Full Paper Aionescu-1

Full Paper Aionescu-1

Uploaded by

KurniawatiCopyright:

Available Formats

Full Paper Aionescu-1

Full Paper Aionescu-1

Uploaded by

KurniawatiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Full Paper Aionescu-1

Full Paper Aionescu-1

Uploaded by

KurniawatiCopyright:

Available Formats

The Annals of the University Dunarea de Jos of Galati

Fascicle VI Food Technology, New Series Year III (XXXIII)

Paper presented at the International Symposium Euro - aliment 2009, 9th 10th of October 2009, Galati ROMANIA

CHEMICAL AND FUNCTIONAL CHARACTERIZATION OF CHICKPEA

PROTEIN DERIVATES

IONESCU AURELIA1, APRODU IULIANA1, DARAB AURA1, GURU GABRIELA2,

BACIU CRISTINA1, NICHITA ANDREI1

1

University Dunrea de Jos Galai, Faculty of Food Science and Engineering

2

University Dunrea de Jos Galai, Faculty of Medicine and Pharmacy

aurelia.ionescu@ugal.ro

Received 4 June 2009

Revised 12 August 2009

Whole flour, defatted flour and freeze dried protein concentrate were obtained from chickpea. Protein

solubility, water and oil absorption capacity, emulsifying capacity and emulsion stability, foaming capacity

and foam stability were used to evaluate the chickpea protein derivates from a chemical and functional

standpoint. The chickpea protein concentrate, obtained by alkaline solubilization (pH 10.5) followed by

isoelectric precipitation at pH= 4.5 and freeze drying, displayed the highest protein content and the best

functional properties. The profiles of the solubility curves corresponding to the chickpea protein

concentrate indicate a minimum solubility at pH ranging from 4 to 5 (i.e., protein solubility of 12.5% in the

case of chickpea protein concentrate) and two domains of maximum solubility at pH 1.8 and 11.8 (i.e.,

protein solubility of 53.2% and 85.7%, respectively, in the case of chickpea protein concentrate). The

profiles of protein solubility curves are similar with the profiles of the emulsifying capacity vs. pH curves.

The foaming capacity increased with the increase of chickpea protein concentration. After 120 hours of

storage the foam stability was higher than 90%. The experimental data show that the chickpea protein

concentrate can be successfully used as food ingredient due to its chemical composition and functional

properties.

Keywords: chickpea, whole flour, defatted flour, protein concentrate, functional properties

1. Introduction

Chickpea (Cicer arientum L.) is considered the 5th valuable legume in terms of worldwide economical

standpoint. Chickpea is planted in Southern and Western areas of Asia and Mediterrana. India is the

principal, high quality chickpea provider, realizing 75% of the world gross production (Grelda et al.,

1997). Chickpea is considered a good source of proteins and carbohydrates. Like other legumes,

chickpeas globulins and albumins represent the two major fractions found in beans. In legumes, the

globulins, represented mainly by legumin and vicinin, reach up to 60-80% out of the extractable proteins

of the beans whereas the albumin fraction, less abundant, represents up to 15-25% out of the beans

proteins (Singh et al., 2008). Albumins play an important role in chickpea beans since they contain most

of the enzymes and proteins with metabolic significance. In addition, they display a higher nutritive value

compared to the globulins due to their high content in lysine and sulfur aminoacids.

The increased demands for food products and functional, pharmaceutical and cosmetic ingredients,

obtained from vegetal sources, determined the interest increment for the production of purified protein

derivates of vegetal origin, such as concentrates, isolates and hydrolysates (Pawar and Ingle, 1988;

Tharanathan and Mahadevamma, 2003). Numerous researchers have been preoccupied with the obtaining

of protein concentrates and isolates from vegetal, animal or microbial sources as well as with the

characterization from these products functional standpoint (Aluko and Yada, 1993; Burgess and Kelly,

1979; Sathe and Salunkhe, 1981; Sathe et al., 1982a; Sathe et al., 1982b; Sanchez-Vioque et al., 1999).

Chemical and functional characterization of chickpea protein derivates 17

In order to obtain food-grade protein isolates, the high molecular weight oligomeric storage proteins from

seeds are generally separated by alkaline solubilization followed by isoelectric precipitation (Derbyshire

et al., 1976; Sanchez-Vioque et al., 1999).

The chickpea proteins are better appreciated compared to the proteins from pigmelion peas, blackgram

and greengram (Kaur and Singh, 2007) due to their high biological value, high biodisponibility, wellbalanced aminoacids content and low content in antinutritional factors (Friedmen et al., 1996 and

Santiago et al., 2001). The low fat content combined with the special characteristics of chickpea beans

justify the nowadays concerns for chickpea protein isolates and concentrates obtaining and their

functional characterization. Sanchez-Vioque et al. (1999) investigated the protein recovery yield in

different experimental conditions, functional properties and the composition of chickpea protein isolates

in direct relations with the possibility of using these isolates in food industry. According to their findings,

the protein isolates characterized by a high absorption capacity of water and oil are adequate for obtaining

cheese, bakery and meat products. On the other hand, the isolates with a good emulsifying capacity can be

successfully used for obtaining products such as frankfurter and cream-like products. Very few scientific

data regarding the lyophilized chickpea protein concentrate obtaining and characterization, from a

chemical and functional standpoint are reported. Therefore, the objectives of the present study were to

obtain whole and defatted chickpea flours and freeze dried protein concentrate and to characterize these

products from the chemical and functional properties standpoint. Concerning the functional properties of

the chickpea proteins, the water and oil absorption capacity, protein solubility profile and emulsifying

capacity for different pH values, emulsions stability, foaming capacity and foam stability were

investigated.

2. Materials and methods

2.1. Materials

The chickpea beans, purchased from a local store specialized in selling vegetable products were used to

obtain the protein derivates: whole flour, defatted flour and lyophilized concentrate.

Analytically pure reagents were used for the chemical tests and treatments. For testing the emulsifying

capacity, the commercial sunflower oil was used.

2.2. Obtaining the whole chickpea flour

After drying, the chickpea beans were milled using a WZ-2 (Sadkiewicz, Polonia) cereal mill. With the

aim to remove the impurities and to obtain an uniform product, the whole flour was passed through a 312

mesh sieve.

2.3. Obtaining the defatted chickpea flour

The defatted chickpea flour was obtained after the removal of fats by extraction with ethanol, at 22C.

The whole flour-ethanol blend (1:5 w/v) was periodically mixed, during the extraction process. The total

removal of fats was achieved after four extraction cycles of four hours each. In order to remove all

ethanol, the chickpea flour was dried at 43C, for 36 hours, in hot air flow.

2.4. Obtaining the lyophilized chickpea protein concentrate

The lyophilized protein concentrate was obtained from defatted chickpea flour. Because the chickpea

proteins display a higher solubility for pH > 9.0, the pH of the defatted flour dispersion prepared in water

was adjusted, by using 2N NaOH, to 10.5. Fiber and starch fractions were removed from the alkaline

18

Ionescu A., Aprodu I., Darab A., Guru G., Baciu C., Nichita A.

dispersion by centrifugation at 3000 rpm, for 20 min (temperature of 4C). Solubilized proteins were

collected as supernatant which subsequently was used for the protein fraction recovery by isoelectric

precipitation (pH 4.5). For pH adjustment, a 2N HCl solution was used. After precipitation, the proteins

were separated by centrifugation at 3000 rpm, for 20 min. (temperature of 4C). The precipitate was

washed with distilled water (pH 7.0) for three times, to achieve a complete removal of any existing

contaminant. The lyophilization of the resulted protein concentrate was performed with Alpha 1-4 LD

Plus freezer. The samples were first frozen for 42 hours at 48C using a Platinum 500 ultra-freezer. The

lyophilization conditions were: heating of the pump for 20 min; main drying for 2 hours at 1 mbar and 20C followed by a final drying for 20 min.

2.5. Proximate chemical composition

Protein, fat and ash contents were determined using the A.O.A.C. methods (1990). The contents in crude

fibers and carbohydrates were estimated by subtracting the sum of ash, fat and protein from the dry

weight of the samples. pH values were recorded with a pH-meter (model Hanna) on a 10 % aqueous

protein dispersion (w/v) at 22 1C.

2.6. Determination of the chickpea protein derivates functional properties

Proteins solubility. Proteins solubility of the chickpea protein derivates was studied at pH values ranging

from 1.8 to 11.8. Initially, suspensions with 5% protein derivate in 0.1 N NaOH, were obtained. For a

better solubilization, the suspensions were stirred for 2 hours, at room temperature, using a magnetic

stirrer. Aliquot parts from the suspension were sampled for the determination of protein solubility at

different pH values achieved after the adjustment with a 2M HCl solution and 1 hour agitation. Before

mineralization, the samples were centrifuged at 3000 rpm, for 30 min. The mineralization has been

performed into a Trade Raypa type installation. From the resulted supernatant, the total nitrogen was

determined according to the semimicro Kjeldahl method. Protein solubility curves were constructed by

using the average values obtained for each considered pH value.

Water and oil absorption. Water absorption capacity was determined by centrifugation, according to the

method described by Sathe et al. (1982a) which was slightly modified. The samples (3 g of protein

derivates) were first dried for 24 hours at 104C and afterwards placed into pre-weighed centrifuge tubes

and dispersed into 25 ml of distilled water. The obtained dispersions were occasionally stirred. After 30

min of storage at 22 1C, the samples were centrifuged for 30 min at 3500 rpm. The supernatant was

removed and the moisture excess was released by drying for 25 min at 50C. The tubes containing the

samples were reweighed. The water absorption capacity was determined for a genuine pH of the protein

suspension and expressed as ml absorbed water/g of protein derivate.

Oil absorption was determined according to the method of Lin et al. (1974). The protein derivate (0.5 g)

was homogenized with 6 ml of sunflower oil into a pre-weighed centrifuge tube. Aiming for a better

proteins dispersion in oil, the content of the tubes was stirred for 1 min, afterwards, the samples were

centrifuged at 3000 rpm, for 25 min, 30 min later the oil separated being removed. Oil absorption capacity

was expressed as ml oil/g of protein derivate.

Emulsifying capacity. In order to study the effect of pH on the emulsifying capacity of the chickpea

protein derivates, 1% (w/v) protein dispersions were obtained. Subsequently, the protein dispersions were

stirred with a magnetic stirrer and the pH adjustments, from 1.8 to 11.8, were made by adding 2M NaOH

or 2M HCl solutions.

For the determination of emulsifying capacity, 50 g of protein suspension were transferred into a blender

vat and the sunflower oil was added, under continuous mixing until the emulsion was destroyed (Beuchat,

1977). Measurements were performed at 22 1C and the emulsifying capacity was expressed as ml of

oil used for the emulsification of 1 g of chickpea protein derivate.

Chemical and functional characterization of chickpea protein derivates 19

Emulsions preparation. The oil/water emulsions, stabilized with chickpea proteins (whole flour or protein

concentrate), were prepared from 50 g of 1% aqueous protein suspension and 30 ml of sunflower oil by

vigorous stirring for 3 min using a Braun mixer at 22C. The temperature control was made by immersing

the samples in a water-ice mixture bath. Each emulsion obtained was immediately assessed from the

physical appearance and texture standpoint.

Emulsion stability during centrifugation. Stability of emulsion was evaluated by measuring the quantity

of released water from the emulsion, after centrifugation, according to the method described by Johnson

and Brekke (1983). The emulsion was centrifuged at 3000 rpm, for 10 min. Emulsion stability, expressed

in terms of percents of water released from emulsion, after centrifugation, was calculated using the

following formula:

% Released water = B/A100,

where A is the total volume of the emulsion (ml) and B is the volume of aqueous phase released from

emulsion, after centrifugation (ml)

Foaming capacity and foam stability. Foaming capacity and foam stability were determined according to

the method described by Lin et al. (1974), slightly modified. 100 ml of 1% (w/v) aqueous chickpea

protein dispersion was homogenized using a Braun blender for 3 min. Dispersion volume was recorded

before and after foaming.

Foaming capacity was expressed as percentage of volume increase after stirring. The foam stability was

recorded at 30, 60, 90, 120, and 150 min storage at room temperature.

2.7. Statistical analysis

Sigma Plot 2001 Software was used for the statistical analysis of the experimental data. Each experiment

was performed in triplicate and the results were expressed as average values. The standard deviations

were smaller than 5%.

3. Results and discussions

3.1. Approximate chemical composition

The chemical composition of the chickpea protein derivates: whole and defatted flour, and lyophilized

concentrate is depicted in Table 1. The protein content of whole flour was 23.08 1.23%, which

corresponds to Kabuli biotype chickpea, with 22.8 24.9% protein content.

By fat removal from the chickpea flour, the proteins content slightly increased up to 23.53 1.31%

whereas fat content decreased from 6.65 0.28% to 0.66 0.02%. The fat content was lower than the one

reported by Sanchez-Vioque et al. (1999), respectively 1.5%. The remaining lipids, mainly nonpolar, play

an important role in the product aromas and they interact with proteins (Kikugawa et al., 1981; SnchezVioque et al., 1998; Rackis et al., 1979).

The total carbohydrates, mainly represented by starch and fibers, are the major constituents of the

chickpea flour. The recorded level of the total carbohydrates was 57.88% for whole flour, and 62.17% for

defatted flour. These findings are in agreement with the carbohydrates levels reported by Kaur and Singh

(2007) for the Kabuli type chickpea, respectively 60.2 2%. The total starch content was 42.5 1.96%,

for the defatted flour. According to Meares et al. (2004), for the chickpea Desi and Kabuli type, amylose

represents 26.1 and 26.4%, respectively, out of the total content of starch which could represent 45.2 and

42.1%, respectively.

Ash content, represented 3.21 0.11% of the whole chickpea flour, was higher than the levels of

2.722.91%, reported by Sanchez-Vioque et al. (1999), and than the levels of 2.712.91%, reported by

20

Ionescu A., Aprodu I., Darab A., Guru G., Baciu C., Nichita A.

Kaur and Singh (2007). For the defatted flour, the ash content was slightly higher than that of whole flour,

respectively 3.53 0.15%.

Lyophilized protein concentrate was characterized by a protein content of 81.54 3.87%, and low

contents in fats, respectively 1.25 0.04%, and in ash, represented by 2.85 0.09%. The ash content was

superior to the content of 0.71%, reported by Sathe et al. (1982b) for the lyophilized lupine protein

concentrate. By refinement, the total carbohydrates level was substantially diminished to 10.33%, level

which is characteristic to the protein concentrates with similar content in proteins (higher than 75%).

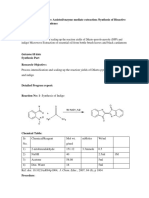

Table 1. Chemical composition of chickpea flours and lyophilized protein concentrate

Whole flour

Defatted flour

Protein concentrate

Moisture, g%

9.18 0.38

10.11 0.43

4.03 0.15

Total proteins, g%

23.08 1.23

23.53 1.31

81.54 3.87

Fats, g%

6.65 0.2 8

0.66 0.2

1.25 0.04

Ash, g%

3.21 0.11

3.53 0.15

2.85 0.09

Carbohydrates, g%

57.88

62.17

10.33

3.2. Proteins solubility

Proteins solubility at different pH values represents a performance indicator of protein flours,

concentrates and isolates when used in different food systems, and gives indications about protein

denaturation degree during chemical and thermal treatments Horax et al. (2004). The proteins solubility

profiles, corresponding to the chickpea flour and protein concentrate, presented in Figure 1, indicate a

minimum of solubility for pH values of 4.0 to 5.0 and two zones of maximum solubility for the extreme

pH values. According to Vani and Zayas (1995), the isoelectric pH of most of vegetal origin proteins

corresponds to values between 4.0 and 5.0. Therefore, the lack of electrical charge for pH = 4.5,

influenced negatively the water binding and the solubility of proteins. Under these conditions, the whole

chickpea flour displayed a protein solubility of 25.84% and the chickpea protein solubility was 12.5%.

For extreme pH values, the net electrical charges are high, and allow rejection forces between the protein

chains and the protein solubility increase. In case of pH = 11.8, the protein solubility was 91.25%, for the

whole flour, and 85.7%, for the protein concentrate, while in the case of pH = 1.8, the proteins solubility

was 58.9%, for the whole flour, and 53.2%, for the protein concentrate. Kinsella (1979), Hermansson

(1979) and Lillford (1983) reported that the reduction in solubility, at very low pH values, is due to the

protein denaturation and insolubilization processes.

The profiles of solubility curves obtained based on our experimental data are in agreement with other

findings regarding soy (Achouri et al., 1998), lentil (Bora, 2002), chickpea (Sanchez-Viogue et al., 1999;

Kaur and Singh, 2007) and rapeseed (Goncalves et al., 1997). The decrease of protein solubility in the

protein concentrate compared to the chickpea flour is the result of protein denaturation during fat

removal, chemical treatments applied for protein purification, and during the lyophilization process.

3.3. Functional properties

3.3.1. Water absorption capacity

Whole flour and protein concentrate from chickpea showed a water absorption capacity of 1265.83 ml

H2O/100 g and 1767.25 ml H2O/100 g product, respectively. Water binding properties of proteins are

determined by their degree of interaction with water.

Water retention capacity of proteins depends on some parameters such as: particle size, steric factors,

conformational characteristics, hydrophilic/hydrophobic balance of aminoacids and presence of lipids,

Chemical and functional characterization of chickpea protein derivates 21

sugars and tannins associated with proteins (Han and Khan, 1990), in greater quantities in flours and

concentrates compared to protein isolates.

Protein solubility,%

100

Defatted flour

80

Protein concentrate

60

40

20

0

1

10

11

12

pH

Figure 1. The solubility profiles for chickpea whole flour and lyophilized protein concentrate

Carbohydrates and other components present in different flours or various concentrates and isolated from

vegetable protein negatively influence the water absorption properties (Kilara et al., 1972; Kinsella, 1979,

Tjahjadi et al., 1988).

The obtained chickpea protein concentrate presented a more reduced water absorption capacity compared

to the isolates analyzed by Snchez-Vioque et al. (1999) (water absorption capacity of 343.7 and 199.5%,

depending on the isolation technique used), but similar to the value reported by Sathe, et al. (1982) for the

chickpea protein concentrate (1.84 ml H2O / g).

These differences are explained by the higher protein content of protein isolates and also can be

accounted for distortions during drying by lyophilization. In addition, Summer et al. (1981) reported

similar water absorption capacity (205%) for the lyophilized chickpea protein concentrate.

Concentrates and protein isolates from chickpea, compared with flour, have a higher capacity to swell,

distort and separate, that allows additional exposure of binding sites of water and increase water

absorption.

3.3.2. Oil absorption capacity

At industrial level, oil absorption capacity is very important in the case of mayonnaise manufacture

(Escamilla-Silva et al., 2003), due to its influence upon the emulsifying capacity.

Whole chickpea flour examined by us, had an oil absorption capacity of 0.72 ml oil / g flour (313 ml

12.2 ml ulei/100 g protein) versus 1.0 ml oil / g flour (426 ml 16.1 ml ulei/100 g protein) for whole

chickpea flour, values lower than those reported by Kaur (2007) (1.05-1.25 g oil /g). These differences

arise from the oil type used (corn oil instead of sunflower oil) and the centrifugation conditions.

Fat removal caused the increase of oil absorption capacity, when flours are used as extension agents in

salamis, and meat substitutes as well as in the bakery production.

Oil absorption capacity varied with the type of protein derivate (Figure 2.), protein solubility and the

degree of protein distortion, being smaller in the case of the protein concentrate (205.1 ml 8.23 ml

oil/100 g protein). The obtained results are comparable with those reported by Kinsella (1979) indicating

significant variation due to the year of cultivation of chickpea (1.59-2.58 ml/g) and with the values

22

Ionescu A., Aprodu I., Darab A., Guru G., Baciu C., Nichita A.

Oil absorption capacity,

g oil/100 g proteins

reported by Paredes-Lopez et al. (1991), for chickpea isolate (1.59-2.58 ml/g) and Sefa-Dedeh

Yiadom-Farkye (1988), for the cowpea isolate (2.0-2.22 ml oil/g).

and

450

400

350

300

250

200

150

100

50

0

Whole flour

Defatted flour

Protein

concentrate

Figure 2. Oil absorption capacity of chickpea flours and protein concentrate

Emulsifying capacity, ml oil/g

3.3.3. Emulsifying capacity -The effect of pH on the emulsifying properties

Emulsions play an important role in the manufacture of food products such as ice cream, mayonnaise,

dressings, emulsified sausages and pastry products. Emulsion, as a heterogeneous structure, consists

mainly of two immiscible phases; the fat phase is, most of the cases, dispersed in the continuous phase.

This structure has a low stability, which can be improved by adding surface active agents - named

emulsifiers, as is the case of chickpea protein derivates. The emulsifying capacity and the emulsion

stability are indicators used to evaluate the emulsion stabilising properties of the vegetable protein

derivates (Han and Khan, 1990; Snchez-Vioque, et al., 1999).

The ability of proteins to form stable emulsions depends on the size, charge, hydrophobic surface and

flexibility of protein molecules (Turgeon et al., 1992). These properties of proteins are affected by

environmental factors such as pH and ionic strength.

Emulsifying capacity of chickpea flour was measured at different pH values of the protein suspension.

Relationship between emulsifying capacity and pH, for each type of protein derivate, is shown in Figure

3.

600

Defatted flour

500

Protein concentrate

400

300

200

100

0

1

10

11

12

pH

Figure 3. The effect of pH value on emulsifying capacity of chickpea whole flour and protein concentrate

Chemical and functional characterization of chickpea protein derivates 23

The emulsifying capacity of chickpea protein concentrate was much higher than that of defatted flour.

Flours and protein concentrates capacity to emulsify oil into the form of fine particles in a protein

suspension, is assigned to soluble proteins. Soluble proteins have surface properties due to their

amphiphilic nature and tendency to form protein films at oil-water interface. In the case of 1% protein

suspension, the protein adsorption at oil-water interface is achieved by controlled diffusion, where the

protein is oriented with lipophilic residues to the oil phase and the hydrophilic aqueous phase.

The emulsifying capacity of proteins depends on the hydrophilic-hydrophobic balance (Chi-Fui et al,

1997), which is affected by the pH value. The maximum levels of emulsifying capacity are recorded at

extreme pH values (EC of 152.67 ml oil/g at pH 2.56, and EC of 550 ml oil/g at pH 11.8). Lower

emulsifying properties were found for the pHi (4.0 to 5.0) of chickpea proteins. The lowest values were

recorded at pH 4.5 (23.3 ml oil/g whole flour and 78 ml oil/g for protein concentrate). At this pH value,

the net electrical charge of proteins was zero and the lowest solubility corresponds to pHi of chickpea

proteins and of vegetable proteins in general. Zhang et al., (2007) reported that at the pHi, the amount of

proteins adsorbed at the oil - water interface is lower and the oil particle size is larger. Creenwedge et al.,

(1974), and Hung and Zayas (1991) found similar emulsifying capacity vs. pH and protein solubility vs.

pH variations.

Our results regarding the dependence of the emulsifying capacity on the pH of protein suspension are

consistent with the results of other researchers for different vegetable proteins (Mwarsanu et al., 1999;

Lawal and Adebowal, 2006).

3.3.4. Foaming capacity and foam stability

Foaming capacity and foam stability are used as indicators of foaming properties of flours, concentrates,

and protein isolates (Mwasaru et al., 1999). Proteins foam when agitated, due to their surface properties.

Whole chickpea flour led to relatively small volume increment and low density foams were formed with

relatively high stability. Foaming capacity of whole flour depends on the concentration of aqueous

suspension. We noted an increase of the foam volume of 27% in the case of 1% protein suspension and of

50% in the case of 5% protein suspension, while a decrease of the foam volume was noticed in the case of

7 and 10% suspensions (Figure 4a.). A similar trend was observed for proteins derived from beans (Sathe

and Salunkhe, 1981; Adebowale and Lawal, 2003).

Defatting led to an improvement of surface properties of chickpea protein and to the foam volume

increase for concentrations ranging from 5% to 60% whole chickpea flour. By increasing the whole flour

concentration, denser and more stable foams are obtained (Figure 4b.). Foam stability of the chickpea

flour was assessed based on the foam volume decrease in time. Foam stability is important because the

choice of suitable foaming agents depends on their ability to maintain the foam for as long time as

possible (Lin et al., 1974).

The whole chickpea flour presented a good stability of the foam (> 90%) after 90 min of storage at room

temperature for samples with a concentration of 5%. According to Adebowale and Lawal (2003),

increased concentrations of chickpea flour protein brings about protein protein interaction improvement,

as a consequence, easing the forming of a multilayered cohesive protein film, at the air/water interface.

Protein film formation provides resistance to coalescence of air bubbles. Also, by increasing the

concentration of chickpea flour ensures the formation of a thicker film, preventing the movement of

proteins away from the film.

Stability of the foam is ensured by the ability of the foam film formed around the air bubbles to remain

intact without leakage, therefore, stable foams can be formed only by agents with a high surface activity

24

Ionescu A., Aprodu I., Darab A., Guru G., Baciu C., Nichita A.

(Cherry and McWatters, 1981). The good stability of the foam resulted from chickpea whole flour

suggests that the globular chickpea proteins have good surface properties.

55

95

Foam stability, %

Foaming capacity, %

30 min

60 min

90 min

100

50

45

40

35

30

90

85

80

75

25

20

70

0

10

Chickpea flour concentration, %

(a)

10

Flour concentration, %

(b)

Figure 4. The influence of defatted flour concentration on foaming capacity (a) and foam stability (b)

65

100

3 min

60

98

5 min

Foam stability, %

Foaming capacity, %

The foaming capacity of 1% (w/v) whole chickpea flour aqueous suspension was lower than that

determined for the protein concentrate, respectively 40%, value that falls within 30.4 to 44.3%, indicated

by Kaur (2007) for the chickpea protein concentrate. For various vegetable protein concentrates, different

values were reported e.g.: soy protein isolate is characterized by a Foaming capacity of 235% (Lin et al,

1974), bean protein concentrates 36 and 58% (Sathe et al.1982; Adebowale and Lawal, 2003), lupine seed

protein 32% (Sathe et al., 1982b) and peas 80% (Akintayo et al., 1999).

The foaming capacity of lyophilized chickpea protein concentrate depended on the concentration of

protein concentrate suspension (Figure 5a). Graham and Phillips (1976) linked the good foaming capacity

on the protein molecules flexibility which can reduce the surface tension; the globular proteins are

relatively difficult to distort on the surface and have a reduced foaming capacity. Most vegetable proteins

are globular proteins with low foaming properties (Sathe et al., 1982).

The foam stability of chickpea concentrate (1%) depended on the time of shaking, being higher in the

case of the samples shaken for 5 min. (Figure 5b). Chickpea protein concentrate showed a relatively high

stability at 22C after 2.5 hours of storage, similar to that reported for chickpea isolate (> 85%), which

suggests that chickpea proteins, soluble in the continuous phase, displayed a higher surface activity.

55

50

45

40

96

94

92

90

88

35

30

86

0

(a)

Chickpea protein concentrate level, %

10

(b)

30 min

60 min

120 min

150 min

Time

Figure 5. Influence of concentration of chickpea protein concentrate dispersion on the foaming capacity (a).

Influence of the shaking time on the foam stability (b)

Chemical and functional characterization of chickpea protein derivates 25

4. Conclusions

Our results concerning the chickpea flours and lyophilized protein concentrate characterization show that

these protein derivates can be successfully used as food ingredients based on their technological

properties. Chickpea flours and protein concentrate displayed good water and oil absorption capacities,

protein solubility and emulsifying capacity. These functional properties are highly dependent on the pH

values. The lowest protein solubility and emulsifying capacity was observed at pH 4.5 which is the

isoelectric pH of chickpea albumins and globulins. Chickpea proteins do not have good foaming

properties, but lead to high stable foams.

References

AOAC, 1990. Official methods of analysis (15th Ed.). Washington, DC:Association of Official Analytical Chemists.

Achouri, A., Zhang, W. and Shying, X. U., 1998. Enzymatic hydrolysis of soy protein isolate and effect of

succinylation on functional properties of resulting protein hydrolysates. Food Research International, 31, 617623.

Adebowale, K.O. and Lawal, O.S., 2003. Foaming, gelation and electrophoretic characteristics of mucuna bean

(Mucuna pruriens) protein concentrates. Food Chemistry, 83, 237 - 246.

Akintayo, E.T., Oshodi, A.A. and Esuoso, K.O., 1999. Effects of NaCl, ionic strength and pH on the foaming and

gelation of pigeon pea (Cajanus cajan) protein concentrates. Food Chemistry, 66, 51 - 56.

Aluko, R.E. and Yada, R.Y., 1993. Relationship of hydrophobicity and solubility with some functional properties of

cowpea (Vigna unguiculata) protein isolate. Journal of the Science of Food and Agriculture, 62, 331-335.

Beuchat, L.R., 1977. Functional and electrophoretic characteristics of succinylated peanut flour protein. Journal of

Agricultural and Food Chemistry, 25, 258261.

Bora, P.S., 2002. Functional properties of native and succinylated lentil (Lens culinaris) globulins. Food Chemistry,

77, 176 - 176.

Burgess, K.J. and Kelly, J., 1979. Technical note: selected functional properties of a whey protein isolate. Journal of

Food Technology, 14, 325.

Cherry, J.P. and McWatters, K.H., 1981. Whippability and aeration in protein functionality in foods. In: Cherry,

J.P., Editor, ACS Symp. Ser., 147, American Chemical Society, Washington, DC, 149.

Chi - Fai, C., Cheung, P.C. and Wong, Z., 1997. Functional properties of protein isolates from three Chinese

indigenous legume seeds. Journal of the Science of Food and Agriculture, 45, 2500 - 2503.

Creenwedge D., Dill, C.W., Tybor, P.T. and Landmann, W.A., 1974. A comparison of the emulsifying capacity of

some protein concentrates. Journal of Food Science, 39, 175 - 179.

Derbyshire, S., Wright, D. J. and Boulter, D., 1976. Legumin and vicilin, storage proteins of legume seeds.

Phytochemistry, 15, 3-24.

Escamilla-Silva, E. M., Guzman-Maldonado, S.H., Cano-Medinal, A. and Gonzalez-Alatorre, G., 2003. Simplified

process for the production of sesame protein concentrate. Differential scanning calorimetry and nutritional,

physicochemical and functional properties. Journal of the Science of Food and Agriculture, 83, 972 - 979.

Friedman, M., 1996. Nutritional value of proteins from different food sources. A review. Journal of Agricultural

and Food Chemistry, 44, 6 - 29.

Goncalves, N., Vioque, J., Clemente, A., Sanchez-Vioque, R. Bautista, J. and Millan, F., 1997. Obtencion y

caracterizacion de aislados proteicos de colza. Grasas y aceites, 48, 282-289.

Graham, D.E. and Phillips, M.C., 1976. The conformation of proteins at the air-water interface and their role in

stabilizing foams. In: R.J. Akers, Editor, Foams, Academic Press, N.Y., 237 - 255.

Grelda, A.Y.F., Moreno-Valencia, J.G., Falcon-Villa Ma del Refugio and Barron-Hoyos, J. M., 1997. Isolation and

partial characterization of starches from dry beans (Phaseolus vulgaris) and chickpeas (Cicer arietinum) grown

in Sonora, Mexico. Starch, 49, 341-345.

26

Ionescu A., Aprodu I., Darab A., Guru G., Baciu C., Nichita A.

Han, J. and Khan, K., 1990. Physicochemical studies of pin-milled and air-classified dry edible bean fractions,

Cereal Chemistry, 67(4), 384 - 390.

Hermansson, A.M., 1979. Methods of studying functional characteristics of vegetable proteins. Journal of American

Oil Chemists Society, 56, 272 - 279.

Horax, R., Hettiarachchy, N.S., Chen, P. and Jalaluddin, M, 2004. Functional properties of isolate protein from

cowpea (Vigna unguiculata Walp). Journal of Food Science, 69, 114-118.

Hung; S.C. and Zayas J.F., 1991. Emulsifying capacity and emulsion stability of milk proteins and corn germ

proteins flour. Journal of Food Science, 56, 1216 - 1218.

Johnson, E.A. and Brekke, J., 1983. Functional properties of acylated pea protein isolates. Journal of Food Science,

48, 722 - 725.

Kaur, M. and Singh, N., 2007. Characterization of protein isolates from different Indian chickpea (Cicer arietinum

L.) cultivars. Food Chemistry, 102, 366 - 374.

Kikugawa, K., Ido, Y. and Mikami, A, 1981. Studies on peroxidized lipids. VI. Fluorescents products derived from

the reaction of primary amines, malonaldehyde and monofunctional aldehydes. Journal of American Oil

Chemists Society, 61, 1574 - 581.

Kilara, A., Humbert, E.S. and Sosulski, F.W., 1972. Nitrogen extractability and moisture absorption characteristics

of sunflower seed products. Journal of Food Science, 37, 771 - 773.

Kinsella, J. E. (1979). Functional properties of soy proteins. Journal of the American Oil Chemists' Society, 56, 940

- 958.

Lawal, O.S. and Adebowale, K.O., 2006. The acylated protein derivates of Canavalia ensiformis (Jack Beans): A

study of functional Characteristics, LWT, 39, 918 - 929.

Lillford, P.J, 1983. Extraction processes and their effect on protein functionality. Plantarum Qualitas Plant Food for

Human Nutrition, 32, 401 - 409.

Lin, M. J. Y., Humbert, E. S. and Sosulki, F. W., 1974. Certain functional properties of sunflower meal products.

Journal of Food Science, 39, 368.

Meares, C. A., Bogracheva, T. Y., Hill, S. E. and Hedley, C. L., 2004). Development and testing of methods to

screen chickpea flour for starch characteristics. Starch/Strke, 56, 215-224.

Mwasaru, M.A., Muhammad, K., Bakar, J. and Cheman, Y.B., 1999. Effect of isolation technique and conditions on

the extractability, physicochemical and functional properties of pigeon pea (Cajanus cajan) and cowpea (Vigna

unguiculata) protein isolates II. Functional properties. Food Chemistry, 67, 445 - 452.

Pawar, V.D. and Ingle, U.M., 1988. Functional properties of raw and cooked moth bean (Phaseolus acontifolius

Jacq) flours. Journal of Food Science and Technology, 25(4), 186-189.

Paredes-Lopez, O., Ordorica-Falmir, C. and Olivares-Vasquez, M. R., 1991. Chickpea protein isolates:

physiochemical, functional and nutritional characterization. Journal of Food Science, 56, 726 - 729.

Rackis, J.J., Sessa, D.J. and Honing, D.H., 1979. Flavor problems of vegetable food proteins. Journal of American

Oil Chemists Society, 56, 262271.

Snchez-Vioque, R., Clemente, A., Vioque, J., Bautista, J. and Milln, F., 1998. Polar lipids of defatted chickpea

flour and protein isolates. Food Chemistry, 63, 357 - 361.

Snchez-Vioque, R., Clemente, A., Vioque, J., Bautista, J. and Milln, F., 1999. Protein isolates from chickpea

(Cicer arietinum L.): chemical composition, functional properties and protein characterization. Food Chemistry,

64, 237-243.

Santiago Cardoso, R.A., Moreira-Arajo, R.S.R., Pinto de Silva, M.E.M. and Aras, J.A.G., 2001. The potential of

extruded chickpea, corn and bovine lung for malnutrition programs. Innovative Food Science and Emerging

Technologies, 2(3), 203 - 209.

Sathe, S. K. and Salunkhe, D. K., 1981. Functional properties of the great Northern bean (Phaseolus vulgaris L.)

Proteins: Emulsion, Foaming, Viscosity, and Gelation Properties. Journal of Food Science, 46, 71-75.

Sathe, S. K., Deshpande, S.S. and Salunkhe, D.K., 1982a. Functional properties of winged bean (Psophocarpus

tetragonolobus L. DC) proteins. Journal of Food Science, 47, 503-509.

Chemical and functional characterization of chickpea protein derivates 27

Sathe, S.K., Deshpande, S.S. and Salunkhe, D.K., 1982b. Functional properties of lupin seeds (Lupinus mutabilis)

proteins and protein concentrates. Journal of Food Science, 47, 491-497, 499-500.

Sefa-Dedeh, S. and Yiadom-Farkye, N.A., 1988. Some functional characteristics of cowpea (Vigna unguiculata),

bambara beans (Voandzeia subterranean) and their products. Canadian Institute of Food Science and

Technology Journal, 21, 266 - 270.

Singh, D.G., Abas, A.W., Kaur, D., and Sogi, Singh, D.S., 2008. Characterisation and functional properties of

proteins of some Indian chickpea (Cicer arietinum) cultivars. Journal of the Science of Food and Agriculture,

88(5), 778 - 786 (9).

Summer, A.K., Nielsen, M.A. and Youngs, C.G., 1981. Production and evaluation of pea protein isolate. Journal of

Food Science, 46, 364 - 367.

Tharanathan, R.N. and Mahadevamma, S., 2003. Grain legumes-A boon to human nutrition. Trends in Food Science

and Technology, 14, 507-518.

Tjahjadi, C., Lin, S. and Breene, W.M., 1988. Isolation and characterization of adzuki bean (Vigna angularis cv.

Takara) proteins. Journal of Food Science, 53, 1438 - 1443.

Turgeon, S.L., Gauthier, S.F., Moll, D. and Lonil, J., 1992 Interfacial properties of tryptic peptides of lactoglobulin. Journal of Agricultural and Food Chemistry, 40, 669 - 675.

Vani, B. and Zayas, J.F., 1995. Wheat germ protein flour solubility and water retention. Journal of Food Science,

4(60), 845 - 851.

You might also like

- A Study of Solubility of Strontium Sulfate: Gil G/DMDocument9 pagesA Study of Solubility of Strontium Sulfate: Gil G/DMFarzad sadeghzadNo ratings yet

- Mass Transfer OperationsDocument9 pagesMass Transfer OperationsarpitkshrNo ratings yet

- Functionality of Barley Proteins Extracted and Fractionated by Alkaline and Alcohol MethodsDocument10 pagesFunctionality of Barley Proteins Extracted and Fractionated by Alkaline and Alcohol MethodsMarcela Jarpa ParraNo ratings yet

- Study of Some Physicochemical and Functional Properties of Quinoa (Chenopodium Quinoa Willd) Protein IsolatesDocument6 pagesStudy of Some Physicochemical and Functional Properties of Quinoa (Chenopodium Quinoa Willd) Protein IsolatesHoracio GorosteguiNo ratings yet

- Ruiz 2016Document33 pagesRuiz 2016Hilda Ayala SalcedoNo ratings yet

- 47-Abstract With Title-212-1-10-20210106Document8 pages47-Abstract With Title-212-1-10-20210106Nayeli MelendrezNo ratings yet

- MJMHS 0413Document8 pagesMJMHS 0413dream11praveennNo ratings yet

- Red Kidney Beans PDFDocument9 pagesRed Kidney Beans PDFMade Harumi PadmaswariNo ratings yet

- Sulfahri,+24091 Article+Text 76620 1 2 20221119Document8 pagesSulfahri,+24091 Article+Text 76620 1 2 202211198lamhoursNo ratings yet

- Optimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeDocument8 pagesOptimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeNancy GonzalezNo ratings yet

- Development of A Functional Fermented Peanut-Based Cheese Analog Using Probiotic BacteriaDocument7 pagesDevelopment of A Functional Fermented Peanut-Based Cheese Analog Using Probiotic BacteriaAneesa khanNo ratings yet

- Characterization of Sacha Inchi Protein Hydrolysates Produced by Crude Papain and Calotropis ProteasesDocument7 pagesCharacterization of Sacha Inchi Protein Hydrolysates Produced by Crude Papain and Calotropis ProteasesNancy GonzalezNo ratings yet

- Protein Isolates From Bambara Groundnut Voandz.Document19 pagesProtein Isolates From Bambara Groundnut Voandz.ilyas.tassineNo ratings yet

- Functional Propieties of Lupin Seed (Lupinus Mutabilis) Protein... (Sathe Et Al.)Document7 pagesFunctional Propieties of Lupin Seed (Lupinus Mutabilis) Protein... (Sathe Et Al.)Lenna TrujilloNo ratings yet

- Digestibility, Textural and Sensory Characteristics of Cookies Made From Residues of Enzyme-Assisted Aqueous Extraction of SoybeansDocument8 pagesDigestibility, Textural and Sensory Characteristics of Cookies Made From Residues of Enzyme-Assisted Aqueous Extraction of SoybeansJhosep Tolentino ChaconNo ratings yet

- Protein Extraction From Sour Cherry Kernel PDFDocument10 pagesProtein Extraction From Sour Cherry Kernel PDFdr.sameer sainiNo ratings yet

- Art 01Document8 pagesArt 01Lavinia Maria BucatariuNo ratings yet

- Characterization of Rice Starch and Protein Obtein by A Fast Alkaline Extraction MethodDocument9 pagesCharacterization of Rice Starch and Protein Obtein by A Fast Alkaline Extraction MethodJuan RincónNo ratings yet

- Biochemical Characteristics of Sorghum Flour Fermented and or Supplemented With Chickpea FlourDocument5 pagesBiochemical Characteristics of Sorghum Flour Fermented and or Supplemented With Chickpea FlourRonin RamosNo ratings yet

- Báo Cáo Tiếng Anh Về NgôDocument13 pagesBáo Cáo Tiếng Anh Về NgôTrang LêNo ratings yet

- s12649-024-02816-6Document10 pagess12649-024-02816-6Master JoelNo ratings yet

- Characterization, Functionality and Antioxidant Activity of Water-Soluble Proteins Extracted From Bombyx Mori LinnDocument14 pagesCharacterization, Functionality and Antioxidant Activity of Water-Soluble Proteins Extracted From Bombyx Mori Linncameliaioana16No ratings yet

- Research Article: Influence of Fenugreek Flour (Addition On The Technofunctional Properties of Dark Wheat FlourDocument9 pagesResearch Article: Influence of Fenugreek Flour (Addition On The Technofunctional Properties of Dark Wheat FlourDanaNo ratings yet

- 10 1155@2020@2845757Document12 pages10 1155@2020@2845757amirayous2001No ratings yet

- Production of Yoghurts From Cow and Soy Composite Milk Using Starter Cultures From Different SourcesDocument7 pagesProduction of Yoghurts From Cow and Soy Composite Milk Using Starter Cultures From Different Sourcesdaisialaba722No ratings yet

- Amino Acid Composition of Cowpea (Vigna Ungiculata L. Walp) Flour and Its Protein IsolatesDocument8 pagesAmino Acid Composition of Cowpea (Vigna Ungiculata L. Walp) Flour and Its Protein IsolatesImaniarNo ratings yet

- PH Modulation On Properties of Mycelium Protein IsDocument16 pagesPH Modulation On Properties of Mycelium Protein Issmptablet361No ratings yet

- Properties of StarchDocument13 pagesProperties of StarchPadmavati KarthicNo ratings yet

- Для Просмотра Статьи Разгадайте КапчуDocument9 pagesДля Просмотра Статьи Разгадайте КапчуDavid FaizNo ratings yet

- Jurrnal in English NadiaDocument15 pagesJurrnal in English NadianadiaNo ratings yet

- 8 fr-2018-106.r2 ZuwariahDocument7 pages8 fr-2018-106.r2 ZuwariahQuyên ĐàoNo ratings yet

- Product Development and Quality Evaluation of Biscuit and Ready To Eat Snack From Cowpea Wheat Flour Blends AFTNSOJ 5 161Document16 pagesProduct Development and Quality Evaluation of Biscuit and Ready To Eat Snack From Cowpea Wheat Flour Blends AFTNSOJ 5 161Sadaf NaeemNo ratings yet

- Preservation of Millet Flour by RefrigerationDocument4 pagesPreservation of Millet Flour by RefrigerationChintia Devi PenditNo ratings yet

- Hilal Cla 2016Document5 pagesHilal Cla 2016Anonymous zIj5DCCANo ratings yet

- 1-s2.0-S0023643820312238-mainDocument8 pages1-s2.0-S0023643820312238-mainnaim mohamadNo ratings yet

- Albumin and Globulin Extraction - ChickPeaDocument7 pagesAlbumin and Globulin Extraction - ChickPealab.xtractNo ratings yet

- Development and Acceptability of Fibre E PDFDocument10 pagesDevelopment and Acceptability of Fibre E PDFGomathi KannusamyNo ratings yet

- Formulation and Characterization of Buckwheat-Barley Supplemented Multigrain BiscuitsDocument9 pagesFormulation and Characterization of Buckwheat-Barley Supplemented Multigrain Biscuitsanwar hussainNo ratings yet

- ArtigoDocument14 pagesArtigoFernanda CorreaNo ratings yet

- Nutritional and Functional Properties of Amaranth Grain Flour Fractions Obtained by Differential SievingDocument16 pagesNutritional and Functional Properties of Amaranth Grain Flour Fractions Obtained by Differential SievingHasmukh PatelNo ratings yet

- Production of Lactic Acid From Starchy-Based Food SubstratesDocument9 pagesProduction of Lactic Acid From Starchy-Based Food SubstratesYoali HdezNo ratings yet

- Manisha Sharma-SynopsisDocument13 pagesManisha Sharma-SynopsisSaira JabeenNo ratings yet

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- Effect of Temperature and Particle Size On The Alkaline Extraction of Protein From Chicken Bone WasteDocument7 pagesEffect of Temperature and Particle Size On The Alkaline Extraction of Protein From Chicken Bone WasteHasdar MuhammadNo ratings yet

- Yamada 2005Document6 pagesYamada 2005Dương Nguyễn Thùy DungNo ratings yet

- Formulation, Processing and Evaluation of Multigrain Porridge Mix From Underutilised Crops of LadakhDocument8 pagesFormulation, Processing and Evaluation of Multigrain Porridge Mix From Underutilised Crops of Ladakhanwar hussainNo ratings yet

- Isolation and Partial Characterization oDocument5 pagesIsolation and Partial Characterization olalalandNo ratings yet

- Porridge MixDocument9 pagesPorridge MixAlyssa NesianandaNo ratings yet

- Publication 13 Fdsc22Document6 pagesPublication 13 Fdsc22simondel2020No ratings yet

- Dhavalagi Pallavi Et AlDocument5 pagesDhavalagi Pallavi Et AlInternational Journal of Clinical and Biomedical Research (IJCBR)No ratings yet

- DocumentDocument8 pagesDocumentwoyox88034No ratings yet

- Chickpea Protein Isolates Physicochemical FunctionDocument5 pagesChickpea Protein Isolates Physicochemical FunctionBrain SmithNo ratings yet

- Ijfans A0274-14Document7 pagesIjfans A0274-14Akash SrivastavNo ratings yet

- J Aoas 2020 03 001Document10 pagesJ Aoas 2020 03 001Raksa SaremNo ratings yet

- Tipe Kristalin Pati GanyongDocument7 pagesTipe Kristalin Pati GanyongfrendystpNo ratings yet

- Manuscript AnjaliD IJFANS V1Document10 pagesManuscript AnjaliD IJFANS V1Annalakshmi ChatterjeeNo ratings yet

- Development of Dietary Fibre Enriched Chevon Rolls by Incorporating Corn BranDocument9 pagesDevelopment of Dietary Fibre Enriched Chevon Rolls by Incorporating Corn BranKhaled Abu-AlruzNo ratings yet

- 10 1016@j FBP 2015 06 003 PDFDocument7 pages10 1016@j FBP 2015 06 003 PDFEddy Ortiz ArceNo ratings yet

- Studi Pengaruh PH Awal Media Dan Konsentrasi Substrat Pada Proses Fermentasi Produksi Bioetanol Dari Hidrolisat TEPUNG BIJI KLUWIH (Actinocarpus Communis) DENGAN MENGGUNAKANDocument10 pagesStudi Pengaruh PH Awal Media Dan Konsentrasi Substrat Pada Proses Fermentasi Produksi Bioetanol Dari Hidrolisat TEPUNG BIJI KLUWIH (Actinocarpus Communis) DENGAN MENGGUNAKANAmila KhairinaNo ratings yet

- Food Science and Biotechnology Volume 22 Issue 1 2013Document7 pagesFood Science and Biotechnology Volume 22 Issue 1 2013Fayzan LabNo ratings yet

- Effect of Wheat Germ On Chemical Sensory and TechnDocument7 pagesEffect of Wheat Germ On Chemical Sensory and TechnNy Antsa RamanoelinaNo ratings yet

- Novel Proteins for Food, Pharmaceuticals, and Agriculture: Sources, Applications, and AdvancesFrom EverandNovel Proteins for Food, Pharmaceuticals, and Agriculture: Sources, Applications, and AdvancesNo ratings yet

- Determination of Co2 in Water2 PDFDocument4 pagesDetermination of Co2 in Water2 PDFWaleed Emara100% (1)

- Water ChemistryDocument25 pagesWater ChemistryMayank TiwariNo ratings yet

- Solubility PDFDocument36 pagesSolubility PDFAshwin Narayan100% (2)

- 3 5 TR 5Document39 pages3 5 TR 5Valdemar Alonso Ojeda SotoNo ratings yet

- Articles: Optimization of Chitin Extraction From Shrimp ShellsDocument7 pagesArticles: Optimization of Chitin Extraction From Shrimp ShellsJuan Pablo EspinosaNo ratings yet

- PESSAT Chemistry Old PaperDocument7 pagesPESSAT Chemistry Old PaperpullagalkNo ratings yet

- Immunology TopicDocument10 pagesImmunology TopicRaj Kumar SoniNo ratings yet

- Extracting and Purifying Morphine From OpiumDocument5 pagesExtracting and Purifying Morphine From OpiumDanielle Scribbins50% (2)

- SOAPS AND DETERGENT NOTESDocument3 pagesSOAPS AND DETERGENT NOTESbosonvoyagernishith1915No ratings yet

- Wa0001.Document8 pagesWa0001.Poorni RenuNo ratings yet

- Untitled 1Document8 pagesUntitled 1Lusti Ayu YuniartiNo ratings yet

- 1998 Paper 2Document16 pages1998 Paper 2api-3826629No ratings yet

- Revision Date Reason (S) For Revision: GPSA Engineering Data Book 14th EditionDocument6 pagesRevision Date Reason (S) For Revision: GPSA Engineering Data Book 14th EditionAsad KhanNo ratings yet

- Research Article: The Solubility of Two Magnetite Powders in Oxalic Acid: Applicability of Empirical ModellingDocument7 pagesResearch Article: The Solubility of Two Magnetite Powders in Oxalic Acid: Applicability of Empirical ModellingDrSrujan Kumar ReddyNo ratings yet

- WWW - Chemre.In: Ranjan E-InstituteDocument26 pagesWWW - Chemre.In: Ranjan E-InstituteSricharanNo ratings yet

- Definition and Properties of A Pharmaceutical SolutionDocument5 pagesDefinition and Properties of A Pharmaceutical SolutionAmeera Shaista Ali0% (3)

- Chapter 7 - Phase DiagramDocument52 pagesChapter 7 - Phase DiagramHoongNo ratings yet

- Aqueous Solubility CRCDocument36 pagesAqueous Solubility CRCKwok King Kingston ChanNo ratings yet

- Etching of Polymeric Surfaces A ReviewDocument42 pagesEtching of Polymeric Surfaces A ReviewWilliams Marcel Caceres FerreiraNo ratings yet

- Kami Export - TB - Practice - Answered66e153370bbe48.66e15338d74f83.23536625Document11 pagesKami Export - TB - Practice - Answered66e153370bbe48.66e15338d74f83.23536625hana.m.elnagar9No ratings yet

- 5 16 53 605 PDFDocument21 pages5 16 53 605 PDFTanay GuptaNo ratings yet

- Acids and BasesDocument17 pagesAcids and Basespadidela swarochishraoNo ratings yet

- Carbonated Yogurt DrinkDocument4 pagesCarbonated Yogurt DrinkKhaled HosniNo ratings yet

- Extrusion Processing of Wheat Gluten Bioplastic: Effect of The Addition of Kraft LigninDocument11 pagesExtrusion Processing of Wheat Gluten Bioplastic: Effect of The Addition of Kraft LigninXuan Phuong HuynhNo ratings yet

- Language of Chemistry I PDFDocument61 pagesLanguage of Chemistry I PDFmuhammad thariqNo ratings yet

- MSDS AZODICARBONAMIDE (Revised 1)Document11 pagesMSDS AZODICARBONAMIDE (Revised 1)Rizqi FirmansyahNo ratings yet

- Report On MicrowaveDocument50 pagesReport On Microwaveprashant mande100% (1)

- Group 1 Experiment 14 and 15Document87 pagesGroup 1 Experiment 14 and 15Chamy CruzNo ratings yet