0 ratings0% found this document useful (0 votes)

279 viewsSAIC & SATR - Instrumentation

SAIC & SATR - Instrumentation

Uploaded by

Adel KlkThis document provides instrumentation material requirements for a project, including:

1. Instrumentation materials must be traceable from manufacturer to installation and use.

2. Materials must be identified using tags, stamps, or labels without affecting function.

3. Materials must conform to requirements and specifications before installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

SAIC & SATR - Instrumentation

SAIC & SATR - Instrumentation

Uploaded by

Adel Klk0 ratings0% found this document useful (0 votes)

279 views8 pagesThis document provides instrumentation material requirements for a project, including:

1. Instrumentation materials must be traceable from manufacturer to installation and use.

2. Materials must be identified using tags, stamps, or labels without affecting function.

3. Materials must conform to requirements and specifications before installation.

Original Description:

SAIC & SATR - Instrumentation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides instrumentation material requirements for a project, including:

1. Instrumentation materials must be traceable from manufacturer to installation and use.

2. Materials must be identified using tags, stamps, or labels without affecting function.

3. Materials must conform to requirements and specifications before installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

279 views8 pagesSAIC & SATR - Instrumentation

SAIC & SATR - Instrumentation

Uploaded by

Adel KlkThis document provides instrumentation material requirements for a project, including:

1. Instrumentation materials must be traceable from manufacturer to installation and use.

2. Materials must be identified using tags, stamps, or labels without affecting function.

3. Materials must conform to requirements and specifications before installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

A11

Traceability - Instrumentation materials shall be traceable from the

manufacturer and supplier through delivery, storage, fabrication,

erection, installation, repair, modification and use.

Schedule "Q"

Attachment lV

Sec. 3.3

A10

Identification - Instrumentation materials shall be identified by using tags,

stamps, color coding, stencils or labels. The location and method of

identification shall not affect the function or quality of the materials.

Schedule "Q"

Attachment lV

Sec. 3.2

A9

QC Before Installation - Instrumentation materials shall conform to all

applicable requirements, standards, and specifications prior to release to

be used as part of the work.

Schedule "Q"

Attachment lV

Sec 7.1

A8 Free of Damage - Instrumentation materials shall be free of damage.

Schedule "Q"

Attachment lV

Sec 7.1

A7

As Designed - Instrumentation materials shall be in accordance with the

Saudi Aramco-approved project-specific design drawings, diagrams,

schedules, lists, databases, and associated documents.

Schedule "G"

Sec. 4.1

A7 New and Unused - Instrumentation materials shall be new and unused.

Schedule "G"

Sec. 4.1

A6

Nonmaterial Requirements The supplier shall provide nonmaterial items

as shown on Form NMR-7930.

34-SAMSS-913

Sec. 9.2

A5

Inspection Items manufactured to this Specification (34-SAMSS-913) are

subject to the minimum inspection requirements as specified in Saudi

Aramco Inspection Requirements Form 175-347600. 9.2

34-SAMSS-913

Sec. 9.1

A4

Cable materials supplied shall be third-party listed as meeting the

requirements of IEC 61158-2, ISA 5.1, FF 569 and NFPA 70 (2002)

SAES-J -904

Sec 3.2

Schedule Q

Attachment lV

Sec 4

Review Quality Documentation for Material Receiving.

Schedule Q,

Att, IV, Sec. 3.1.

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

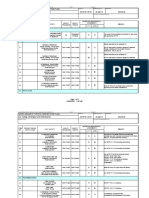

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

1-Oct-05 INST

A3

Documented control system shall be implemented for all Saudi Aramco

supplied material and equipment.

PROJ ECT TITLE WBS / BI / J O NUMBER CONTRACTOR / SUBCONTRACTOR

A. Certification and Third-Party Listing

A1

EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID.

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912

SAUDI ARAMCO INSPECTION LEVEL

LAYOUT DRAWING NUMBER

PLANT NO. EQUIPMENT ID NUMBER(S)

SAUDI ARAMCO USE ONLY

MH's SPENT SCHEDULED INSPECTION DATE & TIME

N/A

TRAVEL TIME QUANTITY INSP.

WORK PERMIT REQUIRED?

ACTUAL INSPECTION DATE & TIME

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE PASS

EC / PMCC / MCC NO. REV. NO. PURCHASE ORDER NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

RE-INSP DATE FAIL

B. General Requirements

CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO TIP NUMBER

A2

Verify that the contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier

locations as required by the inspection level assigned for the materials

and equipment identified in SAER-1972 Inspection Requirements.

Schedule Q

Attachment llI

Sec.1.2

B2

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags / labels

and nameplates, and shipment checked for damage, prior to acceptance

of the shipment

Schedule Q,

Att IV, Sec. 7.1.

Page 1 of 8

B9

Spur Cables Type 'A' cable (#18 AWG), as specified in section 12.8.2 of

IEC-61158-2, shall be used for all spur cabling e.g., Belden YM46698.

SAES-J -904

Sec. 6.4.2

B3

Trunk (Home run) Cabling: Either Type 'A' cable as specified in section

12.8.2 of IEC-61158-2 or Aramco's standard 18 AWG multi-pair,

individually shielded cable for analog signals, per 34-SAMSS-913 Group-

4 cable specification, shall be used for all trunk wiring. (Refer to

attachment 1, 2 & 3 for details of cables)

SAES-J -904

Sec. 6.4.1.1.

B4

The 1900 meter design criteria is acceptable with Aramco's standard

instrumentation cable or with Type-A cable i.e., you do not have to

reduce the total segment length if you use Aramco standard Group-4

instrumentation cable. 18 AWG is the minimum wire size that may be

used, larger wire sizes for the homerun cable are acceptable e.g., 16

AWG.

SAES-J -904

Sec. 6.4.1.1.

B5

Twenty percent (20%) spare pairs shall be provided for all Fieldbus

segment trunk cables, with a minimum of one spare pair. This

requirement includes spares on trunk cable runs between marshalling

racks and junction boxes and between field junction boxes.

SAES-J -904

Sec. 6.4.1.2

B11

34-SAMSS-913,

Sec.6.5.5

B10

Conductor: Stranded, circular copper, per ASTM B3, 7 strands minimum;

tinned, per ASTM B33, if primary insulation may corrode unprotected

copper (e.g.,unstabilized XLPO/XLPE) or if otherwise specified

34-SAMSS-913,

Sec.6.5.1

Primary Insulation Material: Flame retardant PVC or thermoset cross

linked polyolefin (XLPO or XLPE), minimum temperature rating 90C.

34-SAMSS-913,

Sec.6.5.3

B12

B14

B15 Lay of Twist: 40 to 60 mm

34-SAMSS-913,

Sec.6.5.6

34-SAMSS-913,

Sec. 6.3.7 &.

Assembly: Two insulated conductors uniformly twisted into a pair or three

insulated conductors uniformly twisted into a triad

N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE

CONTRACTOR / SUBCONTRACTOR

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

PROJ ECT TITLE WBS / BI / J O NUMBER

PASS FAIL

B6

The decision to use multi-pair or single pair trunk cabling depends on the

number of segments installed in the field junction box. Typically, the

trunk cable will be a multi-pair cable if you have more than one segment

in the junction box. Note that under all circumstances, there will be at

least 2 Fieldbus trunk pairs run together (one active and one spare

minimum).

SAES-J -904

Sec. 6.4.1.2

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

Primary Insulation Voltage Rating:

300 V for Type PLTC and Type ITC Cable

600 V for Type TC Cable

34-SAMSS-913,

Sec.6.5.4

B13

Primary Insulation Thickness: 0.38 mm (15 mils) minimum average

thickness for Types PLTC and ITC Cables .64 mm (25 mils) minimum

average for Type TC Cable

B7

From prior FF projects implemented at Saudi Aramco, the following trunk

installation design is a cost effective solution: From the marshalling

cabinet route a multi-pair cable (e.g., 12-24 pair) to an intermediate

junction box. Note: This intermediate junction box only contains pass-

through terminal blocks i.e., no wiring-blocks. From the intermediate

junction box then route multi-pair cables (e.g., 2-6 pair) to outlying FF

junction boxes. This method reduces the number of FF cables entering

the PIB and reduces the total installed cost of the trunk cabling.

SAES-J -904

Sec. 6.4.1.2

B8

All multi-pair trunk cables shall contain only FF signals i.e., no other

signal type is allowed in a trunk cable.

SAES-J -904

Sec. 6.4.1.3

Page 2 of 8

N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE

CONTRACTOR / SUBCONTRACTOR

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

PROJ ECT TITLE WBS / BI / J O NUMBER

PASS FAIL

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

B25

B26

Cables used in other classified areas shall meet the requirements

outlined in NFPA 70 (NEC), articles 501-505. 2.

SAESJ --902,

Table 2, Note 1

B27

A larger wire size shall be considered to overcome potential voltage

drops. The maximum voltage drop shall not exceed 5%.

SAESJ --902,

Table 2, Note 2

Cables installed in Zone 1 (Class -1, Div.-1) shall be listed as suitable for

that classified area. I

SAESJ --902,

Table 2, Note 1

Outer J acket Marking

The following information shall be clearly marked on the outer jacket of

the cable, in no specific order: a) Manufacturer's name, trade name,

catalog or type number b) Number of pairs/triads c) Conductor size in

mm or AWG d) Voltage rating (300 or 600 V) e) Type of cable (PLTC,

TC or equivalent) f) Approval mark of listing authority (UL, IEC, BS, DIN,

or equivalent) g) "Sunlight resistant" designation, in Manufacturer's

standard nomenclature, for Type TC cable (Optional for Type PLTC

cable) h) "Direct burial" designation, if applicable per UL 13 or UL 1277,

in Manufacturer's standard nomenclature I) "Oil resistant" designation, in

manufacturer's standard nomenclature, for Type TC Cable (preferred for

Types ITC and PLTC Cable)

B24

Cable Reel Marking

Each reel shall have a weatherproof (metal or plastic) tag, securely

attached to a flange of the reel and plainly stating:

a) Manufacturer's trade name

b) Date of manufacture

c) Conductor size

d) Cable rating

e) Type of cable

f) Temperature designation

g) Minimum bend radius

h) Maximum pulling tension

i) Shipping length and diameter of cable

j) Saudi Aramco Purchase Order number

34-SAMSS-913,

Sec.7.2

34-SAMSS-913,

Sec. 7.1

B20

Jacket Color : For all FF cables, spur and trunk, the outer jacket color

shall be orange.

Intrinsically safe applications: Blue

SAES-J -904

Sec.6.4.3.1 and

34-SAMSS-913,

Sec. 6.5.28

B19 J acket Application: Extruded over assembly

34-SAMSS-913,

Sec. 6.3.17.&

34-SAMSS-913,

Sec.6.5.25

J acket Thickness:

Minimum thickness per UL 13, paragraph 13.1 for Type PLTC

Minimum thickness per UL 1277, paragraph 11.3 for Type TC

Minimum thickness per UL 2250, paragraph 16.3 for Type ITC

34-SAMSS-913,

Sec.6.5.26

J acket Material :Flame retardant PVC, minimum temperature rating 90C

dry, 75C wet

B16

Color Code: One black wire, one white wire for pairs; one black wire, one

white wire, one red wire for triads; or as specified on Form 8020-913-

ENG, Line Item 14

34-SAMSS-913,

Sec.6.5.8

B17

B21

B22

J acket Color :For all FF cables, spur and trunk, the conductor color code

shall be; (+signal) black (- signal) white drain/shield bare tinned copper

conductor

SAES-J -904

Sec.6.4.3.3

B23

B18

J acket Color :For all 'armored' FF cables, spur and trunk, the inner and

outer jacket color of the armored cable shall be orange.

SAES-J -904

Sec.6.4.3.2

Page 3 of 8

N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE

CONTRACTOR / SUBCONTRACTOR

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

PROJ ECT TITLE WBS / BI / J O NUMBER

PASS FAIL

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

B28

Type ITC cable shall not be installed on either non-power limited circuits

or powered limited circuits operating at more than 150 volts or more than

5 amperes.

B42 Overall Shield Thickness: 0.022 mm (0.85 mil) minimum

34-SAMSS-913,

Sec. 6.5.20

B30

Conductor Size: 18 AWG or as specified on Form 8020-913-ENG, Line

Item 13 or project specification.

34-SAMSS-913,

Sec. 6.5.2

SAESJ --902,

Table 2. Note 3

34-SAMSS-913,

Sec. 6.5.17

34-SAMSS-913,

Sec. 6.5.16

34-SAMSS-913,

Sec. 6.5.13

Individual Shield Application : Helical, minimum 25% overlap, to provide

100% coverage and electrical isolation from other shields and

conductors

34-SAMSS-913,

Sec. 6.5.15

Individual Shield Thickness: 0.022 mm (0.85 mil) minimum

34-SAMSS-913,

Sec. 6.5.14

B41

Overall Shield Material: Aluminum foil bonded to non-hygroscopic

polyester (Mylar) tape, either: foil free-edge or equal-width foil and tape,

per Manufacturer's standard.

34-SAMSS-913,

Sec. 6.5.19

34-SAMSS-913,

Sec. 6.5.18

B43

Overall Shield Application: Helical, minimum 25% overlap, to provide

100% coverage and electrical isolation from conductors and other

shields

34-SAMSS-913,

Sec. 6.5.21

34-SAMSS-913,

Sec. 6.5.11

B40

Individual Shield Drain Wire Application: In continuous contact with

shield foil

B33 Cable Assembly: Single grouped assembly, per Manufacturer's standard

B38

B35

Individual Shield Material: Aluminum foil bonded to non-hygroscopic

polyester (Mylar) tape, either: foil free-edge or equal-width foil and tape,

per Manufacturer's standard

B36

Individual Shield Drain Wire Conductor: Stranded, circular tinned copper,

per ASTM B33, 7 strands minimum

B37

B34

Communication Wire: Not required. If provided, shall be Manufacturer's

standard size; insulation same as primary insulation; orange color

34-SAMSS-913,

Sec. 6.5.12

Number of Pairs or Triads: Refer to Form 8020-913-ENG, line item 12.

Manufacturer's standard products, meeting or exceeding this number is

acceptable upon approval of Buyer

34-SAMSS-913,

Sec. 6.5.9

B32

Pair/triad Identification: Number designation continuously stamped on

white conductor

34-SAMSS-913,

Sec. 6.5.10

B29

B31

Differences in the manufacturer recommended cable and these

requirements shall be resolved with Instrumentation Unit/PID/P&CSD.

SAESJ --902,

Note 4

B39

Individual Shield Drain Wire Size: Manufacturer's standard, with

minimum size one even gauge size smaller than conductor size

B44

Overall Shield Drain Wire Conductor: Stranded, circular tinned copper,

per ASTM B33, 7 strands minimum

34-SAMSS-913,

Sec. 6.5.22

B45

Overall Shield Drain Wire Size: Manufacturer's standard, with minimum

size one even gauge size smaller than conductor size

34-SAMSS-913,

Sec. 6.5.23

B46

Overall Shield Drain Wire Application: In continuous contact with shield

foil

34-SAMSS-913,

Sec. 6.5.24

Page 4 of 8

N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE

CONTRACTOR / SUBCONTRACTOR

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

PROJ ECT TITLE WBS / BI / J O NUMBER

PASS FAIL

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

REMARKS:

1. Attachment 1--Type A cable as specified in IEC-61158-2, Sec. 12.8.2 , 3rd Edition 2003

5. SAES-J -904 FOUNDATION Fieldbus (FF) Systems , 31 J uly 2004

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. SAES-J -902, Electrical Systems for Instrumentation, 31 J uly 2004

4. 34-SAMSS-913 Instrumentation and Thermocouple Cable, 30 J une 2002

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

2. Attachment 2-- Cable description and specification as specified in IEC-61158-2 - Annex B- 3rd Edition- 2003

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

NOTES:

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

Contractor / Third-Party Saudi Aramco

5. Remarks -Operating at a signal speed of 31.25 kilobits per sec , H1

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

indicates compliance with appropriate standards or performance in a specified manner.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

PID Representative

T&I Witnessed QC Record Reviewed Work Verified

PMT Representative

Name, Initials and Date:

Work is Complete and Ready for Inspection:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), J uly 1993

2. Schedule Q -- Quality Requirements (Pro Forma Contract), November 2003

ATTACHMENTS:

Name, Initials and Date:

Performed Inspection Work / Rework May Proceed Work Verified

Name, Initials and Date:

T&I Witnessed

QC Inspector

Work Verified T&I Witnessed

QC Record Reviewed

QC Record Reviewed

*Person Responsible for Completion of Quality Work / Test Y =YES N =NO F =FAILED

3. Attachment 3 --Fieldbus Typical Cable data

Construction Representative*

REFERENCE DOCUMENTS:

Name, Sign and Date:

Quality Record Approved:

Name, Organization,

Initials and Date:

Proponent and Others

Name, Initials and Date:

QC Supervisor

Page 5 of 8

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

Attachment 1-- Type A cable as specified in IEC-61158-2 -3rd Edition 2003

Page 6 of 8

Attachment 2-- Type A cable as specified in IEC-61158-2 - Annnex B- 3rd Edition- 2003

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

Page 7 of 8

FOUNDATION fieldbus -Cable-Type " A" or Multipair,

individually shielded cable-Material Receiving

SAIC-J-6912 1-Oct-05 INST

Attachment 3 --Fieldbus Typical Cable data

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

Page 8 of 8

You might also like

- SATIP-P-114-01 Rev 7 FinalDocument6 pagesSATIP-P-114-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- ELC-SC-4744-D Electrical Systems Checkout and Commissioning: Commented Copy - Not For Supplier DistributionDocument35 pagesELC-SC-4744-D Electrical Systems Checkout and Commissioning: Commented Copy - Not For Supplier Distributiondidik_wahyudiNo ratings yet

- Saes T 494Document9 pagesSaes T 494Ahamedulla KhanNo ratings yet

- SATR - J - 6702 Rev 0 PDFDocument8 pagesSATR - J - 6702 Rev 0 PDFAdel KlkNo ratings yet

- SAIC & SATR - InstrumentationDocument4 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- QDR-GCS-ESJ-REP-1000 RevADocument31 pagesQDR-GCS-ESJ-REP-1000 RevAshaheen iqbal100% (2)

- ICM-CD-6120.06 Check Sheet CV & Ancillaries CalibratonDocument2 pagesICM-CD-6120.06 Check Sheet CV & Ancillaries CalibratonShivani DubeyNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Pre-Commissioning FormDocument2 pagesSaudi Aramco Pre-Commissioning Formmahdi_gNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationFlorante NoblezaNo ratings yet

- SAIC-J - 6501 - Rev 0Document7 pagesSAIC-J - 6501 - Rev 0Adel KlkNo ratings yet

- Sabp J 900Document9 pagesSabp J 900kartik_harwani4387No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Saes J 400Document16 pagesSaes J 400sijoy josephNo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saes B 063Document6 pagesSaes B 063hasanmnhNo ratings yet

- ELC-SU-366-C Low Voltage Motor Control CentersDocument17 pagesELC-SU-366-C Low Voltage Motor Control CentersAdi Toto HaryonoNo ratings yet

- ICM-CD-6119.06 Check Sheet PSVDocument1 pageICM-CD-6119.06 Check Sheet PSVShivani DubeyNo ratings yet

- SATIP-P-111-01 Rev 7 FinalDocument12 pagesSATIP-P-111-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument37 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- 7.1 Method Statement For Termination & GlandingDocument24 pages7.1 Method Statement For Termination & GlandingMedrouaNo ratings yet

- Control Valve IPF Function Test1Document5 pagesControl Valve IPF Function Test1btjajadiNo ratings yet

- Section-6-Control - Power CablesDocument12 pagesSection-6-Control - Power Cablesthumula.rameshNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- Ages-Sp-04-015-Machinery Instrument SystemDocument79 pagesAges-Sp-04-015-Machinery Instrument Systemsyed muhammad wasimNo ratings yet

- Instr Loop Check PDFDocument3 pagesInstr Loop Check PDFMohamed AdelNo ratings yet

- Toc PL381Document5 pagesToc PL381anjangandak2932No ratings yet

- Saes P 114Document23 pagesSaes P 114HatemS.MashaGbehNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- 26071-100-583-GST-00002 - 001 - Emergency Air Compressor and Dryer Commissioning Procedure U335Document49 pages26071-100-583-GST-00002 - 001 - Emergency Air Compressor and Dryer Commissioning Procedure U335widionosucipto29No ratings yet

- Fjords Saes J 902Document33 pagesFjords Saes J 902aravindNo ratings yet

- FF Design and Project ExecutionDocument24 pagesFF Design and Project ExecutionDuan QingBinNo ratings yet

- NG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedDocument16 pagesNG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedFolarin AyodejiNo ratings yet

- En ACS580 Standard Control Program FW C A5Document440 pagesEn ACS580 Standard Control Program FW C A5joseNo ratings yet

- Sabp Z 002CDocument46 pagesSabp Z 002CBIPIN BALAN100% (1)

- J 16Document29 pagesJ 16Rochdi SahliNo ratings yet

- SATR-J - 6801 - Rev 0 PDFDocument6 pagesSATR-J - 6801 - Rev 0 PDFAdel KlkNo ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- Pre Energization Test ProceduresDocument6 pagesPre Energization Test Proceduressani priadiNo ratings yet

- J 19Document14 pagesJ 19Rochdi SahliNo ratings yet

- Aa 036142 001Document19 pagesAa 036142 001Engr Muhammad Azam ThaheemNo ratings yet

- DPT Calibration FFDocument4 pagesDPT Calibration FFKram Alim VillonNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- TMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRDocument15 pagesTMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRdijoz85No ratings yet

- 3 Oil Processing SystemDocument52 pages3 Oil Processing SystemPatrick da SilvaNo ratings yet

- 23 Samss 020Document44 pages23 Samss 020Cherukunnon Jubu100% (1)

- Maintenance of Substation Room: Saudi Electricity CompanyDocument64 pagesMaintenance of Substation Room: Saudi Electricity CompanyAmmar Lateef GakharNo ratings yet

- PSSR Checklist FT-15-308 & 09 - CAN PlantDocument16 pagesPSSR Checklist FT-15-308 & 09 - CAN PlantMuhammad Umer RanaNo ratings yet

- Exothermic WeldingDocument40 pagesExothermic WeldingMaulik ShahNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument13 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- Koc L 006Document50 pagesKoc L 006roshankumar437No ratings yet

- Pantograph Cables For Marine Loading ArmsDocument7 pagesPantograph Cables For Marine Loading ArmsShahul Hameed RazikNo ratings yet

- CEM Technical Specification Rev - 0Document9 pagesCEM Technical Specification Rev - 0Wellington NascimentoNo ratings yet

- Comment Resolution Sheet 19009 Welding DossierDocument1 pageComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNo ratings yet

- GS-4500 Instrumentation Design and Installation SpecificationDocument76 pagesGS-4500 Instrumentation Design and Installation SpecificationSmart LauNo ratings yet

- Saudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional TestingDocument6 pagesSaudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional Testingkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAdel KlkNo ratings yet

- Kelada, Buire JCGE22Document7 pagesKelada, Buire JCGE22Adel KlkNo ratings yet

- Power Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageDocument7 pagesPower Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageAdel KlkNo ratings yet

- Transmission LineDocument2 pagesTransmission LineAdel KlkNo ratings yet

- Transmission LineDocument2 pagesTransmission LineAdel KlkNo ratings yet

- 3 4 GIZ17 XXX Presentation Clemens HoffmannDocument20 pages3 4 GIZ17 XXX Presentation Clemens HoffmannAdel KlkNo ratings yet

- Modeling and Control of Wind Power System PDFDocument212 pagesModeling and Control of Wind Power System PDFAdel Klk50% (2)

- 3 3 GIZ17 XXX Presentation J HenkelDocument28 pages3 3 GIZ17 XXX Presentation J HenkelAdel KlkNo ratings yet

- 3 1 GIZ17 XXX Presentation Ernesto HuberDocument36 pages3 1 GIZ17 XXX Presentation Ernesto HuberAdel KlkNo ratings yet

- 3 2 GIZ17 XXX Presentation Sandip SharmaDocument49 pages3 2 GIZ17 XXX Presentation Sandip SharmaAdel KlkNo ratings yet

- Ieee 1145Document18 pagesIeee 1145Adel KlkNo ratings yet

- Control For Renewable Energy and Smart Grids IoCT-Part1-06RESGDocument20 pagesControl For Renewable Energy and Smart Grids IoCT-Part1-06RESGOnwunta E K OnwuntaNo ratings yet

- Alfanar Building Cables Wires CatalogDocument12 pagesAlfanar Building Cables Wires CatalogAdel KlkNo ratings yet

- Activity Output Date of Implementation Person Responsible Budget Budget SourceDocument2 pagesActivity Output Date of Implementation Person Responsible Budget Budget Sourceconnie d. julianNo ratings yet

- Ethical and Legal Issues in RetailingDocument14 pagesEthical and Legal Issues in RetailingPoonam Sharma0% (1)

- For Doctors: A Guide To Living and Working in AustraliaDocument8 pagesFor Doctors: A Guide To Living and Working in AustraliaNarii PrassiiNo ratings yet

- Report PPM Sakai Triputra Group by An (130623) ..Document6 pagesReport PPM Sakai Triputra Group by An (130623) ..mauNo ratings yet

- Team Member JD Booklet PDFDocument11 pagesTeam Member JD Booklet PDFomarNo ratings yet

- Scba & FMS PDFDocument74 pagesScba & FMS PDFHamid MasoodNo ratings yet

- Casio Aq140w UputstvoDocument1 pageCasio Aq140w UputstvoalazovicNo ratings yet

- ABAP On HANA AdvancedDocument23 pagesABAP On HANA AdvancedRaul Pritesh100% (1)

- Solar Power Plants Detailed Guide PDFDocument102 pagesSolar Power Plants Detailed Guide PDFEdzwan RedzaNo ratings yet

- Indenting (HM)Document3 pagesIndenting (HM)Mani JatanaNo ratings yet

- Sop of Ipc-2Document3 pagesSop of Ipc-2Jahanzeb KhanNo ratings yet

- AS360 Series Elevator Intergrated Controller Operation Manual V1.00 2013.9.18Document66 pagesAS360 Series Elevator Intergrated Controller Operation Manual V1.00 2013.9.18Javier MartínezNo ratings yet

- PODEM ANUPAM Brochure CraneComponentDocument28 pagesPODEM ANUPAM Brochure CraneComponentJnanamNo ratings yet

- Minemax Scheduler White PaperDocument12 pagesMinemax Scheduler White PaperManuel AragonNo ratings yet

- 29 Farley Fulache Vs ABS CBNDocument2 pages29 Farley Fulache Vs ABS CBNsakuraNo ratings yet

- CEHv6 1DayPrepPracticeQuestionsDocument127 pagesCEHv6 1DayPrepPracticeQuestionsElvis Garcia Reyes100% (1)

- E-Ticket 0706658136310: Kolkata BhubaneswarDocument2 pagesE-Ticket 0706658136310: Kolkata BhubaneswarBanerjee SuvranilNo ratings yet

- Customs ClearanceDocument35 pagesCustoms ClearanceZhizheng ChenNo ratings yet

- DLL TLE 8 WEEk 10Document3 pagesDLL TLE 8 WEEk 10Tr Darren Joy LaluonNo ratings yet

- Research Papers On Real Estate ValuationDocument4 pagesResearch Papers On Real Estate Valuationgxkswirif100% (1)

- Mini Project INTERCOM LM386 by Abid ParwezDocument26 pagesMini Project INTERCOM LM386 by Abid Parwezabidparwez100% (4)

- Cocoa Cutting and Splitting MachineDocument22 pagesCocoa Cutting and Splitting MachineAnil KumarNo ratings yet

- Introduction To HousekeepingDocument41 pagesIntroduction To HousekeepingChristian Alejandrino100% (1)

- The Occupational & Safety Health Management & Workers Productivity: The Relationship & EffectDocument25 pagesThe Occupational & Safety Health Management & Workers Productivity: The Relationship & EffectAhmedAymanNo ratings yet

- Is.13054.1991 0 PDFDocument8 pagesIs.13054.1991 0 PDFRakesh MishraNo ratings yet

- Emergency Simulations: Administrators' GuideDocument64 pagesEmergency Simulations: Administrators' GuideOxfamNo ratings yet

- S4Hana - SD Integration With FICODocument74 pagesS4Hana - SD Integration With FICOBhargav ReddyNo ratings yet

- (20-22398 37) October 27, 2015 Email From Laurence Schneider To First American Bank DE 235, Ex. ADocument8 pages(20-22398 37) October 27, 2015 Email From Laurence Schneider To First American Bank DE 235, Ex. Alschneider68No ratings yet

- Arc Flash Report Example 2015Document110 pagesArc Flash Report Example 2015uplbselesNo ratings yet

- DMTDocument1 pageDMTPipo Canelas100% (3)