Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912

Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912

Uploaded by

Dimitris ZeimpekisCopyright:

Available Formats

Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912

Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912

Uploaded by

Dimitris ZeimpekisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912

Catalogue 1VDD006104 SafeRing - SafePlus 12-24kV - 0912

Uploaded by

Dimitris ZeimpekisCopyright:

Available Formats

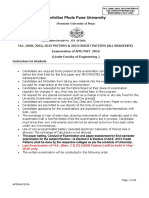

Product catalogue

ABB AS, Power Products Division SF6-insulated Ring Main Unit type SafeRing 12 - 24 kV and SF6-insulated Compact Switchgear type SafePlus 12 - 24 kV

Content

Applications SafeRing .......................................................... 3 Applications SafePlus ........................................................... 5 Design Philosophy ................................................................ 7 SafeRing configurations ........................................................ 8 Technical data SafeRing ........................................................ 11 SafePlus modules ................................................................. 12 C - Cable switch ................................................................... 13 F - Switch-fuse disconnector ................................................. 14 V - Vacuum circuit-breaker .................................................... 15 Sl - Busbar sectionalizer ....................................................... 16 Sv - Busbar sectionalizer ....................................................... 17 D - Direct cable connection ................................................... 18 De - Direct cable connection with earthing switch .................. 19 Be - Busbar earthing ............................................................ 20 CB - Circuit-breaker module .................................................. 21 M - Metering module ............................................................ 22 Mt - Metering tariff module .................................................... 24 Outer assembly........... ......................................................... 25 Cable switch module ............................................................ 26 Vacuum circuit-breaker module ............................................. 27 Switch-fuse module .............................................................. 28 Cable bushings .................................................................... 29 Arc suppressor ..................................................................... 30 Completely sealed system ..................................................... 31 Cable test bushings .............................................................. 32 Mechanisms and interlocks ................................................... 33 External busbars on top ........................................................ 36 Side extension ...................................................................... 38 Base frame ........................................................................... 39 Low voltage compartment ..................................................... 40 Motor operation .................................................................... 41 Transformer protection .......................................................... 43 Fuse selection table .............................................................. 44 Fuse-links ............................................................................. 45 Relays .................................................................................. 46 Combisensor ........................................................................ 51 Cable termination ................................................................. 52 Cable terminations 12kV........................................................ 55 Cable terminations 24kV......................................................... 58 Capacitive voltage indication ................................................. 61 Short-circuit indicator ........................................................... 63 Ronis key interlocks .............................................................. 65 Remote control ..................................................................... 66 Dimensions .......................................................................... 69 Technical data ...................................................................... 75 Environmental certification .................................................... 81

2 Content | Product Catalogue

Applications SafeRing

SafeRing installed in Compact Secondary Substations

SafeRing

RMU type SafeRing CCV / CCF

SafeRing

RMU type SafeRing CCVV / CCFF

SafeRing

SafeRing

RMU type SafeRing DeV / DeF

RMU type SafeRing CCCV / CCCF

Product catalogue | Applications SafeRing 3

Applications SafeRing

DeF

CCF

CCC

DeV

CCV

CCCF

CCFF

CCCC

CCCV

CCVV

SafeRing is a ring main unit for the secondary distribution network. SafeRing can be supplied in 10 different configurations suitable for most switching applications in 12/24 kV distribution networks. It is extendible and combined with the SafePlus concept, which is ABBs flexible, modular compact switchgear, they represent a complete solution for 12/24 kV secondary distribution networks. SafeRing and SafePlus have identical user interfaces. SafeRing is a completely sealed system with a stainless steel tank containing all living parts and switching functions. A sealed steel tank with constant atmospheric conditions ensures a high level of reliability as well as personnel safety and a virtually maintenance-free system. The SafeRing concept offers a choice of either a switch fuse combination or circuit breaker with relay for protection of the transformer. As the first ring main unit, SafeRing can be supplied complete with an integral remote control and monitoring unit.

SafeRing is designed for use in the following applications: Compact secondary substations Small industries Wind power plants Hotels, shopping centres, office buildings, business centres etc. Light mining applications, airports, hospitals, tunnels and underground railways Available modules: C Cable Switch De Direct Cable Connection with Earthing Switch F Switch Fuse-Disconnector V Vacuum Circuit-Breaker

4 Applications SafeRing | Product Catalogue

Applications SafePlus

De

CB

Sl

Sv

Be

Mt

3

A

3 3

3

V

SafePlus is designed for use in the following applications: Compact secondary substations Small industries Wind power plants Hotels, shopping centres, office buildings, business centres etc. Light mining applications, airports, hospitals, tunnels and underground railways Available modules: C Cable Switch De Direct Cable Connection with earthing D Direct Cable Connection F Switch-Fuse Disconnector V Vacuum Circuit breaker Be Busbar earthing Sl Busbar Sectionalizer, load break switch Sv Busbar Sectionalizer, vacuum circuit breaker CB Circuit-breaker module M Metering Module Mt Metering tariff module

Product catalogue | Applications SafePlus 5

Applications SafePlus

SafePlus compact switchgear consisting of: 2-ways section with 2 modules of cable switches air-insulated metering module 2-ways section with 2 modules of switch fuses

SafePlus

SafePlus

SafePlus

CC

FF

REF541

REF541

REF541

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus compact switchgear in fully modular design consisting of: 3 modules of cable switches 3 modules of vacuum circuit breakers in combination with REF relays

6 Applications SafePlus | Product Catalogue

Design philosophy

SafeRing and SafePlus ABB switchgear for secondary distribution Secondary distribution switchgears have been subject to a significant development the past 20 years,resulting in increased functionality and smaller dimensions. The traditional switching cells are substituted with complete switchgear systems. Specific functions as grounding, disconnecting, cable connections, busbar extension, protection and switching have become integrated features in compact functional units. Compact switchgear systems meet customers MV application needs. ABB has always been a part of this development. The current ABB SafePlus range satisfies the most complex system specifications. The most unique specialisation is the development of the cable ring switchgear. The numerous public distribution substations requested a unified switching functionality which evolved into the Ring Main Unit concept. ABB SafeRing range is one major contributor to this specialisation. Two Products One range ABB SafeRing is adapted to the needs in the immense utility distribution network. ABB SafePlus offers more in terms of flexibility and electrical capacity. Both switchgear offer the same customer interface. Customers involvement The applied functionality in ABB SafeRing and SafePlus is a result of input from customers all over the world. Key customers are continuously involved with ABB design staff to ensure optimized switchgear operation. The functionality will always find its background from customer demands. Personnel safety and service Safety is not only a specification and rating issue, but also a real life experience. Standards and associated testing will disclose weakness at time of testing. ABB takes this further to be an objective related to durability and repetitive manufacturing quality.

All products are manufactured in accordance with ISO 9001. The latest edition of relevant IEC standards will always apply to our continuous product development and test program. Integrated functionality is a key objective to reduce the number of moving components, further reducing the risk of any mechanical defect. We are responsible for the environment The location for manufacturing SafeRing and SafePlus is Norway. Norways green policy contributes to focus on environmental factors in manufacturing as well as over the switchgears life span. All products are manufactured in accordance with our ISO 14001 certification. Recycling is confirmed at a 97% level. To simplify this process we will continuously along with our partners develop routines for handling at end of life. Plastic parts are individually marked to simplify the recycling process. Solutions for elimination of gas emission in the rare event of a fault can be supplied. Modern - development and manufacturing Numerical simulations together with long experience will ensure compact and robust design. Dielectric simulations will ensure that compactness will not influence the dielectric capability. The combination of design techniques, experience and the most modern production technology guarantee state of the art products and durability. Complete solutions one supplier Complex applications involving remote control and monitoring can now be supplied from one supplier. This makes large scale implementation feasible, and will simplify engineering and procurement. The control and monitoring unit available for SafeRing is located behind the front cover. This option is also readily available for retrofit, while such demands normally evolve after the switchgear is in service.

Product catalogue | Design philisophy 7

SafeRing configurations

General SafeRing is a ring main unit for the secondary distribution network. SafeRing can be supplied in 10 different configurations suitable for most switching applications in 12/24 kV distribution networks. SafeRing can as an option be delivered as extendable rong main unit. SafeRing combined with the SafePlus concept, which is ABBs flexible, modular compact switchgear represent a complete solution for 12/24 kV secondary distribution networks. SafeRing and SafePlus have identical user interfaces. SafeRing is a completely sealed system with a stainless steel tank containing all the live parts and switching functions. A sealed steel tank with constant atmospheric conditions ensures a high level of reliability as well as personnel safety and a virtually maintenance-free system. The SafeRing concept offers a choice of either a switch fuse combination or circuit breaker with relay for protection of the transformer. SafeRing can be supplied with an integrated remote control and monitoring unit. SafeRing is supplied with the following standard equipment Earthing switches Operating mechanisms with integral mechanical inter locking Operating handle Facilities for padlocks on all switching functions Bushings for cable connection in front with cable covers Lifting lugs for easy handling All 3- and 4-way units are designed for the subsequent fitting of an integral remote control and monitoring unit

Optional features Bushings for connection of external busbar on top of RMU Bushings for side connection (400A) (C-, F- and De modules only) Bushings for cable testing, incl. earthing device (C- and De- modules only) Cable bushings (Interface A, B, C and D) Cable compartment front cover interlocked with earthing switch Interlocking of compartment for cable test bushings Arc suppressor with signal (1NO) wired to terminals (only one each SF 6 tank) Signal (1NO) from internal pressure indicator wired to terminals (only one each SF 6 tank) Latched single spring mechanism for ring cable switch Optional features also available as retrofit Manometer for SF 6 pressure monitoring (temperature compensated) Integrated control and monitoring unit (ICMU) Integrated battery and charger Motor operation Trip coil open Trip coil open and close Aux. switch for load break switch position 2NO + 2NC Aux. switch for vacuum circuit breaker position 2NO + 2NC Aux. switch for disconnected position 2NO + 2NC Aux. switch for earth switch position 2NO + 2NC Aux. switch for fuse blown 1NO Vacuum circuit breaker tripped signal 1NO

Capacitive voltage indicating system Short circuit indicator Cable cover with window Cable cover for double T Arc proof cable compartment Extra base frame (h=450 mm or 290 mm) Top entry box Cable support bars, non-magnetic or adjustable Ronis interlocking system, EL 11 AP Current measuring Prepared for relay test equipment

8 SafeRing configurations | Product Catalogue

SafeRing configurations

SafeRing

DeF Depth: 765 mm Width: 696 mm Height: 1336 mm

SafeRing

CCF Depth: 765 mm Width: 1021 mm Height: 1336 mm

SafeRing

CCCF Depth: 765 mm Width: 1346 mm Height: 1336 mm

SafeRing

CCFF Depth: 765 mm Width: 1346 mm Height: 1336 mm

SafeRing

DeV Depth: 765 mm Width: 696 mm Height: 1336 mm

Product catalogue | SafeRing configurations 9

SafeRing configurations

SafeRing

CCV Depth: 765 mm Width: 1021 mm Height: 1336 mm

SafeRing

CCCV Depth: 765 mm Width: 1346 mm Height: 1336 mm

SafeRing

CCVV Depth: 765 mm Width: 1346 mm Height: 1336 mm

SafeRing

CCC Depth: 765 mm Width: 1346 mm Height: 1336 mm

SafeRing

CCCC Depth: 765 mm Width: 1346 mm Height: 1336 mm

10 SafeRing configurations | Product Catalogue

Technical data SafeRing

SafeRing Switch disconnector Rated voltage Power frequency withstand voltage Lightning impulse withstand voltage Rated normal current Breaking capacities: - active load - closed loop - off load cable charging - off load transformer - earth fault - earth fault cable charging - short-circuit breaking current Making capacity Short time current 0,5 sec. Short time current 1 sec. Short time current 3 sec.

4) 5) 3)

C-module Earthing switch

F-module Switch-fuse disconnector Downstream earthing switch 12/17,5/24 28/38/50 95/95/125 Vacuum

V-module Earthing switch/ disconnector 12/15/17,5/24 28/38/38/50 95/95/95/125 circuit-breaker 12/15/17,5/24 28/38/38/50 95/95/95/125 200/200/200/200

kV kV kV A A A A A A A kA kA kA kA kA

12/15/17,5/24 28/38/38/50 95/95/95/125 630/630/630/630 630/630/630/630 630/630/630/630 135/135/135/135

12/15/17,5/24 28/38/38/50 95/95/95/125

12/17,5/24 28/38/50 95/95/125 see1)

20/20/20 200/150/150/150 115/87/87/87 see2) 52,5/52,5/40/40 52,5/52,5/40/40 see2) 12,5/12,5/12,5 16/16/16/16 40/40/40/40 16/16/16/16 16/16/16 21/21/16/16 21/21/16/16 5/5/5 16/16/16/16 16/16/16/16 16/16/16/16 40/40/40/40

1) 2) 3) 4) 5)

Depending on the current rating of the fuse-link Limited by high voltage fuse-links Maximum rating for bushings Interface A (200 series plug-in) Maximum rating for bushings Interface B (400 series plug-in) Maximum rating for bushings Interface C (400 series bolted)

SafeRing is tested according to IEC publications IEC 60265-1, IEC 6227-1, EC 62271-100, -102, -105, -200 and IEC 60529.

Product catalogue | Technical data SafeRing 11

SafePlus modules

General SafePlus is a metal enclosed compact switchgear system for up to 24 kV distribution applications. The switchgear has a unique flexibility due to its extendibility and the possible combination of fully modular and semi-modular configurations. SafePlus combined with SafeRing, which is ABBs standard ring main unit, represent a complete solution for 12/24 kV distribution networks. SafePlus and SafeRing have identical user interfaces. SafePlus is a completely sealed system with a stainless steel tank containing all live parts and switching functions. A sealed steel tank with constant atmospheric conditions ensures a high level of reliability as well as personnel safety and a virtually maintenance-free system. As an option external busbars can be provided to obtain full modularity. The external busbar kit has to be mounted to the switchgears on site. It is fully insulated and screened to ensure the reliability and climatic independence. The SafePlus system offers a choice of either a switch-fuse combination or a circuit-breaker with relay for protection of the transformer. SafePlus accommodates a wide selection of protection relays for most applications. SafePlus can also be supplied with remote control and monitoring equipment SafePlus (except M- and Mt-modules) is supplied with the following standard equipment: Earthing switches (not for D module) Operating mechanisms with integral mechanical interlocking Operating handle Facilities for padlocks on all switching functions Bushings for cable connection in front (not for Sl, Sv and Be modules) Cable compartment cover Manometer for SF 6 pressure monitoring (temperature compensated) Lifting lugs for easy handling

12 SafePlus modules | Product Catalogue

C - Cable switch

Depth: 765 mm Width: 325 mm Height: 1336 mm

Technical data Switch disconnector Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Breaking capacities: - active load - closed loop - off load cable charging - earth fault - earth fault cable charging Making capacity Short time current 1 sec. Short time current 3 sec. Number of mechanical operations Earthing switch Rated voltage Power frequency withstand voltage Impulse withstand voltage Making capacity Short time current 1 sec. Short time current 3 sec. Number of mechanical operations

kV kV kV A A A A A A kA kA kA 1000 kV kV kV kA kA A 1000

12 28 95 630 630 630 135 200 115 62,5 25 21 close / 12 28 95 62,5 25 21 close /

15 38 95 630

17,5 38 95 630

24 50 125 630 630 630 135 150 87 50 21

630 630 630 630 135 135 150 150 87 87 52,5 50 21 21 open manual 15 17,5 38 38 95 95 52,5 50 21 21 open manual

24 50 125 50 21

Standard features Three position load break switch with disconnector and earthing switch Operating mechanism with two separate operating shafts for load break function and earthing function Switch position indication for load break switch and earthing switch Cable bushings horizontal in front, Interface C (400 series bolted) with integrated voltage divider for voltage indication Cable compartment cover allowing surge arrestor or double cable connection Busbar, 630A Earthing bar Optional features Bushings for connection of external busbar on top of the unit Bushings for side extension (400 A) Bushings for cable testing (incl. earthing device test points) Cable bushings: Interface B (400 series plug-in, In = 400 A) Interface C (400 series bolted) combisensors with integrated capacitor for voltage indication and sensors for current and voltage monitoring Interface D (600 series bolted) Cable compartment front cover interlocked with earthing switch Interlocking of compartment for cable test bushings Arc proof and interlocked cable covers Arc suppressor with signal (1NO) wired to terminals (only one each SF6 tank)

Signal (1NO) from internal pressure indicator wired to terminals (only one each SF 6 tank) Latched single spring mechanism Optional features also available as retrofit Motor operation for load break switch Low voltage compartment / top entry box Base frame (290 or 450 mm) Auxiliary switches for load break switch position and earthing switch position Capacitive voltage indicator, HR-module (Voltage Detecting System, VDS), acc. to IEC 61243 -5, or VPIS, acc. to IEC 61958 with integrated indicator lamps (LED) Indicator lamps, 3-phase VIM-3 Indicator lamp, 1-phase VIM-1 Short circuit indicators Short circuit and earth fault indicators Ronis key interlock External current sensors (CT) for monitoring Cable compartment cover with window, with extra depth (double T, surge arrestors) and arc proof (if existing module have interlocked cable compartment Cable support bars, non-magnetic or adjustable Earthing bar for surge arrestor

Product catalogue | C - Cable switch 13

F - Switch-fuse-disconnector

Depth: 765 mm Width: 325 mm Height: 1336 mm

Technical data Switch-fuse-disconnector Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Breaking capacities: - off load transformer Making capacity Number of mechanical operations Earthing switch downstream Rated voltage Power frequency withstand voltage Impulse withstand voltage Making capacity Short time current 1 sec. Number of mechanical operations

1)

kV kV kV A

12 28 95 200

15 38 95 200

17,5 38 95 200

24 50 125 200 20

1)

A 20 20 20 1) 1) 1) kA 1000 close / open manual kV kV kV kA kA 1000 12 28 95 12,5 5 close / 15 17,5 38 38 95 95 12,5 12,5 5 5 open manual

24 50 125 12,5 5

Limited by high voltage fuse-links

Standard features Three position switch-fuse-disconnector with upstream earthing switch mechanically linked with downstream earthing switch Switch position indication for switch-fuse-disconnector and earthing switches Operating mechanism with double spring for switch-fuse- disconnector function Common mechanism for earthing functions Fuse canisters for DIN type fuse. Only accessible when earthing switches are closed Fuse-link / transformer rating: 12 kV, max 125 A CEF fuses 24 kV, max 63 A CEF fuses Fuse tripping arrangement Optical fuse trip indication Cable bushings horizontal in front, Interface A (200 series plug-in) with integrated capacitor for voltage indication Cable compartment cover allowing surge arrestor or double cable connection Busbar, 630 A Earthing bar Optional features Bushings for connection of external busbar on top of unit Bushings for side extension (400 A) Cable bushings: Interface B (400 series plug-in, In = 400A) Interface C (400 series bolted) Interface C (400 series bolted) combisensors with in tegrated screen for voltage indication and sensors for current and voltage monitoring

14 F - Switch-fuse-disconnector | Product Catalogue

Cable compartment front cover interlocked with earthing switch Signal (1NO) from internal pressure indicator wired to terminals (only one each SF 6 tank) Optional features also available as retrofit Motor operation for switch-fuse-disconnector Low voltage compartment/top entry box Base frame (290 or 450 mm) Auxiliary switches for load break switch position, earthing switch position and fuse blown Capacitive voltage indicator, HR-module (Voltage Detecting System, VDS), acc. to IEC 61243 -5, or VPIS, acc. to IEC 61958 with integrated indicator lamps (LED) Indicator lamps, 3-phase VIM-3 Indicator lamp, single phase VIM-1 Trip coil open Trip coil open and close Cable compartment cover with window, with extra depth (double T, surge arrestors) and arc proof (if existing module have interlocked cable compartment) Cable support bards, non-magnetic or adjustable Earthing bar for surge arrestor Ronis key interlock on earthing switch

V - Vacuum circuit-breaker

Depth: 765 mm Width: 325 mm Height: 1336 mm

1) 2)

Technical data Vacuum circuit-breaker Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Breaking capacities: - short-circuit breaking current Making capacity Short time current 0,5 sec. 1) Short time current 1 sec. 2) Short time current 3 sec. Number of mechanical operations Earthing switch downstream Rated voltage Power frequency withstand voltage Impulse withstand voltage Making capacity Short time current 3 sec. Number of mechanical operations

kV kV kV A kA kA kA

12 28 95

15 38 95 200 /

17,5 38 95 630

24 50 125

21 52,5 16 16 kA 21 2000 close / kV kV kV kA A 1000 12 28 95 52,5 21 close /

21 16 52,5 40 16 16 16 16 21 16 open manual 15 17,5 38 38 95 95 52,5 40 21 16 open manual

16 40 16 16 16

24 50 125 40 16

Maximum rating for bushings Interface A (200 series plug-in) with rated curretn 200 A Maximum rating for bushings Interface B (400 series plug-in)

Standard features 200 A vacuum circuit-breaker for transformer protection or 630 A vacuum circuit-breaker for feeder protection Two position double spring mechanism for vacuum circuit- breaker Three position disconnector/earthing switch downstream vacuum circuit-breaker Three positioning single spring mechanism for disconnector/earthing switch Interlocking between vacuum circuit-breaker and disconnector/earthing switch Switch positioning indication for vacuum circuit-breaker and disconnector/earthing switch Self powered electronic protection relay with ring core CTs on cables (only standard on 200 A) Trip coil (for relay tripping) Cable bushings horizontally in front; Interface A (200 series plug-in) for 200 A vacuum circuit-breaker with integrated capacitor for voltage indication and Interface C (400 series bolted) for 630 A vacuum circuit-breaker with integrated capacitor for voltage indication Cable compartment cover allowing surge arrestor or double cable connection Busbars, 630 A Earthing bar Optional features Bushings for connection of external busbar on top of unit Cable bushings: Interface B (400 series plug-in) Interface D (600 series bolted)

Interface C (400 series bolted) combisensors with integrated voltage divider for voltage indication and integrated sensor for current and voltage monitoring Cable compartment front cover interlocked with earthing switch Arc suppressor (for 630 A vacuum circuit-breaker only) with signal (1NO) wired to terminals (only one each SF 6 tank) Signal (1NO) from internal pressure indicator wired to terminals (only one each SF 6 tank) Optional features also available as retrofit Motor operation for vacuum circuit-breaker Low voltage compartment / Top entry box Base frame (290 or 450 mm) Auxiliary switches; Vacuum circuit breaker position 2NO+2NC, disconnector position 2NO+2NC, earthing switch position 2NO+2NC and vacuum circuit-breaker tripped signal 1NO Capacitive voltage indicator; HR-module (Voltage Detecting System, VDS, acc. to IEC 61243 -5, or VPIS, acc. to IEC 61958 with integrated indicator lamps (LED) Indicator lamps, 3-phase VIM-3 Indicator lamp, 1-phase VIM-1 Trip coil open Trip coil open and close Cable compartment cover with window, with extra depth (double T, surge arrestors) or arc proof (if existing module has interlocked cable compartment) Cable support bars, non-magnetic Ronis key interlock on disconnector / earthing switch Advanced relays type SPAJ, REF and others.

Product catalogue | V - Vacuum circuit-breaker 15

Sl - Busbar sectionalizer

Depth: 765 mm Width: 325 mm Height: 1336 mm

Depth: 765 mm Width: 650 mm Height: 1336 mm Busriser is needed when Sl-module is on right hand side of SF 6-tank

Technical data Busbar sectionalizer Sl Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Breaking capacities: - active load - closed loop - off load cable charging - earth fault - earth fault cable charging Making capacity Short time current 1 sec. Short time current 3 sec. Number of mechanical operations Earthing switch Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Making capacity Short time current 1 sec. Short time current 3 sec. Number of mechanical operations

kV kV kV A A A A A A kA kA kA 1000 kV kV kV A kA kA A 1000

12 28 95 630 630 630 135 200 115 62,5 25 21 close / 12 28 95 630 62,5 25 21 close /

15 38 95 630

17,5 38 95 630

24 50 125 630 630 630 135 150 87 50 21

630 630 630 630 135 135 150 150 87 87 52,5 50 21 21 open manual

15 17,5 24 38 38 50 95 95 125 630 630 630 52,5 50 50 21 21 21 open manual

Standard features Three positioning load break switch with disconnector and earthing switch Operating mechanism with two separate operating shafts for load break function and earthing function Switch position indication for load break switch and earthing switch Busbars, 630 A Earthing bar Optional features Bushings for connection of external busbars on top of the unit Signal (1 NO) from internal pressure indicator wired to ter minals (only one each SF 6 tank) Latched single spring mechanism

Optional features also available as retrofit Motor operation for load break switch Low voltage compartment/Top entry box Base frame (290 or 450 mm) Auxiliary switches, load break switch position 2NO+2NC and earthing switch position 2NO+2NC Ronis key interlock

16 Sl - Busbar sectionalizer | Product Catalogue

Sv - Busbar sectionalizer

Depth: 765 mm Width: 650 mm Height: 1336 mm

Sv is always in combination with busrise module (Br)

Technical data Busbar sectionalizer Sv Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Breaking capacities: - short-circuit breaking ccurrent Making capacity Short time current 3 sec. Number of mechanical operations Earthing switch Rated voltage Power frequency withstand voltage Impulse withstand voltage Making capacity Short time current 3 sec. Number of mechanical operations

kV kV kV A kA kA kA 2000 kV kV kV kA A 1000

12 28 95 630 21 52,5 21 close / 12 28 95 52,5 21 close /

15 38 95 630

17,5 38 95 630

24 50 125 630 16 40 16

21 16 52,5 40 21 16 open manual 15 17,5 38 38 95 95 52,5 40 21 16 open manual

24 50 125 40 16

Standard features 630 A vacuum circuit-breaker Two position double spring mechanism for vacuum circuit- breaker Three position disconnector / earthing switch downstream vacuum circuit-breaker Three position single spring mechanism for disconnector / earthing switch Interlocking between vacuum circuit-breaker and disconnector / earthing switch Switch position indication for vacuum circuit-breaker and disconnector / earthing switch Busbars, 630 A Optional features Bushings for connection of external busbar Signal (1 NO) from internal pressure indicator wired to terminals (only one each SF 6 tank)

Optional features also available as retrofit Motor operation for vacuum circuit-breaker Low voltage compartment / Top entry box Base frame (290 or 450 mm) Auxiliary switches, vacuum circuit-breaker position 2NO+2NC, disconnector position 2NO+2NC and earthing switch position 2NO+2NC Protection relay (metering module is required) Trip coil for relay trip Additional trip coil Ronis key interlock on disconnector / earthing switch

Product catalogue | Sv - Busbar sectionalizer 17

D - Direct cable connection

Technical data Direct cable connection Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Short time current 1 sec. Short time current 3 sec.

kV kV kV A kA kA

12 28 95 630 25 21

15 38 95 630 21

17,5 38 95 630 21

24 50 125 630 21

Depth: 765 mm Width: 325 mm Height: 1336 mm

Standard features Cable bushings horizontally in front, Interface C (400 series bolted) with integrated capacitor for voltage indication. Cable compartment cover allowing surge arrestor or double cable connection Busbars, 630 A Earthing bar Optional features Bushings for connection of external busbars Cable bushings: Interface B (400 series plug-in) (In = 400 A) Interface C (400 series bolted) combisensors with integrated capacitor for voltage indication and sensors for current and voltage monitoring Interface D (600 series bolted) Arc suppressor with signal (1NO) wired to terminals (only one each SF 6 tank) Signal (1NO) from internal pressure indicator wired to terminals (only one each SF 6 tank)

Optional features also available as retrofit Low voltage compartment / top entry box Base frame (290 or 450 mm) Capacitive voltage indicating systems, HR-module (Voltage Detecting System, VDS, acc. to IEC 61243 -5, or VPIS, acc. to IEC 61958 with integrated indicator lamps (LED) Indicator lamps for HR-module, 3-phase VIM-3 Indicator lamp for HR-module, 1-phase VIM-1 Short circuit indicators Earth fault indicators External current sensors (CT) for monitoring Cable compartment cover with window, with extra depth (double T, surge arrestors) or arc proof (if existing module has interlocked cable compartment) Cable support bars, non-magnetic or adjustable Earth bar for surge arrestor

18 D - Direct cable connection | Product Catalogue

De - Direct cable connection with earthing switch

Technical data Direct cable connection with earthing Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Making capacity Short time current 1 sec Short time current 3 sec. Number of mechanical operations

switch kV 12 kV 28 kV 95 A 630 kA 62,5 kA 25 kA 21 1000 close /

15 38 95 630 52,5

17,5 38 95 630 50

24 50 125 630 50 21

21 21 open manual

Depth: 765 mm Width: 325 mm Height: 1336 mm

Standard features Earthing switch Two positioning single spring mechanism Switch position indication Cable bushings horizontal in front, Interface C (400 series bolted) with integrated capacitor for voltage indication Cable compartment cover allowing surge arrestor or double cable connection Busbars, 630 A Earthing bar Optional features Bushings for connection of external busbars Bushings for cable testing, incl. earthing device Cable bushings: Interface B (400 series plug-in) (In = 400 A) Interface C (400 series bolted) combisensors with integrated capacitor for voltage indication and sensors for current and voltage monitoring Interface D (600 series bolted) Cable compartment front cover interlockied with earthing switch Interlocking of compartment for cable test bushings Arc suppressor with signal (1NO) wired to terminals (only one each SF 6 tank) Signal (1NO) from internal pressure indicator wired to terminals (only one each SF 6 tank)

Optional features also available as retrofit Low voltage compartment / Top entry box Base frame (290 or 450 mm) Capacitive voltage indicating systems, HR-module (Voltage Detecting System, VDS, acc. to IEC 612-43-5, or VPIS, acc. to IEC 61958 with integrated indicator lamps (LED) Indicator lamps for HR-module, 3-phase VIM-3 Indicator lamp for HR-module, 1-phase VIM-1 Short circuit indicators Earth fault indicators External current sensors (CT) for monitoring Cable compartment cover with window, with extra depth (double T, surge arrestors) and arc proof (if existing module has interlocked cable compartment) Cable support bars, non-magnetic or adjustable Earth bar for surge arrestor Auxiliary switches, earthing switch position 2NO+2NC Ronis key interlock

Product catalogue | De - Direct cable connection with earthing switch 19

Be - Busbar earthing

Technical data Busbar earthing Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Making capacity Short time current 1 sec Short time current 3 sec. Number of mechanical operations

kV kV kV A kA kA kA 1000

12 28 95 630 62,5 25 21 close /

15 38 95 630 52,5

17,5 38 95 630 50

24 50 125 630 50 21

21 21 open manual

Depth: 765 mm Width: 325 mm Height: 1336 mm

Standard features Earthing switch Two position single spring mechanism Switch position indication for earthing switch Busbars, 630 A Earthing bar Optional features Bushings for connection of external busbars Signal (1NO) from internal pressure indicator wired to ter minals (only one each SF 6 tank) Optional features also available as retrofit Low voltage compartment / Top entry box Base frame (290 or 450 mm) Auxiliary switches, earthing switch position 2NO+2NC Ronis key interlock

20 Be - Busbar earthing | Product Catalogue

CB - Circuit-breaker module

REF541

SafePlus

M

VD4

Technical data Circuit-breaker module Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Breaking capacities: Short-circuit breaking current Making capacity Short time current 1 sec Short time current 3 sec. Number of mechanical operations

kV kV kV A

12 28 95 630 / 1250

24 50 125 630 / 1250

kA 25 20 kA 62,5 50 kA 25 20 kA 25 20 30000 close / open manual

Depth: 800 mm Width: 696 mm Height: 1336 mm

Standard features 630/1250A vacuum circuit breaker Disconnector Earthing switch Bushings for connection of external busbars Auto reclosing sequence Closing and tripping coil Combisensors with Interface C (400 series bolted) Low voltage compartment with different protection relays Optional features Signal (1NO) from internal pressure indicator wired to terminals Optional features also available as retrofit Base frame (290 or 450 mm) Motor operated disconnector / earthing switch Motor operating mechanism, circuit-breaker

A selection of configurable functions Protection: non-directional overcurrent protection, 3 stages directional overcurrent protection, 3 stages non-directional earth-fault protection directional earth-fault protection residual overvoltage protection 3-phase thermal overload 3-phase overvoltage protection under- or overfrequency incl. rate of change, 5 stages Measurement: 3-phase current neutral current 3-phase voltage residual voltage 3-phase power and energy incl. cos phi transient disturbance recorder Optional functionality Capacitor bank protection Capacitor bank control Power quality Auto changeover

Product catalogue | CB - Ciscuit-breaker module 21

M - Metering module

SafePlus

3

A

3

V

Technical data Metering module Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Short time current 1 sec Short time current 3 sec.

kV kV kV A kA kA

12 28 95 630 25 21

15 38 95 630 21

17,5 38 95 630 21

24 50 125 630 21

The M-module is a factory assembled type tested air insulated metering cubicle with conventional CTs and VTs. The M-module is designed for CTs and VTs with dimensions according to DIN 42600 Narrow type. The M-module is also designed for tariff metering. Depth: 802 mm Width: 696 mm Height: 1806 mm

Standard features 2 or 3 pcs (has to be specified) DIN 42600 Narrow type current transformers with ribs 3 pcs DIN 42600 Narrow type single pole voltage trans formers 6 pcs bushings Interface C (400 series bolted) with con nections and external busbars for SafePlus modules on left and right hand side 3 pcs bushings Interface C (400 series bolted) only re quired if the M-module is left hand side or right hand side end module Internal layout with CTs and VTs on left hand side or right hand side dependent of power direction (has to be speci fied) Padlock interlocking to prevent access to live parts Voltage transformers Single pole insulated with measuring and earth fault windings Primary voltage and frequency (50 or 60 Hz) has to be specified Secondary windings --/110:V3/110:3V or --/100:V3/100:3V has to be specified Note: VTs can also be delivered without open Delta Earth fault windings Burden / class has to be specified

22 M - Metering module | Product Catalogue

M - Metering module

Current transformers Single-core or double-core design Secondary side reconnectable possible Primary current max. 600 Amp., has to be specified Secondary current 5 Amp or 1 Amp. has to be specified Burden / class has to be specified Low voltage compartment Terminals for voltage transformers secondary connection 3-pole MCB for measuring voltage 1-pole MCB for earth fault voltage Damping resistor for voltage transformers open delta earth fault windings, to avoid ferro resonance Separating terminals for current transformers secondary windings Space for electronic kWh-meter Optional features Primary fuses for voltage transformers Voltmeter with selector switch, 6 positions +0 A-meter with selector switch, 3 positions +0 Additional meters Ronis key interlocking to prevent access to live parts Cable bottom entry for outgoing cable Metering module delivered for voltage measuring only Metering module delivered without low voltage equipment and wiring Metering module delivered without VTs and CTs, with connections only Optional features also available as rtrofit Base frame (290 or 450 mm)

Product catalogue | M - Metering module 23

Mt - Metering tariff module

SafePlus

Technical data Metering tariff module Rated voltage Power frequency withstand voltage Impulse withstand voltage Rated normal current Short time current 1 sec.

kV kV kV A kA

12 28 95 630 20

24 50 125 630 20

Depth: 1047 mm Width: 800 mm Height: 1806 mm

The Mt-module is a factory assembled type tested air insulated non arc proof metering cubicle with conventional CTs and VTs. The Mt-module is designed for CTs and VTs with dimensions according to DIN 42600 Narrow type and for installation of transformers locally. The Mt-module is manufactured and tested according to IEC 62271-200. It is available in 3 versions: Bottom cable in/out (A) Left side top connection for outgoing cable, bottom cable in (B) Right side top connection for outgoing cable, bottom cable in (C)

3

SafePlus

SafePlus

SafePlus

Standard features 3 pcs DIN 42600 Narrow type current transformers with ribs 3 pcs DIN Narrow type single pole voltage transformers Padlock interlocking to prevent access to live parts MV cable connection to SafePlus cubicle using Elastimold, 3M, Pirelli, Raychem, Kabeldon, etc. connectors MV cable connection inside Mt-module by conventional cable lugs Voltage transformers Single pole insulated with measuring and earth fault wind ings Primary voltage and frequency (50 or 60 Hz) has to be specified Secondary windings --/110:V3/110:3V or --/100:V3/100:3V has to be specified Note: VTs can also be delivered without open Delta Earth fault windings Burden / class has to be specified Current transformers Single-core or double-core design Secondary side reconnectable possible Primary current max 600 Amp, has to be specified Secondary current 5 Amp or 1 Amp has to be specified

24 Mt - Metering tariff module | Product Catalogue

Outer assembly

5 17 1

SafePlus

8 9 Upper front cover 1. Manometer 2. Nameplate module 3. Short circuit indicator 4. Capacitive voltage indication 5. Load break / earthing switch position indicator 6. Push buttons close/open operation 7. Charged spring indicator 8. Self powered protection relay 9. Vacuum circuit-breaker position Lower front cover 10. Nameplate switchgear 11. Fuse blown indicator 12. Disconnector / earthing switch position indicator 13. Capacitive voltage indication Cable compartment cover 14. Cable compartment cover standard 15. Cable compartment cover with inspection window 16. Support bar (removable) Side cover 17. Lifting lug 18. Operating handle (standard on right hand side) Covers Upper and lower front cover have a thickness of 3 mm aluminium which is covered with a polycarbonate foil. These foils contain the mimic diagram of the main circuit with the position indicators for the switching devices. Background colour for these foils is light grey (RAL 7035). The upper front cover is removable. The lower front cover can be opened. There are four different cable compartment covers; standard, with inspection window, arc proof and with extra depth for parallel cables. These covers are manufactured from 1.25 mm aluzink (except the arc proof cover) and are powder painted with colour RAL 7035. All cable compartment covers are removable. Each module has a separate cable compartment which is divided from the others by means of partition walls. These partition walls can easily be removed, allowing a comfortable access for connection of cables. A vertical partition wall is fitted to divide the cable compartment(s) from the rear side of the switchgear / ring main unit. In case of an arc fault inside the SF6 tank, followed by an opening of the pressure relief in the bottom of the tank, this partition wall will prevent the hot gases blowing out from the pressure relief to enter the cable compartments. Side covers are made of 2 millimeter hot rolled steel and powder painted with colour RAL 7035.

Product catalogue | Outer assembly 25

2 3 4 10 11 12 13 18

15

14

16

Cable switch module

The cable switch (C-Module) is a three positioning switchdisconnector and earthing switch using SF6 gas as an arc quenching medium. The switch positioning is close open earthed. In the open position the switch satisfies the disconnector requirements.

C-module equipped with arc suppressor (optional equipment) and cable test bushings (optional equipment).

26 Cable switch module | Product Catalogue

Vacuum circuit-breaker module

The vacuum circuit-breaker (V-Module) has vacuum bottles as interrupters of the current. In series with the circuit-breaker main circuit is connected a three-position disconnector/earthing switch. The operation between vacuum circuit breaker and disconnector/earthing switch is mechanically interlocked.

Product catalogue | Vacuum circuit-breaker module 27

Switch-fuse module

The switch-fuse (F-module) has a three positioning switch disconnector and earthing switch identical to the cable switch (C-module). By means of the fuse tripping device it operates as a switchfuse combination. There is a double earthing switch which in earthed position connects earth to both sides of the fuse-links simultaneously. Both earthing switches are operated in one operation. The switch-fuse and earthing switch is mechanically interlocked to prevent hazardous access to the fuse-links. The lower cover which gives access to the fuse-links is also mechanically interlocked with the earthing switch.

3-ways unit consisting of two C-modules and one F-module. Both C-modules are equipped with arc suppressor (optional equipment) and cable test bushings (optional equipment).

28 Switch-fuse module | Product Catalogue

Cable bushings

The connection of the HV-cables is made by cable bushings. The bushings are made of cast resin with moulded-in conductors. In addition, a screen is moulded in to control the electrical field and is also used as the main capacitor supplying the voltage indicating systems. ABB has produced bushings for SF6 switchgears since 1985. Up to date production facilities and highly advanced robots and test equipment ensure the high quality required for each single device. A very high number of units have been installed worldwide in distribution networks, power stations and industrial complexes. Used together with full-screened connectors an ideal solution for areas with a history of humidity or condensation problems is achieved. The bushings are designed according to Cenelec EN 50181, EDF HN 52-S-61 and IEC 60137. There are 5 different cable bushings: Interface A (200 series with plug-in contact, In=200A) Interface B (400 series with plug-in contact, In=400A) Interface C (400 series with M16 bolted contact, In=630A) Interface C (400 series with M16 bolted contact) and inte grated voltage and current sensors (In=630A) Interface D (600 series with M16 bolted contact, In=630A)

Product catalogue | Cable bushings 29

Arc suppressor

The arc suppressor is an optimal quick-make short circuit device with a mechanical pressure detector that can be installed with each incoming feeder inside the sealed SF6 tank of the SafeRing and SafePlus switchgear. If an arc fault should occur inside the SF6 tank the pressure detector of the arc suppressor will automatically trip the short circuit device of the incoming feeder(s) within milliseconds, thereby transforming the arc fault into a bolted fault. The arc is extinguished without any emission of hot gases and the bolted short circuit will be interrupted by the upstream circuit-breaker. No links or release mechanisms are installed outside the tank. Corrosion and any environmental influences are therefore prevented, giving optimum reliability. The pressure detector is insensitive to pressure changes due to variation in atmospheric temperature or pressure as well as external phenomena such as vibrations or shocks. The arc suppressor will operate for short-circuit currents in the range of 1kArms to 21kArms and it will reduce the generated arc energy to less than 5% of the arc energy released during an arcing time of 1 sec. A signalling device (1NO) will indicate local or remote the tripping of one or more arc suppressors. Since the system is self-contained, an internal arc fault will have no impact on the surroundings. No arc fault tests have to be repeated in combination with channel release systems or transformer stations. The costs of the cleaning work which has to be done after an internal arc fault when the release flap has opened, are reduced to zero.

30 Arc suppressor | Product Catalogue

Completely sealed system

SafeRing and SafePlus use SF6 gas (Sulphur hexafluoride) as insulation and quenching medium. The SF6 is contained in a welded stainless steel tank, which is hermetically sealed. The pressure system is defined as a sealed for life system with an operating life time exceeding 30 years. The leakage rate is less than 0,1% per year. In order to guarantee a reliable and tight welding, all welding work is carried out by computer controlled robots. Electrical and mechanical bushings penetrating the tank are clamped and sealed to the tank by high quality O-rings. The mechanical bushing has in addition a rotating shaft which connects the shaft of the switch to the corresponding shaft of the mechanism. The rotating shaft is sealed by a double set of gas seals. All SF 6-tanks have to pass a leakage test, before gas filling. Leakage test and gas filling are done inside a vacuum chamber. The first step in the leakage test is to evacuate all air inside both SF 6-tank and vacuum chamber simultaneously. Then the SF 6-tank is filled with Helium. Due to the characteristics of Helium this test will detect absolutely all possible leakages. If the SF 6-tank passes this test, the Helium will be evacuated and replaced by SF 6. The SF6-tank has a degree of protection of IP67, and can be immersed into water and still maintain all functions in a satisfactory way.

Product catalogue | Completely sealed system 31

Cable test bushings

As an option, both C- and De-modules can be equipped with cable test bushings situated behind the lower front cover. This cover can be interlocked against the earthing switch to avoid access to the cable test compartment before earthing switch is in closed position. When these bushings are mounted, cable insulation test can easily be done according to the following procedure:

Principle sketch for testing: 1. Close the earthing switch after having checked the voltage indicators 2. Open compartment cover 3. Install the injection device onto the access terminals 4. Open the removable earthing bridge 5. Perform cable testing 6. Re-install the earthing bridge 7. Remove the injection device 8. Close compartment cover 9. Open the earthing switch If the switchgear is not equipped with cable test bushings, cable testing is possible directly at the cable connectors if they are designed for this purpose, please follow the suppliers instruction.

32 Cable test bushings | Product Catalogue

Mechanisms and interlocks

C-module

F-module

V-module

All operating mechanisms are situated outside the SF6-tank behind the front covers with degree of protection of IP2X. This gives the opportunity of easy access to all operating mechanisms if retrofit or service should be required. The speed of operation of these mechanisms is independent of the operator. To prevent access to cable compartment before earthing switch is in closed position, all mechanisms can as an option be supplied with mechanical interlocks which make it impossible to remove the cable compartment covers. It will then also be impossible to operate load break / disconnector switch to open position before cable compartment cover is mounted properly. Each mechanism is equipped with a padlocking device. When adding a padlock to this device, the access to operate the mechanism will be impossible. This device has three holes with diameter 9 millimeter.

Mechanisms front view. SF6-tank with operating mechanisms.

All operating mechanisms are equipped with position indicators for all switches. In order to achieve true indication, indicators are directly connected to the operating shafts of the switches inside the SF6-tank, please see shafts shown with red colour on next page. Operating handle has an anti-reflex system which prevents an immediate re-operation of the switch.

Product catalogue | Mechanisms and interlocks 33

Mechanisms and interlocks

SF6

Air

Cable switch module and Busbar sectionalizer with load break switch (C-mechanism) The mechanism (3PKE) has two operating shafts; the upper one for the load break switch and the lower one for the earthing switch. Both shafts are single spring operated and operate one common shaft which is directly connected to the three position switch (CFE-C) inside the SF6-tank. When both load break switch and earthing switch are in open position, the switch satisfies the specifications of disconnector. Due to the mechanical interlock between the upper and lower operating shaft, it is impossible to operate the load break switch when earthing switch is in earthed position or operate the earthing switch when the load break switch is in closed position. Switch-fuse module (F-mechanism) The mechanism (3PAE) has two operating shafts; the upper one for the load break switch and the lower one for the earthing switch. The upper one operates two springs; one for closing and one for opening. Both springs are charged in one operation. By means of mechanical push buttons it is then possible to close and open the load break switch. The opening spring is always charged when the load break switch is in closed position and will be ready to open the load break switch immediately if one of the HV-fuse-links blow. The blown fuse-link(s) has/have to be replaced before the operator will be able to close the load break switch again. According to IEC 60282-1, all three fuse-links should be replaced, even if only one or two have operated. The lower shaft is single spring operated. Both operating shafts operate one common shaft which is directly connected to the three position switch (CFE-F) inside the SF6-tank. Due to the mechanical interlock between the upper and lower operating shaft, it is impossible to operate the load break switch when earthing switch is in earthed position or operate the earthing switch when the load break switch is in closed position. It will also be impossible to get access to the fuse compartment before earthing switch is in closed position.

C-mechanism

SF6

Air

F-mechanism

34 Mechanisms and interlocks | Product Catalogue

Mechanisms and interlocks

SF6

Air Vacuum circuit breaker and busbar sectionalizer with circuit breaker (V-mechanism) These two modules have two mechanisms; the upper one (2PA) with one operating shaft is for circuit breaker and the lower one (3PKE) with two operating shafts is for disconnector and earthing switch. The upper mechanism has two operating springs; one for closing and one for opening. Both springs are charged in one operation. By means of mechanical push buttons it is then possible to close and open the circuit breaker. The opening spring is always charged when the circuit breaker is in closed position and will be ready to open immediately if the protection relay gives a trip signal. However a quick reclosing is not possible. If the mechanism is equipped with a motor operation a reclosing will take approx. 10 seconds. The lower mechanism is identical to the one described above for cable switch module. There is a mechanical interlock between these two mechanisms which prevents operating of the disconnector and earthing switch when the circuit breaker is in closed position. When the earthing switch is in closed position it will be impossible to operate the disconnector, but the circuit breaker can be closed for testing purpose.

V-mechanism

Product catalogue | Mechanisms and interlocks 35

External busbars on top

SafePlus

On the top of all SafeRing and SafePlus switchgears it is possible as an option to have bushings for connection of external busbars on the left and / or right side. For a SafePlus switchgear consisting of only one module, only one set of bushings on the top is used. When bushings are mounted on the top, you will have these possibilities: 1. When adding a dead end receptacle to each of these bushings, SafeRing/SafePlus will be prepared for future busbar extension.

SafePlus prepared for future extension on right hand side

SafePlus

SafeRing

2. With an external busbar kit, it is possible to connect two or more sections. Since a 5-ways switchgear is the maximum size within one common SF 6-tank, the busbar kit allows a configuration with more than 5 modules. The installation of the external busbars has to de done on site, see separate manual for installation instructions, 1VDD006006 GB.

SafePlus consisting of two sections connected to each other by means of external busbar kit

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus

The complete extension kit and the dead end receptacles are fully screened, earthed and insulated with EPDM rubber. This makes a safe and reliable switchgear extension. In addition protection covers are available as an option.

SafePlus with external busbar cover

36 External busbar on top | Product Catalogue

External busbars on top

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus switchgear can also be configured fully modular. This gives 1250 A busbar rating. The busbars between the modules and the end adapters used on the left and right side are identical to the parts used in the previous example. For the three modules in the middle a special cross adapter is used.

SafePlus with a fully modular design

SafePlus

SafePlus

SafePlus

The length of the external busbars are dependant of the type of modules to be connected.

SafePlus with one incomer (C-module), one Metering module (M-module) and three fused T-offs (F-modules), prepared for future extension

Top view

Top view with busbar cover mounted

Product catalogue | External busbar on top 37

Side extension

SafeRing

SafePlus

On the side of SafeRing and SafePlus C- and F-modules it is possible as an option to have bushings for connection of external busbars on the left and the right side. The rated current of the side connection is limited to 400A. For a 1-way SafePlus C- or F-module, one or two sets of bushings can be installed. This is also applicable for a 2-way unit. When bushings are mounted on the side, you will have these possibilities: 1. When adding a dead end receptacle to each of these bushings, SafeRing/SafePlus will be prepared for future busbar extension. 2. With a special designed connection kit, it will be possible to connect two or more sections. Since a 5-ways switchgear is the maximum size within one common SF6-tank, the busbar kit allows a configuration with more than 5 modules. The second switchgear can consist of maximum 2 modules. The installation of the external busbars has to de done on site, see separate manual for installation instructions, 1VDD006106 GB.

SafePlus

SafePlus

SafePlus

SafePlus

SafePlus switchgear can also be configured fully modular. The busbars between the modules and the end adapters used on the leftmost and rightmost module are identical to the parts used in the previous example.

38 Side extension | Product Catalogue

Base frame

REF 610

REF 610

REF 610

SafePlus

When SafeRing or SafePlus are placed directly on a floor, the height from the floor to the centre of the cable bushings is 595 millimeter. If there is no cable trench, this height might not be sufficient for proper installation of cables. It is then possible to place the switchgear on an additional base frame.

SafePlus

SafePlus

This base frame is available in two different heights; 290 and 450 millimeter. Inside the standard cable compartment for the vacuum circuit-breaker it will be enough space for three current transformers for protection relay. If an earth fault transformer or an extra set of current transformers are required, an additional base frame is necessary, please see examples on left hand side. The base frame has openings for cable entrance from the bottom and from both sides. It is delivered as a kit and has to be assembled on site.

Base frame 450 mm with earth fault transformer and extra set of current transformers

Base frame 290 mm with an extra set of current transformers

Base frame 290 mm with earth fault transformers

Front view

Side view

Rear view

Product catalogue | Base frame 39

Low voltage compartment

SafeRing

If motor operation, coils, auxiliary switches, self powered protection relay etc. are mounted on a SafeRing or SafePlus module, the terminal blocks and the wiring are located behind the front covers. However, an additional top entry box can be mounted on the top of all SafeRing and SafePlus switchgears. Since the top entry box is fixed to the side covers of the SF6 tank, the total width of the switchgear must be covered.

Top entry box with A-meter and selector switch

The top entry box allows entrance of the customers low voltage wiring from the rear side, left hand side and right hand side. Furthermore the top entry box gives the opportunity to install ammeters with position switches, local/remote switch for motor operation etc. Additionally all SafePlus switchgears can be supplied with low voltage compartment. This compartment may be equipped with protection relays, meters, position switches, terminal blocks etc. The compartment is fixed to the side covers of the SF6 tank and must cover the total width of the switchgear. However, each module has a separate hinged door, but there are no partition walls between the modules. The low voltage compartment has the possibility of cable entry from either left or right hand side.

Side view

Top entry box seen from above when front / top covers have been removed

REF541

SafePlus

Low voltage compartment with REF541 relay

40 Low voltage compartment | Product Catalogue

Motor operation

Closing and opening operations of load-break switches and charging of the springs of the mechanisms for the circuit breaker and the switch-fuse combination may be performed with a motor operation. Disconnector in the V-module and all earthing switches do not have this possibility. All motor devices require DC voltage. If control voltage is either 110 or 220 VAC, a rectifier is integrated in the control unit.

Characteristics of motor operation for C-module Rated voltage (V) 24 48 60 110 220 Power consumption (W) or (VA) 90 150 90 90 90 6-9 4-7 6-9 6-9 6-9

Operating cycle for motor operation is CO - 3 min (i.e. it may be operated with a frequency of up to one close and one open operation every third minute). Motors and coils can easily be mounted to the mechanisms after delivery (retrofit). Test voltage for tables below is + 10/ - 15 % for motor operations and closing coils and +10/ -30% for trip coils and opening coils. The motor and coils can easily be mounted to the mechanisms after delivery (retro-fit).

Peak start current (A) 14 13 7 3 1,7 F 6,3 A F4A F4A F2A F1A 6-9 4-7 6-9 6-9 6-9 Fuse

Operation times Closing time (s) Opening time (s)

Characteristics of motor operation for F-module Rated voltage (V)) 24 48 60 110 220 Power consumption (W) or (VA) 160 200 140 140 140 9-14 5-9 8-13 8-13 8-13 Operation times Charge/Closing time (s) Opening time (ms) 40-60 40-60 40-60 40-60 40-60 Peak start current (A) 14 13 7 3 1,7 F 6,3 A F4A F4A F2A F1A Fuse

Characteristics of motor operation for V-module Rated voltage (V) 24 48 60 110 220 Power consumption (W) or (VA) 180 220 150 170 150 10-17 5-9 9-13 9-13 9-14 Operation times Charge/Closing time (s) Opening time (ms) 40-60 40-60 40-60 40-60 40-60 Peak start current (A) 14 13 7 3 1,7 F 6,3 A F4A F4A F2A F1A Fuse

Characteristics of shunt trip coils, closing coils and opening cioils for F-and V-module Rated voltage (V) 24 V DC 48 V DC 60 V DC 110 V DC 220 V DC 110 V AC 230 V AC Power consumption (W) or (VA) 150 200 200 200 200 200 200 40-60 40-60 40-60 40-60 40-60 40-60 40-60 Operation times Closing time (ms) Opening time (ms) 40-60 40-60 40-60 40-60 40-60 40-60 40-60 Peak start current (A) 6 4 3 2 1 2 1 Fuse for closing coil Y2

(Opening coil Y1 is unfused)

F 3,15 A F2A F 1,6 A F1A F 0,5 A F1A F 0,5 A

Product catalogue | Motor operation 41

Motor operation

12 5

13 7 10 11 1 3 2 14 3 15 6 16

3 2

18

17

SafePlus consisting of CFV modules equipped with various auxiliary switches, coils and motor operation 1. Terminal blocks/control unit motor operation 2. Auxiliary switch S7, load break switch 3. Auxiliary switch S10, earthing switch 4. Opening coil Y1 5. Closing coil Y2 6. Auxiliary switch S9, fuse blown 7. Motor operation 8. Relay trip coil Y3 / Y4 / Y5 /Y6* 9. Auxiliary switch S9, circuit breaker tripped signal 10. Auxiliary switch S5, circuit breaker 11. Auxiliary switch S6, mechanism latched 12. Auxiliary switch S8, spring charged 13. Auxiliary switch S14, operating handle, VCB 14. Auxiliary switch S15, operating handle, disconnector 15. Auxiliary switch S7, disconnector 16. Auxiliary switch S13, cable compartment cover 17. Auxiliary switch S20, arc suppressor 18. Auxiliary switch S19, SF6 gas pressure * Depending of the type of protection relay, the V module can only be delivered with one of the relay trip coils.

42 Motor operation | Product Catalogue

Transformer protection

SafeRing

SafeRing and SafePlus offer a choice between a switch fuse combination and circuit breaker in combination with relay for transformer protection. The switch-fuse combination offers optimal protection against short-circuit currents, while the circuit-breaker with relay offers better protection against low over-currents. Circuit breaker with relay is always recommended for higher rated transformers. SafeRing is delivered with a 200 A rated V-module. SafePlus V- module has two options: 200 or 630 A rating. Both for SafeRing and SafePlus the relay is a self powered relay that utilizes the energy from the CTs under a fault situation, for energizing the trip coil. The self powered relay can also be used for cable protection and more details on the different relays can be found in chapter 6.5. Transformer protection with self powered relay. Recommended types: ABB relay type REJ 603 SEG WIC 1 Important features V-module: Relay behind cover. No need for additional low voltage box for the self powered relays used for transformer protection. Typical for vacuum circuit breaker protection: Good protection against short-circuits Very good for protection of over currents Small fault currents are detected in an early stage

SafeRing and SafePlus - Fuse-link selection by selection of fuse-links for the protection of a transformer, itis important that requirements in IEC 62271-105 and in IEC 69787 are fulfilled. In particular annex A in IEC 62271-105 gives a good example of the coordinationof fuse-links, switch and transformer. Correct selection of fuse-links for the protection of the transformer will give: Optimal protection of the transformer No damage on the fuse-links fuse-elements due to the magnetizing inrush current of the transformer No overheating of the fuse-links, the switch-fuse combi- nation or the switchgear due to the full load current or the permissible periodic overlaod current of the transformer A transfer current of the combination which is as low as possible, and less than the rated transfer current of the switch-fuse combination A situation where the fuse-links alone will deal with the condition of a short-circuit on the transformer secondary terminals Fuse-links that discriminate with the low-voltage fuse-links in the event of phase-to-phase faults occurring down stream the low-voltage fuse-links By carefully checking that these rules are followed, fuse-links from any manufacturer can be used in combination with SafeRing and SafePlus as long as the fuse-links are in accordance with the requirements described in chapter 6.5

Product catalogue | Transformer protection 43

Fuse selection table

Fuse table for modules

100% Un (kV) 3 3,3 4,15 5 5,5 6 6,6 10 11 12 13,8 15 17,5 20 22 24 25 16 16 10 10 6 6 6 6 6 6 6 6 6 6 6 6 50 25 25 16 16 16 16 16 10 6 6 6 6 6 6 6 6 75 25 25 25 25 16 16 16 10 10 10 10 10 6 6 6 6 100 40 40 25 25 25 25 25 16 16 16 10 10 10 10 6 6 125 40 40 40 25 25 25 25 16 16 16 16 16 10 10 10 10 160 50 50 40 40 25 25 25 25 25 16 16 16 16 16 10 10

Transformer rating (kVA) 200 50 50 50 40 40 40 40 25 25 25 25 16 16 16 16 16 250 80 63 50 50 50 40 40 25 25 25 25 25 16 16 16 16 315 100 80 63 50 50 50 50 40 25 25 25 25 25 25 16 16 400 125 100 80 63 63 50 50 40 40 40 25 25 25 25 25 25 500 160 125 100 80 80 80 63 50 50 40 40 40 25 25 25 25 630 160 160 125 100 100 100 80 50 50 50 50 40 40 40 25 25 160 160 125 125 100 80 63 63 50 50 50 40 40 40 160 160 160 125 80 80 80 63 63 50 50 50 40 160 160 125 100 100 80 80 63 63 50 50 125 125 125 100 100 80 63 63 63 800 1000 1250 1600

CEF

7,2 kV 12 kV 17,5 kV 24 kV

- The table is based on using fuses type ABB CEF - Normal operating consitions with no overload - Ambient temperature -25oC - +40oC

120% Un (kV) 3 3,3 4,15 5 5,5 6 6,6 10 11 12 13,8 15 17,5 20 22 24 25 16 16 10 10 6 6 6 6 6 6 6 6 6 6 6 6 50 25 25 16 16 16 16 16 10 6 6 6 6 6 6 6 6 75 25 25 25 25 16 16 16 10 10 10 10 10 6 6 6 6 100 40 40 25 25 25 25 25 16 16 16 10 10 10 10 6 6 125 40 40 40 25 25 25 25 16 16 16 16 16 10 10 10 10 160 50 50 40 40 25 25 25 25 25 16 16 16 16 16 10 10

Transformer rating (kVA) 200 63 63 50 40 40 40 40 25 25 25 25 16 16 16 16 16 250 80 80 63 50 50 40 40 25 25 25 25 25 16 16 16 16 315 100 80 80 63 50 50 50 40 25 25 25 25 25 25 16 16 400 125 100 80 80 80 63 63 40 40 40 25 25 25 25 25 25 500 160 125 100 80 80 80 80 50 50 40 40 40 25 25 25 25 125 125 100 100 80 63 50 50 50 40 40 40 25 25 160 125 125 100 80 80 63 50 50 50 40 40 40 160 160 125 80 80 80 80 63 50 50 50 40 125 100 100 80 80 63 63 50 50 125 125 100 100 80 80 63 63 630 800 1000 1250 1600

CEF

7,2 kV 12 kV 17,5 kV 24 kV

- The table is based on using fuses type ABB CEF - Normal operating consitions with 20% overload - Ambient temperature -25oC - +40oC

44 Fuse selection table | Product Catalogue

Fuse-links

SafeRing and SafePlus are designed and tested for fuse-links according to IEC 60282-1 The dimensions of the fuse-links have to be in accordance with IEC 60282-1, Annex D. The fuse-links have to be type I with terminal diameter equal to 45 +1 mm and body length (e) equal to 442 mm. The dimensions of the fuse-links can also to be in accordance with DIN 43625 and the length of the fuse canister is based on the use of fuse-links with length 442 mm. For installation of shorter fuses, (<24kV ) a fuse adapter will be needed. Please note: When inserting the fuse-link into the canister, the striker-pin must always face outwards against the fuse holder. Fuse adapter has to be fixed to the fuse-link contact part which faces inwards in the fuse canister. 1600 kVA is the maximum size of distribution transformer which can be fed from a SafeRing / SafePlus switch-fuse module. For higher rated transformers, we recommend our vacuum circuit breaker module with CTs and protection relay. The below table shows CEF fuse-links for use in SafeRing/ SafePlus. For more technical data, we refer to our ABB Poland catalogue. In order to find the correct fuse-link compared to the transformer rating in kVA, please see the selection table on previous page.

Fuse holder

Fuse-link

Fuse adapter

Type CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF CEF

Rated voltage kV 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 3,6/7,2 12 12 12 12 12 12 12 12 12 12

Rated current A 6 10 16 25 40 50 63 80 100 125 160 6 10 16 25 40 50 63 80 100 125

e / D mm 192/65 192/65 192/65 192/65 192/65 192/65 192/65 192/87 192/87 292/87 292/87 292/65 292/65 292/65 292/65 292/65 292/65 292/65 292/87 292/87 442/87

Type CEF CEF CEF CEF CEF CEF CEF CEF CEF

Rated voltage kV 17,5 17,5 17,5 17,5 17,5 17,5 17,5 17,5 17,5

Rated current A 6 10 16 25 40 50 63 80 100

e / D mm 292/65 292/65 292/65 292/65 292/87 292/87 292/87 442/87 442/87

CEF CEF CEF CEF CEF CEF CEF

24 24 24 24 24 24 24

6 10 16 25 40 50 63

442/65 442/65 442/65 442/65 442/65 442/87 442/87

Product catalogue | Fuse-links 45

Relays

SafePlus can be delivered with a V-module with 630A vacuum circuit-breaker. This chapter describes the different choices of protection relays and feeder terminals that can be used in SafePlus. These relays require an additional low voltage compartment. For transformer protection with max. 200A vacuum circuit breaker see chapter 6.4. Standard test procedure is functional test of trip circuit of the relays. All customer settings must be done on site. REF type feeder terminals are configured according to customer specification for protection functions. Special control requirements on request only. The V-module can also be delivered prepared for protection relays. This is defined in two types: Trip coil and auxiliary contact. Cut out in LV-compartment, trip coil, aux contact, wiring and drawings. This is applicable for relays delivered complete from our factory or if we have received necessary documentation on the relay. Other types of relays on request.

There are three main groups of relays delivered: A. ABB feeder protection relays B. Self powered relays C. ABB feeder terminals type REF 54x A. ABB offers a wide range of feeder protection relays. These relays have been sold for a long period and have an excellent reputation for reliability and secure operation. These relays have either 18-80VDC or 80-265VAC/DC auxiliary supplies and are connected to conventional CTs and VTs. B. Self powered relays are suitable for rough conditions and places without possibility of auxiliary supply. SafeRing and SafePlus can be delivered with different types to fulfil all relevant needs in a distribution network. C. ABB feeder terminals, type REF 54x provides cost-effective solutions for different protection, monitoring and control applications. The terminals enable the use of accurate and reliable current and voltage sensors as well as conventional CTs and VTs.

46 Relays | Product Catalogue

Relays

ABB feeder protection relays Protection and measurement Type of faults Short circuits Short circuits Short circuits Short circuits Short circuits Earth fault Earth fault Earth fault Earth fault Earth fault Earth fault Earth fault Additional functions Additional functions Type of measurements current Type of measurements current Type of measurements current Type of measurements current Auto-reclosing

1)

Relay IEEE device no. 51 50/51/51B 50/51B 51 50/51 51N 51N 50N/51N 67N 67N 67N 59N 46 62BF 3I> 3 I >> 3 I >>> 2I> 2 I >> Io > Io >/SEF Io >>/Io-o> Io >-->/SEF Io >-->/SEF Io >> --> Uo > I> CBFP 31/21 Io I Uo 79 Non-directional overcurrent, low-set stage Non-directional overcurrent, high-set stage Non-directional overcurrent instantaneous stage/blockable Two-phase non-directional overcurrent, low-set stage Two-phase non-directional overcurrent, high-set stage Non-directional earth fault, low-set stage Non-directional earth fault, low-set stage sensitive Non-directional earth fault, high-set stage Directional earth fault, sensitive, In=1A and 5A Directional earth fault, sensitive, In=0,2A and 1A Directional earth fault, high-set stage Residual overvoltage Phase discontinuity Circuit-breaker failure Three-phase / two-phase current Neutral current Degree of unbalance Residual voltage X X X X X X X X X X X X X X X X X X X X X X X X X X X X IEC symbol Protection function REX X X X

1)

REF 610 X X X

REF 615 X X X

521

Available protection functions dependant of version

Self-powered relays Functionality Features Protection functions Protection functions Protection functions Protection functions Protection functions Characteristic curves Characteristic curves Additional functions Additional functions Additional functions Additional functions Measuring circuit Measuring circuit Climatic withstand Climatic withstand

1)

Relay Description Phase overdurrent (multi-characteristic) Short-curcuit protection Number of overcurrent elements Earth fault current Number of earth fault elements Overcurrent element Earth fault current Trip indication Electro-impulse input remote tripping (voltage) Auxiliary power, voltage (option) Rated secondary current Measuring range, start current I> (A) Storage temperature (C) Operating temperature (C)

-

IEEE device no. 50/51 50/51 50/51B 50N/51N