0 ratings0% found this document useful (0 votes)

525 viewsAsme CCase 1987-2

Asme CCase 1987-2

Uploaded by

ADAMJSRAOThis document discusses a Code Case regarding the use of nickel-iron-chromium Alloy UNS N08811 in Section I and Section VIII, Division 1 construction at temperatures of 1100°F and above. The Code Case approves the use of this alloy provided that maximum allowable stress values do not exceed those listed in Table 2, the material meets the chemical requirements in Table 1, it is treated as P-No. 45 for welding qualifications, and temperature dependent stress parameters adhere to the values given. Documentation and marking of the material must include the Case number.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Asme CCase 1987-2

Asme CCase 1987-2

Uploaded by

ADAMJSRAO0 ratings0% found this document useful (0 votes)

525 views2 pagesThis document discusses a Code Case regarding the use of nickel-iron-chromium Alloy UNS N08811 in Section I and Section VIII, Division 1 construction at temperatures of 1100°F and above. The Code Case approves the use of this alloy provided that maximum allowable stress values do not exceed those listed in Table 2, the material meets the chemical requirements in Table 1, it is treated as P-No. 45 for welding qualifications, and temperature dependent stress parameters adhere to the values given. Documentation and marking of the material must include the Case number.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document discusses a Code Case regarding the use of nickel-iron-chromium Alloy UNS N08811 in Section I and Section VIII, Division 1 construction at temperatures of 1100°F and above. The Code Case approves the use of this alloy provided that maximum allowable stress values do not exceed those listed in Table 2, the material meets the chemical requirements in Table 1, it is treated as P-No. 45 for welding qualifications, and temperature dependent stress parameters adhere to the values given. Documentation and marking of the material must include the Case number.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

525 views2 pagesAsme CCase 1987-2

Asme CCase 1987-2

Uploaded by

ADAMJSRAOThis document discusses a Code Case regarding the use of nickel-iron-chromium Alloy UNS N08811 in Section I and Section VIII, Division 1 construction at temperatures of 1100°F and above. The Code Case approves the use of this alloy provided that maximum allowable stress values do not exceed those listed in Table 2, the material meets the chemical requirements in Table 1, it is treated as P-No. 45 for welding qualifications, and temperature dependent stress parameters adhere to the values given. Documentation and marking of the material must include the Case number.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

81

Asme BPVC Code Cases 1998 Edition CCASE11987 06-15-98 12:57:17

CASE

1987-2

CASES OF ASME BOILER AND PRESSURE VESSEL CODE

Approval Date: November 25, 1992

See Numeric Index for expiration

and any reafrmation dates.

Case 1987-2

Nickel-Iron-Chromium Alloy UNS N08811

Section I and Section VIII, Division 1

Inquiry: May nickel-iron-chromium Alloy UNS

N08811, conforming to the requirements of Alloy UNS

N08810 in Specications SB-163, SB-407, SB-408, SB-

409, SB-515, and SB-564 and having met the additional

requirements given in Table 1, be used in Section I

and Section VIII, Division 1, welded construction at

temperatures of 1100F and above?

Reply: It is the opinion of the Committee that nickel-

iron-chromium Alloy UNS N08811 as described in the

Inquiry and otherwise conforming to the requirements

of Alloy UNS N08810 in Specications SB-163, SB-

407, SB-408, SB-409, SB-515, and SB-564 may be

used in Section I and Section VIII, Division 1, welded

construction at 1100F and above providing the follow-

ing requirements are met.

(a) The maximum allowable stress values shall be

those listed in Table 2.

(b) Material shall conform to all other applicable

requirements of SB-163, SB-407, SB-408, SB-409, SB-

515, and SB-564.

(c) The material shall be treated as P-No. 45 for

all welding procedure and performance qualications

conducted in accordance with Section IX.

(d) For Section I, which requires a temperature depen-

dent parameter y [see PG-27.4, Note (6)], the y values

shall be as follows:

(1) 1150F and below, y p 0.4

(2) 1200F, y p 0.5

(3) 1250F and above, y p 0.7

(e) For external pressure values, use Fig. NFN-9 of

Section II, Part D.

(f) This Case number shall be shown on the docu-

mentation and marking of the material and recorded

on the Manufacturers Data Report.

This is Electrontic File Page # 81

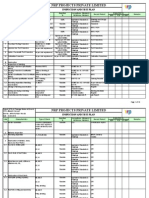

TABLE 1

CHEMICAL REQUIREMENTS

Element Percent

Aluminum and titanium 0.85 to 1.20

Carbon 0.06 to 0.10

(Solution anneal at

2100F or higher.)

TABLE 2

MAXIMUM ALLOWABLE STRESS

Metal Temperature, F,

Not Exceeding Stress, ksi

1100 12.9

1150 10.4

1200 8.3

1250 6.7

1300 5.4

1350 4.3

1400 3.4

1450 2.7

1500 2.2

1550 1.7 [Note (1)]

1600 1.4 [Note (1)]

1650 1.1 [Note (1)]

NOTE:

(1) Section VIII, Division 1 only.

Asme BPVC Code Cases 1998 Edition CCASE11987 06-15-98 12:57:17

This is Electrontic File Page # 82

You might also like

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- Vefv1100m 5Document1 pageVefv1100m 5Tariq HussainNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- Fcaw NC IiDocument59 pagesFcaw NC IiAnskey berthomeNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- Storing and Redrying Electrodes-Lincoln ElectricDocument3 pagesStoring and Redrying Electrodes-Lincoln ElectricjasminneeNo ratings yet

- NDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofDocument9 pagesNDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofrony16novNo ratings yet

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNo ratings yet

- ASMEDocument27 pagesASMERoy Dreina100% (1)

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- PWHTDocument3 pagesPWHTharishcsharmaNo ratings yet

- AB-036386 Hardness Testing For Welding Procedure QualificationDocument1 pageAB-036386 Hardness Testing For Welding Procedure QualificationAmr MahmoudNo ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- Tube Expanding ProcedureDocument1 pageTube Expanding ProceduremaryamgoodarzidanaNo ratings yet

- Gtaw NC Ii TR PDFDocument62 pagesGtaw NC Ii TR PDFRocz RocoNo ratings yet

- PQR TemplateDocument2 pagesPQR TemplateBruno PlachaNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Nde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTDocument2 pagesNde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTfizanlaminNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- ASME9 DrawingDocument1 pageASME9 DrawingÇağrı TansuğNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- SMN-J-PR-00-145 - Rev02 - Re-Instatement, Bolt Tightening Procedure For Piping SystemDocument12 pagesSMN-J-PR-00-145 - Rev02 - Re-Instatement, Bolt Tightening Procedure For Piping Systemono_czeNo ratings yet

- ASME U StampDocument12 pagesASME U StampShaheen Andre ChikkuNo ratings yet

- Koc MP 018Document17 pagesKoc MP 018Subhajit Bhattacharya100% (1)

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Guidelines Regarding The Handling of Cable Drums During Transport and StorageDocument5 pagesGuidelines Regarding The Handling of Cable Drums During Transport and StorageJegan SureshNo ratings yet

- Suggested Holding & Baking Temperature For Welding Electrodes & FluxesDocument2 pagesSuggested Holding & Baking Temperature For Welding Electrodes & FluxesKoushik NandiNo ratings yet

- Fracture TestDocument1 pageFracture TestYuvaraj SathishNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- 2019-5 TechPresentation BeachDocument141 pages2019-5 TechPresentation Beachaneeshta100% (1)

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- 44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTDocument6 pages44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTAvinash Shukla100% (1)

- DPR FormatDocument79 pagesDPR FormatMITHUNNo ratings yet

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- Multiple Choice Questions Paper I: ASME Awareness and Section VIII Code. 1Document4 pagesMultiple Choice Questions Paper I: ASME Awareness and Section VIII Code. 1RahulNo ratings yet

- 331 Heat Treatment: ASME B31.3-2012Document4 pages331 Heat Treatment: ASME B31.3-2012Stephen RajNo ratings yet

- Body of Knowledge PDFDocument1 pageBody of Knowledge PDFAda RamirezNo ratings yet

- P91 Heating CurveDocument1 pageP91 Heating CurveiplaruffNo ratings yet

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanNo ratings yet

- BPQ REV. 0 Interactive FormDocument2 pagesBPQ REV. 0 Interactive FormcosmicbunnyNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- FILLER WIRE-COuNTRY COMPAREDocument55 pagesFILLER WIRE-COuNTRY COMPAREJR MohanNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- KochDocument181 pagesKochRichard FelipNo ratings yet

- Weld Procedure Summary: SR# Wps No. Process Aws No. P.No. Base Metal Thickness Range Diameter Range PWHTDocument5 pagesWeld Procedure Summary: SR# Wps No. Process Aws No. P.No. Base Metal Thickness Range Diameter Range PWHTshantilalNo ratings yet

- Asme Ccase - 2083Document2 pagesAsme Ccase - 2083ADAMJSRAONo ratings yet

- Ut TwiDocument266 pagesUt TwiADAMJSRAONo ratings yet

- Asme Ccase - 2083Document2 pagesAsme Ccase - 2083ADAMJSRAONo ratings yet

- Asme CCase 2091-2Document2 pagesAsme CCase 2091-2ADAMJSRAONo ratings yet

- API Exam Set 10Document26 pagesAPI Exam Set 10ADAMJSRAONo ratings yet

- Asme CCase 2079-1Document2 pagesAsme CCase 2079-1ADAMJSRAONo ratings yet

- API Exam Set 11Document11 pagesAPI Exam Set 11ADAMJSRAONo ratings yet

- Asme Ccase - 2058Document2 pagesAsme Ccase - 2058ADAMJSRAONo ratings yet

- Asme Ccase - 2059Document2 pagesAsme Ccase - 2059ADAMJSRAONo ratings yet

- Asme CCase 2067-2Document2 pagesAsme CCase 2067-2ADAMJSRAONo ratings yet

- Asme CCase 2063-3Document2 pagesAsme CCase 2063-3ADAMJSRAONo ratings yet

- Asme Ccase - 2046Document2 pagesAsme Ccase - 2046ADAMJSRAONo ratings yet

- Asme CCase 2029-2Document2 pagesAsme CCase 2029-2ADAMJSRAONo ratings yet

- Asme CCase 2038-4Document2 pagesAsme CCase 2038-4ADAMJSRAONo ratings yet

- Asme CCase 2043-2Document2 pagesAsme CCase 2043-2ADAMJSRAONo ratings yet

- Asme Ccase - 2034Document2 pagesAsme Ccase - 2034ADAMJSRAONo ratings yet

- Asme Ccase - 1998Document2 pagesAsme Ccase - 1998ADAMJSRAONo ratings yet

- Is 5528 1985Document21 pagesIs 5528 1985vrkbkdnhcwjqlvjhxqNo ratings yet

- Deformation Behaviour of Aluminium Alloy AlDocument55 pagesDeformation Behaviour of Aluminium Alloy AlPrashant TiwariNo ratings yet

- AlchromDocument1 pageAlchromnitin chauhanNo ratings yet

- Plates - S420G2 MDocument2 pagesPlates - S420G2 MAdisak AumpiemNo ratings yet

- Astm A 703Document15 pagesAstm A 703hlagos123No ratings yet

- Design Collection 2012: Modern Simplicity I Modern Simplicity II Cool Vintage BasicDocument2 pagesDesign Collection 2012: Modern Simplicity I Modern Simplicity II Cool Vintage BasicAbdelmuneimNo ratings yet

- Threaded Mechanical Branch TeeDocument2 pagesThreaded Mechanical Branch TeeJulian RiverosNo ratings yet

- Welder Coc IIDocument3 pagesWelder Coc IItimketaNo ratings yet

- Fcaw Bohler Ti60k2 - Lot 613912Document1 pageFcaw Bohler Ti60k2 - Lot 613912Ahmad KamilNo ratings yet

- Assignment II Advanced MFGDocument11 pagesAssignment II Advanced MFGAyu AdiNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Outer Diameter & Wall Thickness, ASME B36.10Document1 pageOuter Diameter & Wall Thickness, ASME B36.10Jack QuNo ratings yet

- Welding Handbook v69 v69Document405 pagesWelding Handbook v69 v69horstiillingNo ratings yet

- Tin Plated Solutions enDocument1 pageTin Plated Solutions endanyNo ratings yet

- Ready To Export MachineDocument5 pagesReady To Export Machinesanthosh.smtsNo ratings yet

- Properties Materials 5Document8 pagesProperties Materials 5ayariseifallahNo ratings yet

- Static Equipment in Oil and Gas IndustryDocument93 pagesStatic Equipment in Oil and Gas IndustryRaghavanNo ratings yet

- Sinopec M1010Document2 pagesSinopec M1010Yoong TanNo ratings yet

- Engineering Materials PresentationDocument26 pagesEngineering Materials Presentationguravdr100% (2)

- Sagui 1933 - Ancient MinesDocument21 pagesSagui 1933 - Ancient MinesGeorge T100% (1)

- Inconel 718 ThesisDocument6 pagesInconel 718 Thesisafjrydnwp100% (2)

- Metal Solid IronDocument48 pagesMetal Solid IronX800XL100% (1)

- Stainless Steel Piping Fabrication-EGDocument8 pagesStainless Steel Piping Fabrication-EGYusufNo ratings yet

- The Essential CNC Cost Reduction ChecklistDocument5 pagesThe Essential CNC Cost Reduction Checklistajaxleon100% (1)

- Vegetable Charcoal - TdsDocument1 pageVegetable Charcoal - TdsLisa BulianNo ratings yet

- Comparison of Hardness For Mild Steel After Normalizing and Hardening ProcessesDocument17 pagesComparison of Hardness For Mild Steel After Normalizing and Hardening Processesyaswanth kumarNo ratings yet

- Bimetal Production and Applications: A. A. BykovDocument9 pagesBimetal Production and Applications: A. A. BykovGerman BarcenasNo ratings yet

- Unit 1 Casting ProcessesDocument247 pagesUnit 1 Casting ProcessesSandip AwaghadeNo ratings yet

- AMADA Bending BookDocument70 pagesAMADA Bending Bookأبومحمدالزيات100% (1)

- Dish Volume CalcDocument48 pagesDish Volume Calclakumas15No ratings yet