0 ratings0% found this document useful (0 votes)

202 viewsAssignment 01

Assignment 01

Uploaded by

Ratan Sadanandan O MThis document contains 12 assignments related to machine design and mechanical engineering. The assignments cover topics such as designing multiple disc clutches, band brakes, pulley systems, and V-belt drives to meet specific power transmission requirements. The problems provide technical specifications and ask the reader to determine key dimensions, forces, and other parameters required to complete the machine design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Assignment 01

Assignment 01

Uploaded by

Ratan Sadanandan O M0 ratings0% found this document useful (0 votes)

202 views2 pagesThis document contains 12 assignments related to machine design and mechanical engineering. The assignments cover topics such as designing multiple disc clutches, band brakes, pulley systems, and V-belt drives to meet specific power transmission requirements. The problems provide technical specifications and ask the reader to determine key dimensions, forces, and other parameters required to complete the machine design.

Original Description:

Machine Design Questions

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document contains 12 assignments related to machine design and mechanical engineering. The assignments cover topics such as designing multiple disc clutches, band brakes, pulley systems, and V-belt drives to meet specific power transmission requirements. The problems provide technical specifications and ask the reader to determine key dimensions, forces, and other parameters required to complete the machine design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

202 views2 pagesAssignment 01

Assignment 01

Uploaded by

Ratan Sadanandan O MThis document contains 12 assignments related to machine design and mechanical engineering. The assignments cover topics such as designing multiple disc clutches, band brakes, pulley systems, and V-belt drives to meet specific power transmission requirements. The problems provide technical specifications and ask the reader to determine key dimensions, forces, and other parameters required to complete the machine design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

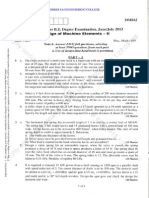

DEPARTMENT OF MECHANICAL ENGINEERING

S8 ME MACHINE DESIGN II Assignment No.1 To be submitted on 23-01-2014

1. A multiple disc clutch has three discs on the driving shaft and two on the driven shaft. The inside diameter of the

contact surface is 120 mm. The maximum pressure on the contact surface is limited to 0.1 N/mm

2

. Design the clutch

to transmit 20 kW at 1500 rpm. Assume uniform wear condition and coefficient of friction between surfaces =0.3

2. An automotive single plate clutch has inside and outside diameters of 160 and 240 mm respectively. Clamping force

is provided by nine springs, each compressed 5 mm to give a force of 900 N when the clutch is new. The molded

friction material provides a conservatively estimated coefficient of friction of 0.4 when in contact with the flywheel and

pressure plate. Maximum engine torque is 280 Nm.

(a) What is the safety factor with respect to slippage of a brand new clutch ?

(b) What is the safety factor after initial wear has occurred ?

3. A cone clutch is to be designed to transmit 55 kW at 900 rpm. Determine the main dimensions of the clutch and the

axial force required to engage the clutch. Given:

Face angle of cone = 12.5

Width of face = Half of the mean radius

Normal pressure between contact faces = 0.125 MPa

Coefficient of friction = 0.3

4. A single plate clutch is to transmit 20 kW at 1500 rpm. The faces of the clutch are lined with a special material to

enhance the coefficient of friction to 0.3. The permissible bearing pressure is 0.25 MPa. The clutch is engaged by 4

springs of 30 mm mean diameter, arranged symmetrically. The spring compresses by 2.5mm for disengagement with

an increase of pressure of 10%. Determine: (i) diameter of the clutch facing (ii) diameter of the spring wire and (iii)

number of coils in the spring. Assume uniform pressure. Working shear stress and the modulus of rigidity for the

spring wire may be assumed to be 350 MPa and 80 GPa respectively.

5. A multiple disc clutch has 5 discs on the driving shaft and 4 on the driven. The outside diameter of contact is 300mm

and inside diameter 180mm. Assuming uniform wear and coefficient of friction as 0.25, find the maximum axial

intensity of pressure between the discs for transmitting 40 kW at 1500rpm.

6. A differential band brake is to be designed to support a load of 400kN around a barrel of 450mm diameter. The brake

is to be mounted on the 800mm diameter drum. The two ends of the band are attached to pins on opposite sides of the

fulcrum of brake lever at 40mm and 120mm. The length of the lever is 900mm. The angle of lap is 240 and the

coefficient of friction is 0.3. Choosing suitable values for the stresses, give the main design calculations for the lever,

band and fulcrum pin.

(Lateral connections of the bands on the lever are such that the bands are always perpendicular to the lever.)

7. (a) Make an exploded view of the double-block brake of Figure-1 and show all forces and moments

required for equilibrium of each part. =0.25; width, b=100 mm. (b) Find the value of p

max

for each shoe and the

value of the torque exerted by the brake. Also find the absorbed power.

Figure-1 Figure-2

8. Two identical shoes are used in an internal brake as shown in figure-2(b). For a coefficient of friction of 0.3, calculate

the braking torque developed by each shoe. Note that the sense of drum rotation is counter-clockwise. (b) It is

proposed to make the torques developed by the two shoes equal by actuating them with a hydraulic cylinder having two

diameters as shown (See figure-2(a)). Determine the necessary ratio of the two diameters and sketch the cylinder

horizontally to show how it should be placed (which end for which shoe).

9. A simple band brake has 750mm drum fitted with a steel band 4mm thick, lined with brake lining having a coefficient

of friction of 0.25 when not sliding. The arc of contact is 245. This brake drum is attached to a 600mm hoisting

drum that sustains a rope load of 8kN. The operating force has a moment arm of 1500mm and the band is attached

125mm from the pivot point. (a) Find the force required to just support the load. (b) What force is required if the

direction of rotation is reversed? (c) What width of steel band is required if its tensile stress is limited to 50MPa.

10. An electric motor drives a compressor by means of a flat leather belt. The following data are known:

For motor pulley: Diameter=250 mm; Angle of wrap=4 radians; Coefficient of friction=0.25 ; Speed=1200 r.p.m.

For compressor pulley: Diameter=1500 mm; Angle of wrap=3.5 radians; Coefficient of friction=0.3. (Note

that an idler pulley is used.)

The belt is 6 mm 200 mm cross section and has a density 970 kg/m

3

. If the maximum allowable belt tension is

2.7 kN, determine the power capacity.

11. A V-belt drive transmits 11 kW at 900 r.p.m. of the smaller sheave. The sheave pitch diameters are 173 mm and 346

mm. The centre distance is 0.76 m. If the maximum permissible working force per belt is 560 N, determine the

number of belts required, if the coefficient of friction is 0.15 and the groove angle of the sheave is 34. The belt mass

=0.194 kg/m.

12. A V-belt is to transmit 15 kW from a motor to a compressor. Motor speed is 1150 r.p.m. and the compressor speed 400

r.p.m. Specify the details of the V-belt drive.

You might also like

- Torque Specifications: Service Specifications - 2Az-Fxe Engine MechanicalDocument3 pagesTorque Specifications: Service Specifications - 2Az-Fxe Engine MechanicaldiemnganNo ratings yet

- 4R70W Rebuild ChecklistDocument26 pages4R70W Rebuild ChecklistSamuel Zuniga88% (8)

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Unit IDocument3 pagesUnit Imahendra babu mekalaNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- ME4001D Assign 1Document3 pagesME4001D Assign 1vivek geddamNo ratings yet

- Assignment 2Document3 pagesAssignment 2sonawanepmsNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- FinallDocument175 pagesFinallremeceldo dagamac100% (1)

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- Dme - Ii (17me64) : Assignement 01Document3 pagesDme - Ii (17me64) : Assignement 01NAVEEN H ENo ratings yet

- Clutch Design TutorialDocument1 pageClutch Design TutorialimisschesaNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuNo ratings yet

- Brake SheetDocument3 pagesBrake Sheetparagmishra1986No ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Assignment - 2 (18me603 - Dme)Document4 pagesAssignment - 2 (18me603 - Dme)arunkish2004No ratings yet

- Design ProblemsDocument13 pagesDesign ProblemsAristotle RiveraNo ratings yet

- Design ExercisesDocument13 pagesDesign ExercisesBookieeNo ratings yet

- Assignment - 1: MEN303 Design of Mechanical Systems Submission Date: 28-06-2018Document2 pagesAssignment - 1: MEN303 Design of Mechanical Systems Submission Date: 28-06-2018Amit KapoorNo ratings yet

- Dynamics of Machines 4 Units New Question BankDocument4 pagesDynamics of Machines 4 Units New Question BankgbharathreddysNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Chp4 2 - BrakesDocument36 pagesChp4 2 - BrakesAzhar BaigNo ratings yet

- Assignment 1QS8ME Winter2020Document2 pagesAssignment 1QS8ME Winter2020VinayakNo ratings yet

- 15.DTS Unit-V QuestionsDocument4 pages15.DTS Unit-V QuestionsSoundararajanNo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- AssignmentDocument4 pagesAssignmenttusharsonar210No ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Assignment No1MDDocument4 pagesAssignment No1MDPradeep MirajgaveNo ratings yet

- Machine DesignDocument6 pagesMachine DesignRishi SinghNo ratings yet

- Tutorial Sheet-II MEC3110/317 (Machine Design II)Document4 pagesTutorial Sheet-II MEC3110/317 (Machine Design II)Prateeksha ShakyaNo ratings yet

- Dme Model QuestionDocument2 pagesDme Model QuestiondharaniventhanNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- Machine Design I TutorialDocument3 pagesMachine Design I TutorialbngelotrNo ratings yet

- Design of Machine Element-IIDocument53 pagesDesign of Machine Element-IIPramod R Bidve100% (1)

- Question PapersDocument89 pagesQuestion PapersDreamer ChavanNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsDocument5 pagesMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SNo ratings yet

- Imp Qoestions MDDocument3 pagesImp Qoestions MDvenuedNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- Dme Model QPDocument3 pagesDme Model QPCody LeeNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- Tutorial 6 PDFDocument2 pagesTutorial 6 PDFkalirajgurusamyNo ratings yet

- Final Design Work SheetDocument7 pagesFinal Design Work SheetKINDUNo ratings yet

- CAD/CAMDocument2 pagesCAD/CAMNarayanarao PalagaraNo ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Assignment 1Document1 pageAssignment 1Naveen VermaNo ratings yet

- Model Question BankDocument4 pagesModel Question BankVinod BalakrishnanNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Consignment Tracking 140920142009359Document2 pagesConsignment Tracking 140920142009359Ratan Sadanandan O MNo ratings yet

- Assignment 02 - Machine DesignDocument2 pagesAssignment 02 - Machine DesignRatan Sadanandan O MNo ratings yet

- Vectors Maths DelDocument6 pagesVectors Maths DelRatan Sadanandan O MNo ratings yet

- 2013 - Winter - Make Up Exam AnnouncementDocument2 pages2013 - Winter - Make Up Exam AnnouncementRatan Sadanandan O MNo ratings yet

- Material Science and Metallurgy SeminarDocument28 pagesMaterial Science and Metallurgy SeminarRatan Sadanandan O MNo ratings yet

- KOMATSU Commemorative BookDocument49 pagesKOMATSU Commemorative BookAlexander Alva Rodriguez100% (1)

- Assignment 01Document2 pagesAssignment 01Ratan Sadanandan O MNo ratings yet

- Submited By: Roots Industries India LimitedDocument20 pagesSubmited By: Roots Industries India LimitedKavin ChanderNo ratings yet

- Benchmarking For Quality Management & Technology: Article InformationDocument18 pagesBenchmarking For Quality Management & Technology: Article InformationRAMADHIAN EKAPUTRANo ratings yet

- Coatings Word October 2013Document84 pagesCoatings Word October 2013sami_sakrNo ratings yet

- Studiu de Caz RoverDocument6 pagesStudiu de Caz RoverMatei Stefan VladNo ratings yet

- Customer Satisfaction Survey Xtracare IOCDocument44 pagesCustomer Satisfaction Survey Xtracare IOCKKMP2010No ratings yet

- World Survey Reports On International Human Resourse ManagementDocument26 pagesWorld Survey Reports On International Human Resourse ManagementgurgurgurgurNo ratings yet

- SJS Corporate PresentationDocument20 pagesSJS Corporate PresentationP K Senthil KumarNo ratings yet

- Đề 8 - Tailieubachkhoa TOEICDocument20 pagesĐề 8 - Tailieubachkhoa TOEICPhan Văn DựNo ratings yet

- Assignment List With Due DatesDocument1 pageAssignment List With Due DatesRacaz EwingNo ratings yet

- Production Operation Management General Motor Halol ChevroletDocument27 pagesProduction Operation Management General Motor Halol ChevroletApoorv JainNo ratings yet

- Comparison and Contrast Essay 3 Final DraftDocument4 pagesComparison and Contrast Essay 3 Final Draftapi-259376307No ratings yet

- Database-Mm2100 Company Name ListDocument15 pagesDatabase-Mm2100 Company Name ListRina RachmanNo ratings yet

- Jeep Chrysler Corporation Marketing PlanDocument5 pagesJeep Chrysler Corporation Marketing PlanJaswani R.L Rana100% (1)

- Front Suspension Over/under A-Arm Leaf Spring & Solid AxleDocument18 pagesFront Suspension Over/under A-Arm Leaf Spring & Solid AxleNirmit SharmaNo ratings yet

- Customer SatisfactionDocument73 pagesCustomer SatisfactionNeha Yadav67% (6)

- Toyota Al Futtaim FinalDocument15 pagesToyota Al Futtaim FinalVanessa_Dsilva_1300No ratings yet

- HDS Auto Service CatalogueDocument9 pagesHDS Auto Service CatalogueHDS Inc.No ratings yet

- Vance and Heins Oval SliponsDocument4 pagesVance and Heins Oval SliponsWeinhoferNo ratings yet

- Aws WJ 201203Document146 pagesAws WJ 201203laercioudesc_100% (1)

- Actuator (Kirloskar) 1Document5 pagesActuator (Kirloskar) 1meghanahariNo ratings yet

- Design and Development of 3-Way Dropping DumperDocument7 pagesDesign and Development of 3-Way Dropping Dumpersuraj dhulannavarNo ratings yet

- Introduction To Lean Manufacturing: Achieving World-Class Organizational ResultsDocument75 pagesIntroduction To Lean Manufacturing: Achieving World-Class Organizational ResultsAshokNo ratings yet

- 15P35H0256Document91 pages15P35H0256Manoj JainNo ratings yet

- CONSUMER SATSIFACTION Palampur Maruti SuzukiDocument37 pagesCONSUMER SATSIFACTION Palampur Maruti SuzukiSourav BawaNo ratings yet

- Auto Feed Drills & Tappers (English)Document36 pagesAuto Feed Drills & Tappers (English)azzszoNo ratings yet

- Aficionado November 2011Document28 pagesAficionado November 2011dearmrbrettNo ratings yet