due to gravity, ft/s

2

= 32.2 ft/s

2

A

DL

= maximum vertical deflection of the truss due to the dead load, ft.

= 0.0444 ft. (from a separate analysis with w = 0.20 klf per truss)

f = 0.18*SQRT(32.2 / 0.0444) = 4.85 Hz > 3.0 Hz minimum desirable, OK

f > 2.86 ln (180 / W)

where:

W =

= 2 trusses x 0.20 klf x 72.00 ft.

= 28.8 k (Dead Load Only)

2.86 ln (180 / 28.80) = 5.24 Hz

f = 4.85 Hz is not greater than 5.24 Hz, include a portion of the pedestrian live load.

- Estimate the fundamental frequency in the vertical direction, f, by approximating the truss as a simply

supported uniform beam:

- The fundamental frequency in a vertical mode without consideration of live load should be greater than

3.0 Hz to avoid the first harmonic.

- Apply the lateral force, C, at the top end of post and design as a cantilever combined with axial load.

The lateral force, C, is taken as 1.0% of the end post axial load.

For illustration purposes, assume higher harmonics (second, third, etc.) are a concern. The bridge

should be proportioned such that the following criteria is satisfied:

full weight of the supported structure including dead load and an allowance for

actual pedestrian live load, k

Assume some pedestrian live load contribution and re-evaluate the expression:

W = DL + 10%LL = 28.8 + 0.10 x 2 x (0.450 klf x 72.00 ft.) = 35.28 k

2.86 ln (180 / 35.28) = 4.66 Hz < f = 4.85 Hz OK

Lateral Direction

Assume the lateral wind bracing is 3 x 3 x 1/4" structural tubing.

f = 0.18*SQRT(g / A

DL_Lat

)

where:

g = acceleration due to gravity, ft/s

2

= 32.2 ft/s

2

A

DL_Lat

= maximum lateral deflection of the truss due to the dead load, ft.

= 0.0844 ft. (from a separate analysis)

f = 0.18*SQRT(32.2 / 0.0844) = 3.52 Hz > 1.3 Hz minimum desirable, OK

FATIGUE: (Specification, Article 3.5)

Use AASHTO Signs, Article 11.7.3

AASHTO Signs, Article 11.7.4 - Not used as it is assumed that the Pedestrian Bridge

is not over a highway

PNW = 5.2 Cd IF

C

d

= wind drag coefficient per AASHTO Signs, Table 3-6

= 2.00

IF = wind importance factor per AASHTO Signs, Table 3-2

= 1.00

PNW = 10.4 psf

WS

H

= total horizontal wind on superstructure, plf

= (2 trusses x 1.03 SF/ft. + 0.83 SF/ft.) x 10.4 psf

= 31 plf

- The fundamental frequency in a lateral mode without consideration of live load should be greater than

1.3 Hz to avoid the first harmonic.

- Estimate the fundamental frequency in the lateral direction, f

lat

, by approximating the truss as a simply

supported uniform beam rotated 90 degrees:

FATIGUE Cont'd:

Maximum Member Force:

Bottom Chord, Member L05-L06 = 5.6 kips (from a separate

Analysis)

f = Stress Range

= (5.6 kips / 4.98 in

2

)

= 1.12 in

2

(f ) s (F)n (AASHTO LRFD Eq. 6.6.1.2.2-1)

where:

= 1.0 (Specification, Article 3.7)

f = 1.12 ksi

(F)n = (F)TH (Specification, Article 4.1)

where

(F)n = 16 ksi (Category B -base metal)

(AASHTO Signs, Table 11-3)

(1.0)(1.12) s 16

1.12 < 16 OK

Welded Member connections and Fracture Toughness Requirements are outside the limits

of this Pedestrian Bridge design example. They will be the responsibility of the designer.

You might also like

- AISC Design Guide 24 - Hollow Structural Section Connections - 2nd Edition100% (7)AISC Design Guide 24 - Hollow Structural Section Connections - 2nd Edition356 pages

- 1.carter, Charles J. - Geschwindner, Louis F. - Liu, Judy - Unified Design of Steel Structures-Providence Engineering Corp (2017) PDF75% (4)1.carter, Charles J. - Geschwindner, Louis F. - Liu, Judy - Unified Design of Steel Structures-Providence Engineering Corp (2017) PDF626 pages

- FIB-Guidelines For The Design of Footbridges100% (1)FIB-Guidelines For The Design of Footbridges127 pages

- Spreadsheet For Single Span Cast in Place Concrete Bridge Design100% (1)Spreadsheet For Single Span Cast in Place Concrete Bridge Design16 pages

- The Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionFrom EverandThe Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionNo ratings yet

- Barrier Design by Yield Line Aashto LRFDNo ratings yetBarrier Design by Yield Line Aashto LRFD2 pages

- Design of Large Footings For One Way ShearNo ratings yetDesign of Large Footings For One Way Shear8 pages

- Tower Analysis Report Monopole 13 M - 2tenant - 120kph88% (8)Tower Analysis Report Monopole 13 M - 2tenant - 120kph40 pages

- Behavior of Steel Box Girders With Top Flange BracingNo ratings yetBehavior of Steel Box Girders With Top Flange Bracing9 pages

- Codes Standards: AASHTO Vehicle Live LoadingNo ratings yetCodes Standards: AASHTO Vehicle Live Loading4 pages

- Analysis and Design of Arch-Type Pedestrian BridgeNo ratings yetAnalysis and Design of Arch-Type Pedestrian Bridge18 pages

- Design of Type C and Aashto Type IV Girder BridgesNo ratings yetDesign of Type C and Aashto Type IV Girder Bridges473 pages

- The AASHTO LRFD Bridge Design SpecificationsNo ratings yetThe AASHTO LRFD Bridge Design Specifications5 pages

- Integral Abutment Bridge Design (Modjeski and Masters) PDFNo ratings yetIntegral Abutment Bridge Design (Modjeski and Masters) PDF56 pages

- Research Programs: Investigation of Prefabricated Steel-Truss Bridge Deck SystemsNo ratings yetResearch Programs: Investigation of Prefabricated Steel-Truss Bridge Deck Systems70 pages

- AASHTO LRFD - The HL-93 Live Load Model - Dynamic Load AllowanceNo ratings yetAASHTO LRFD - The HL-93 Live Load Model - Dynamic Load Allowance1 page

- Design of RCC T - Girder Deck Using Morice & Little Method100% (4)Design of RCC T - Girder Deck Using Morice & Little Method33 pages

- Seismic Analysis and Design of Concrete Bridge Systems100% (1)Seismic Analysis and Design of Concrete Bridge Systems25 pages

- PCI 6th Edition - Headed Concrete Anchors (HCA)No ratings yetPCI 6th Edition - Headed Concrete Anchors (HCA)104 pages

- LRFD Design Example-Precast Balanced Cantilever Bridge Desig100% (4)LRFD Design Example-Precast Balanced Cantilever Bridge Desig139 pages

- AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)83% (6)AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)698 pages

- Welcome To Inhouse Training Session: Design of PiperackNo ratings yetWelcome To Inhouse Training Session: Design of Piperack23 pages

- LRFD Ex1-Bridge-3span Continuous Straight Composite I GirderNo ratings yetLRFD Ex1-Bridge-3span Continuous Straight Composite I Girder84 pages

- The RC Slab Culvert Analysis and Design Report67% (3)The RC Slab Culvert Analysis and Design Report5 pages

- Behavior, Design and Construction of Horizontally Curved Composite Steel Box Girder Bridges100% (1)Behavior, Design and Construction of Horizontally Curved Composite Steel Box Girder Bridges286 pages

- Fastmarkets Steel Prices & News Daily 2023-11-13No ratings yetFastmarkets Steel Prices & News Daily 2023-11-1318 pages

- 2016 To 2010 Spec Comparison - Final PDFNo ratings yet2016 To 2010 Spec Comparison - Final PDF42 pages

- Transverse Plate-To-squarerectangular Hss ConnectionsNo ratings yetTransverse Plate-To-squarerectangular Hss Connections7 pages

- ASTM-A500-A500M-21a Standard Specification For Cold-Formed WeldedNo ratings yetASTM-A500-A500M-21a Standard Specification For Cold-Formed Welded5 pages

- 2016 To 2010 Spec Comparison - Final PDFNo ratings yet2016 To 2010 Spec Comparison - Final PDF42 pages

- Pipe Bending - Nigerian Gas & Steel LTDNo ratings yetPipe Bending - Nigerian Gas & Steel LTD16 pages

- Article HSS WF Column Selection Guide 020724-PpgfiyNo ratings yetArticle HSS WF Column Selection Guide 020724-Ppgfiy27 pages

- HSS Article HSS ColumnSplices 0118 060120 r1No ratings yetHSS Article HSS ColumnSplices 0118 060120 r14 pages

- (Steel) HSS Dimensions Section Properties A500 BrochureNo ratings yet(Steel) HSS Dimensions Section Properties A500 Brochure24 pages

- Steel & Wire Products Manufacturing Mulugeta100% (3)Steel & Wire Products Manufacturing Mulugeta38 pages

- A1085-13 Standard Specification For Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS) PDFNo ratings yetA1085-13 Standard Specification For Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS) PDF5 pages

- Steel Standards: ASTM A252 ASTM A500 CSA G40.21No ratings yetSteel Standards: ASTM A252 ASTM A500 CSA G40.211 page

- UPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, Dimensions, PropertiesNo ratings yetUPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, Dimensions, Properties2 pages

- AISC Design Guide 24 - Hollow Structural Section Connections - 2nd EditionAISC Design Guide 24 - Hollow Structural Section Connections - 2nd Edition

- 1.carter, Charles J. - Geschwindner, Louis F. - Liu, Judy - Unified Design of Steel Structures-Providence Engineering Corp (2017) PDF1.carter, Charles J. - Geschwindner, Louis F. - Liu, Judy - Unified Design of Steel Structures-Providence Engineering Corp (2017) PDF

- Spreadsheet For Single Span Cast in Place Concrete Bridge DesignSpreadsheet For Single Span Cast in Place Concrete Bridge Design

- The Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionFrom EverandThe Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second Edition

- Tower Analysis Report Monopole 13 M - 2tenant - 120kphTower Analysis Report Monopole 13 M - 2tenant - 120kph

- Behavior of Steel Box Girders With Top Flange BracingBehavior of Steel Box Girders With Top Flange Bracing

- Analysis and Design of Arch-Type Pedestrian BridgeAnalysis and Design of Arch-Type Pedestrian Bridge

- Design of Type C and Aashto Type IV Girder BridgesDesign of Type C and Aashto Type IV Girder Bridges

- Integral Abutment Bridge Design (Modjeski and Masters) PDFIntegral Abutment Bridge Design (Modjeski and Masters) PDF

- Research Programs: Investigation of Prefabricated Steel-Truss Bridge Deck SystemsResearch Programs: Investigation of Prefabricated Steel-Truss Bridge Deck Systems

- AASHTO LRFD - The HL-93 Live Load Model - Dynamic Load AllowanceAASHTO LRFD - The HL-93 Live Load Model - Dynamic Load Allowance

- Design of RCC T - Girder Deck Using Morice & Little MethodDesign of RCC T - Girder Deck Using Morice & Little Method

- Seismic Analysis and Design of Concrete Bridge SystemsSeismic Analysis and Design of Concrete Bridge Systems

- LRFD Design Example-Precast Balanced Cantilever Bridge DesigLRFD Design Example-Precast Balanced Cantilever Bridge Desig

- AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)

- Welcome To Inhouse Training Session: Design of PiperackWelcome To Inhouse Training Session: Design of Piperack

- LRFD Ex1-Bridge-3span Continuous Straight Composite I GirderLRFD Ex1-Bridge-3span Continuous Straight Composite I Girder

- Behavior, Design and Construction of Horizontally Curved Composite Steel Box Girder BridgesBehavior, Design and Construction of Horizontally Curved Composite Steel Box Girder Bridges

- Transverse Plate-To-squarerectangular Hss ConnectionsTransverse Plate-To-squarerectangular Hss Connections

- ASTM-A500-A500M-21a Standard Specification For Cold-Formed WeldedASTM-A500-A500M-21a Standard Specification For Cold-Formed Welded

- Article HSS WF Column Selection Guide 020724-PpgfiyArticle HSS WF Column Selection Guide 020724-Ppgfiy

- (Steel) HSS Dimensions Section Properties A500 Brochure(Steel) HSS Dimensions Section Properties A500 Brochure

- A1085-13 Standard Specification For Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS) PDFA1085-13 Standard Specification For Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS) PDF

- UPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, Dimensions, PropertiesUPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, Dimensions, Properties