0 ratings0% found this document useful (0 votes)

236 views72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems Corporation

72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems Corporation

Uploaded by

Balaji VenkatesanThis document provides information about Japan AE Power Systems Corporation's 72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker (MAE-027A).

The circuit breaker uses vacuum interrupters and dry air insulation instead of SF6 gas to prevent global warming. It has excellent breaking performance due to the vacuum interrupters and can handle multiple strokes and evolving faults. Maintenance is reduced since vacuum interrupters require no inspection.

The document provides details on the circuit breaker's type, ratings, construction, dimensions, performance testing, and standard connections. It utilizes dry air at a rated pressure for insulation and alarm and lockout functions if pressure decreases.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems Corporation

72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems Corporation

Uploaded by

Balaji Venkatesan0 ratings0% found this document useful (0 votes)

236 views4 pagesThis document provides information about Japan AE Power Systems Corporation's 72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker (MAE-027A).

The circuit breaker uses vacuum interrupters and dry air insulation instead of SF6 gas to prevent global warming. It has excellent breaking performance due to the vacuum interrupters and can handle multiple strokes and evolving faults. Maintenance is reduced since vacuum interrupters require no inspection.

The document provides details on the circuit breaker's type, ratings, construction, dimensions, performance testing, and standard connections. It utilizes dry air at a rated pressure for insulation and alarm and lockout functions if pressure decreases.

Original Description:

72kV vacuum Circuit Breaker

Original Title

72kV VCB

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides information about Japan AE Power Systems Corporation's 72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker (MAE-027A).

The circuit breaker uses vacuum interrupters and dry air insulation instead of SF6 gas to prevent global warming. It has excellent breaking performance due to the vacuum interrupters and can handle multiple strokes and evolving faults. Maintenance is reduced since vacuum interrupters require no inspection.

The document provides details on the circuit breaker's type, ratings, construction, dimensions, performance testing, and standard connections. It utilizes dry air at a rated pressure for insulation and alarm and lockout functions if pressure decreases.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

236 views4 pages72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems Corporation

72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems Corporation

Uploaded by

Balaji VenkatesanThis document provides information about Japan AE Power Systems Corporation's 72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker (MAE-027A).

The circuit breaker uses vacuum interrupters and dry air insulation instead of SF6 gas to prevent global warming. It has excellent breaking performance due to the vacuum interrupters and can handle multiple strokes and evolving faults. Maintenance is reduced since vacuum interrupters require no inspection.

The document provides details on the circuit breaker's type, ratings, construction, dimensions, performance testing, and standard connections. It utilizes dry air at a rated pressure for insulation and alarm and lockout functions if pressure decreases.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

At a glance

Powered by AI

The circuit breaker uses dry air insulation instead of SF6 gas to prevent global warming and is designed for reliable performance.

The circuit breaker is designed to interrupt short-circuit and fault currents.

Current interruption is performed using vacuum interrupters which allow for excellent insulation recovery and breaking performance.

Japan AE Power Systems Corporation Japan AE Power Systems Corporation

72.5kV Dry Air Insulated

Dead Tank

Vacuum Circuit Breaker

MAE-027A

MAE-027A

Landic Shimbashi Building, 8-3, Nishi-shimbashi 3-chome,

Minato-ku, Tokyo, 105-003, Japan

Japan AE Power Systems Corporation

Phone +81-3-5405-8932 Fax +81-3-5405-8915

Web: www.jaeps.com

1

Features

72.5kV Dry Air Insulated

Dead Tank VCB

The Dry Air Insulated Dead Tank VCB

was born of superb technology and

abundant production experience of

Japan AE Power Systems Corporation.

It is a circuit breaker employing

vacuum interrupters and dry air for

insulation. In order to use no SF6,

which is global warming gas, there is

no fear to decomposition of gas due to

current interruption. It is therefore a

highly reliable and high-performance

circuit breaker.

1 2

Contribution to global warming prevention

Dry air insulation are employed instead of SF6 gas insulation. GWP (Global Warning Potential) of

SF6 is 23,900.

Excellent breaking performance

Since each current breaking section employs a vacuum interrupter, insulation recovery

characteristics are excellent. It exhibits superb characteristics in cases of short-circuit interruption

and short line fault interruption.

Sufficient capability against multiple strokes

and evolving faults

Since the vacuum interrupters used are of completely self-arc-diffusion type, this circuit breaker is

the only unit that is capable of disposing of multiple strokes and evolving fault currents.

Reduction of maintenance labor

Use of vacuum interrupters in the current breaking sections eliminates requirements of inspection

for these sections. Therefore, man-hours can be saved for maintenance and inspection.

31.5 40

80

31.5 (3s)

100

40 (3s)

3 4

2

Type and Ratings

1 Type and Ratings

2 Installable number of BCT per a bushing

Notes a) MR : Multi Ratio, SR : Single Ratio

b) RF= 2.0

c) Please contact us for BCT as per IEC standard.

Type

Rated voltage (kV)

Withstand voltage

Rated frequency (Hz)

Rated normal current (A)

Rated short circuit breaking current (kA)

Rated transient recovery

voltage

First pole to clear factor

Rated short circuit making current (kA)

Rated short time current (kA)

Rated breaking time (cycle)

Rated opening time (s)

Make time with no load (s)

Operating duty

Closing control voltage (Vdc)

Rated tripping voltage (Vdc)

Supply voltage for

charging motor

Rated dry-air pressure

Closing operation system

Tripping control system

Applicable standard

NBVOA-60740BB NBVOA-60732BB

72.5

140

350

50 / 60

2000

1.47

1.5

3

0.04

0.08

O-0.3s-CO-15s-CO

48, 100, 110, 125, 250

48, 100, 110, 125, 250

48, 100, 110, 125, 250

60, 120, 240

72.5 psig (0.5MPa-g) (at 20)

Spring

Spring

IEC 62271-100-2003, ANSI C37.06-2000

1 min power frequency (kV rms)

1.2x50s impulse (kV peak)

Rate of rise

(kV/s)

(Vdc)

(Vac)

Rated current

20005

12005

6005

MRSR

MR

SR

MR

SR

MR

SR

Accuracy class

C800

C400

C200

C200

C800

C400

C200

C200

C800

C400

C200

C200

Number of BCT

3

3

3

3

3

3

3

3

1

3

3

3

3 Construction

1 Overall construction

For each phase, a current breaking vacuum interrupter is

accommodated in the grounded tank. The operation

system is such that closing and tripping are effected by

spring force.

The operating mechanism and 3-phase interlinkage are

assembled on a common base, which is installed on the

frame legs.

2 Internal construction

The overall structure is composed mainly of grounded

tank, vacuum interrupters (VI), insulating rods, bushings

and main circuit terminals. Each grounded tank is filled

with dry air maintained at a rated pressure of 72.5 psig

(0.5MPa-g) (20).

Internal construction of vacuum circuit breaker

3 Dry air system

Dry air is used for insulation and sealed at the

rated pressure of 72.5 psig (0.5MPa-g). The

internal pressure is supervised with a density

monitor.

When the dry air pressure lowers to 58.0 psig

(0.4MPa-g) (20), the alarm contact of pressure

switch is actuated.

Dry air system

Rated

Alarm

Lock-out

72.5psig (0.5MPa-g)

65.3psig (0.45MPa-g)

58.0psig (0.4MPa-g)

Main Circuit Terminal

Bushing

Conductor

BCT

Rupture Disk

Insulator

VI

Tank

Insulating Pipe

Insulating Rod

Pressing Mechanism

Main Shaft

5 6

4 External Dimensions

Outline drawing

5

6

1 Withstand voltage characteristics

Performance of withstand voltage is assured at the specified dry-

air pressure. Even though the dry air pressure has been lowered

to the alarming level, the required insulation level can be assured.

In addition, even though this pressure lowers to the atmospheric

pressure, the circuit breaker withstands the rated voltage.

2 Current passing performance

Since the main contacts are located under vacuum, their surfaces

are never oxidized and current passing performance is therefore

stabilized. In the closing mode of circuit breaker, a pressing force

is exerted between main contacts by the effect of pressing spring

and sufficient tolerance is assured against closing current and

short-time current.

3 Interruption performance

4 Mechanical life

Due to adoption of simplified operating mechanism, switching

characteristics are extremely stabilized. Frequent switching

perf ormance has al so been veri f i ed t hrough cont i nuous

mechanical switching test by repeating switching operations more

than 10,000 times.

5 Electrical life

Since current breaking is performed in the vacuum interrupter,

arcing energy generated during current interruption is extremely

low and contact erosion is minimal. This implies long contact life.

Load current switching : 10,000 times

Rated breaking current switching : 20 times

Performance of the circuit breaker has been designed in accordance with ANSI and IEC standard, and

verified by type test. All products are shipped after confirmation of various performances by acceptance test

based on these standards.

Current breaking is accomplished by a vacuum interrupter with

superb insulation recovery performance. Therefore, excellent

current breaki ng perf ormance i s demonst rat ed agai nst

short-circuit current (BTF) and even against short line fault

current (SLF) and out of phase interruption. In addition, the

vacuum interrupter is of completely self-arc-diffusion type and it

will assure exact current breaking in half a cycle even in case of

multiple-stroke and evolving fault.

Performance of the vacuum circuit breaker has been verified in

accordance with ANSI and IEC. Its reliability has been confirmed

t hrough suf f i ci ent pract i cal perf ormance t est i ng such as

mechanical life test, long-term charging test, temperature test, etc.

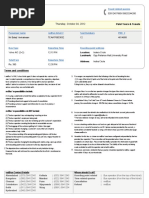

Connections

Standard connection diagram

Performance

Dimensions

Pollution level

Light / Medium

Heavy / Very heavy

A B C D E

Mass w/o BCT

lbs kg

99

2520

113

2870

46

1160

52

1330

80

2030

83

2100

43

1090

49

1240

140

3550

156

3970

4200

1900

4400

2000

Unit : inch (mm)

1 3 5 7 9 11

2 4 6 8 10 12

23 25 27 29 31

24 26 28 30 32

SPARE AUX.SW.CONTACTS (15a,15b)

52

13 15

14 16

33 35 37 39

34 36 38 40

19

20

17

18

21

22

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

LI

REC

100W

H1

20AT

HEATER, LIGHT &

RECEPTACLE CIRCUIT

240W

L

N

TH1 DR

FUH2

FUH1

ALARM CIRCUIT

MX 63GX2 63GX1

A1

A2

A3

A4

A5

A6

A7

A8

63GX3

63GX1

52

63GA

(-)

(+)

RIL

TRIP #1 CIRCUIT

PT1

NT1

CS

52T1

FUT12

FUT11

T11 T12

T13

T16

T14

T15

63GX1

TRIP #2 CIRCUIT

63GX2

52

63GA

(-)

(+)

RIL

PT2

NT2

CS

52T2

FUT22

FUT21

T21 T22

T23

T24

T26

T25

63GX2

88M

88M

MOTOR CIRCUIT

PM

NM

(-)

(+)

FMD2

FMD1

88M

M01

M02

M03

M04

M05

52M

(-)

MOTOR CONTROL & CLOSE CIRCUIT

TK

(+)

88

MX

94

52

52C

52

88M

MX

LS TK

94

PC

NC

63GX1

63GX2

CS

FUC2

FUC1

63GX3

63GB

R1

C01 C02 C03

C05 C04

C06

C07

C08

C09

C10

C11

C12

C13

C14

C15

C16

C17

52

94

MX

P

52 Auxiliary switch

52C Closing coil

52M Motor(charging closing spring)

52T1,52T2 Tripping coil

63GA,63GB Temperature-compensated

pressure switch

Sign Name/Usage

63GX1,63GX2,63GX3 Magnetic contactor

88M

94 Untipumping relay

DR Door switch

LI Light bulb

H1 Cabinet heater

(forlow air pressure alarm)

Magnetic switch (for motor)

LS Limit switch

(for charging close spring)

FUXXX

CS Trip/close switch

Fuse

TH1 Thermostat for cabinet heater

MX Magnetic contactor

(for motor run time alarm)

TK Timer for motor run time alarm

(setting : 3 min)

REC Receptacle

R1 Resistor

P P

LOW AIR

LOCKOUT

TRIP #1

LOW AIR

LOCKOUT

TRIP #2

MOTOR

RUN

TIME

LOW AIR

DENSITY

1

2

Z-Z

Z

Z

You might also like

- ACB ManualDocument42 pagesACB Manual4usangeetNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- RMUDocument81 pagesRMUtejpalv100% (2)

- 3ap1fg 72 eDocument2 pages3ap1fg 72 efelipe_rodrigos80% (5)

- 3ap1fg 72 eDocument2 pages3ap1fg 72 eenmavel2No ratings yet

- VC e 1402Document36 pagesVC e 1402lymacsausarangNo ratings yet

- ABB CatalogueDocument9 pagesABB CatalogueSai KiranNo ratings yet

- VCB, ViderDocument47 pagesVCB, Viderhs_handsomeNo ratings yet

- Catalogo CB41Document22 pagesCatalogo CB41MJ100% (1)

- Air Circuit Breaker: Catalogue 2012Document20 pagesAir Circuit Breaker: Catalogue 2012Addin Galih PrakosoNo ratings yet

- Amted399086en (Web)Document180 pagesAmted399086en (Web)aleksandaralNo ratings yet

- Frako ProductsDocument56 pagesFrako Productsjb10No ratings yet

- Vacuum Circuit BreakerDocument12 pagesVacuum Circuit Breakerherovhung12100% (1)

- DS 2471 ZX-Family enDocument2 pagesDS 2471 ZX-Family enAndrei HorhoianuNo ratings yet

- Single Phase Recloser CatalogDocument8 pagesSingle Phase Recloser CatalogCesar VenturoNo ratings yet

- Power Factor Correction: Phasecap CompactDocument4 pagesPower Factor Correction: Phasecap CompactvanbaoqnNo ratings yet

- Sivacon 4RB PowerQualitySolution Pi enDocument56 pagesSivacon 4RB PowerQualitySolution Pi enkiderilke100% (1)

- SF6 GCB 24 - 36 KVDocument4 pagesSF6 GCB 24 - 36 KVMichael Parohinog GregasNo ratings yet

- VCB SiemensDocument8 pagesVCB Siemensmukesh_gd_jhaNo ratings yet

- 841 VCB HVF&HVG Catalogue 2012.1Document56 pages841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasNo ratings yet

- Surge Arrestors CGLDocument16 pagesSurge Arrestors CGLgosalhs9395No ratings yet

- Surge Arrester General (IN) English PDFDocument16 pagesSurge Arrester General (IN) English PDFBalan PalaniappanNo ratings yet

- Ltesa Ais Catalogue-VcbDocument20 pagesLtesa Ais Catalogue-VcbSharafat AliNo ratings yet

- 1vga673004 - General Specification (Unigear Family)Document10 pages1vga673004 - General Specification (Unigear Family)Riza Ibn AdriansyahNo ratings yet

- Zelio Time Re8ta31buDocument6 pagesZelio Time Re8ta31buAssis Antoniazzi LavorattiNo ratings yet

- Frako ProductsDocument56 pagesFrako Productserkamlakar2234No ratings yet

- Sivacon 8PT-Busbar Rear-Technical CatalogueDocument69 pagesSivacon 8PT-Busbar Rear-Technical CatalogueLaurentiu CatalinNo ratings yet

- 1.eclipse Datasheet Issue 4-20-51b73d7fe49f9Document2 pages1.eclipse Datasheet Issue 4-20-51b73d7fe49f9mariomatoNo ratings yet

- 12 KV Outdoor Type Ring Main UnitDocument10 pages12 KV Outdoor Type Ring Main Unitzeeshan SiddiquiNo ratings yet

- Susol - VCB - E - 1303 (07-11-2013)Document152 pagesSusol - VCB - E - 1303 (07-11-2013)lymacsausarangNo ratings yet

- Susol VCB - E1110Document136 pagesSusol VCB - E1110Ngoc NguyenNo ratings yet

- 01 s0201 RCCB F 360 XDocument16 pages01 s0201 RCCB F 360 XfndprojectNo ratings yet

- Vd4 Vacuum Circuit-Breaker With Embedded PolesDocument32 pagesVd4 Vacuum Circuit-Breaker With Embedded Polesjiajun8No ratings yet

- Specification 33KV GIS ZX0.2Document16 pagesSpecification 33KV GIS ZX0.2BADRI VENKATESHNo ratings yet

- Air Circuit Breaker Product Catalogue and ACB Price List - ShopelectDocument4 pagesAir Circuit Breaker Product Catalogue and ACB Price List - ShopelectShopElectNo ratings yet

- LSIS Vacuum ContactorDocument36 pagesLSIS Vacuum ContactoredgarcooNo ratings yet

- Sabre Range Brochure WebDocument64 pagesSabre Range Brochure WebKadirou BigstarNo ratings yet

- Watlow Power Switching DevicesDocument38 pagesWatlow Power Switching DevicesEliasNo ratings yet

- Technical Specification VCB PanelDocument14 pagesTechnical Specification VCB PanelDarshit VyasNo ratings yet

- RE11RCMUDocument5 pagesRE11RCMUbogdy0073No ratings yet

- CT720g S774AAR5S2NCDocument45 pagesCT720g S774AAR5S2NCAnonymous CJnGHNNo ratings yet

- Cirucit Breakers VCB y VCSDocument0 pagesCirucit Breakers VCB y VCSNelson Garvizu0% (1)

- AMS-24kV-En Instruction ManualDocument10 pagesAMS-24kV-En Instruction ManualLê Nguyên TríNo ratings yet

- Vol. 12-High & Low Voltage SwitchDocument49 pagesVol. 12-High & Low Voltage SwitchHùng NguyenNo ratings yet

- Merlin Gerin Circuit Breaker Application Guide Full MGD5032Document212 pagesMerlin Gerin Circuit Breaker Application Guide Full MGD5032Tecnologia WilconNo ratings yet

- Merlin Gerin Circuit Breaker Application Guide TechnicalDocument55 pagesMerlin Gerin Circuit Breaker Application Guide TechnicaltajakaNo ratings yet

- Quint DC Ups 24dc 20Document9 pagesQuint DC Ups 24dc 20danielliram993No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Pugh MatrixDocument6 pagesPugh MatrixBalaji VenkatesanNo ratings yet

- Cable GlandsDocument20 pagesCable GlandsBalaji VenkatesanNo ratings yet

- Thursday, October 04, 2012: Rajkot To Ahmedabad Patel Tours & TravelsDocument1 pageThursday, October 04, 2012: Rajkot To Ahmedabad Patel Tours & TravelsBalaji VenkatesanNo ratings yet

- Bossard E-Shop: Button Head Socket Cap ScrewsDocument1 pageBossard E-Shop: Button Head Socket Cap ScrewsBalaji VenkatesanNo ratings yet

- Minutes: Tools For TransformationDocument1 pageMinutes: Tools For TransformationBalaji VenkatesanNo ratings yet

- Honeywell PLC - Specification ReplyDocument3 pagesHoneywell PLC - Specification ReplyBalaji VenkatesanNo ratings yet

- Baby Shield HCH1847041Document2 pagesBaby Shield HCH1847041Balaji VenkatesanNo ratings yet

- Design of A New Generation of Internal Arc Resistant SwitchgearDocument8 pagesDesign of A New Generation of Internal Arc Resistant SwitchgearBalaji VenkatesanNo ratings yet

- First Step For BusinessDocument19 pagesFirst Step For BusinessBalaji VenkatesanNo ratings yet

- Book - Capacitive Current Interruption With High Voltage Disconnector Switch - Yajing ChaiDocument171 pagesBook - Capacitive Current Interruption With High Voltage Disconnector Switch - Yajing ChaiBalaji VenkatesanNo ratings yet

- Rent AgreementDocument9 pagesRent AgreementBalaji VenkatesanNo ratings yet

- Math Collection by MutaherDocument62 pagesMath Collection by MutaherMezbah UddinNo ratings yet

- AVS - Grouting PracticeDocument145 pagesAVS - Grouting PracticeTrudeep Dave100% (3)

- JUDAY101Document7 pagesJUDAY101Edmond BajadoNo ratings yet

- Rainbow in A Jar: ProblemDocument1 pageRainbow in A Jar: ProblemPrayogo DidiNo ratings yet

- Hydraulic Formulas Pumps Motors Cylinders and PipingDocument1 pageHydraulic Formulas Pumps Motors Cylinders and PipingBharath KumarNo ratings yet

- Easypaisa Mobile Account API Integration GuideDocument9 pagesEasypaisa Mobile Account API Integration Guidezain.yasin141No ratings yet

- Phrygian Mode in All KeysDocument2 pagesPhrygian Mode in All Keysfauno_ScribdNo ratings yet

- Vapor Compression Cycle: Refrigeration & Air-Conditioning by Wilbert F. Stoecker / Jerold W. Jones (Chapter 10)Document16 pagesVapor Compression Cycle: Refrigeration & Air-Conditioning by Wilbert F. Stoecker / Jerold W. Jones (Chapter 10)nauman khanNo ratings yet

- Synthesis of 119 Superheavy Elements Using Ca-And Ti-Induced ReactionsDocument9 pagesSynthesis of 119 Superheavy Elements Using Ca-And Ti-Induced ReactionsPako GomezNo ratings yet

- The Application of Excel Software in Chemical Thermodynamics CalculationDocument3 pagesThe Application of Excel Software in Chemical Thermodynamics CalculationDaniel GarcíaNo ratings yet

- Cutoff Details CSIR UGC NET December 2015 ResultDocument5 pagesCutoff Details CSIR UGC NET December 2015 ResultSuyash Kumar SinghNo ratings yet

- 5 - Chiller Plant ControlDocument55 pages5 - Chiller Plant ControlGerardo Zamorano100% (4)

- Beginning Garment MakingDocument69 pagesBeginning Garment MakingHanisha Mulchandani100% (4)

- ABAQUS - Tutorial 4 Part Module: 1 Creating The PlateDocument3 pagesABAQUS - Tutorial 4 Part Module: 1 Creating The PlateSrashmiNo ratings yet

- Ie323 Sample Major 1 Exam SolutionDocument6 pagesIe323 Sample Major 1 Exam Solutionmajdoleen hassanainNo ratings yet

- Worksheet Area of Triangles and Compound ShapesDocument3 pagesWorksheet Area of Triangles and Compound ShapesEunice TiuNo ratings yet

- Onqor: Product BulletinDocument2 pagesOnqor: Product BulletinAhmed ChahineNo ratings yet

- Improving Mathematics Performance Through DLP-Learning Activity Sheets in The New NormalDocument17 pagesImproving Mathematics Performance Through DLP-Learning Activity Sheets in The New Normallp sheena sindaNo ratings yet

- Generating Gear GrindingDocument83 pagesGenerating Gear GrindingfendynovapamelaNo ratings yet

- Polymer Science: Molecular Weights of PolymersDocument22 pagesPolymer Science: Molecular Weights of PolymersMeeit GuleriaNo ratings yet

- Rashid Khan (Salesforce Administrator & Developer)Document4 pagesRashid Khan (Salesforce Administrator & Developer)Nihar AliNo ratings yet

- Cable Drum IR ValueDocument2 pagesCable Drum IR ValueMuralimohan PandianNo ratings yet

- Optimal Sample Size Selection For Torusity Estimation Using A PSO Based Neural NetworkDocument14 pagesOptimal Sample Size Selection For Torusity Estimation Using A PSO Based Neural NetworkSiwaporn KunnapapdeelertNo ratings yet

- Within Reach: Bringing High-Field MRDocument7 pagesWithin Reach: Bringing High-Field MRNadia DominguezNo ratings yet

- Connected Speech ChartDocument3 pagesConnected Speech ChartMagali Meaca100% (2)

- Balancing Redox Rns - Half-Reaction Method PracticeDocument2 pagesBalancing Redox Rns - Half-Reaction Method PracticeJaspar GlagovsNo ratings yet

- Second Law of Thermodynamics - WikipediaDocument131 pagesSecond Law of Thermodynamics - WikipediaPallab ChakrabortyNo ratings yet

- Chapter2.3-CPU Sched - QeuestionDocument7 pagesChapter2.3-CPU Sched - QeuestionNguyễn Trí DũngNo ratings yet

- GEMW M1 Lecture 2 (Z19)Document190 pagesGEMW M1 Lecture 2 (Z19)Lorenz Brian AngNo ratings yet

- Image Processing-IntroductionDocument35 pagesImage Processing-IntroductionBENAZIR BEGAM RNo ratings yet