0 ratings0% found this document useful (0 votes)

226 viewsCast Steel Gate Valve - VS01 (ASME 150)

Cast Steel Gate Valve - VS01 (ASME 150)

Uploaded by

sghinausThis document provides information on cast steel gate valves, including their applications, installation, materials, and pressure-temperature ratings. Specifically, it states that:

1) Derval gate valves are used as efficient shut-off valves for water, steam, air, gas, oil, and crude oil in applications requiring minimal pressure drop.

2) Due to their design, the valves should be operated in the fully open or fully closed position only, as partial opening risks seat damage from concentrated flow.

3) The valves are installed horizontally with a vertical stem and used widely in oil/gas, chemical, power, and water/waste industries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Cast Steel Gate Valve - VS01 (ASME 150)

Cast Steel Gate Valve - VS01 (ASME 150)

Uploaded by

sghinaus0 ratings0% found this document useful (0 votes)

226 views4 pagesThis document provides information on cast steel gate valves, including their applications, installation, materials, and pressure-temperature ratings. Specifically, it states that:

1) Derval gate valves are used as efficient shut-off valves for water, steam, air, gas, oil, and crude oil in applications requiring minimal pressure drop.

2) Due to their design, the valves should be operated in the fully open or fully closed position only, as partial opening risks seat damage from concentrated flow.

3) The valves are installed horizontally with a vertical stem and used widely in oil/gas, chemical, power, and water/waste industries.

Original Title

Cast Steel Gate Valve - VS01 [ASME 150]

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides information on cast steel gate valves, including their applications, installation, materials, and pressure-temperature ratings. Specifically, it states that:

1) Derval gate valves are used as efficient shut-off valves for water, steam, air, gas, oil, and crude oil in applications requiring minimal pressure drop.

2) Due to their design, the valves should be operated in the fully open or fully closed position only, as partial opening risks seat damage from concentrated flow.

3) The valves are installed horizontally with a vertical stem and used widely in oil/gas, chemical, power, and water/waste industries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

226 views4 pagesCast Steel Gate Valve - VS01 (ASME 150)

Cast Steel Gate Valve - VS01 (ASME 150)

Uploaded by

sghinausThis document provides information on cast steel gate valves, including their applications, installation, materials, and pressure-temperature ratings. Specifically, it states that:

1) Derval gate valves are used as efficient shut-off valves for water, steam, air, gas, oil, and crude oil in applications requiring minimal pressure drop.

2) Due to their design, the valves should be operated in the fully open or fully closed position only, as partial opening risks seat damage from concentrated flow.

3) The valves are installed horizontally with a vertical stem and used widely in oil/gas, chemical, power, and water/waste industries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

CAST STEEL GATE VALVES

ASME CLASS 150 LBS.

FIG. VS01

APPLICATION:

Derval gate valves are used as efficient

shut-off valves with flow in either direction

for water, saturated steam, air, gas, oil and

crude oil products. They are utilized in

applications where minimum pressure drop

is necessary.

Due to their specific design, gate valves

should be operated in the full-open or full-

close position. Concentrated flow across

the seats of a partially opened gate valve

risks possible seat damage, therefore throt-

tling is not recommended.

Operating parameters are in accordance

with ASME B16.34 standard.

INSTALLATION:

Derval gate valves are normally installed in

hori zontal pi pe wi th verti cal stem

(handwheel up).

The high quality Derval valves are installed

in a large variety of services in the Oil &

Gas field, Chemical and Petrochemical

industry,in On-shore and Off-shore dril-

ling/refining, Power Generation, Water and

Wastewater Treatment industries.

s.r.l.

DERVAL S.r.l.

Via Guido Rossa, 13

20024 Garbagnate Milanese

(Milano) - Italy

Phone: +39 02 990.20.302

Fax: +39 02 990.25.461

Web: www.derval.it

E-mail: info@derval.it

s.r.l.

CAST STEEL GATE VALVES - CLASS 150 LBS. - FIG. VS01

scheda 150:famiglia LP -bozza 2 30/09/10 15:03 Pagina 1

DESCRIPTION AND FEATURES GENERAL DESIGN SPECIFICATIONS

BOLTED BONNET Design ASME B16.34 / API600 / BS1414 / ISO 10434

OUTSIDE SCREW AND YOKE (OS&Y) Face to Face ASME B16.10

RISING STEM ASME B16.5 (2" ~ 24")

NON RISING HANDWHEEL ASME B16.47 ( 26")

SOLID or FLEXIBLE WEDGE BW Ends ASME B16.25

RENEWABLE SEATS Test API 598 / API 6D / BS 6755 / EN 12266

on request : ISO 5210 TOP FLANGE, LOCKING DEVICE, Markin g MSS-SP25 / P.E.D. ( 97/23/EC )

Special NACE MR 01.75 - 01.03 / ATEX 94/9/EC

STANDARD MATERIAL OF PARTS

ITEM

01 Body ASTM A216 Gr.WCB

02 Seat Rings Stellite Gr. 6 Faced

03 Wedge ASTM A216 Gr.WCB+13Cr Faced

04 Stem ASTM A182 F6a

05 Gasket

*

Stainless Steel + Graphite

06 Bonnet ASTM A216 Gr. WCB

07 Bonnet Bolt Nuts ASTM A194 Gr. 2H(M)

08 Bonnet Bolts ASTM A193 Gr. B7(M)

09 Backseat Bushing ASTM A276 Type 410

Braided Graphite & Die Formed

Graphite Ring

11 Eye Bolts Pins Carbon Steel

12 Gland Eyebolt ASTM A193 Gr. B7(M)

13 Gland ASTM A276 Type 410

14 Gland Flange ASTM A216 Gr. WCB

15 Eye Bolt Nuts ASTM A194 Gr. 2H(M)

16 Grease Nipple Carbon Steel

17 Stem Nut ASTM A439 Gr. D-2 / ASTM B148 9A

18 Retaining Nut Carbon Steel

19 Handwheel Steel

20 Handwheel Nut Carbon Steel

21 Screw Carbon Steel

22 Yoke ASTM A216 Gr. WCB

23 Yoke Pan Bolt Nuts ASTM A194 Gr. 2H(M)

24 Yoke Pan Bolts ASTM A193 Gr. B7(M)

25 Bearing Steel

26 Lantern Ring On Request ASTM A276 Type 410

End Flange

MATERIAL

SEE DERVAL'S SPECIAL FEATURES FOR FURTHER EXECUTION

10

PART NAME

Stem Packing

*

*

Recommended Spare Parts

MAXIMUM ALLOWABLE NON-SHOCK WORKING PRESSURE:

RECOMMENDED FOR 18" & LARGER

YOKE BALL BEARING LANTERN RING GEAR OPERATOR

STANDARD FOR 28" & LARGER

For 10" & Larger For 14" & Larger On Request

T (C) -29 ~38 50 100 150 200 250 300 350 375 400 425

P (Bar) 19,6 19,2 17,7 15,8 14,0 12,1 10,2 8,4 7,4 6,5 5,6

The followin g tables su gg est standard combination of body / bonnet materials and trim (seat, stem, disc or wed g e) composition. Different compositon are available upon request

ITEM CARBON STEEL

LOW TEMP.

CARBON STEEL

-29 ~ 427 C -46 ~ 343 C -29 ~ 468 C -29 ~ 593 C -29 ~ 593 C -29 ~ 649 C -29 ~ 649 C -196 ~ 816 C -196 ~ 816 C -196 ~ 427 C -196 ~ 454 C

1 A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

2 A 182 F6a A182 F304 A 182 F6a A 182 F6a A 182 F6a A 182 F6a A 182 F6a A182 F304 A182 F316 A182 F304L A182 F316L

3 A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

4 A 182 F6a A182 F304 A 182 F6a A 182 F6a A 182 F6a A 182 F6a A 182 F6a A182 F304 A182 F316 A182 F304L A182 F316L

CL150-300 304(L)+Graphite 304(L) + Graphite

CL600-2500

Ring Joint

6 A216WCB A352LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

7 Bonnet Bolt Nuts A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8M A194 Gr.8 A194 Gr.8M

8 Bonnet Bolts A193 B7 A193 L7 A193 B16 A193 B16 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8M A193 B8 A193 B8M

9 Backseat Bushing A276 410 A276 304 A276 304 A276 304 A276 304 A276 304 A276 304 A276 304 A276 316 A276 304L A276 316L

10

11

12 Gland Eye Bolts A193 B7 A193 L7 A193 B16 A193 B16 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8M A193 B8 A193 B8M

13 Gland A276 410 A276 304 A276 304 A276 316 A276 304L A276 316L

14 Gland Flange A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

15 Eye Bolt Nuts A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8M A194 Gr.8 A194 Gr.8M

16 Grease Nipple

17 Stem Nut

18 Retaining Nut

19 Handwheel

20 Handwheel Nut

21 Screw

22 Yoke A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

23 Yoke Pan Bolt Nuts A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8M A194 Gr.8 A194 Gr.8M

24 Yoke Pan Bolts A193 B7 A193 L7 A193 B16 A193 B16 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8M A193 B8 A193 B8M

25 Bearing

26 A276 410 A276 304 A276 304 A276 316 A276 304L A276 316L

(1): Base material shall be at least equal in corrosion resistance to the body material ( Acc. to API 600 Std.)

(2): Base material only.See trim material for wedge surface

Note: Flanged end ratings terminate at 538C for class 150 Lbs.

Stainless Steel: At temperatures over 538C, use the material only when the carbon contents is 0.04% or higher.

Derval S.r.l. reserves the right to substitute materials listed above with alternative material approved for designated service.

The API TRIM N 8 is supplied on Derval Valves as standard trim. Materials for other trims are in accordance with the following table. Other trims also according to customer's requirement.

Note: The chart above only lists out some common composition of steel gate valve parts. We may provide other different parts material composition according to the customer's request

or based on the actual valve working condition.

a) Permissible, but not recommended for prolunged usage above 427C (800F)

b) Not to be used over 343C (650F)

c) Permissible, but not recommended for prolunged usage above 468C (875F)

d) Not to be used over 593C (1100F)

e) At temperature over 538C (1000F), use only when carbon content is 0,04 or higher

f) Not to be used over 427C (800F)

g) Not to be used over 454C (850F)

Flanged end ratings terminate at 538C (1000F) for class 150

Seat Ring

(1)

Wedge

(2)

Stem

Gasket

316(L) + Graphite

316(L)

5

304(L)

316(L) + Graphite

316(L)

STAINLESS STEEL PART NAME

Body

TEMPERATURE (C)

ALLOY STEEL

Stainless Steel

Carbon steel Stainless Steel

Stem Packing Braided Graphite & Die Formed Graphite Ring Braided Graphite & Die Formed Graphite Ring Braided Graphite & Die Formed Graphite Ring

Eye Bolt Pins

Steel

Carbon steel A276 410

A276 410

Alloy steel

Steel

A439 D2C / B148 9A A439 D2C / B148 9A

Carbon steel Stainless Steel

A439 D2C / B148 9A

Alloy steel

Steel

Stainless Steel

Stainless Steel

Alloy steel

Alloy steel

Steel

A276 304

TRIM MATERIALS (API 600 STANDARD)

CAST STEEL GATE VALVE STANDARD MATERIALS OF PARTS (ASTM)

Lantern Ring On Request

Bonnet

Carbon steel

Steel Steel

Carbon steel

1 2 5 8 9 10 11 12 13 14 15 16 17

F6 304 F6-HF F6-HFS Monel 316 Monel-HFS 316-HFS Alloy 20 Alloy 20-HFS 304-HF 316-HF 347-HF

2 13Cr. 304 HF HF Monel 316 HF HF Alloy 20 HF HF HF HF

3 13Cr. 304 HF 13Cr. Monel 316 Monel 316 Alloy 20 Alloy 20 HF HF HF

4 F6 F304 F6 F6 Monel F316 Monel F316 Alloy 20 Alloy 20 F304 F316 F347

9 Backseat Bushing F6 304 F6 F6 Monel 316 Monel 316 Alloy 20 Alloy 20 304 316 347

Stem

TRIM N

DERVAL DESCRIPTION

Seat Surface

Wedge Surface

PRESSURE - TEMPERATURE RATINGS

Group 1.1 Group 1.3 Group 1.5 Group 1.9 Group 1.10 Group 1.13 Group 1.14 Group 2.1 Group 2.2 Group 2.1 Group 2.2

A216 WCB

(a)

A352 LCB

(b)

A217 WC1

(c)

A217 WC6

(d)

A217 WC9

(d)

A217 C5 A217 C12 CF8

(e)

CF8M

(e)

CF3

(f)

CF3M

(g)

-29 to 38 19,6 18,4 18,4 20,0 20,0 20,0 20,0 19,0 19,0 19,0 19,0

50 19,2 18,1 18,3 19,2 19,2 19,2 19,2 18,4 18,4 18,4 18,4

100 17,7 17,3 17,7 17,7 17,7 17,7 17,7 15,7 16,2 15,7 16,2

150 15,8 15,8 15,8 15,8 15,8 15,8 15,8 13,9 14,8 13,9 14,8

200 14,0 14,0 14,0 14,0 14,0 14,0 14,0 12,6 13,7 12,6 13,7

250 12,1 12,1 12,1 12,1 12,1 12,1 12,1 11,7 12,1 11,7 12,1

300 10,2 10,2 10,2 10,2 10,2 10,2 10,1 10,2 10,2 10,2 10,2

350 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4

400 6,5 - 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5

425 5,6 - 5,6 5,6 5,6 5,6 5,6 5,6 5,6 5,6 5,6

450 4,7 - 4,7 4,7 4,7 4,7 4,7 4,7 4,7 - 4,7

500 2,8 - 2,8 2,8 2,8 2,8 2,8 2,8 2,8 - 2,8

525 1,9 - 1,9 1,9 1,9 1,9 1,9 1,9 1,9 - -

540 - - - - - - - - - - -

600 - - - - - - - - - - -

650 - - - - - - - - - - -

700 - - - - - - - - - - -

750 - - - - - - - - - - -

800 - - - - - - - - - - -

(Hydr.) Shell Test 29,4 27,6 27,6 30,0 30,0 30,0 30,0 28,5 28,5 28,5 28,5

(Hydr.) Seat Test 21,6 20,2 20,2 22,0 22,0 22,0 22,0 20,9 20,9 20,9 20,9

(Pneum.) Seat Test 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5

ASME 150

WORKING PRESSURES (bar)

ASTM MATERIALS

SERVICE

TEMPERATURE

C

The following pressure-temperature charts are derived from ASME B16.34. They will cover the most commonly used body and bonnet materials in the industry.

All Derval Valves are designed to operate through the pressure and temperature ranges shown in these charts for a particular ASME Class Rating and ASTM Material.

Pressure temperature ratings are based on ASME B16.34 (bar/C)

ASTM GROUP MATERIAL STANDARD TO ASME B16.34

CAST STEEL GATE VALVES - CLASS 150 LBS.

s.r.l.

scheda 150:famiglia LP -bozza 2 30/09/10 15:03 Pagina 2

DESCRIPTION AND FEATURES GENERAL DESIGN SPECIFICATIONS

BOLTED BONNET Design ASME B16.34 / API600 / BS1414 / ISO 10434

OUTSIDE SCREW AND YOKE (OS&Y) Face to Face ASME B16.10

RISING STEM ASME B16.5 (2" ~ 24")

NON RISING HANDWHEEL ASME B16.47 ( 26")

SOLID or FLEXIBLE WEDGE BW Ends ASME B16.25

RENEWABLE SEATS Test API 598 / API 6D / BS 6755 / EN 12266

on request : ISO 5210 TOP FLANGE, LOCKING DEVICE, Markin g MSS-SP25 / P.E.D. ( 97/23/EC )

Special NACE MR 01.75 - 01.03 / ATEX 94/9/EC

STANDARD MATERIAL OF PARTS

ITEM

01 Body ASTM A216 Gr.WCB

02 Seat Rings Stellite Gr. 6 Faced

03 Wedge ASTM A216 Gr.WCB+13Cr Faced

04 Stem ASTM A182 F6a

05 Gasket

*

Stainless Steel + Graphite

06 Bonnet ASTM A216 Gr. WCB

07 Bonnet Bolt Nuts ASTM A194 Gr. 2H(M)

08 Bonnet Bolts ASTM A193 Gr. B7(M)

09 Backseat Bushing ASTM A276 Type 410

Braided Graphite & Die Formed

Graphite Ring

11 Eye Bolts Pins Carbon Steel

12 Gland Eyebolt ASTM A193 Gr. B7(M)

13 Gland ASTM A276 Type 410

14 Gland Flange ASTM A216 Gr. WCB

15 Eye Bolt Nuts ASTM A194 Gr. 2H(M)

16 Grease Nipple Carbon Steel

17 Stem Nut ASTM A439 Gr. D-2 / ASTM B148 9A

18 Retaining Nut Carbon Steel

19 Handwheel Steel

20 Handwheel Nut Carbon Steel

21 Screw Carbon Steel

22 Yoke ASTM A216 Gr. WCB

23 Yoke Pan Bolt Nuts ASTM A194 Gr. 2H(M)

24 Yoke Pan Bolts ASTM A193 Gr. B7(M)

25 Bearing Steel

26 Lantern Ring On Request ASTM A276 Type 410

End Flange

MATERIAL

SEE DERVAL'S SPECIAL FEATURES FOR FURTHER EXECUTION

10

PART NAME

Stem Packing

*

*

Recommended Spare Parts

MAXIMUM ALLOWABLE NON-SHOCK WORKING PRESSURE:

RECOMMENDED FOR 18" & LARGER

YOKE BALL BEARING LANTERN RING GEAR OPERATOR

STANDARD FOR 28" & LARGER

For 10" & Larger For 14" & Larger On Request

T (C) -29 ~38 50 100 150 200 250 300 350 375 400 425

P (Bar) 19,6 19,2 17,7 15,8 14,0 12,1 10,2 8,4 7,4 6,5 5,6

The followin g tables su gg est standard combination of body / bonnet materials and trim (seat, stem, disc or wed g e) composition. Different compositon are available upon request

ITEM CARBON STEEL

LOW TEMP.

CARBON STEEL

-29 ~ 427 C -46 ~ 343 C -29 ~ 468 C -29 ~ 593 C -29 ~ 593 C -29 ~ 649 C -29 ~ 649 C -196 ~ 816 C -196 ~ 816 C -196 ~ 427 C -196 ~ 454 C

1 A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

2 A 182 F6a A182 F304 A 182 F6a A 182 F6a A 182 F6a A 182 F6a A 182 F6a A182 F304 A182 F316 A182 F304L A182 F316L

3 A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

4 A 182 F6a A182 F304 A 182 F6a A 182 F6a A 182 F6a A 182 F6a A 182 F6a A182 F304 A182 F316 A182 F304L A182 F316L

CL150-300 304(L)+Graphite 304(L) + Graphite

CL600-2500

Ring Joint

6 A216WCB A352LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

7 Bonnet Bolt Nuts A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8M A194 Gr.8 A194 Gr.8M

8 Bonnet Bolts A193 B7 A193 L7 A193 B16 A193 B16 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8M A193 B8 A193 B8M

9 Backseat Bushing A276 410 A276 304 A276 304 A276 304 A276 304 A276 304 A276 304 A276 304 A276 316 A276 304L A276 316L

10

11

12 Gland Eye Bolts A193 B7 A193 L7 A193 B16 A193 B16 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8M A193 B8 A193 B8M

13 Gland A276 410 A276 304 A276 304 A276 316 A276 304L A276 316L

14 Gland Flange A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

15 Eye Bolt Nuts A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8M A194 Gr.8 A194 Gr.8M

16 Grease Nipple

17 Stem Nut

18 Retaining Nut

19 Handwheel

20 Handwheel Nut

21 Screw

22 Yoke A216 WCB A352 LCB A217 WC1 A217 WC6 A217 WC9 A217 C5 A217 C12 A351 CF8 A351 CF8M A351 CF3 A351 CF3M

23 Yoke Pan Bolt Nuts A194 2H A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.4 A194 Gr.8 A194 Gr.8M A194 Gr.8 A194 Gr.8M

24 Yoke Pan Bolts A193 B7 A193 L7 A193 B16 A193 B16 A193 B16 A193 B16 A193 B16 A193 B8 A193 B8M A193 B8 A193 B8M

25 Bearing

26 A276 410 A276 304 A276 304 A276 316 A276 304L A276 316L

(1): Base material shall be at least equal in corrosion resistance to the body material ( Acc. to API 600 Std.)

(2): Base material only.See trim material for wedge surface

Note: Flanged end ratings terminate at 538C for class 150 Lbs.

Stainless Steel: At temperatures over 538C, use the material only when the carbon contents is 0.04% or higher.

Derval S.r.l. reserves the right to substitute materials listed above with alternative material approved for designated service.

The API TRIM N 8 is supplied on Derval Valves as standard trim. Materials for other trims are in accordance with the following table. Other trims also according to customer's requirement.

Note: The chart above only lists out some common composition of steel gate valve parts. We may provide other different parts material composition according to the customer's request

or based on the actual valve working condition.

a) Permissible, but not recommended for prolunged usage above 427C (800F)

b) Not to be used over 343C (650F)

c) Permissible, but not recommended for prolunged usage above 468C (875F)

d) Not to be used over 593C (1100F)

e) At temperature over 538C (1000F), use only when carbon content is 0,04 or higher

f) Not to be used over 427C (800F)

g) Not to be used over 454C (850F)

Flanged end ratings terminate at 538C (1000F) for class 150

Seat Ring

(1)

Wedge

(2)

Stem

Gasket

316(L) + Graphite

316(L)

5

304(L)

316(L) + Graphite

316(L)

STAINLESS STEEL PART NAME

Body

TEMPERATURE (C)

ALLOY STEEL

Stainless Steel

Carbon steel Stainless Steel

Stem Packing Braided Graphite & Die Formed Graphite Ring Braided Graphite & Die Formed Graphite Ring Braided Graphite & Die Formed Graphite Ring

Eye Bolt Pins

Steel

Carbon steel A276 410

A276 410

Alloy steel

Steel

A439 D2C / B148 9A A439 D2C / B148 9A

Carbon steel Stainless Steel

A439 D2C / B148 9A

Alloy steel

Steel

Stainless Steel

Stainless Steel

Alloy steel

Alloy steel

Steel

A276 304

TRIM MATERIALS (API 600 STANDARD)

CAST STEEL GATE VALVE STANDARD MATERIALS OF PARTS (ASTM)

Lantern Ring On Request

Bonnet

Carbon steel

Steel Steel

Carbon steel

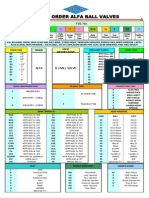

1 2 5 8 9 10 11 12 13 14 15 16 17

F6 304 F6-HF F6-HFS Monel 316 Monel-HFS 316-HFS Alloy 20 Alloy 20-HFS 304-HF 316-HF 347-HF

2 13Cr. 304 HF HF Monel 316 HF HF Alloy 20 HF HF HF HF

3 13Cr. 304 HF 13Cr. Monel 316 Monel 316 Alloy 20 Alloy 20 HF HF HF

4 F6 F304 F6 F6 Monel F316 Monel F316 Alloy 20 Alloy 20 F304 F316 F347

9 Backseat Bushing F6 304 F6 F6 Monel 316 Monel 316 Alloy 20 Alloy 20 304 316 347

Stem

TRIM N

DERVAL DESCRIPTION

Seat Surface

Wedge Surface

PRESSURE - TEMPERATURE RATINGS

Group 1.1 Group 1.3 Group 1.5 Group 1.9 Group 1.10 Group 1.13 Group 1.14 Group 2.1 Group 2.2 Group 2.1 Group 2.2

A216 WCB

(a)

A352 LCB

(b)

A217 WC1

(c)

A217 WC6

(d)

A217 WC9

(d)

A217 C5 A217 C12 CF8

(e)

CF8M

(e)

CF3

(f)

CF3M

(g)

-29 to 38 19,6 18,4 18,4 20,0 20,0 20,0 20,0 19,0 19,0 19,0 19,0

50 19,2 18,1 18,3 19,2 19,2 19,2 19,2 18,4 18,4 18,4 18,4

100 17,7 17,3 17,7 17,7 17,7 17,7 17,7 15,7 16,2 15,7 16,2

150 15,8 15,8 15,8 15,8 15,8 15,8 15,8 13,9 14,8 13,9 14,8

200 14,0 14,0 14,0 14,0 14,0 14,0 14,0 12,6 13,7 12,6 13,7

250 12,1 12,1 12,1 12,1 12,1 12,1 12,1 11,7 12,1 11,7 12,1

300 10,2 10,2 10,2 10,2 10,2 10,2 10,1 10,2 10,2 10,2 10,2

350 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4 8,4

400 6,5 - 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5

425 5,6 - 5,6 5,6 5,6 5,6 5,6 5,6 5,6 5,6 5,6

450 4,7 - 4,7 4,7 4,7 4,7 4,7 4,7 4,7 - 4,7

500 2,8 - 2,8 2,8 2,8 2,8 2,8 2,8 2,8 - 2,8

525 1,9 - 1,9 1,9 1,9 1,9 1,9 1,9 1,9 - -

540 - - - - - - - - - - -

600 - - - - - - - - - - -

650 - - - - - - - - - - -

700 - - - - - - - - - - -

750 - - - - - - - - - - -

800 - - - - - - - - - - -

(Hydr.) Shell Test 29,4 27,6 27,6 30,0 30,0 30,0 30,0 28,5 28,5 28,5 28,5

(Hydr.) Seat Test 21,6 20,2 20,2 22,0 22,0 22,0 22,0 20,9 20,9 20,9 20,9

(Pneum.) Seat Test 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5,5

ASME 150

WORKING PRESSURES (bar)

ASTM MATERIALS

SERVICE

TEMPERATURE

C

The following pressure-temperature charts are derived from ASME B16.34. They will cover the most commonly used body and bonnet materials in the industry.

All Derval Valves are designed to operate through the pressure and temperature ranges shown in these charts for a particular ASME Class Rating and ASTM Material.

Pressure temperature ratings are based on ASME B16.34 (bar/C)

ASTM GROUP MATERIAL STANDARD TO ASME B16.34

CAST STEEL GATE VALVES - CLASS 150 LBS.

s.r.l.

scheda 150:famiglia LP -bozza 2 30/09/10 15:03 Pagina 2

CAST STEEL GATE VALVES

ASME CLASS 150 LBS.

FIG. VS01

APPLICATION:

Derval gate valves are used as efficient

shut-off valves with flow in either direction

for water, saturated steam, air, gas, oil and

crude oil products. They are utilized in

applications where minimum pressure drop

is necessary.

Due to their specific design, gate valves

should be operated in the full-open or full-

close position. Concentrated flow across

the seats of a partially opened gate valve

risks possible seat damage, therefore throt-

tling is not recommended.

Operating parameters are in accordance

with ASME B16.34 standard.

INSTALLATION:

Derval gate valves are normally installed in

hori zontal pi pe wi th verti cal stem

(handwheel up).

The high quality Derval valves are installed

in a large variety of services in the Oil &

Gas field, Chemical and Petrochemical

industry,in On-shore and Off-shore dril-

ling/refining, Power Generation, Water and

Wastewater Treatment industries.

s.r.l.

DERVAL S.r.l.

Via Guido Rossa, 13

20024 Garbagnate Milanese

(Milano) - Italy

Phone: +39 02 990.20.302

Fax: +39 02 990.25.461

Web: www.derval.it

E-mail: info@derval.it

s.r.l.

CAST STEEL GATE VALVES - CLASS 150 LBS. - FIG. VS01

scheda 150:famiglia LP -bozza 2 30/09/10 15:03 Pagina 1

You might also like

- Faslt 0020 enDocument6 pagesFaslt 0020 enshashikanth79No ratings yet

- ISV Gate - SB-900.0Document4 pagesISV Gate - SB-900.0SH1961No ratings yet

- Kit 11011Document28 pagesKit 11011Reza VakilNo ratings yet

- Kitz Gate ValveDocument28 pagesKitz Gate ValvemohamedfirozNo ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- JC Catalogue Gate Valves BBDocument24 pagesJC Catalogue Gate Valves BBMahdi DalyNo ratings yet

- Piping ComponentDocument19 pagesPiping ComponentArindomNo ratings yet

- API 594 Dual PLT CheckDocument18 pagesAPI 594 Dual PLT Checkandy131078No ratings yet

- Goodwin CatalogDocument56 pagesGoodwin Catalogcavillalobosb8167No ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- Cat 4160-SC A00 ParkerDocument8 pagesCat 4160-SC A00 ParkerFabian Antonio RoldanNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- GK Catalogue - Updated 22 Sep 21Document10 pagesGK Catalogue - Updated 22 Sep 21mvb 012No ratings yet

- 6.47 AVS Simplex Duplex N Fabricated Strainer CATDocument17 pages6.47 AVS Simplex Duplex N Fabricated Strainer CATselva84No ratings yet

- Literature Force Floating Ball Valve CatalogDocument16 pagesLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- JIS Standard ValveDocument8 pagesJIS Standard ValveJong JavaNo ratings yet

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- 61502Document10 pages61502balajivangaruNo ratings yet

- Floating Ball ValveDocument2 pagesFloating Ball ValveDidit SusantoNo ratings yet

- rc91261 G10-UscDocument8 pagesrc91261 G10-Usceww08No ratings yet

- Kunkle Safety RV Model 91Document6 pagesKunkle Safety RV Model 91gbogboiweNo ratings yet

- Petrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321Document21 pagesPetrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321raj_hp2000No ratings yet

- Selection Chart CreatorDocument201 pagesSelection Chart CreatorrenepunterNo ratings yet

- rc61180 b09Document9 pagesrc61180 b09eww08No ratings yet

- Cast Steel Gate Valve Standard Materials of PartsDocument1 pageCast Steel Gate Valve Standard Materials of Partsshashikanth79No ratings yet

- How To Order Alfa ValveDocument0 pagesHow To Order Alfa ValveZoebairNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- Pipe Fitter Hand Book-1 PDFDocument1 pagePipe Fitter Hand Book-1 PDFpanduranganraghuramaNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- NeedleValve LT0389Document8 pagesNeedleValve LT0389zkmostafaNo ratings yet

- Canalta Parts CatalogueDocument25 pagesCanalta Parts Cataloguellando1No ratings yet

- ASME B1634 CatalogueDocument5 pagesASME B1634 Cataloguedqnam200367No ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Ep31492 PDFDocument11 pagesEp31492 PDFJilJilNo ratings yet

- Ansi - 2012 - Ball ValveDocument12 pagesAnsi - 2012 - Ball ValveFAR_A_DAYNo ratings yet

- Meridian Gate Globe CheckDocument4 pagesMeridian Gate Globe Checkkresimir.mikoc9765No ratings yet

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocument5 pagesComeval Cast Steel Gate Valve ANSI 150 PDFblizanacNo ratings yet

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiNo ratings yet

- Powell Gate ValvesDocument3 pagesPowell Gate Valveszguy360No ratings yet

- Mot So Loai Van Hay DungDocument14 pagesMot So Loai Van Hay DungNguyễn Xuân NamNo ratings yet

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamNo ratings yet

- BK16-M-DS-003 - A - Data Sheet For Manual ValvesDocument3 pagesBK16-M-DS-003 - A - Data Sheet For Manual ValvesHiếu NguyênNo ratings yet

- Ansi 150Document4 pagesAnsi 150GabrielPantilicaNo ratings yet

- GLT Id Valves CatalogDocument80 pagesGLT Id Valves Catalogdjoko witjaksonoNo ratings yet

- Valv. Comp. 150v CNMDocument11 pagesValv. Comp. 150v CNMJim SmithNo ratings yet

- Spirax Sarco Commissioning Strainer 1Document3 pagesSpirax Sarco Commissioning Strainer 1swaraj4uNo ratings yet

- Ep33411 b11Document9 pagesEp33411 b11salamrefighNo ratings yet

- High Temp. Alloy UNS N02200 N07080: Uns No Description Brand/Trp ASTM EquivalentDocument36 pagesHigh Temp. Alloy UNS N02200 N07080: Uns No Description Brand/Trp ASTM Equivalent윤병택No ratings yet

- Bolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.From EverandBolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.No ratings yet

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizNo ratings yet

- Lesson PlansDocument11 pagesLesson PlansFemi TokunboNo ratings yet

- MS-06-64 Swagelok SC-06 Photovoltaic Process SpecificationDocument4 pagesMS-06-64 Swagelok SC-06 Photovoltaic Process SpecificationLiu YangtzeNo ratings yet

- BrochureDocument28 pagesBrochureAshish SharmaNo ratings yet

- Cast Iron Weld RepairDocument1 pageCast Iron Weld RepairssNo ratings yet

- Flare Line Failure CaseDocument20 pagesFlare Line Failure CaseHitesh Panchal100% (1)

- Tata Corus Case Analysis at GargDocument35 pagesTata Corus Case Analysis at GargNikhil Garg86% (7)

- OA1553 QBDocument3 pagesOA1553 QBDhana MuruganNo ratings yet

- Worksheets and AssignmentDocument4 pagesWorksheets and AssignmentGebrekiros ArayaNo ratings yet

- BCSA Historical Structural Steelwork HandbookDocument77 pagesBCSA Historical Structural Steelwork HandbookMihail-Alexandru DontuNo ratings yet

- Operations & Supply Chain of Tata Steel: by Pankaj Singh Rawat 0807PGPM22Document11 pagesOperations & Supply Chain of Tata Steel: by Pankaj Singh Rawat 0807PGPM22melotusNo ratings yet

- Galvanized Steel Inspection GuideDocument20 pagesGalvanized Steel Inspection GuidePham Ngoc Khan100% (2)

- High Speed Rail ConstructionDocument26 pagesHigh Speed Rail ConstructionRahul Gupta100% (1)

- Atomic Structure of STAINLESS STEEL E316Document8 pagesAtomic Structure of STAINLESS STEEL E316Parikshit UjoodhaNo ratings yet

- Midrex ProcessDocument13 pagesMidrex ProcessAnca Elena100% (1)

- SCTT31 PDFDocument20 pagesSCTT31 PDFAnh Quoc VuNo ratings yet

- Katalog TEKIRO ToolsDocument131 pagesKatalog TEKIRO ToolslukasNo ratings yet

- Untitled DocumentDocument8 pagesUntitled Documentmj digitalNo ratings yet

- Defects On & in SlabsDocument26 pagesDefects On & in Slabsfoush bashaNo ratings yet

- X1 MaterialData 420SS 062519Document2 pagesX1 MaterialData 420SS 062519Nicola MerzagoraNo ratings yet

- Corwire Katalog YiceDocument54 pagesCorwire Katalog YiceAlexandar Marinkovic100% (1)

- 08 - An Analysis On Financial Performance of Tata Steel LimitedDocument5 pages08 - An Analysis On Financial Performance of Tata Steel Limitedkritika agarwalNo ratings yet

- 3 - Some Terminologies in WeldingDocument26 pages3 - Some Terminologies in WeldingmkhazwanNo ratings yet

- Materials List: Alloy FamilyDocument3 pagesMaterials List: Alloy FamilydiwakarNo ratings yet

- Additional API 571 Practice Questions Flashcards - QuizletDocument4 pagesAdditional API 571 Practice Questions Flashcards - QuizletMohammad Aamir Perwaiz100% (1)

- Eutectrode 4004nDocument2 pagesEutectrode 4004ndnageshm4n244No ratings yet

- Machine Design Examination 8Document5 pagesMachine Design Examination 8SYBRELLE CRUZNo ratings yet

- W7 320 Furnace - Technology PDFDocument104 pagesW7 320 Furnace - Technology PDFAtiq Ur RehmanNo ratings yet

- 010 Cleveland Kettle KEL-40-T PDFDocument29 pages010 Cleveland Kettle KEL-40-T PDFGaryNo ratings yet

- 02-Specification Mock ExamDocument9 pages02-Specification Mock ExamCRISTIAN SILVIU IANUC100% (1)