4l80e GD

4l80e GD

Uploaded by

Jose CencičCopyright:

Available Formats

4l80e GD

4l80e GD

Uploaded by

Jose CencičOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

4l80e GD

4l80e GD

Uploaded by

Jose CencičCopyright:

Available Formats

Back

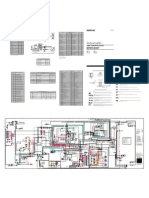

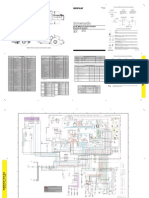

4L80EGeneral Reference Data

Clutch, Band & Solenoid Application Chart

Overdrive Overrun

Clutch

Clutch

Cooler return:

Bottom/Front fitting on 91-96 models OR

Rear Fitting on 97up models

Overrun

Roller

Clutch

Forward

Clutch

Direct

Clutch

Intermediate

Band

Intermediate

Sprag

Intermediate

Clutch

Low/Reverse

Band

Low

Roller

Shift

Sol

A

Shift

Sol

B

On

Off

On

Off

On

Off

Locked

On

Off

Park

Applied

Reverse

Applied

Neutral

Overdrive

1st Speed

Locked

Applied

Overdrive

2nd Speed

Locked

Applied

Overdrive

3rd Speed

Locked

Applied

*OR

Applied

Overdrive

4th Speed

Input

Speed

Sensor

Mainline Pressure Tap

Idle Drive 42-65 Max 165-185

Idle Reverse 120-125 Max 280-305

Output

Speed

Sensor

Applied

Drive

1st Speed

Applied

Locked

Applied

Drive

2nd Speed

Applied

Locked

Applied

Drive

3rd Speed

Applied

Locked

Applied

Drive 2

1st Speed

Applied

Locked

Applied

Drive 2

2nd Speed

Applied

Locked

Applied

Manual Low (1)

Applied

Locked

Applied

*OR = Overrunning

*OR

Off

Off

Applied

*OR

Applied**

*OR

Off

On

Applied

*OR

Applied**

*OR

On

On

Locked

On

Off

Applied

Applied

Locked

Applied

*OR

Off

Off

*OR

Applied**

*OR

Off

On

*OR

On

Off

*OR

Off

Off

Locked

On

Off

Locked

Applied

Applied

Low Roller

Turns

Turns

Hold Shaft

Applied

Applied** = Applied but ineffective

Electrical

Connector

Trans Basic Operation:

The 4L80E is a RWD 4 speed unit with

TCC. Shift delay, shift feel, and TCC are

all electronically controlled by TCM

through the use of solenoids mounted on

the valve body.

Originally designated the 4L80E, other

similar model variations are designated

as 4L80E-HD, and 4L85E.

Locked

Intermediate Sprag

Electrical

Data

Next

Page

Hold

Support

TransGo 2006

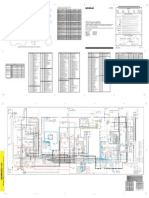

4L80EGeneral Reference Data

= Checkball

Electrical Notes/Data:

1st design (flat blade type terminals) connector had 12 wires including 2 separate 12v supply wires.

The 1st design internal harness was discontinued and must be serviced with the 2nd design which

also requires a new pigtail to be spliced onto the vehicle harness in place of the original.

The 2nd design internal harness uses only a single 12v supply instead of 2 separate ones like the 1st

design. When converting a vehicle from 1st design to 2nd design, one of the 12v supply wires

(Terminal K) is not used. As a result of the 12v supply consolidation, the 2nd design uses only 11

wires.

When comparing the 1st and 2nd designs, the terminal letter designations were changed as well as

the locations.

1st Design Case Connector 1991-1993

Flat Blade Terminal Design

C

2nd Design Case Connector 1993 up

Round Pin Terminal Design

B C

A B

D

N

G

H

L

M

R

J

L M

Terminal ID

1st Design

Terminal ID

2nd Design

Function

Resistance

Shift Solenoid A Control (Ground)

20-30

Shift Solenoid B Control (Ground)

20-30

12v Supply

NA

Range Switch A

NA

Range Switch B

NA

Range Switch C

NA

Temp Sensor High

3.5k-4k @ 70F

Temp Sensor Low

180-250 @200F

PWM (TCC) Solenoid Control (Ground)

11-15

Not Used

12v Supply

Force Motor (High)

Force Motor (Low)

4.5-6.0

TransGo 2006

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Diagrama Electrico 320cDocument2 pagesDiagrama Electrico 320cMilton Hernandez Pérez95% (21)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- 12H, 140H, and 160H Electrical System Motor Grader Standard VersionDocument2 pages12H, 140H, and 160H Electrical System Motor Grader Standard Versionmateo apolinar100% (5)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Th103 Electric ShematicDocument2 pagesTh103 Electric Shematicvic13rNo ratings yet

- Diagrama D6HDocument2 pagesDiagrama D6HPepe Alonzo75% (8)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Senr1256 01Document2 pagesSenr1256 01omarNo ratings yet

- 248B SCL HidraulicDocument2 pages248B SCL Hidraulicalex ro100% (2)

- M 318Document2 pagesM 318Franz JW Monteza100% (2)

- GM 6L80 Transmissions: How to Rebuild & ModifyFrom EverandGM 6L80 Transmissions: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Muncie 4-Speed Transmissions: How to Rebuild & ModifyFrom EverandMuncie 4-Speed Transmissions: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (7)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- GM Cat 910f Electrical SchematicDocument2 pagesGM Cat 910f Electrical Schematicqwureyquwery100% (3)

- Exc Cat #20 312Document2 pagesExc Cat #20 312Washington Santamaria50% (2)

- 12oh Motoniveladora Version Standar 5fm Plano ElectricoDocument2 pages12oh Motoniveladora Version Standar 5fm Plano Electricomiguelcastillo100% (1)

- Cs 663e Electrical DagDocument2 pagesCs 663e Electrical Dagqwureyquwery0% (1)

- 140h Sist. Electrico - SisDocument2 pages140h Sist. Electrico - SisRodrigo Chacca100% (4)

- Caterpillar CB 534 D Sistema ElectricoDocument6 pagesCaterpillar CB 534 D Sistema ElectricoCarlos IrabedraNo ratings yet

- Slant Six Racing ManualDocument51 pagesSlant Six Racing ManualNorEaster1100% (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Camaro 5th Gen 2010-2015: How to Build and ModifyFrom EverandCamaro 5th Gen 2010-2015: How to Build and ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- How to Build Max-Performance Chevy LT1/LT4 EnginesFrom EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesRating: 3 out of 5 stars3/5 (1)

- How to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsFrom EverandHow to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsRating: 3.5 out of 5 stars3.5/5 (4)

- How to Swap Ford Modular Engines into Mustangs, Torinos and MoreFrom EverandHow to Swap Ford Modular Engines into Mustangs, Torinos and MoreRating: 4 out of 5 stars4/5 (6)

- Camaro Special Editions: Includes pace cars, dealer specials, factory models, COPOs, and more: Includes pace cars, dealer specials, factory models, COPOs, and moreFrom EverandCamaro Special Editions: Includes pace cars, dealer specials, factory models, COPOs, and more: Includes pace cars, dealer specials, factory models, COPOs, and moreNo ratings yet

- Chrysler A-833 Transmissions: How to Rebuild and ModifyFrom EverandChrysler A-833 Transmissions: How to Rebuild and ModifyRating: 5 out of 5 stars5/5 (15)

- 12 GDocument2 pages12 GMoises Carrera AnguloNo ratings yet

- 4L60 (700-R4) - General Reference Data: Clutch & Band Application Chart Trans Basic OperationDocument1 page4L60 (700-R4) - General Reference Data: Clutch & Band Application Chart Trans Basic OperationDrewsomeNo ratings yet

- Tractor d6gDocument2 pagesTractor d6gFrank Agurto Luciano100% (1)

- RENR1156Document2 pagesRENR1156Leopoldo Del Campo100% (1)

- 45rfe GD PDFDocument2 pages45rfe GD PDFeurospeed2100% (4)

- CAT GRADER 14H 7WJ664-UP Electrical System SchematicDocument2 pagesCAT GRADER 14H 7WJ664-UP Electrical System Schematicduongpndng100% (2)

- Cat - Dcs.sis - Controller (12H - 8MN)Document2 pagesCat - Dcs.sis - Controller (12H - 8MN)Warley Moraes Oliveira100% (1)

- TF500 GD PDFDocument2 pagesTF500 GD PDFeurospeed2No ratings yet

- C4 General DataDocument1 pageC4 General DataGypsyRNo ratings yet

- Sistema Electrico d5c Serie 7ps832Document2 pagesSistema Electrico d5c Serie 7ps832Jose MunizNo ratings yet

- 631e Plano ElectricoDocument2 pages631e Plano ElectricoMario Olivares Arambula100% (1)

- Plano Electrico Del MotorDocument2 pagesPlano Electrico Del MotorSINTRONONIREYNA0% (1)

- 2010-07-25 113120 416-438 Series II Elec PDFDocument2 pages2010-07-25 113120 416-438 Series II Elec PDFmasakpNo ratings yet

- G4a El - GDDocument1 pageG4a El - GDacmemail583No ratings yet

- Plano Electrico PDFDocument2 pagesPlano Electrico PDFIvan Alex Escobar67% (3)

- Renr1166 01Document2 pagesRenr1166 01Leopoldo Del Campo100% (1)

- 5 R 55 NDocument2 pages5 R 55 NJoão EzerNo ratings yet

- 938G+ +Electrical+SystemDocument2 pages938G+ +Electrical+Systemhenotharenas100% (5)

- Plano Electricidad Cat 325Document2 pagesPlano Electricidad Cat 325aguadojorgeNo ratings yet

- Cat 214BDocument20 pagesCat 214BNacer Mezghiche67% (3)

- Electric 120H 5FM PDFDocument2 pagesElectric 120H 5FM PDFrprim100% (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Jaw Crusher Manufacturer: Fuel Gases and Heating ValuesDocument4 pagesJaw Crusher Manufacturer: Fuel Gases and Heating ValuesJose CencičNo ratings yet

- Acid Base Titration Lab 6Document11 pagesAcid Base Titration Lab 6Jose Cencič0% (1)

- Piston Skirt ClearanceDocument5 pagesPiston Skirt ClearanceJose CencičNo ratings yet

- Aspirin & AnalgesicsDocument14 pagesAspirin & AnalgesicsJose CencičNo ratings yet

- VW Vin Decoder 2007Document2 pagesVW Vin Decoder 2007Jose Cencič100% (1)

- Alternator BibleDocument43 pagesAlternator BibleJose Cencič100% (1)

- Brookfield DV2T Extra Viscometer - Brookfield EngineeringDocument3 pagesBrookfield DV2T Extra Viscometer - Brookfield EngineeringJose CencičNo ratings yet

- TH350 GDDocument1 pageTH350 GDJose CencičNo ratings yet

- The 09G Flared Shift ProblemsDocument3 pagesThe 09G Flared Shift ProblemsJose Cencič100% (1)

- Asco To GoldringDocument45 pagesAsco To GoldringJose CencičNo ratings yet

- Industrial Burners, Combustion Equipment - Maxon CorporationDocument2 pagesIndustrial Burners, Combustion Equipment - Maxon CorporationJose CencičNo ratings yet

- EKC 202ABC ManualDocument16 pagesEKC 202ABC ManualJose CencičNo ratings yet

- EKC 202ABC ManualDocument16 pagesEKC 202ABC ManualJose CencičNo ratings yet

- James Walker - O RingsDocument32 pagesJames Walker - O RingsJaime OroNo ratings yet

- Accounting For Special TransactionsDocument11 pagesAccounting For Special Transactionsjohn carloNo ratings yet

- 2014 Winter Model Answer PaperDocument36 pages2014 Winter Model Answer PaperBharatNo ratings yet

- Haryana Mains 2022 - Paper 1Document2 pagesHaryana Mains 2022 - Paper 1Sukriti tripathiNo ratings yet

- Four Thousand Two Hundred Fifty: Happier (Expensive) More Expensive (Bad) WorseDocument3 pagesFour Thousand Two Hundred Fifty: Happier (Expensive) More Expensive (Bad) WorseFrank Garcia LeonNo ratings yet

- Net Dimm Update GuideDocument9 pagesNet Dimm Update Guiderzlpratama18No ratings yet

- Display 05122017Document65 pagesDisplay 05122017NDTV80% (5)

- Walmart Case Study Unit 6.assignementDocument13 pagesWalmart Case Study Unit 6.assignementKyteNo ratings yet

- GD&T 1Document69 pagesGD&T 1JayanthiANo ratings yet

- Binomial ExpansionsDocument5 pagesBinomial ExpansionsShafiqueDeshongNo ratings yet

- OS InfoDocument138 pagesOS InfoSindhu BalakrishnaachariNo ratings yet

- Workshop Motorcycle Center Employment Contract: Day(s) /week(s) / Month(s) / Year(s), Ending OnDocument3 pagesWorkshop Motorcycle Center Employment Contract: Day(s) /week(s) / Month(s) / Year(s), Ending OnSan Day EshNo ratings yet

- Fria (Basic Concept)Document4 pagesFria (Basic Concept)Thea Faye B. CAHUYANo ratings yet

- AppCenter 2.0 Build 1173 Release NotesDocument13 pagesAppCenter 2.0 Build 1173 Release NotesHatem ElbeziNo ratings yet

- Thermodynamic 01Document5 pagesThermodynamic 01Tapan BadheiNo ratings yet

- Fusion MSRA55 OwnersManualDocument21 pagesFusion MSRA55 OwnersManualHoward 148No ratings yet

- Abstract Classes and Interface in JAVADocument33 pagesAbstract Classes and Interface in JAVATed MosbyNo ratings yet

- High School Essay WritingDocument5 pagesHigh School Essay WritingafabkkkrbNo ratings yet

- Conductors and Insulators Phet WorksheetDocument2 pagesConductors and Insulators Phet WorksheetHeri E. Asysyakiri0% (1)

- Infertility Afp-2023Document8 pagesInfertility Afp-2023residents 2020No ratings yet

- TotpagesDocument10 pagesTotpagesGilmer Calderon QuispeNo ratings yet

- 66994e564d8d5f8772d7fa42 DECA ASM 2024 ICDC Preliminary 1Document6 pages66994e564d8d5f8772d7fa42 DECA ASM 2024 ICDC Preliminary 1op48395No ratings yet

- Spss 1Document122 pagesSpss 1Azka Faradiba Anjani HulayyaNo ratings yet

- Prac - Res. 1 Quarter 2 Module 6Document14 pagesPrac - Res. 1 Quarter 2 Module 6cloydsolis0No ratings yet

- Service: Caddy Kasten/Kombi 1996Document11 pagesService: Caddy Kasten/Kombi 1996Jan Svein HammerNo ratings yet

- Metal-Oxide Varistors (Movs) Radial Leaded-High Surge P SeriesDocument24 pagesMetal-Oxide Varistors (Movs) Radial Leaded-High Surge P SeriesnorbertoNo ratings yet

- NetBrain System Setup Guide Two-Server DeploymentDocument52 pagesNetBrain System Setup Guide Two-Server Deploymentajrob69_187428023100% (1)

- Notice of ConstructionDocument1 pageNotice of ConstructionJc JüsäyänNo ratings yet

- B. Tech. I SVNIT II Semester SyllabusDocument3 pagesB. Tech. I SVNIT II Semester SyllabusDiya DishaNo ratings yet

- SWOT Analysis of China Pakistan Economic Corridor (CPEC) : StrengthsDocument3 pagesSWOT Analysis of China Pakistan Economic Corridor (CPEC) : StrengthsZawar Hussain100% (1)