Bohler - w302 Superior

Bohler - w302 Superior

Uploaded by

Hugo Mario Ariza PalacioCopyright:

Available Formats

Bohler - w302 Superior

Bohler - w302 Superior

Uploaded by

Hugo Mario Ariza PalacioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Bohler - w302 Superior

Bohler - w302 Superior

Uploaded by

Hugo Mario Ariza PalacioCopyright:

Available Formats

BOHLER W302 SUPERIOR

Big Block Premium H13

Hot Work Tool Steel

BOHLER W302 SUPERIOR

Chemical Composition (Average %)

C

Si

Mn

Cr

Mo

0.39

1.10

0.40

5.20

1.40

0.95

0.003

Standard

AISI

DIN

JIS

ISO

H13

1.2344

SKD61

40CrMoV5

Properties

Stress Relieving:

A premium grade H13 hot work tool steel

featuring:

Intended to relieve stresses created by

rough machining. Under protective atmosphere heat through to 1200F (650C),

hold for two hours. Cool slowly in furnace

to 930F (500C), continue cooling in air.

Very good toughness properties meet

ing the requirements of NADCA 207-97,

and the superior quality levels of

NADCA 207-2003

Very good heat checking resistance

Good temper resistance and high

temperature strength

Excellent polishability and texturability

Manufactured for flats greater than 18

in thickness

The term SUPERIOR refers to Bohlers

unique processing method which includes

electro-slag remelting (ESR) to obtain a

steel with superior mechanical properties.

Application

Dies, cores and inserts for the high pressure die casting of aluminum, magnesium

and zinc alloys.

Hot forging, shearing, pressing and extrusion tooling including: dies, die holders,

liners and stems.

The excellent polishability and toughness

properties of W302 Superior also make it

an excellent choice for demanding larger

block plastic molding applications.

Heat Treatment*

Impact Toughness of Bohler W302 Superior

Bohler W302 Superior meets the North American

Die Casting Association (NADCA) specification for

superior H13 die steel and is guaranteed to meet an

average minimum 10 ft-lbs. Charpy V-notch value.

Annealing:

Under protective atmosphere, heat

through to 1560F (850C). Slow, controlled cooling in the furnace at a rate of 20

-40F/hour (10 to 20C/hr) down to 1200F

(650C), continue cooling in air.

Hardness after annealing: max. 229 HB

Hardening (under protective atmosphere):

Initial preheat:

Second preheat:

Third preheat:

Hardening

temperature:

heat through to

1200F (650C)

heat through to

1550F (840C)

heat through to

1740F (950C)

1870-1920F

(1020-1050C)

Temperature

Soak Time

As-Quenched

Hardness

1870F (1020C)

1920F (1050C)

30 min.

15 min.

53 2 HRC

54 2 HRC

Quenching:

Vacuum: Using an inert gas at positive

pressure, quench as rapidly as possible to

avoid unwanted transformation products.

For large, complex tool geometries and

thick cross sections may require an interrupted (i.e.,step) quench procedure. An

interrupted quench at 840-1020F(450550C), equalize so the temperature differential between the surface and

center(Ts and Tc) is less than 200F or a

maximum of 30 minutes after Ts reaches

the interrupt temperature, whichever

occurs first. Continue the quench.

Regardless of quenching media, tool

must be tempered immediately after

reaching 150F (65C).

*Note: Leave adequate machine stock

prior to heat treatment to allow for any

dimensional changes or distortion which

may occur.

BOHLER W302 SUPERIOR

Tempering Curve

Tempering:

Select the tempering temperature from

the graph based on the hardness

requirements. A minimum of two tempers with intermediate cooling to room

temperature is required. For optimum

properties, avoid tempering in the

range of 800-980F (425-525C).

Holding time one hour per inch of wall

thickness or hold at temperature for a

minimum of two hours.

Heat Treatment Sequence

*Immediately begin 1st temper once tool has been quenched to 150F

BOHLER W302 SUPERIOR

CCT Diagram

Chemical composition %:

C

0.43

0.43

Si

0.90

0.90

Mn

0.37

0.37

P

0.018

0.018

S

0.003

0.012

Cr

4.98

4.98

Mo

1.22

1.22

Ni

0.27

0.27

V

1.03

1.03

Austenitizing temperature: 1870F (1020C)

Holding time: 15 minutes

Cooling Curve

a

b

c

d

e

f

0.4

1.03

18

36

90

180

HV10 (Vickers Hardness)

568

590

598

520

410

215

: Duration of cooling from 1470-930F (800-500C) in seconds x 10-2

W

0.05

0.05

BOHLER W302 SUPERIOR

Hot Strength Chart

1 . . . . . . .Tensile strength

Nitriding:

2 . . . . . . .0.2% proof stress

Suitable for bath, gas or plasma/ion nitriding and nitrocarburizing. The surface

treatment temperature must be maintained

at 50-90F (10-30C) below the last tempering temperature of the tool. The case

depth should be limited to a maximum of

.003 inches (0.1 mm) for hot work

applications and the formation of a

white-layer must be avoided.

3 . . . . . . .Reduction of area %

Heat Treated to 175 KSI

Surface Treatment

Repair Welding

Weld repairs may be performed

successfully when proper procedures are

followed.

Preheat and Interpass Temperature:

620-710F (325-375C)

Filler Metal: AISI H13-type

Post Weld Heat Treatment:

Heat Treated to 230 KSI

Hardened Condition: Stress temper at

50-90F (10-30C) below the last tempering temperature.

Annealed Condition: Perform annealing

procedure, as specified in heat treatment

section, prior to hardening.

Electrical Discharge Machining:

When the EDM process is performed on a

tool in the hardened condition, a brittle, resolidified layer will be formed on the die

surface. The surface integrity of the die

should be improved as follows:

1) All cavity surfaces must be stoned/

polished to remove the brittle layer.

2) A stress temper at 50-90F (10-30C)

below the last tempering temperature

of the tool should be performed after

polishing.

BOHLER W302 SUPERIOR

Recommendation for machining

(Annealed condition, average values)

Turning with carbide tipped tools

depth of cut, inches (mm)

.02.04 (0.5-1)

feed, inches/rev, (mm/rev)

.004.012 (.1.3)

US Grade (ISO Grade)

C6, C7 (P10, P20)

cutting speed

indexable carbide inserts

edge life 15 min., fpm (m/min.) 655-1020 (200-310)

brazed carbide tipped tools

edge life 30 min., fpm (m/min.) 490-850 (150-260)

.04-.16 (1-4)

.008-.016 (.2-.4)

C5, C6, C7 (P10, P20, P30)

.16-.31 (4-8)

.012-.024 (.3-.6)

C5 (P30, M20)

>.31 (>8)

.020-.060 (.5-1.5)

C5 (P30, P40)

425-720 (130-220)

330-590 (100-180)

160-390 (50-120)

330-690 (100-210)

280-425 (85-130)

160-295 (50-90)

6 to 8

12

-4

6 to 8

12

-4

6 to 8

12

-4

cutting angles for brazed carbide tipped tools

clearance angle

6 to 8

rake angle

12

angle of inclination

0

Turning with HSS tools

depth of cut, inches (mm)

.02 (.5)

feed, inches/rev, (mm/rev)

.004 (.1)

HSS-grade BOHLER

S700/S10-4-3-10

cutting speed

edge life 60 min., fpm (m/min.) 100-150 (30-45)

rake angle

14

clearance angle

8

angle of inclination

0

.12 (3)

.002 (.5)

70-100 (22-30)

14

8

0

.24 (6)

.04 (1.0)

.40 (10)

.06 (1.5)

60-70 (18-22)

14

8

-4

40-60 (12-18)

14

8

-4

Milling with carbide tipped cutters

feed, inches/tooth, (mm/tooth)

cutting speed, fpm (m/min)

US grade C6 (ISO Grade P25)

US grade C5 (ISO Grade P40)

to .008 (to .2)

.008-.016 (.2 to .4)

330-490 (100-150)

200-300 (60-100)

200-360 (60-110)

130-230 (40-70)

.12-.31 (3-8)

.001-.002 (.02-.05)

C3 (K10)

115-160 (35-50)

115 to 120

5

.31-.80 (8-20)

.002-.005 (.05-.12)

C3 (K10)

115-160 (35-50)

115 to 120

5

Drilling with carbide tipped tools

drill diameter, inches (mm)

feed, inches/rev, (mm/rev)

US Grade (ISO Grade)

cutting speed, fpm (m/min)

top angle

clearance angle

.80-1.6 (20-40)

.005-.007 (.12-.18)

C3 (K10)

115-160 (35-50)

115 to 120

5

>.4 (>10)

> .06 (>1.5)

25-40 (8-16)

14

8

-4

BOHLER W302 SUPERIOR

Physical Properties

Density at

70F (20C)

930F (500C)

1100F (600C)

.282 lbs/in3 (7.8 g/cm3)

.276 lbs/in3 (7.64 g/cm3)

.275 lbs/in3 (7.60 g/cm3)

Specific heat at

70F (20C)

930F (500C)

1100F (600C)

.110 Btu/lbF 460 (J/kg K)

.131 Btu/lbF 550 (J/kg K)

.141 Btu/lbF 590 (J/kg K)

Electric resistivity at

70F (20C)

930F (500C)

1100F (600C)

0.020 Ohm x in2/in (0.52 Ohm mm2/mm)

0.034 Ohm x in2/in (0.86 Ohm mm2/mm)

0.038 Ohm x in2/in (0.96 Ohm mm2/mm)

Modulus of elasticity at

70F (20C)

930F (500C)

1100F (600C)

31.2 x 106psi (215 x 103 N/mm2)

25.5 x 106psi (176 x 103 N/mm2)

23.9 x 106psi (165 x 103 N/mm2)

Thermal expansion between 70F and

in/in F x 10-6 from 70F to: (m/m C x 10-6 from 20C to:)

200F (100C) 400F (200C) 570F (300C)

6.4 (11.5)

6.7 (12.0)

6.8 (12.2)

750F (400C) 930F (500C) 1100F (600C) 1300F (700C)

6.9 (12.5)

7.2 (12.9)

7.2 (13.0)

7.3 (13.2)

Thermal conductivity at 70F and

Btu/ft h F from 70F to : (W/m C from 20C to:)

70F (20C)

200F (100C) 400F (200C)

570F (300C) 750F (400C)

930F (500C) 1100F (600C) 1300F (700C)

Annealed Condition

15.5 (26.8)

15.7 (27.2)

16.2 (28.1)

17.4 (30.1)

17.9 (31.0)

18.2 (31.5)

18.7 (32.3)

19.3 (33.4)

15.6 (27.1)

15.9 (27.5)

16.0 (27.70)

16.3 (28.3)

16.9 (29.3)

17.5 (30.4)

Hardened Condition

14.4 (25.0)

14.7 (25.5)

As regards to applications and processing steps that are not expressly mentioned in this product description/data sheet, the

customer shall in each individual case be required to consult us.

To purchase Bohler and Uddeholm products

please contact:

2595

USAMeadowvale Blvd.

Mississauga,

ONDrive

L5N 7Y3

4902 Tollview

www.bucanada.ca

Rolling Meadows, IL 60008

email:

info@bucanada.ca

www.bucorp.com

email: info@bucorp.com

Sales:

Tel:

(800) 665-8335

Sales:

Fax:

Tel: (905)

(800)812-8658

638-2520

Fax: (905) 812-8659

BD 70 - 09/04/1,500

BOHLER W302 SUPERIOR

Canada

2595 Meadowvale Blvd.

Mississauga, Ont. L5N 7Y3

www.bucanada.ca

email: info@bucanada.ca

The data contained in this brochure shall not be binding and shall, in case of a contract conclusion, not be regarded as

warranted. These data shall merely constitute average values that become binding only if explicitly specified in a contract

concluded with us. The manufacture of our products does not involve the use of substances detrimental to health or to the

ozone layer.

You might also like

- Method Statement For The Protective Coating - Corrosion Protection of Steel Structures GeneralDocument11 pagesMethod Statement For The Protective Coating - Corrosion Protection of Steel Structures GeneralTony Nellicken100% (2)

- TIG Welding Amp Charts PDFDocument2 pagesTIG Welding Amp Charts PDFEnrico959100% (1)

- Rheocasting Structural Components: Martin Hartlieb, Per Jansson, Jean-Claude Tawil, Stéphane BergeronDocument41 pagesRheocasting Structural Components: Martin Hartlieb, Per Jansson, Jean-Claude Tawil, Stéphane BergeronSoria LugoNo ratings yet

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocument17 pagesPreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- Alcoa AP BrochureDocument8 pagesAlcoa AP BrochureGanesh AshokanNo ratings yet

- NADCA-High Temp DieDocument12 pagesNADCA-High Temp DiejalilemadiNo ratings yet

- Eutectic 29029Document2 pagesEutectic 29029Imam SitumeangNo ratings yet

- Systematic Analysis of Induction Coil FailuresDocument3 pagesSystematic Analysis of Induction Coil FailuresGulie Cosmin IonutNo ratings yet

- 7 Pyrotek CrossfeederDocument27 pages7 Pyrotek CrossfeederMuhamad Hafidz RyansyahNo ratings yet

- TriMarkCatalog PDFDocument50 pagesTriMarkCatalog PDFSelvakpm06No ratings yet

- FestoDocument144 pagesFestoDanielNo ratings yet

- Incometer Topometer en 10037930Document20 pagesIncometer Topometer en 10037930Josephi_abbasNo ratings yet

- Semi Solid Metal Fact SheetDocument4 pagesSemi Solid Metal Fact SheetTrung Duong MinhNo ratings yet

- Magnesium Alloys: The American Foundry Society Technical Dept., Schaumburg, IllinioisDocument3 pagesMagnesium Alloys: The American Foundry Society Technical Dept., Schaumburg, IllinioissaranNo ratings yet

- MCM AllDocument7 pagesMCM AllPalanisamy RajaNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- Trivalent Chromates FAQDocument3 pagesTrivalent Chromates FAQfastenersworldNo ratings yet

- SKD61-Forged Hot Work Tool SteelDocument1 pageSKD61-Forged Hot Work Tool SteelAgustine SetiawanNo ratings yet

- Optimization of Shrinkage Porosity in Grinding Media Balls by Casting Design Modification and Simulation Technique-IJRASETDocument12 pagesOptimization of Shrinkage Porosity in Grinding Media Balls by Casting Design Modification and Simulation Technique-IJRASETIJRASETPublicationsNo ratings yet

- Alucast 2014 Final ReportDocument12 pagesAlucast 2014 Final Reporta10000816No ratings yet

- Aluminum Alloys For High TemperatureDocument18 pagesAluminum Alloys For High TemperatureFluf LvpNo ratings yet

- Aluminum A380Document4 pagesAluminum A380syuepiNo ratings yet

- Hot Rolled Steel SheetDocument40 pagesHot Rolled Steel SheetsyaefulNo ratings yet

- Basics of Cold FormingDocument51 pagesBasics of Cold FormingPrakash RNo ratings yet

- Coveral MTS 1584 PDFDocument2 pagesCoveral MTS 1584 PDFArchit Jhunjhunwala100% (2)

- Casting Design RulesDocument44 pagesCasting Design RulesZeel PatelNo ratings yet

- Electroflux - The Success Factor in Electroslag Remelting (Esr)Document18 pagesElectroflux - The Success Factor in Electroslag Remelting (Esr)Pradeep DahiyaNo ratings yet

- Hot Dip Galvanizing of Sheet Metal-SpangleDocument6 pagesHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNo ratings yet

- Mould MonitoringDocument8 pagesMould MonitoringFrederico LopesNo ratings yet

- Nitriding Is A Surface-Hardening Heat Treatment ThatDocument39 pagesNitriding Is A Surface-Hardening Heat Treatment ThatBharatiyulamNo ratings yet

- Worm Gear Boxes PDFDocument60 pagesWorm Gear Boxes PDFNitesh Kumar GuptaNo ratings yet

- Magmahpdc Gating Geometry Optimization: Committed To Casting ExcellenceDocument8 pagesMagmahpdc Gating Geometry Optimization: Committed To Casting ExcellencemaniacraghuNo ratings yet

- Cif Purge Plug Systems en 3Document3 pagesCif Purge Plug Systems en 3abdeljalil elbadrNo ratings yet

- K-Alloy BrochureDocument2 pagesK-Alloy BrochureBill BremanNo ratings yet

- Pm0uk Dmu Evo Series PDF DataDocument32 pagesPm0uk Dmu Evo Series PDF Datamail2jyothishdsNo ratings yet

- Turret Bearing Deflection MonitoringDocument1 pageTurret Bearing Deflection MonitoringVinay RajputNo ratings yet

- Distortion in Heat TreatmentDocument34 pagesDistortion in Heat TreatmentAmit100% (1)

- Alspek H: The Direct Measurement of Hydrogen in Aluminium AlloysDocument4 pagesAlspek H: The Direct Measurement of Hydrogen in Aluminium AlloysAnonymous 5OZXPX9xdNo ratings yet

- Aluminium Insight 2011-02 Lomag Mag RemovalDocument1 pageAluminium Insight 2011-02 Lomag Mag Removalnabeel1981No ratings yet

- U02P01 B.A.A Intro MetalCastingDocument35 pagesU02P01 B.A.A Intro MetalCastingmaria100% (1)

- Powerpoint Presentation On Magnesium SuperplasticityDocument23 pagesPowerpoint Presentation On Magnesium SuperplasticityashvaniNo ratings yet

- Resistivity of Aluminum OxideDocument4 pagesResistivity of Aluminum OxidereaktorenergiNo ratings yet

- FerrousDocument538 pagesFerrousPutoy Itoy100% (1)

- Different Type of Flanges As Per IS:4865,4866,4868,4869:1968, AISI, DIN EtcDocument2 pagesDifferent Type of Flanges As Per IS:4865,4866,4868,4869:1968, AISI, DIN EtcFatima MirNo ratings yet

- OTE Outotec Pallet Cars For Sintering and PelletizDocument4 pagesOTE Outotec Pallet Cars For Sintering and PelletizShukla Suyash100% (1)

- Arcelor Deep Draw MaterialDocument7 pagesArcelor Deep Draw MaterialJayDadrassNo ratings yet

- Int J Metal Casting 2015 Defect ClassificationDocument13 pagesInt J Metal Casting 2015 Defect ClassificationDouglas RodriguesNo ratings yet

- Corrosion Resistance in FastenersDocument26 pagesCorrosion Resistance in FastenersShreyas IyengarNo ratings yet

- حكم المحكمة الدستورية بدستورية جعل الولاية التعليمية على الطفل للحاضنDocument9 pagesحكم المحكمة الدستورية بدستورية جعل الولاية التعليمية على الطفل للحاضنFARHAT BLOGS LlBRARYNo ratings yet

- Sandvik Versatile Tools 2018Document153 pagesSandvik Versatile Tools 2018jaajaNo ratings yet

- Introduction of Linco Baxo Group of Companies Petrochem 2018 EngDocument37 pagesIntroduction of Linco Baxo Group of Companies Petrochem 2018 Engmuhammad abidinNo ratings yet

- DanCut Rev1 en PDocument8 pagesDanCut Rev1 en PDaniel ConwayNo ratings yet

- Achenbach ExtractDocument56 pagesAchenbach ExtractCatanescu Alexandru-LaurentiuNo ratings yet

- Manpro Combined (Casting Welding)Document400 pagesManpro Combined (Casting Welding)dhruv rohillaNo ratings yet

- Effect of Niobium On The As-Cast Microstructure of Hypereutectic High Chromium Cast IronDocument4 pagesEffect of Niobium On The As-Cast Microstructure of Hypereutectic High Chromium Cast IronMatheus BoligonNo ratings yet

- Casting Manufacturing Lab ReportDocument16 pagesCasting Manufacturing Lab ReportNiko KoNo ratings yet

- Chapter - 3 Part 2 - Casting - Processes Types PDFDocument73 pagesChapter - 3 Part 2 - Casting - Processes Types PDFMohammad TahaNo ratings yet

- Continuous Roll Casting of AluminiumDocument4 pagesContinuous Roll Casting of AluminiumLuis HernandezNo ratings yet

- Steel Grades and QualitiesDocument16 pagesSteel Grades and QualitiesArnold TunduliNo ratings yet

- Aisi D2: Cold Work Tool SteelDocument7 pagesAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoNo ratings yet

- Aisi A2: Cold Work Tool SteelDocument21 pagesAisi A2: Cold Work Tool SteelRahul NambiarNo ratings yet

- Tubo Sin Costura, Nps 6, SCH. 40, ASME B36.10MDocument1 pageTubo Sin Costura, Nps 6, SCH. 40, ASME B36.10MHugo Mario Ariza PalacioNo ratings yet

- TRN NMD 0018 00 Rev - 01 - PDFDocument19 pagesTRN NMD 0018 00 Rev - 01 - PDFHugo Mario Ariza PalacioNo ratings yet

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard seals-SNL 515-612 + 22215 K + H 315Document2 pagesSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard seals-SNL 515-612 + 22215 K + H 315Hugo Mario Ariza PalacioNo ratings yet

- Title: Benefit-Cost Analysis of Building Information Modeling (BIM) in A Railway Site Authors: Min Ho, Shin, PH.DDocument11 pagesTitle: Benefit-Cost Analysis of Building Information Modeling (BIM) in A Railway Site Authors: Min Ho, Shin, PH.DHugo Mario Ariza PalacioNo ratings yet

- Basic Concepts of Stairwell PressurizationDocument4 pagesBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNo ratings yet

- Introduction To The Draft ISO 19650 andDocument3 pagesIntroduction To The Draft ISO 19650 andHugo Mario Ariza PalacioNo ratings yet

- Shaft Design and CalculationDocument4 pagesShaft Design and CalculationHugo Mario Ariza PalacioNo ratings yet

- Regconomica - Proyecto Norma Técnica Colombiana 430 04Document1 pageRegconomica - Proyecto Norma Técnica Colombiana 430 04Hugo Mario Ariza PalacioNo ratings yet

- Architecturally Exposed Structural Steel 05125Document16 pagesArchitecturally Exposed Structural Steel 05125Hugo Mario Ariza PalacioNo ratings yet

- CertificateOfCompletion - Solidworks Simulation For Finite Element AnalysisDocument1 pageCertificateOfCompletion - Solidworks Simulation For Finite Element AnalysisHugo Mario Ariza PalacioNo ratings yet

- Weld Stress CalculationsDocument9 pagesWeld Stress CalculationsHugo Mario Ariza PalacioNo ratings yet

- Hose Stream Demands Part-1 PDFDocument4 pagesHose Stream Demands Part-1 PDFHugo Mario Ariza PalacioNo ratings yet

- BlazeMaster Sample Specification - CanadaDocument4 pagesBlazeMaster Sample Specification - CanadaHugo Mario Ariza PalacioNo ratings yet

- Active Listening - EbookDocument1 pageActive Listening - EbookHugo Mario Ariza PalacioNo ratings yet

- FLSmidth - Truck Wagon Loading PDFDocument7 pagesFLSmidth - Truck Wagon Loading PDFHugo Mario Ariza PalacioNo ratings yet

- Report RX87DRN100L4 TF 131332185591905454Document1 pageReport RX87DRN100L4 TF 131332185591905454Hugo Mario Ariza PalacioNo ratings yet

- Calculo Banda TrasnportadoraDocument10 pagesCalculo Banda TrasnportadoraHugo Mario Ariza PalacioNo ratings yet

- Install App and Run It With Trial Mode - Close App - Copy and Replace DLL Crack To Install Dir WWW - Downloadly.IrDocument1 pageInstall App and Run It With Trial Mode - Close App - Copy and Replace DLL Crack To Install Dir WWW - Downloadly.IrHugo Mario Ariza PalacioNo ratings yet

- Welding Class 1Document73 pagesWelding Class 1omkardashetwarNo ratings yet

- Teknovak Presentation PDFDocument22 pagesTeknovak Presentation PDFSinan YıldızNo ratings yet

- Mig ReportDocument14 pagesMig ReportDhana KumaranNo ratings yet

- Authors BookDocument176 pagesAuthors BookOliwiaNo ratings yet

- Welding Types and Positions and DefectsDocument10 pagesWelding Types and Positions and Defectssam_antony2005No ratings yet

- DATA SetDocument5 pagesDATA SetFer MabNo ratings yet

- Amada Thick Turret Forming ToolingDocument20 pagesAmada Thick Turret Forming ToolingAFAB Machinery and Tools LtdNo ratings yet

- Sehati Super Parket Catalog 2021Document18 pagesSehati Super Parket Catalog 2021Merdelin LinNo ratings yet

- Manufacturer's Welding Procedure (WPS) N.: Issued atDocument7 pagesManufacturer's Welding Procedure (WPS) N.: Issued atBelin InversoNo ratings yet

- MMS Unit 3 Hardening of SteelsDocument17 pagesMMS Unit 3 Hardening of SteelsPraveen KolukulaNo ratings yet

- 研究中的案例研究方法Document7 pages研究中的案例研究方法h68d71n2No ratings yet

- 6 Guidelines For Documenting A Successful CNC ProgramDocument1 page6 Guidelines For Documenting A Successful CNC ProgramrlwersalNo ratings yet

- Machining Science: Jigs & FixturesDocument26 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Material Is Either ASTM A653 Gr. Class 1, A1011 HSLAS Gr. 55 Class 1, or A1011 SS Gr. 55Document7 pagesMaterial Is Either ASTM A653 Gr. Class 1, A1011 HSLAS Gr. 55 Class 1, or A1011 SS Gr. 55pbatraNo ratings yet

- Seminar Laser Polishing Abstract-016 CorrectionsDocument2 pagesSeminar Laser Polishing Abstract-016 Correctionsyogesh shindeNo ratings yet

- DWR At1Document1 pageDWR At1ZaidiNo ratings yet

- 039 Katalog KrisbowDocument1 page039 Katalog KrisbowDermawan PurbaNo ratings yet

- PART1Document13 pagesPART1Abegail Villanueva100% (1)

- Dual PhaseDocument3 pagesDual Phaseahmed ezwaiNo ratings yet

- Heat Treatmne TTGMKTDocument105 pagesHeat Treatmne TTGMKTAryan RajNo ratings yet

- Unit 1 - 3D Designing - TinkerCAD - Mayank SinghDocument8 pagesUnit 1 - 3D Designing - TinkerCAD - Mayank Singhsamah mahdyNo ratings yet

- 20160323093435-52CrMoV4 (51CrMoV4) PDFDocument1 page20160323093435-52CrMoV4 (51CrMoV4) PDFMartin HristovNo ratings yet

- Application Form For CSL - YCMDocument3 pagesApplication Form For CSL - YCMLâm VõNo ratings yet

- Mabar ReadingDocument2 pagesMabar Readingkopi susuNo ratings yet

- Supratec MBR-600Document4 pagesSupratec MBR-600unconformistNo ratings yet

- Research Work Sy Msc. CS Project Format 2024-25Document7 pagesResearch Work Sy Msc. CS Project Format 2024-25dereakshay212No ratings yet

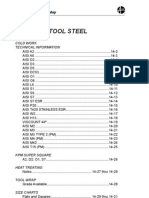

- 014 ToolSteelDocument36 pages014 ToolSteelramptechNo ratings yet

- Grinding With Tube MillDocument43 pagesGrinding With Tube MillrecaiNo ratings yet