Deaera Design

Deaera Design

Uploaded by

Bhanu K PrakashCopyright:

Available Formats

Deaera Design

Deaera Design

Uploaded by

Bhanu K PrakashOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Deaera Design

Deaera Design

Uploaded by

Bhanu K PrakashCopyright:

Available Formats

DESIGN OF THE DEAERATOR

The deaerator is designed for a typical 200 MW unit. The deaerator is designed for

the maximum flow of condensate. The quantity of flow is about 11% more than for

100%load.

The deaerator selected is tray type counter flow direct contact and high!pressure

type. The pressure of the deaerator is " #g.cm

2

$abs%. The pressure is maintained at

" #g.cm

2

$abs% at all loads by means of pressure regulating &al&es. The guaranteed

residual oxygen in the deaerated water is 0.01ppm $' 10 g(litre%. )t is possible to

achie&e in actual operation e&en less than 0.00" ppm $' " g(litre%.

*omenclature+ !

a Thermal diffusi&ity m

2

(h

c ,pecific heat #cal(#g.-

. .iameter m

/ 0rea of heating surfaces m

2

g 0cceleration due to gra&ity m(sec

2

h 1eight of water column m

i 2nthalpy per unit mass #cal(#g

# 3&erall heat transfer coefficient #cal(h.m2.-

4 Total length of heated surface m

5 5ressure #g(cm

2

or atm

6 6uantity of flow #g(sec or #g(hr

q 6uantity of flow M

7

(sec or m

7

(hr

T 0bsolute temperature t8 2"7 9 :

t Temperature 9 -

T; or t; ,aturated temperature of &apour 9: or 9 - respecti&ely.

< <olume m

7

& ,pecific &olume m

7

(#g

<elocity m (sec or m(hr

=

<apour or gas &elocity m (sec or m(hr

xy> -o!ordinates

g ,pecific weights #g (m

7

Thic#ness m

-oefficient of discharge

0ngle degrees

Thermal conducti&ity #cal(m.h.9-

.imensionless temperature

.imensionless co!ordinate

Time sec or hr

-oefficient of contraction

5age 1 of 17

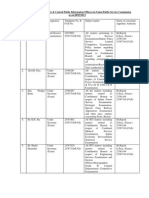

DATA FOR DESIGNING

Condensate

The quantity of condensate to be deaerated t(h ?@A.A

2nthalpy of condensate at inlet #cal (#g 1?".2B

3xygen content of the condensate ent. .eaerator g(litre ?0

3xygen content of deaerated water g(litre 10

Temperature of the condensate - 1?A

Steam to deaerator

Extraction

steam

Spindle

steam

6uantity of steam t(h ?.7B2 2.7

5ressure of the steam #g(cm

2

$a% 17.22 ".?

2nthalpy of steam #cal(#g @02."7 @20.2@

Temperature of the steam - BB" B"@

Steam from deaerator $To sealing C2Dectors%

6uantity t(h ?.7

2nthalpy of steam #cal(#g A?E.@A

Condensate from H.P Heater

6uantity t(h 100."2

2nthalpy #cal(#g 1E0.B"

HEAT A!ANCE

Heat inp"t to t#e "nit

Main condensate heat input

$?@A.A x 10

7

x ?".2B%

10

A

#cal(h E2.1?

15 drains heat input

$100."2 x 10

7

x 1E0.B"%

10

A

#cal(h 1E.2

2xtraction steam heat input

$?.7B2 x 10

7

x @02."7%

10

A

#cal(h B.2E

,pindle steam heat input

$2.7 x 10

7

x @20.2@%

10

A

#cal(h 1.@E

Total heat input 10

A

#cal(h 11".?7

Heat o"tp"t from t#e "nit

1eat ta#en by feed water

$A@E x 10

7

x 1A?.")

10

A

#cal(h 11B

1eat ta#en by eDector and sealing

steam

$?.7x 10

7

x A?E.@A)

10

A

#cal(h 7.BE

1eat ta#en by &ent steam $)nitially the

quantity of the &ent is

assumed as B?0 #g(h%

$0.B? x 10

7

x A?E.@A)

10

A

#cal(h 0.2@"

Total heat output 10

A

#cal(h 11"."@"

-omparing the output it is higher than the input so the extraction steam is

increased by an amount of B00 #g(h.

0dditional heat input

0.B00 x @02."7 x 10

7

10

A

#cal(h 0.721

5age 2 of 17

0dditional heat output

0.B00 x 1A?." x 10

7

10

A

#cal(h 0.0AA

Therefore

1eat input

$11".?7 8 0.721%

10

A

#cal(h 11".@?1

1eat output

$11"."@" 8 0.0.0AA%

10

A

#cal(h 11".@77

*ow the input and output quantities balances.

Total input quantity of steam

1 2xtraction of steam F ?."B7 t(h

2. ,pindle steam F 2.700 t(h

6uantity of flash steam $from 1.5 -ondensate%

4et 6s be the quantity of flash steam then 6s x A?E.E 8 $100."2 ! 6s% x 1A?."

F 100."2 x 1E0.B"

F

1A?."% $A?E.E

1A?."% $1E0.B" x 100."2

F ?.0B t(h

Total input steam to deaerator F ?."B7 8 2.700 8 ?.0B F

17.0@7 t(h

,team ta#en out from deaerator

1. ,ealing and eDector steam

F ?.70 t(h

2. <ent steam

F 0.B? t(h

Total

F ?."? t(h

Therefore

,team for deaerator F 17.0@7 G ?."? F ".777 t(h

The &olume of condensate to be deaerated F ?@A.A x 1.102 x 10

7

litres.

,team for deaeration F

10 x 1.102 x ?@A.A

10 x ".777

7

E

F 11.72 x 10

7

mg(litre.

120T TH0*,/2H -04-I40T)3*

1ere water is being heated on the principle of direct contact between &apour and liquid. This

increases the rate of condensation of the &apour. The water is bro#en to a number of fine Dets to

increase the contact surface between water and steam. The Det is assumed to be continuous and the

effect of pulsations caused by the interaction of the forces of gra&ity inertia and surface tension is

neglected.

The energy equation is written in the cylindrical co!ordinates assuming both molecular conduction and

isotropic turbulalent conduction ta#e place. The radial temperature gradient is considered to be much

greater than the axial gradient. Inder these conditions the energy equation becomes

5age 7 of 17

,

_

R

t

.

R

1

R

t

c.

x

t

.

2

2

T

x

$ E%

The dimensionless co!ordinates are introduced

o

R

x

x

x

R

R

1

x

t t"

t t"

Where

x

and

X

R are the &elocity and radius of the Det at a distance J from the end of the no>>le

respecti&ely.

Ho is the radius of the no>>le $hole in the plate%K and t1 is the initial temperature of the Det.

The solution of the partial differential equation $ E% is written in the form of the product of two functions.

) f(x).(

2

A.e

Where ;0= is an arbitrary constant

)n an isotropic turbulent steam the turbulent diffusion of the heat is proportional to the &elocity and

radius of the Det.

i.e.

x x. T

R . .C. $ 11 %

where is an empirical constant.

,ubstituting the &alue of

T

from equation $ 11 % into the equation $ E % and reducing the equation to

dimension form we ha&e

1

x ) .R . (a R

R

2

2

x x o

2

x x

+

The &alue of f$x% in equation$ 10 % is selected such that

2

x x.

x x o

R

) .R . (a R

f(x)

dx

d +

$ 17 %

The expression for local &elocity and local radius of a free cylindrical Det of the form

2

0

2

0

x

gx 2 1

+

$ 1B %

2

0

2

0

x

gx 2

1 4

R

R

$ 1? %

The surface area of the Det is

1

1

1

]

1

,

_

gx 2

1

g k

R 4!

dx R 2! "

4

2

0

2 x

0

2

0 0

x

$ 1A %

5age B of 17

The &elocity of Det at no>>le outlet is expressed by

2g#

$

Where

-oefficient of discharge.

1 F 1ydraulic head of the liquid before entering the no>>le in m

F -oefficient of contraction of the Det.

,ubstituting the expression for

x

and

x

R into eqn $ 1? % we get

1

1

1

]

1

,

_

+

+

gR 2

1

gR %

2

x

R

a

dx

R

R (a R

f(x)

4

%

2

0

0

2

0

2

%

2

0 x

2

0 0

x

0

2

x x

x x x 0

$ 1@ %

.ifferentiating 2qn $10 % and substituting the corresponding deri&ati&es into 2qn $ 12 % we obtain

The solution is

0 ()

) d(

( d

.

1

) d(

) ( d

2

2

+ +

%

$ 1E %

) ( & C ) ( ' C ()

0 2 0 1

+

$ 20 %

The boundary conditions are

0 () 0( 1(

The initial conditions are 1 0K x

/or xF0 i.e. for the axis of the Det the Lessel function of >ero order of the first #ind M0 has finite

&alue while the Lessel function of >ero order of the second #ind N0 becomes infinite. -onsequently

for a finite &alue of the temperature at the axis of the Det integration constant -2 must be >ero.

Then

) ( .' C ()

0 1

and

i

i

x f

i i

i

e J A

1

0

2

% $

% $

$ 21 %

)t follows from the initial conditions that

1

0

0

i

i

i i

J A % $

)t is well #nown in this case

% $

i i i

i

J

A

2

from tables of Lessel functions we find the &alues of for which

0 % $

i o

J

The a&erage temperature of the liquid in the Det at location x is

1

0

1

2

2

4

2

i

i

x f

i

x

i

e d

% $

.

$ 22 %

/inally

5age ? of 17

% $ . % $ . % $ .

OO

. . .

O

x f x f x f

x

x

e e e

t t

t t

87 74 47 0 78 5

0534 0 1312 0 6915 0

+ +

$ 27 %

When f$x%P "0.0? we can use the simplified equation retaining only the first term of the series $ 27 %.

The error is negligible

f(x) %.)*

0.+)1%e

x

Ta#ing logarithm of 2q $ 2B % we obtain the con&enient expression

2.%2f(x) 0.1+

t t

t t

,og

x

"

1

"

+

$ 2? %

)n more general form the equation $ 2? % may be written as

f(x) C C

t t

t t

,og

2 1

x

"

1

"

+

$ 2A %

-1 F 0.1A0K -2 F 2.?2K

1

1

1

]

1

,

_

+ + 1

2

1

5

2

4

5

2

0

0

2

0

2

5

2

0

2

0 0

gR

gR

R

a

x f

x

% $

/or freely falling cylindrical Det

/rom the gi&en data

The water inlet temperature t1 F 1?A-

The pressure of the deaerator p F " #g(cm

2

$a%

The saturation temperature t= F 1AB.1"-

,elected &alues+

The diameter of the hole $no>>le% do F 0.00A m

The height water column abo&e the entry

of the no>>le $hole% h F 0.0@0 m

The effecti&e heating length of water Det ) F 0.220 m

-oefficient of contraction F 0.@0

-oefficient of discharge F 0."0

We ha&e

% $ log

O

O

x f C C

t t

t t

x

2 1

1

+

and

5age A of 17

1

1

1

]

1

,

_

+ + 1

2

1

5

2

4

5

2

0

2

0

2

5

2

0

2

0 0

gx

R

R

a

x f

x

% $

Where

a F Thermal diffusi&ity F A22 x 10

!A

m

2

(h

x F 0.220 mK Ho F 0.007 mK F ? x 10

!B

K gF E.@1 m(sec

2

1.1m(sec @0 2.E.@1.0.0

0.@

0."

2g#

$

1

1

]

1

,

_

+ +

1

1.21

B 2xE.@1x0.A

1

0.007 x E.E1 x 0.@ x ?

x1.1 x10 ? x 2

0.007 x 1.1

x0.220 x10 A22

f$x%

B

?

2

?

2 B

2

A

F0.007@B 8 0.01B? $7.B2% F .0?7BB

x

t t

t t

O

O

log

1

0.1A0 8 2.?2 x 0.0?7BB F 0.2EB?

N$%ER OF TRA&S

,ince it is not possible to heat the water exactly to its boiling point it is heated to a temperature

0.2? - less than its oiling point while it is falling as a free Det.

t=!tx F 0.2? - F x

47 3

25 0

0 156 17 164

1

.

.

. .

log log

O

O

x

t t

t t

The no.of Trays required F

0.2EB?

7.B"

F 11."or 12 trays

The &alue of high we select @ trays.

356 2 8 2945 0 . . log

O

O

x

t t

t t

x

5 10.

O

O

x

x

t t

t t

i.e. t=!tx F 0."@

i.e. The water is heated to a temperature 0."@- less than its boiling point. The remaining

temperature can be achie&ed by collecting the water in a trough and intensi&ely scrubbed bubbled by

superheated steam. The time required to heat the water to its boiling point tends to infinity as the

water temperature increases.

DIA%ETER OF THE DEAERATOR

The recommended &alue of &olumetric loading of the tray type deaerator is

0.B to 0.@ x 10

A

#cal(m

7

h.

,elected &alue F 0.@ x10A #cal(m

7

.h

The quantity of condensate F ?@A.?AA t(h

The enthalpy of incoming condensate F 1?".2B #cal(#g

2nthalpy of saturated water F 1A?." #cal(#g

-hange in enthalpy F 1A?." G 1?B.2" #cal(#g

4oading of the deaerator F @.BA x 10

7

x ?@A.?AA #cal(h

5age " of 17

4et . be the diameter of the deaerator and the deaerator height $@ x 0.7% 2.B m

<olume of the deaerator F 2.B x . x

B

Q

2

m

7

<olumetric loading F

2.B x . x

B

Q

?@A.?AA x 10 x @.BA

2

7

This should be within the selected &alue of 0.@ x 10A #cal(m

7

h

i.e. F

A

2

7

10 x 0.@

2.B x . x

B

Q

?@A.?AA x 10 x @.BA

A

7

10 x 0.@ x 2.B x Q

?@A.?AA x 10 x B x @.BA

. i.e. . 1.@1? m

The diameter of the deaerator selected as 2.@ m in order to accommodate the holes in the tray.

N$%ER OF HO!ES PER TRA&

Weight of the condensate to be

.eaerated F ?@A.?AA t(h F

7A00

?@A.?AAx10

7

#g(sec

,pecific &olume of water at a mean F 0.0011020 #g(m

7

Temperature of 1A09-

<olume of water passing throR the holes F 1A7 x0.0011020 F 0.1"E? m

7

(sec

The diameter of the hole F 0.00A m

1eight of the water column abo&e

The hole F 0.0@0 m

-oefficient of discharge F 0."

<olume of water flowing throR hole F 1.2? x 0." x

B

x0.00A Q

x 0 2gh Sx

2

F 2B."x10

!A

m

7

(sec

The number of holes required(Tray F

2B."

10 x 0.1"E?

A

F "2A0 holes.

The holes are arranged in staggered position at a pitch of 1@ mm

5ro&ided holes F ""?0 (tray

5ercentage reser&e F A.@% 100 x

"2A0

"2A0% $""?0

CA!C$!ATION FOR DETER%INING THE '$ANTIT& OF STEA% TO E (ENTED

0s mentioned earlier to #eep the partial pressure of the dissol&ed gases in the deaerator at desired

low le&el it is necessary to remo&e the gases from deaerator.

This is done by &enting non!condensable gases along with portion of steam. The residual oxygen

content depends on the amount of &ent sent to atmosphere. )t is calculated as follows.

.

5age @ of 17

4et

.p Weight of the steam for deaerator including the &ent steam in mg(litre of water.

T# Weight of oxygen carried away by the steam in the &ent in mg(litre of steam

52 5artial pressure of oxygen in the &ent mixture.

5p .eaerator pressure atm.

mp Molecular weight of steam

m# Molecular weight of oxygen

$x% Weight of steam to be &ented mg(litre of water.

Then we ha&e

#

p

2

p

#

p

m

m

5

5

T

.

$ 2" %

1ere .p F U11.72 x 10

7

8 $x%V mg(litre

The initial concentration of oxygen F ?0 g(litre

The final concentration of oxygen F 10 g(litre

The weight of oxygen to be remo&ed F B0 g(litre F B0 x 10

!7

mg(litre

The weight of steam to be &ented F $x% mg(litre.

,pecific &olume of steam F 0.2""@ m

7

(#g

F 0.2""@ x10

!7

litre (#g

<olume of steam F $x%x 0.2""@ x10

!7

litre

T# F

. 10 x 0.2""@ x $x%

10 x B0

7 !

7

mg (litre of steam

5artial pressure of steam in the &ent

The residual oxygen in the water F 10 g(litre

i.e.

2

o

m

F

72

10 x 10

A

moles ( litre.

/or this residual oxygen the corresponding equilibrium pressure is calculated using

1enryRs 4aw

C

-

.

2

o

e

Where 5e equilibrium partial pressure

- F 1enryRs -onstant for water at 1AB.1" 9- F 1.02" x 10

!7

2

o

m

F Molality of oxygen

7

A

1.02"x10

1

x

72

10 x 10

e

P F 0.70B? x10

!7

ata

)n practice it has been found that the partial pressure of the oxygen in the &ent should be

2.?

1

times the equilibrium pressure to ha&e better desorption of gas.

1ence 52 F 5e(2.? F 0.70B? x10

!7

(2.? F 0.121@ x 10!7 ata

Mp F 1@K m# F 72K 5p F " ata

,ubstituting the &alues in eqn $ 2" %

5age E of 17

( ) [ ]

72

1@

x

10 x 0.121@

"

10 x B0

10 x 0.2""@ x x 11.72x10

7 7

7 7

+

$x% F0."7 x 10

7

mg(litre

The weight of steam to be &ented F 0."7 x 1.102 F 0.@0? #g ( tonne of water

Weight of steam to be &ented per hour F 0.@0? x ?@A.A F B"7 #g(h

THE DISTRI$TOR

)n order to distribute the condensate uniformly through out the section of the deaerator a distributor is

pro&ided. )t is a trough consisting of ;<= notches and holes to distribute the water. The notch angle is

E09.

The quantity of condensate to be distributed F ?@A.?AA t(h

The &olume of condensate F

7A00

1.0E"B x ?@A.?AA

F 0.1"@? m

7

/or a ;<= with angle E09 the quantity of

.ischarge $6% is gi&en by F

?

h g 2 W

1?

@

Where

6 F .ischarge m

7

(sec

1 F 1ead causing flow m

F /actor gi&en by equation F 0.?A? 8 .0@A@ x 0.0E0

!0.0?

for A notches h F E0.mm F 0.0A0 m

F 0.A?2@

6uantity of flow throR A notches F

?

0.0E x E.@1 x 2 x

1?.

@

x 0.A?2@ x A

F 0.022B m

7

( sec

/or the remaining 2A notches the head

causing flow F

2

110

F "".@ mm F .0""@ m F 0.A?7

Therefore 6 F

?

0.0""@ x 0.A?7 x

1?

@

x 2A

F 2A x2.A" x10!7 F 0.0AEB m

7

The total flow throR notches F 0.022B 8 0.0A7B F 0.0E1 m

7

( sec

The hole diameter F 0.02? m

The head causing flow F 0.BA0 m

.ischarge throR one hole F

2gh x 0 x S

m

7

(sec

-oefficient of discharge F 0.A

0rea of the hole 0 F

4

2

0.02? x Q

F B.E2 x 10!B m

2

5age 10 of 17

.ischarge throR one hole F 0.A x B.E2 x 10!B x B.B7 x 0.BA m

7

(sec.

F @.@? x 10!B m

7

( sec

*o. of holes pro&ided F EB

.ischarge through holes F EB x @.@? x 10!B F @72.? x 10!B m

7

( sec

Total discharge throR notches and holes F 0.0@72? 8 0.0E1@ F 0.1"?0? m

7

( sec

The remaining &olume of condensate F 0.1"@? G 0.1"?0? F 0.002B? m

7

( sec.

This quantity of condensate is allowed to o&erflow.

DIA%ETER OF THE CONDENSATE PIPE

<olume of water flow F 0.1"@? m

7

( sec

4et us select the &elocity as F 2 m ( sec

0rea required F

2

0.1"@?

F 0.@E2? m

2

)nternal diameter of the pipe should be F 0.77A m

The selected pipe si>e F 7A@ x 11 mm

<elocity of water F

2

0.7BA x Q

B x 0.1"@?

F 1.E m (sec

DIA%ETER OF THE (ENT STEA% PIPE

The quantity of the steam to be &ented F B"7 #g(h

,pecific &olume of steam at " ata F 0.2""@ m

7

( #g

0mount of steam escaping throR pipeF

7A00

B"7 x 0.2""@

F 0.07AB m

7

( sec

4et us select a &elocity of 1? m ( sec

/low area required F

1?

0.07AB

F 0.002B m

2

.iameter of the pipe required F

Q

B x 0.002B

F ??.2 mm

,elected pipe diameter F ?0 mm $nominal%

5age 11 of 17

<elocity of steam F

2

0.0?1 x Q

B x 0.07AB

F 1".A m ( sec

DIA%ETER OF THE E)TRACTION STEA% PIPE

The quantity of steam sent to deaerator directly through the bubbling chamber is ?0% of the extraction

steam. This steam is admitted at two points

Maximum quantity of steam flowing

Through one pipe F B.A t (h

<olume of steam F

7A00

1000 x 0.7"00 x B.A

F 0.B"2? m

7

(sec

,elected steam &elocity F 2? m (sec

0rea required F

2?

0.B"2?

F 0.01@E m

2

.iameter of the pipe required F

Q

B x 0.01@E

F 1?B.? mm

0 pipe with nominal bore of 1?0 mm has been selected.

The &elocity for the selected pipe F 2A.@ m ( sec.

CONSTR$CTION OF THE DEAERATOR

The deaerator is made up of carbon steel sheet welded to which the torishperical heads are welded.

0ll the other elements are housed inside. The eight rows of perforated trays are welded to the shell.

The perforated trays are of stainless steel material $0),) 70B%. Lelow the last row of trays a collecting

trough is pro&ided. ,team enters this collecting trough through the chamber. 0 distribution trough is

pro&ided to distribute the water uniformly through out the entire cross section of deaerator o&er the

first row of perforated trough. The condensate enters the deaerator through a pipe and it flows &ia the

notches and the holes in the distributors to the perforated tray. The water is splitted to ""?0 Dets by the

perforated trays. While water cascades the steam that is admitted to the bottom of the deaerator

flows upward and heats the water. Meanwhile the diffusion of the dissol&ed gases ta#es place. The

perforated trays are #ept precisely hori>ontal. When there is o&erloading of the deaerator ta#es place

the water o&erflows through o&er flow plates. )n order to brea# the water into thin films ;<= notches are

pro&ided. When the deaerator is loaded excessi&ely the water will o&er flow in thic# films and proper

deaeration will not ta#e place. This will increase the residual oxygen content in the deaerated water.

When the water flow is less the cascade will get deformed. The water will flows through the

perforated trays are collected at the bottom by a trough where it is intensi&ely bubbled by

superheated steam. 0ny remaining oxygen will be remo&ed here and the water is completely heated

to its boiling point. /rom here the water flows to feed water tan# through the pipe.

5age 12 of 17

The trays are mounted in the channels which are welded to the shell. The welded type construction is

made anticipating no maDor defects occur during life period. 1owe&er manholes are pro&ided for

periodical maintenance.

The dissol&ed gases that are collected at the top of the deaerator will be sent to atmosphere through

the &ent pipe. The amount of &ent can be controlled by means of &al&e pro&ided. 5ro&isions are made

to connect pressure gauge and thermometer. The deaerator is supported by four= ) ; beams and is

directly mounted on feed water tan#.

5age 17 of 17

You might also like

- N11 Nozzle CalDocument9 pagesN11 Nozzle Calגרבר פליקסNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Four Laws FinalDocument40 pagesFour Laws FinalsubesinghNo ratings yet

- Foam Glass Data SheetDocument2 pagesFoam Glass Data SheetMohamed KareemNo ratings yet

- RVK Energy LTD: Sheet 1 of 6Document6 pagesRVK Energy LTD: Sheet 1 of 6lightsonsNo ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- Cost 3 TPH 12kg Fo Fired Boiler p0Document3 pagesCost 3 TPH 12kg Fo Fired Boiler p09913489806No ratings yet

- Finned Tube Heat ExchangerDocument4 pagesFinned Tube Heat ExchangerneelNo ratings yet

- SH, RH DesignDocument8 pagesSH, RH DesignJKKNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- Design of Condenser: 1) Heat Balance 2) Temeprature DifferenceDocument1 pageDesign of Condenser: 1) Heat Balance 2) Temeprature DifferenceBhawani Pratap Singh PanwarNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Heat ExcDocument4 pagesHeat ExctetirichieNo ratings yet

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocument9 pagesPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie Martinez100% (1)

- Lug On SkidDocument8 pagesLug On Skidmiteshpatel191No ratings yet

- Nozzle FEA CalculationDocument64 pagesNozzle FEA CalculationberylqzNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh Patel100% (1)

- Probad: Code-Based Strength Calculations of Pressure PartsDocument11 pagesProbad: Code-Based Strength Calculations of Pressure PartsRanjit Koshy AlexanderNo ratings yet

- MecaStack MatindokDocument59 pagesMecaStack MatindokmedyNo ratings yet

- Asme Tubesheet (Heater 10m2)Document23 pagesAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- Storage Tanks Online Course, Part IiiDocument5 pagesStorage Tanks Online Course, Part IiiJavier GarcíaNo ratings yet

- FD Aerofoil 1590x2640Document4 pagesFD Aerofoil 1590x2640Prakash WarrierNo ratings yet

- Ismc 200 Ismc 150 Ismc 150 Ismc 100 Ismc 150 Ismc 100Document12 pagesIsmc 200 Ismc 150 Ismc 150 Ismc 100 Ismc 150 Ismc 100lightsonsNo ratings yet

- Sample TEMA FIXED TUBE Type Heat Exchanger ReportDocument67 pagesSample TEMA FIXED TUBE Type Heat Exchanger Report9913489806No ratings yet

- Design ReportDocument30 pagesDesign Reportshahroze mustafaNo ratings yet

- Alloy C Torispherical Dished End CalculationDocument7 pagesAlloy C Torispherical Dished End Calculation9913489806No ratings yet

- CALCULATION SHEET For BoilerDocument6 pagesCALCULATION SHEET For BoilerAliDadKhanNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- TEMA Shell Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNo ratings yet

- Stress On 2 SaddlesDocument3 pagesStress On 2 SaddlesVlanic StudioNo ratings yet

- Pressure VesselDocument6 pagesPressure VesselKiranNo ratings yet

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Torispherical HeadDocument5 pagesTorispherical HeadLiaquat AliNo ratings yet

- Combined Load TowerDocument21 pagesCombined Load TowerHusin SaputraNo ratings yet

- 11.3 Chimney System DesignDocument3 pages11.3 Chimney System DesignkolkNo ratings yet

- Ellipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesEllipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet

- Hemispherical EndsDocument3 pagesHemispherical EndsEng-CalculationsNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Vessel ThicknessDocument7 pagesVessel ThicknessShishupal ChoudharyNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishNo ratings yet

- Annexure Wind LoadDocument36 pagesAnnexure Wind LoadVijeswara RaoNo ratings yet

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- Heat Transfer FinsDocument13 pagesHeat Transfer FinsChirag BansalNo ratings yet

- Total Points Noted in Each Section Must Clearly Show Equations With Values and Units, Drawings, Assumptions, Etc.Document6 pagesTotal Points Noted in Each Section Must Clearly Show Equations With Values and Units, Drawings, Assumptions, Etc.Amirul ArifNo ratings yet

- Solutions To Exercise Six - More Unsteady Heat TransferDocument4 pagesSolutions To Exercise Six - More Unsteady Heat TransferC Hua Ngu100% (1)

- Heat Chap07-052Document27 pagesHeat Chap07-052zetseatNo ratings yet

- Instructions: 1. Attempt All Questions. 2. Make Suitable Assumptions Wherever Necessary. 3. Figures To The Right Indicate Full MarksDocument2 pagesInstructions: 1. Attempt All Questions. 2. Make Suitable Assumptions Wherever Necessary. 3. Figures To The Right Indicate Full MarkscharulapNo ratings yet

- HW 02Document4 pagesHW 02Tabitha HowardNo ratings yet

- (Ref. Code: ME/LM/HTHP/R00) : Centurion Institute of TechnologyDocument79 pages(Ref. Code: ME/LM/HTHP/R00) : Centurion Institute of TechnologyNabin Chandra SahuNo ratings yet

- A Step Change of Magnitude 4 Is Introduced Into A System Having The Transfer FunctionDocument8 pagesA Step Change of Magnitude 4 Is Introduced Into A System Having The Transfer FunctionFarid SarrafNo ratings yet

- Heat Transfer and Heat - ExchangersDocument6 pagesHeat Transfer and Heat - ExchangersVinh Do ThanhNo ratings yet

- HT Inclass 2cDocument5 pagesHT Inclass 2cLime LimeNo ratings yet

- HW 13Document5 pagesHW 13Yahya TawakalNo ratings yet

- Xs 03Document2 pagesXs 03rishanshawkatNo ratings yet

- Appendices 10.A & 10.B:: An Educational PresentationDocument43 pagesAppendices 10.A & 10.B:: An Educational PresentationAmeya10No ratings yet

- ResEng_F2024_Assignment_4Document2 pagesResEng_F2024_Assignment_4bashirautos6192No ratings yet

- P2Document55 pagesP2Abdulla BaderNo ratings yet

- 2011Document6 pages2011rmp_wlafica19No ratings yet

- nu3MATLAB CodesDocument73 pagesnu3MATLAB CodesbotametunosegaNo ratings yet

- Alkaloids MPADocument12 pagesAlkaloids MPAUrugonda VenumadhavNo ratings yet

- Samsung India Electronics PVT LTD - Electronics Audio and Homeapplinces and Mobiles DivisionDocument2 pagesSamsung India Electronics PVT LTD - Electronics Audio and Homeapplinces and Mobiles DivisionBhanu K PrakashNo ratings yet

- Yoga SutraDocument25 pagesYoga SutraBhanu K PrakashNo ratings yet

- Walk in Interview: Hrrect@ecil - Co.inDocument2 pagesWalk in Interview: Hrrect@ecil - Co.inBhanu K PrakashNo ratings yet

- Sakshi EpaperDocument3 pagesSakshi EpaperBhanu K PrakashNo ratings yet

- PointsDocument35 pagesPointsBhanu K PrakashNo ratings yet

- List of Appellate Authority & Central Public Information Officers in Union Public Service Commission As On 08/03/2013Document4 pagesList of Appellate Authority & Central Public Information Officers in Union Public Service Commission As On 08/03/2013Bhanu K PrakashNo ratings yet

- Automatic Heat DetectorDocument8 pagesAutomatic Heat DetectorBhanu K PrakashNo ratings yet

- Option Entry Detailed Not IDocument1 pageOption Entry Detailed Not IBhanu K PrakashNo ratings yet

- Instrumentation and Measurement: Csci 599 Class Presentation Shreyans MehtaDocument22 pagesInstrumentation and Measurement: Csci 599 Class Presentation Shreyans MehtaBhanu K PrakashNo ratings yet

- Cou Rs E S Tructure: (3rd and 4th Semesters)Document57 pagesCou Rs E S Tructure: (3rd and 4th Semesters)Bhanu K PrakashNo ratings yet

- B.pahrmacy 4-2 Advanced Supply-2013Document1 pageB.pahrmacy 4-2 Advanced Supply-2013Bhanu K PrakashNo ratings yet

- Five Hundred Thousand Great British PoundsDocument1 pageFive Hundred Thousand Great British PoundsBhanu K PrakashNo ratings yet

- Jawaharlal Nehru Technological University Hyderabad: Date & Day R09 R07 NR ORDocument1 pageJawaharlal Nehru Technological University Hyderabad: Date & Day R09 R07 NR ORBhanu K PrakashNo ratings yet

- EIE and EIE PRO - Using The Headphone Select Switch and Monitor KnobDocument1 pageEIE and EIE PRO - Using The Headphone Select Switch and Monitor KnobBhanu K PrakashNo ratings yet

- Cou Rs E S Tructure: (3rd and 4th Semesters)Document57 pagesCou Rs E S Tructure: (3rd and 4th Semesters)Bhanu K PrakashNo ratings yet

- Solubility Pretest-0Document4 pagesSolubility Pretest-0Yustinus ErickoNo ratings yet

- Es 13 Thy Prob Set 1 I. Stresses: Max MaxDocument5 pagesEs 13 Thy Prob Set 1 I. Stresses: Max MaxMichael Sean DeangNo ratings yet

- Cross-Sectional Areas of Adsorbed Nitrogen, Argon, Krypton, and Oxygen On Carbons and Fumed Silicas at Liquid Nitrogen TemperatureDocument6 pagesCross-Sectional Areas of Adsorbed Nitrogen, Argon, Krypton, and Oxygen On Carbons and Fumed Silicas at Liquid Nitrogen TemperatureJuan Manuel Uceda PérezNo ratings yet

- As H 23b OpticsDocument48 pagesAs H 23b OpticsHany ElGezawyNo ratings yet

- Predictions of The Maxwell Model: T D T e TDocument4 pagesPredictions of The Maxwell Model: T D T e TShawn WaltzNo ratings yet

- PHY227-Lecture19 Spectros PDFDocument7 pagesPHY227-Lecture19 Spectros PDFSayan MondalNo ratings yet

- Unit 5-PolymerDocument27 pagesUnit 5-PolymerN x10No ratings yet

- Part 3 - 010405Document101 pagesPart 3 - 010405Sakthi venkateshNo ratings yet

- Bomb CalorimeterDocument9 pagesBomb CalorimeterSameeh Kaddoura100% (2)

- Transformers Manufacturing Process - Electrical Controls & Switchgear LTDDocument8 pagesTransformers Manufacturing Process - Electrical Controls & Switchgear LTDRaghavendra M RNo ratings yet

- Experimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemDocument13 pagesExperimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemBurak TuncerNo ratings yet

- Jacketed Vessel Design CalculusDocument4 pagesJacketed Vessel Design Calculusmaspiqdo100% (1)

- Chapter 2: Design For Shear and TorsionDocument51 pagesChapter 2: Design For Shear and TorsionMunther MohdNo ratings yet

- SB 637 (Asme)Document8 pagesSB 637 (Asme)Cristiane KassaNo ratings yet

- Poster-Excitons-polaritons HiperbólicosDocument6 pagesPoster-Excitons-polaritons HiperbólicosDihNavroskiNo ratings yet

- Ut B e Ut 0.067 B A Ut 0.107 0.107 B e Abe: Shigley's MED, 11 Edition Chapter 6 Solutions, Page 1/58Document59 pagesUt B e Ut 0.067 B A Ut 0.107 0.107 B e Abe: Shigley's MED, 11 Edition Chapter 6 Solutions, Page 1/58Muhammad HazimNo ratings yet

- Question Set For Press Tool 1Document3 pagesQuestion Set For Press Tool 1shubhamukey628No ratings yet

- ASTEC GFRP Permanent Technical Data SheetDocument1 pageASTEC GFRP Permanent Technical Data SheetMysara MohsenNo ratings yet

- Compressor FormulaDocument1 pageCompressor FormulaMangal Singh100% (1)

- SKG 16 Training 2005Document30 pagesSKG 16 Training 2005endri2000100% (1)

- DLVO Theory (And Other Stuffs)Document34 pagesDLVO Theory (And Other Stuffs)AFZBNo ratings yet

- Fracture Mechanics de Zg514: BITS PilaniDocument38 pagesFracture Mechanics de Zg514: BITS PilaniMAHESHWARAN T SNo ratings yet

- Advanced Pharmaceutical AnalysisDocument4 pagesAdvanced Pharmaceutical AnalysisRezaul RazibNo ratings yet

- Lecture 09 PDFDocument25 pagesLecture 09 PDFRachit ShahNo ratings yet

- Study of DiffusionDocument14 pagesStudy of Diffusionmahbub1332No ratings yet

- Hardox 400 PlateDocument3 pagesHardox 400 PlateAli TalebiNo ratings yet

- Chapter - One Introduction To Open Channel HydraulicsDocument8 pagesChapter - One Introduction To Open Channel Hydraulicsሽታ ዓለሜNo ratings yet

- Corrosion Resistance of Chromium-Free Conversion Coatings Deposited OnDocument10 pagesCorrosion Resistance of Chromium-Free Conversion Coatings Deposited OnbexigaobrotherNo ratings yet