Encased Columns

Uploaded by

jimmyfontanaEncased Columns

Uploaded by

jimmyfontanaEng. & Tech. Journal, Vol.30 , No.

15 , 2012

Strength and Ductility of Concrete Encased

Composite Beams

Dr.Ammar A. Ali

Building and Construction Engineering Department, University of Technology/Baghdad

Email:ammarbagh@yahoo.com

Saad N. Sadik

Building and Construction Engineering Department, University of Technology/Baghdad

Dr.Wael S. Abdul-Sahib

Building and Construction Engineering Department, University of Technology/Baghdad

Received on: 25/9/2011 & Accepted on: 1/3/2012

ABSTRACT

Experimental research was conducted to investigate the structural behavior of

concrete-encased composite beams. Specimens were tested under lateral loading.

The test results indicate that the behavior and failure mode of the beam are greatly

affected by the steel beam core. The beams showed highly ductile behavior. The

design flexural strength of concrete-encased beams is calculated from both the

elastic and plastic stress distribution on the composite section. The deflection at the

mid-span of the beam cannot be well predicted using linear elastic theory.

Keywords: Composite, beam, encased, strength

. .

.

.

.

INTRODUCTION

omposite construction employs structural members that are composed of

two materials: structural steel (rolled or built-up) and reinforced concrete.

Examples of composite members shown in Fig. (1) include (a) concreteencased steel section, (b) concrete-encased steel beams, (c) steel beams interactive

with and supporting concrete slabs, and (d) concrete-filled steel columns. In

contrast with classical structural steel design, which considers only the strength of

the steel, composite design assumes that the steel and concrete work together in

resisting loads. The inclusion of the contribution of the concrete results in more

economical designs, as the required quantity of steel can be reduced. Composite

beams can take several forms. One of these forms is consisting of beams encased in

2701

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

concrete (Fig.1.b). This is a practical alternative when the primary fireproofing

structural steel is to encase it in concrete and as well the contribution of concrete

could be accounted to share in the strength of the beam [1].

Work on encased beams dates back to 1922 in the report of the National

Physical Laboratory tests on filler joist panels [2]. Many researches followed for

both fully and partially encased beams [3, 4, 5, and 6]. Two types of composite

beams are addressed in AISC 2010, Chapter I [7]: fully encased steel beams which

depend on the natural bond of concrete to steel for composite action and those

beams with mechanical anchorage to the slab using headed stud shear connectors

or other types of connectors (such as channels) which do not have to be encased.

The present study here is coming to look for applicability of this form in the

construction process used in Iraq. This comes from the feasibility of this form and

it may be just insertion of the steel beam in the slabs of different thicknesses

including or excluding shear connectors to form hidden or projected beams. The

advantages of composite beams are:

(a) Concrete-encased

steel section

(b) Concrete-encased

steel beam

(d) Concrete-filled

Steel tubes

Figure (1) Composite sections

(c) Composite beam

Increased strength for a given cross sectional dimension.

Good fire resistance in the case of concrete encased beams.

Corrosion protection in encased beams.

2702

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

Significant economic advantages over either pure structural steel or

reinforced concrete alternatives.

Identical cross sections with different load and moment resistances can be

produced by varying steel thickness, the concrete strength and

reinforcement. This allows the outer dimensions of a beam to be held

constant, thus simplifying the construction and architectural detailing.

Concrete encased steel beams are also stronger in resisting impact loads.

Test Specimens

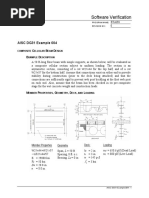

Two specimens were designed to represent a prototype beam used in mediumrise buildings. The test specimens had a square cross section of 150150 mm and

of 1.4 m span. Fig. (2) shows the configuration of the cross section. The test

specimens consisted of the structural steel shape, longitudinal reinforcement,

transverse reinforcement, and concrete.

The I-shaped structural steel used in the specimens is a hot-rolled section with

material properties given in Table(1). The ratio of the structural steel area to the

gross area was 3.6%. The centroids of both the structural steel shape and the

geometric center of the beam cross section are coincident.

As shown in Fig.(2), a longitudinal bar was placed at each corner of the beam.

The longitudinal bars were applied to tensile test and were of minimum yield

strength of 592 MPa, 12 mm in diameter and deformed. In addition, cross ties of 6

mm in diameter were used to engage the longitudinal bars and to enhance the

deformation ductility of the beam. The stirrups spacing was 160 mm center to

center. The measured material strengths are given in Table(1).

RC Section

Steel Section

d = 100 mm

bf

ds

db

b f = 50 mm

R

t f = 5.7 mm

R

N.A

b = 150 mm

tf

tw

t w = 3 mm

F y = 273.5 MPa

R

d b = 12 mm

d s = 6 mm

c = 7 mm

h = 150 mm

A b = 452.4 mm2

R

Figure (2) Composite beam cross-section of test specimen.

2703

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

Table (1). Measured mechanical properties of structural

steel andreinforcement.

Material

Yield strength (MPa)

Ultimate strength

(MPa)

Steel

273.5

461

Rebar (12 mm)

592

680

The concrete cube strength was 31.3 MPa, of three specimens measured at time

of testing (28 days). The mix design for concrete is done depending on the

American Concrete Institute (ACI) mix design method.

TEST SETUP AND TEST PROCEDURE

Fig.(3) is showing the test machine and Fig.(4) illustrates the test setup for

simulating the loading state of a beam. Roller and hinge supports were used at ends

of the specimen. With this test setup, the bending moment is peak at mid-span of

the specimen.

The lateral load was applied by a hydraulic jack to the midpoint of the beam,

using a load step of 5 kN.

Figure (3) Test setup.

2704

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

Applying lateral force

Beam specimen

700 mm

700 mm

Figure (4) Schematics of test setup.

BEHAVIOR AND FAILURE MODE

For both specimens, flexural cracks initially occurred at load of 40 kN;

afterwards, the cracks progressively grew as shown in Fig.(5). The response of the

specimens is presented in the loaddisplacement curves of Figs.(8) and (9).

It can be seen that the beam is showing linear behavior until 60 kN load;

afterwards, the nonlinearity of the curve began and the beam will behave

plastically as a plastic hinge occurring at the mid-span at loads of 110 kN and 100

kN for specimens 1 and 2, respectively. Ductility of the beam is very high that

because of the high percentage of steel area and this is one of the favorable features

for seismic construction.

The failure in the concrete is first by cracking of the tension zone and later by

crushing of the compression zone. The steel shape and reinforcement continue in

the plastic region and high deflection will be produced. The failure phenomena

were similar for both specimens.

ANALYSIS

The AISC LRFD Specification [7] permits two methods of design for encased

steel beams. In the first method, the design strength of the encased section is based

on the plastic moment capacity, b M p , of the steel section alone. In the second

method, the design strength of the encased section is based on the first yield of the

tension flange assuming composite action of the concrete that is in compression

and the steel section. Either way, there is no need to consider local buckling or

lateral-torsional buckling of the steel beam because such buckling is inhibited.

R

2705

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

Figure (5) Flexural failure.

The properties of the section components are as given in Fig.(2).

Concrete strengths are specified in terms of the characteristic cube strengths,

f cu , measured at 28 days. To convert to cylinder compressive strength a factor of

0.8 is used here.

It is used four 12 mm-diameter bars as longitudinal reinforcement of f y = 592

MPa and tied with undeformed 6 mm-stirrups. f y is the yielding strength of the

steel reinforcement bars.

The distribution of internal normal strains and stresses on the cross section

of a beam is shown in Fig.(5) assuming no slippage between steel and concrete [1].

It is based on the idealized stress-strain diagram for structural steel in Fig.(6),

which is a simplified version of the actual stress-strain curves.

R

(a) Strain.

2706

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

fs

fs

(b) Initial stresses

0.85f'c

fs

fy

(c) Block stress in concrete

0.85f'c

fy

fy

(d) Yielding of steel section and rebars

fy

fy

(e) Full yielding of steel section.

Figure (6) Strains and stresses diagrams.

2707

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

As shown in Fig.(6), the normal strain distribution is always linear, neglecting

the shear deformation effect. The magnitude of strain is proportional to the distance

from the neutral (or centroidal) axis. On one side of the neutral axis, the fibers of

the flexural member are in tension (or elongation); on the other side, in

compression (or shortening). The distribution of normal stresses depends on the

magnitude of the load. Under initial loads before yielding, stresses (which are

proportional to strains in Fig. (6.a) are also linearly distributed on the cross section

for both steel and concrete (Fig. 6.b). The strain will increase under additional load

and this will lead concrete to behave nonlinearly and here stress block may be used

to represent stresses in the concrete as shown in Fig. 6.c [10]. The maximum stress

in steel, however, is the yield stress F y (Fig. 6.d). Yielding will proceed inward,

from the outer fibers to the neutral axis as shown in Fig.(6.e), as the load is

increased, until a plastic hinge is formed. Forming plastic hinge will lead to

crushing concrete in compression zone and the steel section will work alone. The

idealized plastic behavior of structural steel is shown in Fig.(7).

Stress, MPa

Fy

E

1

y

Strain, mm/mm

Figure (7) Idealized stress-strain diagram for structural steel.

Another relationship depending on BS 5400: Part 5, Appendix C [8]

requirements that assume for concrete-encased section the plastic neutral axis will

be within the flange [9]. This is illustrated in Fig.(8).

Only beams which are compact (i.e., not susceptible to local buckling) and

adequately braced (to prevent lateral-torsional buckling) can attain this upper limit

of flexural strength. The relationships between moment and maximum (extreme

fiber) bending stresses, tension or compression, at a given cross section have been

derived in a number of engineering mechanics textbooks. At the various stages of

loading, they are as follows:

Until initial yielding:

M = Sf b

R

..(1)

2708

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

At initial yielding:

M y = SF y

R

Strength and Ductility of Concrete

Encased Composite Beams

..(2)

At full plastification (i.e., plastic hinge):

M p = ZF y

(3)

Where

M = bending moment due to the applied loads, N.mm.

M y = bending moment capacity at yielding, N.mm.

M p = full plastic moment capacity, N.mm.

S = elastic section modulus, mm3.

Z = plastic section modulus, mm3.

f b = maximum normal stress due to bending, MPa.

F y = specified minimum yield stress for steel section, MPa.

Elastic section modulus S = I / c.

Where I is the moment of inertia of the cross section about its centroidal axis; and c

is the distance from the centroid to the extreme fiber.

R

0.85f'c

yp

fy

fy

Figure (8) Stresses at plastification.

The total area of steel section A s is, A s = 835.8 mm2,

and distance between the extreme face of the flange and location of center of area

of upper half of steel section, , is:

R

2 +

=10.8 mm

2

2

4 4

. . (4)

a = 100-210.8 = 78.4 mm

= 32763 mm3

P

M p = F y Z + 0.5A b f y (h-d r )

R

(5)

2709

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

Where

f y = yield strength of steel reinforcement.

A b = area of reinforcement.

d r = the cover to reinforcement.

For the moment strength of bare steel section as per AISC LRFD [7]:

M p 1 = 8.9 kN.m.

P p 1 = 25.6 kN.

The load strength P p 1 which is so conservative compared with experimental load

P p = 98 kN. But, if the effect of reinforcement is included as in Eq.(5), the moment

and load strengths will be:

M p 2 = 27.3 kN.m.

P p 2 = 75.6 kN.

The great effect of reinforcement in strength of the composite section could be

noticed here.

Applying procedure as given by Davidson [9],

R

= 0.5 + 0.5 0.87 ( )

M p 3 = 26.4 kN.m.

R

. . (6)

P p 3 = 75.3 kN.

R

If assuming that the reinforcement in the top and bottom layers is fully yielded in

Eq.(6):

M p 4 = 28.6 kN.m.

R

P p 4 = 81.8 kN.

R

In the above, M p i is the moment strength and P p i is the maximum center load,

R

. . (7)

The comparison above shows that using bare steel shape as recommended by

AISC LRFD [7] will be very conservative for this case. Adding the effect of

longitudinal reinforcement will enhance the prediction of the experimental load.

This may be due to the high ratio of reinforcement for the 150150 mm section

which is 35% of the total steel area. Also the high yielding strength of

reinforcement compared to the steel shape. British Standards (BS) procedure as

presented by Davidson [9] is giving similar results, if longitudinal reinforcement is

included. Results of procedure given by Davidson, assuming not full yielding of

reinforcement, will be more close to the experimental results and difference will be

16% in the safe side. The comparison is given in Fig.(9).

2710

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

Experimental, S

Experimental, S

Load, kN

Pp

Pp4

Pp2&Pp3

Pp1

Displacement, mm

Figure (9) Ultimate strength comparison using

Different methods.

DEFLECTIONS

Deflection is a serviceability limit state, not one of strength, so deflections

should always be computed with service loads. The deflections due to loading

applied to the composite beams shall be calculated using elastic analysis with the

flexural stiffness equal to the mean value of E s I 1 and E s I 2 . E s is the modulus of

elasticity for structural steel, I 1 is the second moment of area of the effective

equivalent steel section assuming that concrete in tension is uncracked, and I 2 is

the second moment of area of the steel section only neglecting the concrete.

Computing I 1 the moment of inertia about the x-axis of the whole beam,

R

1 = 0 + ( )2 +

1 3

+ ( ) ( )2

12

. . (8)

In this formula:

I 0 = moment of inertia of steel about its own axis, mm4.

b = width of section, mm.

h = depth of section, mm.

A s = area of steel, mm2.

y b = distance from the bottom of the beam to the neutral axis of the whole

beam, mm.

+ ( )

=

y s = distance between the steel's neutral axis and the bottom of the beam, mm.

A c(trans) = transformed area of the concrete = hb / n,

R

2711

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

y c = distance between the neutral axis of the concrete and the bottom of the

beam.

E c = modulus of elasticity of concrete, and

n = modular ratio

The ACI 318-08 Building Code [10] gives the value of E c as 1.5 0.043 (in

MPa) for values of w c between 1440 and 2560 kg/m3 and for normal concrete it

may be taken as 4700 where

R

140

Experimental, S2

120

Load, kN

100

Theoritical (linear)

Pp

Pp4

Pp2&Pp3

80

60

Theoritical modified

(linear)

40

Pp1

20

0

0

10

20

30

Displacement, mm

Figure (10) Load-displacement behavior.

w c = unit weight of concrete (kg/m3) (normal weight concrete weighs

approximately 2400 kg/m3).

R

= 28-day compressive strength of concrete (MPa).

Now applying the previous steps, having:

b f = 50 mm, d = 100 mm, t f = 5.7 mm, t w =3 mm.

R

h = 150 mm, b = 150 mm, c = 7 mm, d b = 12 mm, d t = 6 mm.

R

2712

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

= 25 MPa, , = 592 MPa, = 273.5 MPa, E s = 200 000 MPa.

R

E c = 4700 = 23 500 MPa.

R

200000

23500

= 8.5.

A s = 836 mm2, A c(trans) = 2647 mm2.

R

A total = 3483 mm2.

R

y b = 75 mm.

R

I 0 = 1424333 mm4.

R

I 1 = 6387568 mm4 .

R

I 2 = I 0 = 1424333 mm4.

R

It can be seen from Fig. 10 that using the average modified stiffness of the

section gave more close result to predict the behavior within the linear region than

that of the uncracked section.

CONCLUSIONS

Flexural tests were conducted to evaluate the structural behavior of the

proposed composite beam using I-shape steel section with reinforced concrete

encasement. The following conclusions were drawn from the results:

(1) The ultimate strength of the proposed system exceeded the design value. It

failed due to concrete crushing in the compression zone without bond or local

failure. This behavior was in accordance with the design objective, i.e., complete

composite action before yield and partial composite action after yield. This design

concept enabled the proposed system to develop sufficient ductility, strength, and

consequently effective composite behavior, without causing serviceability

problems.

(2) The flexural strength determined using the plastic stress distribution on the

steel section for the limit state of yielding (plastic moment) as adopted by AISC

LRFD is too conservative for the case of reinforced concrete encasement.

(3) It is found that considering the effect of the longitudinal reinforcement in the

strength of the section important to get more close to experimental results.

(4) Using BS method as in [8] with fully yielded reinforcement will lead to

strength as conservative as 16%.

(5) Deflection estimation using simplified method within the linear region is

more accurate by using the modified flexural stiffness.

REFERENCES

[1] Rokach, A.J., Theory and Problems of Structural Steel Design, McGraw Hill,

New York, NY., 1991.

2713

Eng. & Tech. Journal, Vol.30 , No.15 , 2012

Strength and Ductility of Concrete

Encased Composite Beams

[2] Adekola, A.O., "Elastic and plastic behaviour of cased beams", Build. Sci.

Vol.2, pp. 321-330, Pergamon Press 1968, Printed in Great Britain.

[3] Kindmann, R. and Bergmann, R., "Effect of reinforced concrete between the

flanges of the steel profile of partially encased composite beams", J. Construct.

Steel Research, 27, 107-122, 1993.

[4] Roeder, C.W., Chmielowski, and Brown, C.B., "Shear connector requirements

for embedded steel sections", ASCE Journal of Structural Engineering, Vol. 125,

No. 2, February, 1999.

[5] Hegger, J. and Goralski, C., "Structural behavior of partially concrete encased

composite sections with high strength concrete", In: Composite construction in

steel and concrete V: proceedings of the 5th international conference, Structural

Engineering Institute of the American Society of Civil Engineers. Reston, VA:

American Society of Civil Engineers, 2006.

[6] Elghazouli, A.Y. and Treadway, J., "Inelastic behaviour of composite members

under combined bending and axial loading", Journal of Constructional Steel

Research 64, 10081019, 2008.

[7] AISC, Specification for Structural Steel Buildings, American Institute of Steel

Construction, Chicago, IL., 2010.

[8] British Standards Institution, Steel, concrete and composite bridges. Part 5:

Code of practice for design of composite bridges. BS 5400, BSI, London, 1979.

[9] Davison, B. and Owens, G.W. (Editors), "Steel Designer's Manual" 6th edition,

Blackwell Scientific publications, Oxford, 2003.

[10] ACI, Building Code Requirements for Structural Concrete (ACI 318M-08)

and Commentary, Farmington Hills, MI., 2008.

2714

You might also like

- Custody Transfer Metering Skid - Sea TransportationNo ratings yetCustody Transfer Metering Skid - Sea Transportation518 pages

- ALUMINUM MULTI-STORY CURTAIN WALL STRUCTURE CALCULATIONNo ratings yetALUMINUM MULTI-STORY CURTAIN WALL STRUCTURE CALCULATION187 pages

- Explanatory Examples On Indian Seismic Code IS 1893 (Part I)No ratings yetExplanatory Examples On Indian Seismic Code IS 1893 (Part I)27 pages

- Supplemenatry Calculations For 750x750 Column Near Pool AreaNo ratings yetSupplemenatry Calculations For 750x750 Column Near Pool Area4 pages

- General Notes On Modeling Using SAP - ECG - v1No ratings yetGeneral Notes On Modeling Using SAP - ECG - v139 pages

- Zamildesignmanualnew 131129110110 Phpapp01 PDFNo ratings yetZamildesignmanualnew 131129110110 Phpapp01 PDF282 pages

- ReportClinkerStorageBuildingRev1 11.02.13No ratings yetReportClinkerStorageBuildingRev1 11.02.13228 pages

- Design of Shear Reinforcement in A Singly Reinforced BeamNo ratings yetDesign of Shear Reinforcement in A Singly Reinforced Beam8 pages

- Design Report - Modele Knitting Building Steel Building - NarayanganjNo ratings yetDesign Report - Modele Knitting Building Steel Building - Narayanganj34 pages

- Glass Panel (2-Side Supported) : Calculation SheetNo ratings yetGlass Panel (2-Side Supported) : Calculation Sheet1 page

- Journal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin LuNo ratings yetJournal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin Lu12 pages

- QES PEVC-ENG262 - Checklist For Tower Foundation Design & DrawingNo ratings yetQES PEVC-ENG262 - Checklist For Tower Foundation Design & Drawing2 pages

- 04 Lateral Torsional Buckling ResistanceNo ratings yet04 Lateral Torsional Buckling Resistance4 pages

- Lecture 3 Bending and Shear in Beams PHG A8 2oct16No ratings yetLecture 3 Bending and Shear in Beams PHG A8 2oct1630 pages

- "Deckslab" - Slab On Metal Deck Analysis / Design: Program DescriptionNo ratings yet"Deckslab" - Slab On Metal Deck Analysis / Design: Program Description26 pages

- Abt - Corner Bracket Structural Design ReportNo ratings yetAbt - Corner Bracket Structural Design Report21 pages

- Software Verification: AISC-360-16 Example 001No ratings yetSoftware Verification: AISC-360-16 Example 0014 pages

- General Notes Table 1: Bearing Baseplate AssemblyNo ratings yetGeneral Notes Table 1: Bearing Baseplate Assembly20 pages

- AD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionNo ratings yetAD 288 Discontinuous Columns in Simple Construction Beam-Column Connection3 pages

- Sample Ribbed Slab Design by TCC SpreadsheetsNo ratings yetSample Ribbed Slab Design by TCC Spreadsheets3 pages

- ASIC Steel Interchange - Shear Flow in Plastic DesignNo ratings yetASIC Steel Interchange - Shear Flow in Plastic Design2 pages

- Combination Number Partial Safety Coefficient Load Type Partial Safety Coefficinet Load Type Partial Safety Coefficient Load TypeNo ratings yetCombination Number Partial Safety Coefficient Load Type Partial Safety Coefficinet Load Type Partial Safety Coefficient Load Type1 page

- Software Verification: AISC-360-10 Example 002No ratings yetSoftware Verification: AISC-360-10 Example 0023 pages

- Design Report - Coolant Recycling PROJECT-Rev-0 - Kips FTNo ratings yetDesign Report - Coolant Recycling PROJECT-Rev-0 - Kips FT135 pages

- Staad (1) .Pro 2006 Technical Reference (Halid)No ratings yetStaad (1) .Pro 2006 Technical Reference (Halid)702 pages

- Strength and Ductility of Concrete Encased Composite Beams: DR - Ammar A. AliNo ratings yetStrength and Ductility of Concrete Encased Composite Beams: DR - Ammar A. Ali14 pages

- Journal of Constructional Steel Research: E.L. Tan, B. UyNo ratings yetJournal of Constructional Steel Research: E.L. Tan, B. Uy10 pages

- Mechanical Design Basics of Tall ColumnsNo ratings yetMechanical Design Basics of Tall Columns45 pages

- Schwinger Representation of Spin Hamiltonian: X y X y ZNo ratings yetSchwinger Representation of Spin Hamiltonian: X y X y Z2 pages

- Periodic Surprises in Electromagnetism: Photonic CrystalsNo ratings yetPeriodic Surprises in Electromagnetism: Photonic Crystals29 pages

- Ajay Kumar Garg Engineering College, Ghaziabad Department of Mechanical Engineering Sessional Test-2No ratings yetAjay Kumar Garg Engineering College, Ghaziabad Department of Mechanical Engineering Sessional Test-27 pages

- Q. 1 - Q. 9 Carry One Mark Each & Q. 10 - Q. 22 Carry Two Marks EachNo ratings yetQ. 1 - Q. 9 Carry One Mark Each & Q. 10 - Q. 22 Carry Two Marks Each5 pages

- The Eternal Original Fundamental Particle of The Universe: Dadarao DhoneNo ratings yetThe Eternal Original Fundamental Particle of The Universe: Dadarao Dhone6 pages

- R.F Of: Theory of Color Centers in Ionic Crystals. IINo ratings yetR.F Of: Theory of Color Centers in Ionic Crystals. II10 pages

- Summary 2. Introduction & Theories 3. Methodology 4. Results & Discussion 5. Conclusion & Recommendation 6. Tutorial 7. References and AppendicesNo ratings yetSummary 2. Introduction & Theories 3. Methodology 4. Results & Discussion 5. Conclusion & Recommendation 6. Tutorial 7. References and Appendices4 pages

- Instructional Manual For Dead Weight Pressure Gauge TesterNo ratings yetInstructional Manual For Dead Weight Pressure Gauge Tester6 pages

- University of Engineering & Technology, Peshawar, Pakistan: Free Vibration in Undamped M.D.O.F SystemsNo ratings yetUniversity of Engineering & Technology, Peshawar, Pakistan: Free Vibration in Undamped M.D.O.F Systems53 pages

- Custody Transfer Metering Skid - Sea TransportationCustody Transfer Metering Skid - Sea Transportation

- ALUMINUM MULTI-STORY CURTAIN WALL STRUCTURE CALCULATIONALUMINUM MULTI-STORY CURTAIN WALL STRUCTURE CALCULATION

- Explanatory Examples On Indian Seismic Code IS 1893 (Part I)Explanatory Examples On Indian Seismic Code IS 1893 (Part I)

- Supplemenatry Calculations For 750x750 Column Near Pool AreaSupplemenatry Calculations For 750x750 Column Near Pool Area

- Design of Shear Reinforcement in A Singly Reinforced BeamDesign of Shear Reinforcement in A Singly Reinforced Beam

- Design Report - Modele Knitting Building Steel Building - NarayanganjDesign Report - Modele Knitting Building Steel Building - Narayanganj

- Glass Panel (2-Side Supported) : Calculation SheetGlass Panel (2-Side Supported) : Calculation Sheet

- Journal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin LuJournal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin Lu

- QES PEVC-ENG262 - Checklist For Tower Foundation Design & DrawingQES PEVC-ENG262 - Checklist For Tower Foundation Design & Drawing

- Lecture 3 Bending and Shear in Beams PHG A8 2oct16Lecture 3 Bending and Shear in Beams PHG A8 2oct16

- "Deckslab" - Slab On Metal Deck Analysis / Design: Program Description"Deckslab" - Slab On Metal Deck Analysis / Design: Program Description

- AD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionAD 288 Discontinuous Columns in Simple Construction Beam-Column Connection

- ASIC Steel Interchange - Shear Flow in Plastic DesignASIC Steel Interchange - Shear Flow in Plastic Design

- Combination Number Partial Safety Coefficient Load Type Partial Safety Coefficinet Load Type Partial Safety Coefficient Load TypeCombination Number Partial Safety Coefficient Load Type Partial Safety Coefficinet Load Type Partial Safety Coefficient Load Type

- Design Report - Coolant Recycling PROJECT-Rev-0 - Kips FTDesign Report - Coolant Recycling PROJECT-Rev-0 - Kips FT

- Strength and Ductility of Concrete Encased Composite Beams: DR - Ammar A. AliStrength and Ductility of Concrete Encased Composite Beams: DR - Ammar A. Ali

- Journal of Constructional Steel Research: E.L. Tan, B. UyJournal of Constructional Steel Research: E.L. Tan, B. Uy

- Schwinger Representation of Spin Hamiltonian: X y X y ZSchwinger Representation of Spin Hamiltonian: X y X y Z

- Periodic Surprises in Electromagnetism: Photonic CrystalsPeriodic Surprises in Electromagnetism: Photonic Crystals

- Ajay Kumar Garg Engineering College, Ghaziabad Department of Mechanical Engineering Sessional Test-2Ajay Kumar Garg Engineering College, Ghaziabad Department of Mechanical Engineering Sessional Test-2

- Q. 1 - Q. 9 Carry One Mark Each & Q. 10 - Q. 22 Carry Two Marks EachQ. 1 - Q. 9 Carry One Mark Each & Q. 10 - Q. 22 Carry Two Marks Each

- The Eternal Original Fundamental Particle of The Universe: Dadarao DhoneThe Eternal Original Fundamental Particle of The Universe: Dadarao Dhone

- R.F Of: Theory of Color Centers in Ionic Crystals. IIR.F Of: Theory of Color Centers in Ionic Crystals. II

- Summary 2. Introduction & Theories 3. Methodology 4. Results & Discussion 5. Conclusion & Recommendation 6. Tutorial 7. References and AppendicesSummary 2. Introduction & Theories 3. Methodology 4. Results & Discussion 5. Conclusion & Recommendation 6. Tutorial 7. References and Appendices

- Instructional Manual For Dead Weight Pressure Gauge TesterInstructional Manual For Dead Weight Pressure Gauge Tester

- University of Engineering & Technology, Peshawar, Pakistan: Free Vibration in Undamped M.D.O.F SystemsUniversity of Engineering & Technology, Peshawar, Pakistan: Free Vibration in Undamped M.D.O.F Systems