80%(10)80% found this document useful (10 votes)

4K viewsSimultaneous Operations (SIMOPS)

Simultaneous Operations (SIMOPS)

Uploaded by

Desmond ChangThis document provides guidelines for planning and conducting simultaneous operations (SIMOPS) to ensure safety in the Gulf of Mexico region. It details requirements for developing a field-specific SIMOPS plan, including defining roles and responsibilities, communication processes, and emergency response procedures. Each SIMOPS plan must be approved by management and kept up to date. Specific personnel are assigned responsibility for overseeing SIMOPS at the field, activity, and vessel level to facilitate coordination and ensure all risks are addressed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Simultaneous Operations (SIMOPS)

Simultaneous Operations (SIMOPS)

Uploaded by

Desmond Chang80%(10)80% found this document useful (10 votes)

4K views19 pagesThis document provides guidelines for planning and conducting simultaneous operations (SIMOPS) to ensure safety in the Gulf of Mexico region. It details requirements for developing a field-specific SIMOPS plan, including defining roles and responsibilities, communication processes, and emergency response procedures. Each SIMOPS plan must be approved by management and kept up to date. Specific personnel are assigned responsibility for overseeing SIMOPS at the field, activity, and vessel level to facilitate coordination and ensure all risks are addressed.

Original Description:

Simultaneous Operations (SIMOPS)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides guidelines for planning and conducting simultaneous operations (SIMOPS) to ensure safety in the Gulf of Mexico region. It details requirements for developing a field-specific SIMOPS plan, including defining roles and responsibilities, communication processes, and emergency response procedures. Each SIMOPS plan must be approved by management and kept up to date. Specific personnel are assigned responsibility for overseeing SIMOPS at the field, activity, and vessel level to facilitate coordination and ensure all risks are addressed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

80%(10)80% found this document useful (10 votes)

4K views19 pagesSimultaneous Operations (SIMOPS)

Simultaneous Operations (SIMOPS)

Uploaded by

Desmond ChangThis document provides guidelines for planning and conducting simultaneous operations (SIMOPS) to ensure safety in the Gulf of Mexico region. It details requirements for developing a field-specific SIMOPS plan, including defining roles and responsibilities, communication processes, and emergency response procedures. Each SIMOPS plan must be approved by management and kept up to date. Specific personnel are assigned responsibility for overseeing SIMOPS at the field, activity, and vessel level to facilitate coordination and ensure all risks are addressed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 19

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 1 of 19

GoM Region Simultaneous Operations (SIMOPS) Safe Work

Practice (SWP)

Document Number: CD # UPS-US-SW-GOM-HSE-DOC-00678-2

Document Authority:

GoM Director Ops

and OMS

Document Custodian: GoM CoW Authority

Scope: GoM H&S Doc Admin:

GoM H&S Document

Management Administrator

Issue Date: 06/12/08 Issuing Dept: GoM H&S

Revision Date: 10/15/12 Control Tier: 2 GoM H&S

Next Review Date: 03/01/15 OMS Element:

3.1 Risk Assessment and

Management

1 Purpose/Scope

This Safe Work Practice (SWP) details the prerequisites and guidelines for the planning and execution of

Simultaneous Operations (SIMOPS) to ensure the safety of personnel and protection of equipment and

the environment.

SIMOPS shall be defined as conducting independent operations in which the events of any one operation

may impact the safety of personnel or equipment or the environment of another operation. Typically this

involves production operations, drilling operations, and project execution operations, but may include any

incidence where concurrent operations create risk.

The SIMOPS prerequisites and guidelines detailed below apply to all operations in the GoM. This

includes but is not limited to: topsides, subsea, drilling, completion, well work, construction, marine, and

pipeline or production activities. This includes activities not only onboard a producing facility but any

simultaneous operations that occur field- or lease-wide.

2 Key Responsibilities

Proper coordination, communication and control are critical to the safe conduct of SIMOPS.

3 General Requirements

It is the intent of these guidelines to establish procedures for planning and coordination and outline rules

to ensure that SIMOPS are conducted without incident.

3.1 Field SIMOPS Plan

Each field in the GoM shall have an approved field SIMOPS plan. A "field" is defined as any BP-operated

developing or producing operation. SIMOPS plans may be required for operations outside of a field

where SIMOPS risks exist between concurrent operations.

This document should be kept evergreen and shall include:

Field description or project area description (including all fixed obstructions, infrastructure, and

bathymetry)

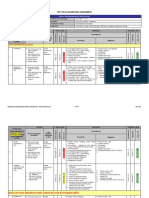

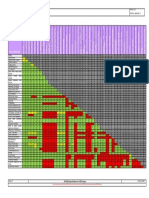

A field SIMOPS matrix (see Appendix B in this chapter for definitions of some example areas this

should cover) that includes pre-risk assessed activities (see Appendix C in this chapter for an

example matrix)

Organization and Roles and Responsibilities

Daily communications process specifying time and participants; the daily written report requirements

and distribution must also be defined

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 2 of 19

Key contact information

The plan shall include or reference existing procedures for:

Description of emergencies and All Stop Criteria

Emergency Response and Incident Notification Procedure

Identification of Health, Safety, Security and Environment (HSSE) plan. If a contractor plan is being

used, a bridging document must exist that reconciles the BP and contractor GoM HSE policies.

Identification of Control of Work processes, including MOCs for change-out of key personnel

The plan should consider additional resources that may be required based on field activity complexity,

such as a dedicated SIMOPS coordinator.

The field SIMOPS plan shall be in compliance with the BSEE, Coast Guard, BSEE approved Deep Water

Operations Plan (DWOP) and class regulations.

Any deviation from or changes to an approved SIMOPS plan requires Management of Change with

appropriate Line and Technical Authority sign-off. This should include the SIMOPS plan signature

authority and should be communicated and understood by all affected parties (see Section 4.4.2).

Everyone has the duty to stop the job at any time the SIMOPS plan is not, or cannot be followed, or at

any time the SIMOPS plan is not clear.

The appropriate Vice President or Area Operations Manager is accountable for ensuring this field

SIMOPS plan is kept up to date and is the highest level of sign-off. This should be a controlled document

stored in the appropriate document management database.

3.2 Adding an Activity to the Field SIMOPS Plan

For each new activity which involves field SIMOPS the following documents are required:

Work plan/pack and detailed procedure

Risk assessment of that procedure, including risk assessment of SIMOPS

A reference document that addresses the requirements outlined in Section 3.1 above with particular

emphasis on roles and accountabilities

3.3 Development of Field SIMOPS Plan

Roles Responsibilities

Vice President or Area

Operations Manager

Ensures that the field has a SIMOPS Plan

Final level of approval for the field SIMOPS plan

Operations Support

Lead or Equivalent

Accountable for additional activity approval

Field SIMOPS plan preparation

Offshore Installation

Manager

Accountable for field SIMOPS plan content

Project Manager Accountable for their project's additional activity SIMOPS requirements

(per Section 3.2) to supplement the field SIMOPS plan

Act as integrator, working with the Activity Person in Charge (see

Section 3.4) to ensure planned activities are aligned with the field

SIMOPS plan in advance

Ensure planned field activities are included in the Integrated Field

Planning (IFP) process

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 3 of 19

3.4 Execution of SIMOPS Plan

Each field shall appoint a field SIMOPS team. The field SIMOPS team shall include at a minimum the

following individual roles and responsibilities

Roles Responsibilities

Vice President or Area

Operations Manager

Ensures field SIMOPS plan is followed and is working

Operations Support Lead

or Equivalent

Accountable for allocating adequate resources to support the field

SIMOPS plan

OIM/Field Person-In-

Charge (FPIC)

The Field Person-in-Charge (FPIC) is the BP Offshore Installation Manager

(OIM) unless otherwise stated. This individual is accountable for execution

of the field SIMOPS plan and will have complete control to determine

which operation or phase of work has precedence at any given time. The

FPIC shall communicate daily with the Activity Person(s)-in-Charge (APIC)

with respect to field SIMOPS activity. The FPIC or designee shall

communicate with each Vessel Person(s)-in-Charge (VPIC) upon entry and

departure from the particular field

Accountable for execution of the field SIMOPS plan

Ensures that all key stakeholders (rig, vessel and facilities) are briefed

and engaged, including contractors. Must have broad communications

across the crews and shifts

Monitor daily field SIMOPS activity

Chair daily field SIMOPS review(s) (daily call)

Evaluate the risk of planned simultaneous operations and ensure

mitigation plans are in place

Project Manager Facilitate the briefing and engagement of key stakeholders, including

contractors, and report back to the OIM for approval that engagement

has been adequate

Activity Person-in-Charge

(APIC)

The individual accountable for executing a specific defined activity. The

APIC shall communicate with the FPIC with respect to field SIMOPS

activity. When a marine vessel/unit is a component of the activity, the APIC

shall also be accountable for vessel coordination. The APIC shall

communicate with the respective VPIC with respect to executing the

marine activity. Examples of potential APICs are a Operations Support

Lead or Equivalent, Well Site Leader or BP Representative on a vessel

When a single vessel is performing the activity, the APIC may assume the

additional accountabilities of the VPIC.

Monitor daily SIMOPS activity

Facilitate daily activity SIMOPS review(s)

Attend daily field SIMOPS review(s)

Ensure that risks associated with the planned operations are

understood and communicated to the FPIC

Accountable for executing a specific defined activity. When a marine

vessel/unit is a component of the activity, the APIC shall also be

accountable for vessel coordination

Vessel Person-in-Charge

(VPIC)

The individual aboard the vessel accountable for executing that specific

vessel's activity under the direction of the APIC. The VPIC shall

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 4 of 19

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

Roles Responsibilities

communicate with the APIC with respect to activity SIMOPS. The VPIC

shall communicate with the FPIC prior to entry, upon entry and upon

departure from the particular field. The VPIC shall also be accountable for

monitoring onboard vessel SIMOPS and identifying and reporting any

SIMOPS activity that may impact the vessel's ability to perform the

intended work scope (activity). In some circumstances the FPIC and APIC

can be the same person; and the APIC and VPIC can be the same person.

Examples of potential VPICs are a Well Site Leader, BP Representative on

a vessel, MODU OIM, Captain, Mate or Dynamic Position Operator

Monitor daily vessel SIMOPS activity

Facilitate daily vessel SIMOPS review(s)

Attend daily activity SIMOPS review(s)

Attend daily field SIMOPS review(s) - upon request

Execute specific vessel activity under the direction of the APIC

Officer-in-Charge The Officer in Charge of the navigational watch is the master's

representative and is primarily responsible at all times for the safe

navigation of the vessel. Examples of potential Officers in Charge are a

MODU OIM, Captain, Mate or Dynamic Position Operator

Field SIMOPS

Coordinator

(FSC)

The FSC, if needed as an additional resource, shall provide support to the

OIM and field SIMOPS team. Depending on the complexity of the activity

set, the FPIC and asset management may determine a dedicated FSC is

required

4 General Procedure

4.1 Identify Scope of SIMOPS Activity

Each asset must have a process in place to clearly define a detailed work scope of the field SIMOPS

activity to allow for an appropriate level risk assessment to be performed. The scope must be defined

early enough so that the activity risk assessment can be referenced against the asset's scheduled work

activities to ensure any known SIMOPS conflicts are addressed. The Integrated Field Planning (IFP)

process may be utilized to satisfy the criteria and timescale for this advance notice requirement. A typical

SIMOPS process flow chart is shown in Appendix D.

4.2 Risk Assessment

An appropriate level risk assessment should be conducted and should include known SIMOPS risks by

referencing the published field activity schedule. Some key SIMOPS risks would include dropped objects,

vessel collision, aviation, construction (including subsea) diving, DP failure, and loss of containment of

hydrocarbons. (Refer to Appendix E in this SWP for an example of a dropped objects prevention and

mitigation plan checklist.)

A daily risk assessment discussion should also take place as part of the 24 hour look ahead during the

daily SIMOPS meeting.

Additionally, a SIMOPS matrix (BP) or equivalent tool to evaluate risks shall exist for each SIMOPS plan.

4.3 Risk Mitigation

For risks identified in risk assessments, mitigation controls should be identified and put into place. Clearly

defined All Stop Criteria (with defined approval authorities) should also be outlined as part of the risk

mitigation process. In addition to mitigation controls resulting from risk assessments such as the

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 5 of 19

Dropped Objects Study, the field SIMOPS plan shall include a process to mitigate risk on a daily basis. If

additional risks are identified during the established, daily communications forum, mitigation controls

must be executed before the activity can commence or continue. Identification of these mitigation

controls may require a separate discussion outside of the daily communication forum.

4.4 Communication/Training of Field SIMOPS Plan and Activity Specific Information

No activity should take place prior to approval of the SIMOPS plan and appropriate communication and

training. The field SIMOPS plan shall be reviewed with all project manager(s), the Operations Support

Lead or Equivalent and the appropriate APICs and FPICs prior to execution of any SIMOPS activities. The

field SIMOPS plan shall be inclusive of any activity specific information as defined in Section 3.1. The

review of the plan shall be completed as early as necessary to allow for a clear understanding of the risks

and mitigation controls. If multiple shifts or crews will be engaged in this SIMOPS activity, then more

than one review may be required to cover all crews/shifts.

4.4.1 Communication during Execution of SIMOPS Activity Plan

During the execution of the field SIMOPS plan for a SIMOPS activity, daily routine verbal and written

communication must occur as defined in the plan. Participants should ensure all work groups clearly

understand the scope of work that is forecast for the next 24 hours with an emphasis on SIMOPS risk

mitigation. Ensure standing orders are in place for non-routine communications and provide clear

instructions as to when to notify the FPIC.

4.4.2 Changes to Work Scope

Stop the job, assess the risks, and initiate an MOC, if required, for all changes in work scope after the

activity risk assessment and approved mitigation controls have been established.

4.5 Drilling, Completion, Remedial Rig Operations, or Well Maintenance near

Producing Infrastructure

4.5.1 Potential Undesirable Events and Mitigation

Well control is a primary concern during these operations. If there is difficulty in maintaining well control

(e.g., unexpected pressures, gas cut mud, lost circulation, etc.), joint communications shall occur with all

parties (production, drilling, etc.) to determine if production operations should be shut in. Well control

procedures should be followed carefully.

Note: First priority must be given to controlling the well and to the safety of the personnel on board.

The greatest well control hazard is wellbore intersection with a producing well. Prior directional planning

is intended to avoid this interference. The plan should be reviewed by the appropriate individuals (Wells

Manager, Wells Program Manager, etc.).

Critical areas of SIMOPS are defined as areas in which explosive or ignitable mixtures are present or

potentially present due to the release of flammable gases or vapors. During simultaneous operations,

care shall be taken to avoid potential sources of ignition and damage to equipment in such areas. Critical

areas include the wellheads, mud tanks and pumps, shale shaker, degasser, de-sander, producing wells,

and all equipment for field processing of oil and gas.

4.5.2 Regulatory Requirements

In addition to the above general requirements, the BSEE has specific requirements for conducting rig

operations in close proximity to production facilities and other hazards.

The regulation at 30 CFR 250.406 requires the shut-in of all producible wells located in the affected well

bay below the surface and at the wellhead when (1) a drilling rig or related equipment is moved on or off

a platform, (2) a drilling unit is moved or skid between wells on a platform, or (3) a mobile offshore drilling

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 6 of 19

unit (MODU) is moved within 500 feet of a platform. You may resume production once the MODU is in

place, secured, and ready to begin drilling operations.

The Appendices to the Rig Move NTL No. 2004-G09 provide guidance on how to comply with 30 CFR

250.406. They describe the various types of rigs and phases of rig movement, specify when wells must

be shut in, and delineate the documentation to be submitted to the appropriate BSEE Gulf of Mexico

OCS Region (GOMR) District Office to obtain approval for a departure under 30 CFR 250.142.

The Shallow Hazards NTL No. 2007-G01 includes requirements for moving rigs near pipelines and other

seafloor hazards. This includes onsite preparation and rig move requirements.

4.5.3 BP Requirements

BP's Global Drilling and Well Operations Policy has specific requirements for conducting risk

assessments prior to moving a rig onto an offshore location, conducting risk assessments for

simultaneous operations and collision avoidance while drilling on multi-well locations.

4.6 Marine

SIMOPS involving marine vessels/units shall be managed consistent with the field SIMOPS plan.

4.6.1 Identify Activity

The field SIMOPS plan shall contain or reference a process for identifying and monitoring marine activity.

4.6.2 Risk Assessment (Identify and Evaluate Risks)

Collision is the primary SIMOPS marine risk. Any marine vessel/unit operating less than 500 meters from

another marine vessel/unit or hazard to navigation shall be deemed a marine risk. Circumstances that

may contribute to collision risk are vessel traffic density, environmental conditions (visibility, sea state,

wind, and current), navigational aids status, vessel maneuvering characteristics and capabilities,

temporary measures in effect, vessel position reference systems, acoustic management, vessel defects

and other special circumstances. Details on marine SIMOPS guidance can be found in Appendix G in

this SWP.

4.7 Subsea Operations

Subsea operations may be conducted in the field to support any one of the following activities:

construction, production, drilling, and seabed surveys. Each has a unique set of risks (e.g. collision,

dropped object) to be managed via a SIMOPS plan.

4.7.1 ROV Activities

Remotely Operated Vehicles (ROVs) may be deployed from any one of the production facilities, Mobile

Offshore Drilling Units (MODUs) or in-field vessels and could be in support of production optimization

(valve operation), inspection, repair, or component replacement, maintenance and underwater

construction. Typically this will be carried out at seabed facilities, risers, pipelines, dynamic umbilicals,

moorings, floating hulls and jackets.

4.7.2 Diving Activities

Diving activities typically are required only for critical maintenance and inspection of near-surface facilities

such as jacket structures, sea chest valves, and riser porches. In addition to compliance with the field

SIMOPS plan, to manage risk, diving operations will be performed in strict compliance with BP GoM

Diving Procedures.

4.7.3 Underwater Construction Activities

This includes installation and recovery of risers, manifolds, pipelines, trees, flow line jumpers, umbilicals

and associated sub-structures. This may be performed from and with a range of facilities and techniques.

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 7 of 19

4.7.4 Survey Activities

Surveys may be performed at the seabed typically by a number of vessel surface supported techniques,

such as seismic, core sampling, route corridor surveys and metrology. In addition to ROVs, there are

circumstances where non-surface connected autonomous ROVs may be deployed to carry out such

functions.

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 8 of 19

5 Appendices, Key Documents, Tools, References

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 9 of 19

Appendix A:

SIMOPS Acronyms List

Acronym Definition

AOM Area Operations Manager

APIC Activity Person In Charge

BOP Blow Out Preventer

CDP Company Designated Person

D&C Drilling and Completions

DP Dynamic Positioning

DWOP BSEE-approved Deepwater Operations Plan

FPIC Field Person In Charge

FSC Field SIMOPS Coordinator

HAZID Hazard Identification

HAZOP Hazard and Operability Study

HSSE Health, Safety, Security, Environment

IFP Integrated Field Planning

J SEA/RA J ob Safety and Environmental Analysis/Risk Assessment

MASP Maximum Anticipated Surface Pressure

MODU Mobile Offshore Drilling Unit

OIM Offshore Installation Manager

OM Operations Manager

PIC Person in Charge

PM Project Manager

POB Personnel on Board

PTW Permit to Work

ROV Remotely Operated Vehicle

RP Recommended Practice

SCR Steel Catenary Riser

SCSSV Surface Controlled Subsurface Safety Valve

SIMOPS Simultaneous Operations

SWP Safe Work Practice

TBD To Be Determined

USCG United States Coast Guard

VMS Vessel Management System

VPIC Vessel Person In Charge

VRP Vessel Response Plan (Coast Guard-related)

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 10 of 19

Appendix B:

Typical SIMOPS Activity Definitions

Activity Definition

Boat Operations

Boat alongside Platform operations include offloading and back

loading of cargo or bulk material from workboat.

BOP Lifting/Handling

Movement of BOP(s), BOP equipment over well slots, hydrocarbon

piping, flexible flowlines and hoses.

Bulk Methanol/Diesel

Transfer

Operations that include moving these flammable fluids through a

hose.

Coiled Tubing

Operations

Any entry into a well with coiled tubing.

Coiled Tubing

(through rotary)

Work done as part of the drilling/completion or workover operation

(from Rig Floor).

Completion Operations Workover rig and drilling rig activities.

Confined Space Entry

Personnel working in confined spaces where insufficient oxygen,

toxic or combustible gases may be present. Any space enclosed or

partially enclosed area, either above or below deck with limited

access.

Construction Operations

Equipment installation, removal or modification, repairs to processing

systems, pipelines or the platform structure; and crane lifts

considered as heavy lifts per BSEE or the Crane Operation

Maintenance Program or any equipment or materials that could

penetrate a deck plate if dropped while over wells and production

equipment.

Cold Construction

Operations

Any cold work or construction/repair activities with contract crews.

Installation of equipment not requiring opening of vessels or welding,

etc.

Excess Casing Pressure

(Operations)

Pressure on A or B annulus in excess of 20% of design pressure.

Derrick Barge (Lifting)

Time period when barge moves to a position where a decision is

made to shut down operations and/or begins to make lifts toward the

platform, until lift is set and lifting equipment is away from the

platform. Period could start when the barge approaches the platform

if there is some other need to apply restrictions, such as excessive

flare radiation.

Diving

Diving to inspect or do maintenance whether from the facility or

another vessel. Non-ROV.

Drilling (unknown area)

Drilling in unfamiliar areas where you have no past experience in

formation, pressures or hole trends.

Drilling in Reservoir

Drilling in known area. Drilling in hole section with known/expected

hydrocarbons.

Drilling Riserless

Drilling operations conducted without a riser installed between the

wellhead and the surface facility.

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 11 of 19

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

Activity Definition

Explosives above

Mudline

Electro-explosive devices (detonators) in wireline operations;

perforators, pipe cutters, severing tools and string shot (back-off).

Fire and Gas / ESD

Inoperable

Fire and gas system and/or Emergency Shut Down (ESD) inoperable

or placed out of service.

Flaring

Depressurization or venting of process vessel or compressors via

flare system.

Heavy Lifts (Platform,

Crane) Over Live

Production Equipment

Heavy lifts over production equipment includes Platform cranes or

from a barge/workboat. Platform crane lifts which exceed 75% of

rated load limit, at a given angle, are considered heavy lifts. Heavy

lifts by platform cranes require that wells, pressurized lines, and

production facilities located in the path of heavy lifts be shut-in if not

protected by solid steel decking.

Hot Work (Outside

Designated Areas)

Hot work is defined as any activity, which generates a spark, flame or

other ignition source under normal conditions. Welding in any

location of the platform other than the designated safe welding area.

Most likely includes major/minor construction projects and includes

safety work plans with OIM approval.

Hull Internal Inspection Entry in hull below water-tight doors.

Open Hydrocarbon

Systems

Open vessels, piping open to atmosphere prior to positive isolation

and purging.

Over side Work

Work outside handrails, over open area or water. Work within green

tagged scaffolding is NOT considered over side work.

Painting/Coating

Painting and coating at offshore location and discharge regulations

also apply.

Pigging (Export Lines)

Work associated with loading, running and retrieving a pig out of an

export pipeline.

Pipeline Operations

Any and all activity related to pipeline operations, with operations

including all pipelines in the area, BP operated or third party

operated. The pipeline includes risers, SCRs, PLETS, Wye Sleds,

Subsea Tie-ins, Launchers, Receivers and other pipeline

appurtenances for the transportation of oil, gas and products.

Pressure Testing

(BOP, Casing, etc.)

Pressure testing during drilling operations involving BOPs and casing.

Also, involving a lubricator, BOPs and grease injection head, or a

shooting nipple, i.e., pressure control equipment during any wireline

work.

Production Operations Flowing of any well, except as part of a back surge.

ROV Activity

Remotely Operated Vehicle (ROV) activity in controlled area of the

field.

Running Riser Running of outer production riser or drill riser.

Securing Wells

Any time wells are shut in due to heavy lifts in the well bay or for

hurricane evacuation, the SSVs, manual masters and the SCSSVs will

be closed. Once the wells are shut in, the umbilicals and flowlines

need to be bled down.

Skidding Drill Rig Movement of rig or major components on the deck of the facility.

Snubbing Live Well

Snubbing Operations associated with well control or production

operations. A formal detailed prognosis will be developed and

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 12 of 19

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

Activity Definition

outlined for each snubbing operation. Snubbing operations concerns

are pollution and uncontrolled well flow.

Well Clean-Up

Unloading of Well, start up/clean up prior to directing well to normal

flow path.

Well Control

(Drilling)

Well control conditions and the corrective actions necessary to

maintain proper well control. Any time primary well control is lost

either downhole or at surface.

Well Control

(producing)

Abnormal well control conditions and the corrective actions

necessary to maintain well control on Producing Well.

Well Stimulation

(through Rotary)

Work done as part of the drilling/completion/workover operations.

Wellbore Proximity

(Collision)

Conducting drilling operations where there is potential for

intersection with an existing wellbore.

Wireline

(Production Operations)

Wire line electrical or slick line on producing well. Work not done as

part of the drilling/completion or workover operation. (Not done from

rig floor).

Wireline (Rig Operations)

Wireline electrical or slickline through rotary. Electric or slickline

operations from the rig floor.

Workover Operations

A conventional or concentric workover activity when performing

remedial work on any wells.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 13 of 19

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

Appendix C:

Example SIMOPS Matrix (Atlantis)

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 1 of 19

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 1 of 19

Appendix D:SIMOPS Process Flow Chart

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 2 of 19

Appendix E:

Dropped Objects Plan Guidance

Severe damage to subsea infrastructure is a major concern due to dropped objects as well as damage

due to BOP lift-off and well-to-well BOP moves.

A Dropped Objects Prevention and Mitigation Plan must be developed to ensure infrastructure is

protected and that there is a contingency plan in effect should there be a dropped objects incident.

The Dropped Objects Prevention and Mitigation Plan typically should include:

Actions following a dropped object incident

Preemptive production shut-in:

During special deployments and recoveries if winch or crane systems are in use

During open water works

During seabed construction activities

During BOP well-to-well move

During tie-in of wells and infrastructure

Where the system may be exposed to only one barrier between hydrocarbon production and the

environment

Production equipment maintenance

Well intervention

Other activities considered risky and outside the planned activities

Emergency production shut-in using an emergency shut-in system

Dropped load during vessel-to-vessel transfer

Dropped load during a load deployment or recovery with a winch or drill pipe

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 3 of 19

Appendix G:

Marine SIMOPS Risk Management

Acoustic Management Plan Guidance

An acoustic frequency management plan is developed when two or more vessels in the same area are

using acoustics for position referencing, ROV tracking, clump weight tracking and surveying. The plan is

needed to ensure maximum vessel safety and to avoid acoustic disruptions.

The Frequency Management Plan assumes there is no safe distance where acoustics will not interfere. A

typical acoustic frequency management plan will list frequencies in the Medium Frequency (MF) band of

19-kHz to 36-kHz band width where a frequency separation of 500-Hz is used. A 250-Hz separation may

be possible, but opens up the possibility of extensive interference. A separation of 500-Hz is, therefore,

recommended.

A frequency management plan produces a set of compatible channel allocations and guidelines that will

allow each vessel to operate freely and without concern as to the effect their acoustic operations may

have on other vessels nearby. There is no need to enable and disable channels, which improves

efficiency and safety.

A more extensive plan may be developed for multiple vessel and survey operations. Use of a digital

acoustic system opens up to an increased number of safe channels in the MF band. Use of 28 carrier

frequencies combined with 16 codes give 448 unique frequencies, i.e., 224 interrogation and 224 reply

frequencies. This system has little or no affect on any tone-based acoustics, specifically High Precision

Acoustic Positioning (HiPap).

A seismic survey operation generates noise in the water column and may give acoustic disturbance. Any

seismic activity near an area where acoustics are in use needs to be planned. DP operators, in particular,

must be informed of seismic activities to ensure steps are taken during seismic or other acoustic

operations near a dynamically positioned vessel.

Provide Mitigations

The field SIMOPS plan shall include or reference a process to mitigate marine vessel/unit collision risk.

When a Safety Zone is established around a facility, the BP 500 Meter Zone Practice also shall apply.

Every vessel operating in a field shall at all times maintain a proper look-out by sight and by hearing as

well as by all other available means (including radar) appropriate in the prevailing circumstances and

conditions so as to make a full appraisal of the situation and of the risk of collision. The field SIMOPS

team may monitor vessel traffic if deemed necessary.

Vessel congestion, restricted visibility, adverse weather, or other hazardous circumstances require the

control, supervision, or other management of traffic and communications, including specifying times of

entry, movement, or departure from or within a field.

Note:

Nothing in this document or any field SIMOPS plan is intended to relieve any vessel,

owner, operator, charterer, master, or person directing the movement of a vessel from

the consequences of any neglect to comply with any other applicable law or regulation

(e.g., the International Regulations for Prevention of Collisions at Sea, 1972 (72

COLREGS or the Inland Navigation Rules) or of the neglect of any precaution which

may be required by the ordinary practice of seamen, or by the special circumstances

of the case.

Additional Precautions

All non-essential activity on the bridge of vessels in close proximity is not allowed.

Switching between DP station keeping modes shall be avoided in close proximity.

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 4 of 19

BOEMRE 30 CFR Subpart 250

BP Drilling and Wells Operations Directional Survey Handbook

6 Definitions

Term Definition

SIMOPS Conducting independent operations in which the events of any one

operation may impact the safety of personnel or equipment or the

environment of another operation

Marine Activity Any and all activity related to BP's operations and use of floating production

units or vessels whether on the high seas, coastal waters, in harbors or on

inland waterways, including marine terminals

Marine Vessel/Unit A generic term covering all vessels/units engaged in marine activity. Any

vessel designed for the carriage of goods, equipment or people on the high

seas, coastal waters or inland waterways, for the provision of services, or

any offshore facility requiring positive buoyancy

Risk Assessment The process of estimating the likelihood that an incident will occur;

estimating the magnitude of the consequential loss, including the

environmental impact, and making a judgment as to the significance of the

risk. The scale of the risk is a function of both likelihood and consequence.

Refer to Integrity Management Standard Element 3 for further information

on risk assessment methodologies

Revision Log

Revision Date Authority Custodian Revision Details

06/15/2012

GoM H&S

Director

GoM Safety

Programs Lead

Reformatted document to meet new GoM

document control template standardization

guidelines. Appendices included in the main

document

03/01/12

GoM HSSE

Director

GoM HSSE

Programs

Manager

Changed Asset Manager references to Area

Operations Managers, Removed OPM

position since all facilities now have OIMS

only, Changed MMS references to BOEMRE

07/17/08

GoM HSSE

Director

GoM HSSE

Programs

Manager

All corrections made were in Section F,

including adding correct links to Appendices,

deleting out-of-date references, and

clarifying the titles of some of the references

06/01/2008

GoM HSSE

Director

GoM HSSE

Programs

Manager

Key requirement is for each field to have an

approved field SIMOPS plan

More rigor and guidance for completing a

SIMOPS plan added

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

GoM Region Simultaneous Operations (SIMOPS) Safe Work Practice (SWP) Page 5 of 19

Control Tier: 2-GoM H&S Revision Date: 06/15/12

Document Number: UPS-US-SW-GoM-HSE-DOC-00678-2 Print Date: 11/30/2012

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING.

02/28/06

S. Garner/

S. Tink/

R. DeLeonardis/

C. Jackson

Kathy Kanocz

Clarified who is in charge when drilling and

operations on same facility. Added example

simops matrices Atlantis and Na Kika.

Added SIMOPS Work Task Definitions.

Changed CD # from 10074 to UPS-US-SW-

GOM-HSE-DOC-00132-2 to conform to new

numbering nomenclature inside of the new

GoM HSSE doc base. Changed 3 authorities

and 1 custodian.

02/01/02

S. Garner/

B. Herbert/

R. White/

S. Flynn

Ray Britt

Initial issue as controlled document. Prior

revision history located in hard-copy

consolidated manual.

You might also like

- Simultaneous Operation (SIMOPS) : Term of Referance (Tor)Document25 pagesSimultaneous Operation (SIMOPS) : Term of Referance (Tor)kokykarkar88% (8)

- 11 SIMOPs Procedure 11Document14 pages11 SIMOPs Procedure 11riyazali100% (7)

- Manual of Permitted Operations (MOPO)Document7 pagesManual of Permitted Operations (MOPO)Aniekan Akpaidiok100% (2)

- Wire Line Operation and EquipmentDocument122 pagesWire Line Operation and Equipmentmissaoui100% (4)

- Jsa Nitrogen PurgingDocument2 pagesJsa Nitrogen Purgingmohammedsouqi75% (8)

- HSE - 5.7 Procedure For Pre-Startup Safety Review ManagementDocument43 pagesHSE - 5.7 Procedure For Pre-Startup Safety Review Managementazimjoon67% (6)

- Port Facility Security Plan Empty FormDocument37 pagesPort Facility Security Plan Empty FormAbdel Naser AlsheikhNo ratings yet

- SIMOPS Check ListDocument8 pagesSIMOPS Check ListWawan Setiawan100% (3)

- SIMOPs Matrix - Combined - Rev-1Document1 pageSIMOPs Matrix - Combined - Rev-1DebadityachatterjeeNo ratings yet

- HSE Plan - FPSO Topside PDFDocument48 pagesHSE Plan - FPSO Topside PDFdndudc100% (3)

- Safety Moment - SIMOPS Gas VentingDocument7 pagesSafety Moment - SIMOPS Gas VentingfareedfksNo ratings yet

- D and D CatalogDocument139 pagesD and D Catalogmglsite1No ratings yet

- Slickline - Lectures. Tools. OperationsDocument44 pagesSlickline - Lectures. Tools. OperationsOmer Abuzeid100% (3)

- C Simops CBTDocument43 pagesC Simops CBTboypardede3552100% (1)

- SIMOPS Procedure - Pro-Saf-010-Ieoc Rev01-FinalDocument13 pagesSIMOPS Procedure - Pro-Saf-010-Ieoc Rev01-Finalkhaled100% (2)

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 pageManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- TSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina ElfDocument18 pagesTSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina Elfiwansalma100% (5)

- Simops MatrixDocument17 pagesSimops MatrixthinkpadNo ratings yet

- Simops RossDocument26 pagesSimops RossantonNo ratings yet

- Risk Assesment Tie-In (Mechanical)Document5 pagesRisk Assesment Tie-In (Mechanical)Galih SukmaNo ratings yet

- JSA-GF-008 Jacket Deck InstallationDocument9 pagesJSA-GF-008 Jacket Deck InstallationAmy Alvarez San RomanNo ratings yet

- Hazards and Effects Management ProcessDocument12 pagesHazards and Effects Management ProcessrwerwerwNo ratings yet

- Example Matrix of Permitted OperationsDocument3 pagesExample Matrix of Permitted OperationsKocic Gradnja67% (3)

- JSA-Road Crossing of 6'' PipelineDocument6 pagesJSA-Road Crossing of 6'' PipelineRidha Bennasr100% (2)

- 01 Offshore HSE Plan ProcedureDocument31 pages01 Offshore HSE Plan ProcedureAbdul Hakam Mohamed Yusof75% (4)

- Retail Permit To Work System - Job Hazard AnalysisDocument7 pagesRetail Permit To Work System - Job Hazard AnalysisSanthosh Kumar100% (1)

- Guideline Preparation of Port Area Security PlanDocument26 pagesGuideline Preparation of Port Area Security PlanAiman IlhamNo ratings yet

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 pageManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Welding HabitatDocument12 pagesWelding HabitatDesmond Chang100% (4)

- TCP PDFDocument43 pagesTCP PDFMoung Dia100% (1)

- 03a-Simultaneous Operations Operational ProcedureDocument11 pages03a-Simultaneous Operations Operational Proceduremichel louis friedman100% (2)

- SimopsDocument24 pagesSimopsgilbertotiburcio100% (1)

- BUNDUQ-HSE-SOP-05 Simultaneous Operations (SIMOPS)Document56 pagesBUNDUQ-HSE-SOP-05 Simultaneous Operations (SIMOPS)Rizwana100% (1)

- HSE Practice SIMOPS ProcedureDocument17 pagesHSE Practice SIMOPS ProcedureAjay Krishnan83% (6)

- Simops PR88POGC001 PDFDocument24 pagesSimops PR88POGC001 PDFOsman Kozu100% (1)

- Simops Risk AssessmentDocument3 pagesSimops Risk Assessmentzineddinmakram100% (1)

- Simultaneous Operations (SIMOPS)Document156 pagesSimultaneous Operations (SIMOPS)Ahmed Lepda100% (6)

- SIMOPS SMG 06-007-2016 (Final)Document18 pagesSIMOPS SMG 06-007-2016 (Final)Ayman Alradi100% (1)

- SIMOPS Simultaneous Operations For Onshore and Offshore FacilitiesDocument4 pagesSIMOPS Simultaneous Operations For Onshore and Offshore FacilitiesGhasem BashiriNo ratings yet

- Mopo SimopsDocument1 pageMopo SimopsMichael GanNo ratings yet

- Simops Mopo MatrixDocument6 pagesSimops Mopo MatrixPrathap SelvamNo ratings yet

- Simultaneous OperationsDocument22 pagesSimultaneous OperationsOgbadiboNo ratings yet

- SimopsDocument6 pagesSimopsravikrss100% (2)

- Jsa Nitrogen PurgingDocument2 pagesJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- Simultaneous Operations (Simops) Study: ObjectivesDocument6 pagesSimultaneous Operations (Simops) Study: ObjectivesMuhammad.SaimNo ratings yet

- WELLBERG JHA FOR FIRST AND SECONDLINE WELLHEAD MAINTENANCE SERVICES - UnlockedDocument8 pagesWELLBERG JHA FOR FIRST AND SECONDLINE WELLHEAD MAINTENANCE SERVICES - UnlockedAnthony H TL80% (5)

- SWP06 MSW WorkatHeight ChevronDocument34 pagesSWP06 MSW WorkatHeight Chevronpriyanta100% (1)

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- JSA For Geotechnical Investigation at OffshoreDocument5 pagesJSA For Geotechnical Investigation at OffshoreHilbrecht De PedroNo ratings yet

- Part IV - 02 Marine OperationsDocument5 pagesPart IV - 02 Marine Operationssalah abddayemNo ratings yet

- Risk Assessment For Offshore Refuelling Rev 0Document9 pagesRisk Assessment For Offshore Refuelling Rev 0ringbolt100% (1)

- PL-PBI-HSE 001 Project HSE PlanDocument22 pagesPL-PBI-HSE 001 Project HSE PlanTadaya KasaharaNo ratings yet

- PN3-PRO-HSE-038 Offshore Drilling Safety Case - Rev 01Document180 pagesPN3-PRO-HSE-038 Offshore Drilling Safety Case - Rev 01aymenmoataz100% (5)

- Hazards On An Offshore Platform A ReviewDocument8 pagesHazards On An Offshore Platform A ReviewWendy Tie Kai SingNo ratings yet

- SP 2062 HSE Specification Specifications For HSE CasesDocument84 pagesSP 2062 HSE Specification Specifications For HSE CasesDaniel Martinez0% (1)

- Risk Assessment For Tank 2Document4 pagesRisk Assessment For Tank 2Ace2201100% (1)

- Hse in Drilling OperationsDocument13 pagesHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- Offshore Technical Safety FAQDocument12 pagesOffshore Technical Safety FAQPillai Sreejith100% (15)

- 0006 - 033 Simultaneous Operations (Simops)Document8 pages0006 - 033 Simultaneous Operations (Simops)baseet gazaliNo ratings yet

- 2013 HSE Annual Report Web FINALDocument74 pages2013 HSE Annual Report Web FINALThiếu Nhiều Thứ100% (1)

- 7c - IOGP 432 Table 1 Draft v3 04062016Document32 pages7c - IOGP 432 Table 1 Draft v3 04062016Idada Ezekiel100% (1)

- Simops Ross PPDocument12 pagesSimops Ross PPzineddinmakram100% (1)

- Port Barrow Gorgon Construction Operations Port Operations Daily Schedule and Simops ProcedureDocument24 pagesPort Barrow Gorgon Construction Operations Port Operations Daily Schedule and Simops ProcedureafasfNo ratings yet

- Chap 2Document21 pagesChap 2adrien_ducaillouNo ratings yet

- ITS 2016 Boston - Tugconomy PaperDocument6 pagesITS 2016 Boston - Tugconomy PaperPietGebruikerNo ratings yet

- Blowout Technical RefrenceDocument89 pagesBlowout Technical Refrenceparsa2400No ratings yet

- Markl SIFs & Asme ViiiDocument3 pagesMarkl SIFs & Asme ViiiDesmond ChangNo ratings yet

- Stressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Document4 pagesStressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Desmond ChangNo ratings yet

- Stressman Engineering - Study - Stresses in Branch Connections at Different AnglesDocument7 pagesStressman Engineering - Study - Stresses in Branch Connections at Different AnglesDesmond ChangNo ratings yet

- Induction BendsDocument16 pagesInduction BendsDesmond Chang100% (1)

- PFD Calculation Program: #Value! #Value! #Value!Document4 pagesPFD Calculation Program: #Value! #Value! #Value!Desmond ChangNo ratings yet

- Lopa Workbook Sept 2005Document12 pagesLopa Workbook Sept 2005Desmond Chang100% (1)

- SIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDocument2 pagesSIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDesmond ChangNo ratings yet

- Permit To Work Flow ChartDocument2 pagesPermit To Work Flow ChartDesmond ChangNo ratings yet

- Weld End Preparation at Unequal Wall ThicknessesDocument4 pagesWeld End Preparation at Unequal Wall ThicknessesDesmond ChangNo ratings yet

- Standards IndexDocument32 pagesStandards IndexDesmond Chang100% (1)

- Piping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDocument52 pagesPiping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDesmond Chang100% (1)

- Ansys - DynamicsDocument13 pagesAnsys - DynamicsNono_geotecNo ratings yet

- PDMS Update AvevaDocument21 pagesPDMS Update AvevaDesmond ChangNo ratings yet

- The Basics of Arc WeldingDocument35 pagesThe Basics of Arc WeldingDesmond ChangNo ratings yet

- ANSYS Modal AnalysisDocument40 pagesANSYS Modal AnalysisDesmond Chang100% (1)

- 116 012 22 SCXTechnicalSpecs DE142 en USDocument7 pages116 012 22 SCXTechnicalSpecs DE142 en USAlan CastroNo ratings yet

- Om Series Kickover PDFDocument2 pagesOm Series Kickover PDFSufian R EllabbadNo ratings yet

- SSSV & SCP ManualDocument77 pagesSSSV & SCP Manualyasirism0% (1)

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- Bridge PlugsDocument9 pagesBridge Plugskaveh-bahiraeeNo ratings yet

- Sliding Sleeves Catalog Evolution Oil ToolsDocument35 pagesSliding Sleeves Catalog Evolution Oil ToolsEvolution Oil Tools100% (1)

- A Type PerforatorDocument0 pagesA Type PerforatorLazaro DhNo ratings yet

- Prakarsa-Iliadi - Slickline - Rigless Application 20180307Document90 pagesPrakarsa-Iliadi - Slickline - Rigless Application 20180307Asfan100% (1)

- JET - 36 - Coiled Tubing Downhole Tools UpdateDocument144 pagesJET - 36 - Coiled Tubing Downhole Tools UpdateMohamedIbrahim75% (4)

- Object Practical No.05: To Demonstrate The Mechanism & Function of Perforation TechniquesDocument22 pagesObject Practical No.05: To Demonstrate The Mechanism & Function of Perforation TechniquesdilshadaliNo ratings yet

- SLK-PR-04.00 Procedure Shift SSDDocument4 pagesSLK-PR-04.00 Procedure Shift SSDDonald TchiroueNo ratings yet

- Oil States Catalog: Well Servicing EquipmentDocument18 pagesOil States Catalog: Well Servicing EquipmentLudovic LandemaineNo ratings yet

- Swecs External 02SWECs External 02042014 - PRODUCTS042014 - ProductsDocument42 pagesSwecs External 02SWECs External 02042014 - PRODUCTS042014 - ProductsrelaxjackNo ratings yet

- Fishing Agitator Activation ProcedureDocument3 pagesFishing Agitator Activation ProcedureMehdi Mehdi100% (1)

- Pioneer Petrotech Services Inc.: PPS26 Surface Read-Out (SRO) GaugeDocument1 pagePioneer Petrotech Services Inc.: PPS26 Surface Read-Out (SRO) Gaugeflo basukiNo ratings yet

- Well Intervention OperationsDocument53 pagesWell Intervention OperationsLuis Arturo Gómez LunaNo ratings yet

- 4 RBP Evo-TrieveDocument2 pages4 RBP Evo-TrievelfbenahmedNo ratings yet

- m1 Frac PlugDocument2 pagesm1 Frac PlugfelipeNo ratings yet

- Magnum Composite Plug Catalog 06-30-10Document21 pagesMagnum Composite Plug Catalog 06-30-10Emad JamshidiNo ratings yet

- Goebor S Operating InstructionsDocument12 pagesGoebor S Operating InstructionsElgi Zacky ZachryNo ratings yet

- Template For BHA Drawing (Version 1) (Version 1)Document22 pagesTemplate For BHA Drawing (Version 1) (Version 1)Basel SaidawiNo ratings yet

- 82CT Communication Tool For 3 1/2-In. Rod-Piston TRSV Operation ManualDocument10 pages82CT Communication Tool For 3 1/2-In. Rod-Piston TRSV Operation Manualsong Li100% (1)

- Sandvik Wireline Catalogue 2007 PDFDocument31 pagesSandvik Wireline Catalogue 2007 PDFGeorge BoafoNo ratings yet

- LM Recommended Spares - 2018 - Rev ADocument8 pagesLM Recommended Spares - 2018 - Rev AFelipe Bernal100% (1)

- IADC/SPE 59209 A New Selective Lateral Re-Entry SystemDocument6 pagesIADC/SPE 59209 A New Selective Lateral Re-Entry SystemJorge FernandoNo ratings yet

- PGFT Fishing Course: S/L Fishing Page 1Document57 pagesPGFT Fishing Course: S/L Fishing Page 1Slbcar Looging100% (2)