QAP General

QAP General

Uploaded by

cvssbvCopyright:

Available Formats

QAP General

QAP General

Uploaded by

cvssbvOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

QAP General

QAP General

Uploaded by

cvssbvCopyright:

Available Formats

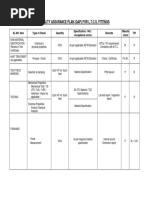

QUALITY ASSURANCE PLAN

Pre-Engineered Steel Building / Steel Structure

NAME OF CUSTOMER :

DESCRIPTION CHARACTERISTIC TYPE OF CHECK EXTENT OF CHECK

DOCUMENT NO REVISION NO DATE

INSPECTION BY

: PCT/QC/QAP/General : :

REMARKS

JOB NO:

SPEC. CODES & STANDARDS FOR ACCEPTANCE CRITERIA

FORMAT OF RECORDS PCT Client/TPI

RAW MATERIAL a) Chemical Properties b) Mechanical Properties c) Dimensions a) Chemical Properties b) Mechanical Properties c) Dimensions a) Chemical Properties b) Mechanical Properties c) Dimensions a) Mill TC Verification b) Mill TC Verification c) Measurement a) Mill TC Verification b) Mill TC Verification c) Measurement a) Mill TC Verification b) Mill TC Verification c) Measurement a) 100% b) 100% c) 1No./ Incoming Vehicle a) 100% b) 100% c) 1No./ Incoming Vehicle ASTM A 572 Gr 50 or equivalent material a) R b) R c) I a) R b) R c) I a) Mill TC b) Mill TC c) PCT-Inspection report a) Mill TC b) Mill TC c) PCT-Inspection report a) Mill TC b) Mill TC c) PCT-Inspection report

1.1 Steel Plate

1.2 Hot Rolled & Hollow Sections (Beam/Channel/Angle Bar, Beams, pipes etc.) 1.3 Purlin & Panel Coils

IS2062 E250 WA For HR sections IS 1239, IS 4923, I S 1161 for Pipe / Hollow sections ASTM A 792 Gr . 50 / 80 a) 100% a) R b) 100% for Panel b) R c) 1No./ Incoming Vehicle ASTM A 653 Gr 50 for GI & c) I ASTM A 1011 Gr 50 for Plain Purlins

BOUGHT OUT ITEMS a) Chemical properties b) Mechanical properties c) Dimension a) Material b) Dimensions a) Mfr. TC Verification b) Mfr.TC Verification c) Measurement a) Mfr. TC Verification b) Measurement a) 100 % b) 100 % c) Sample-1 in 3000 a) 100 % b) Random Sample

ASTM A 325, A563 & A 436

2.1 Bolts, Nuts & Washers (Fasteners) 2.2 Doors, Windows, FRP ventilators, skylights etc. 3 FABRICATION PROCESS

As per Drawing & client Specifications

a) R b) R c) I a) R b) R

a) Manufacturer TC b) Manufacturer TC c) PCT-Inspection report a) Manufacturer TC b) PCT-Inspection report

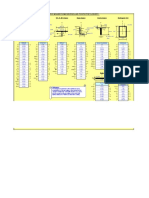

3.1 Fabrication of Primary Structure 3.2 Final Inspection (Before Painting) 4 WELDING & NDT

a) Dimension a) Dimension b) Part Identification a) Procedure Specification b) Procedure Qualification c) Welder Qualification a) Visual Defects b) Weld size c) Surface Defects d)Under surface defects a) Surface preparation b) Surface Coating a) Dimensions b) Surface & Shape

a) Measurement a) Measurement b) Verification a) Verification / Review b) Verification / Review c) Verification / Review a) Visual b) Measurement c) DP Test d) Ultrasonic Test a) Measurement & Visual b) Measurement- DFT a) Measurement b) Visual

a) 50 % a) 100% b) 100% a) 100% b) 100 % c) 100 % a) 100% b) 50 % c) 1 Joint /Day d) 1 Joint / Day a) 1 Sample / Day b) 1 Sample / Day a) 1 Sample / Shift b) Random

Fabrication-As Per Dwg. and MBMA Fabrication-As Per Dwg. and MBMA

a) I a) I

a) PCT-Inspection report a) PCT-Inspection report

4.1 Welding Procedure

AWS D1.1 -2010

4.2 Welding Inspection

AWS D1.1 -2010

a) R b) R c) R a) I b) I c) I d) I a) I

a) WPS b) PQR c) WPQ a) PCT-Inspection report b) PCT-Inspection report c) PCT-Inspection report d) PCT-Inspection report a) PCT-Inspection report b) PCT-Inspection report a) PCT-Inspection report

SURFACE CLEANING & PAINTING As per Client requirement and Specifications As per Drawing , MBMA & client Specifications

5.1 Surface Cleaning & Painting process 6 Roll Forming 6.1 Purlin & Roof Sheeting Roll Forming LEGEND :R - Review I - Inspection

a) I

PCT - Phenix Construction Technology AWS - American Welding Society

ASTM- American Society for Material & Testing IS - Indian Standard MBMA - Metal Building Manufacturer's Association Reviewed & Approved by : _________________________ Customer / Third Party Insp.

Prepared by : ____________________ Phenix - Head Q.A./Q.C.

You might also like

- Quality Assurance Plan: Pre-Engineered Steel Building50% (2)Quality Assurance Plan: Pre-Engineered Steel Building3 pages

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping Works67% (6)Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping Works4 pages

- Inward Material Inspection Report: Project Name: Job Code: LocationNo ratings yetInward Material Inspection Report: Project Name: Job Code: Location2 pages

- Imir - Incomming Material Inspection ReportNo ratings yetImir - Incomming Material Inspection Report2 pages

- Inspection and Quality Control in ManufacturingNo ratings yetInspection and Quality Control in Manufacturing598 pages

- Chhaparia Industries LTD.: In-Process Inspection ReportNo ratings yetChhaparia Industries LTD.: In-Process Inspection Report4 pages

- Engineers To Healthcare Industry®: Quality Assurance Protocol (QAP)No ratings yetEngineers To Healthcare Industry®: Quality Assurance Protocol (QAP)9 pages

- Comments Resolution Sheet For Commented QAPNo ratings yetComments Resolution Sheet For Commented QAP10 pages

- Quality Assurance Plan (Qap) For L.T.C.S. FittingsNo ratings yetQuality Assurance Plan (Qap) For L.T.C.S. Fittings2 pages

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)No ratings yetVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)4 pages

- Quality Assurance Plan For Is 2062 E250 GR BRNo ratings yetQuality Assurance Plan For Is 2062 E250 GR BR2 pages

- Company Nam: Dimensional Layout Inspection ReportNo ratings yetCompany Nam: Dimensional Layout Inspection Report1 page

- Test Certificate: Signature Not VerifiedNo ratings yetTest Certificate: Signature Not Verified1 page

- WET IC - Quality Month Inauguration-10864 PDFNo ratings yetWET IC - Quality Month Inauguration-10864 PDF137 pages

- Surface Preparation & Painting ProcedureNo ratings yetSurface Preparation & Painting Procedure9 pages

- Master List of Monitoring & Measuring EquipmentNo ratings yetMaster List of Monitoring & Measuring Equipment1 page

- Project: Laying of Pipeline and Associated Works For Hassan-Cherlapally Pipeline (HCPL) Project-Schedule - INo ratings yetProject: Laying of Pipeline and Associated Works For Hassan-Cherlapally Pipeline (HCPL) Project-Schedule - I2 pages

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2No ratings yetSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 22 pages

- Quality Assurance Plan - Manufacturing & Testing of Conveyor Belt100% (1)Quality Assurance Plan - Manufacturing & Testing of Conveyor Belt2 pages

- NK-QMS-04-10 Customer Complaint RegisterNo ratings yetNK-QMS-04-10 Customer Complaint Register1 page

- Raw Material & Bought Out Items InspectionNo ratings yetRaw Material & Bought Out Items Inspection3 pages

- Vdocuments - MX Quality Assurance in Peb Pre Engineered Steel BuildingsNo ratings yetVdocuments - MX Quality Assurance in Peb Pre Engineered Steel Buildings1 page

- Project Standards and Specifications Mechanical Design Rev01No ratings yetProject Standards and Specifications Mechanical Design Rev0111 pages

- Quality Control & Quality Assurance Engineer - Job DescriptionNo ratings yetQuality Control & Quality Assurance Engineer - Job Description2 pages