Mooring Winch Brake Capacity Calculation PDF

Mooring Winch Brake Capacity Calculation PDF

Uploaded by

vdevivCopyright:

Available Formats

Mooring Winch Brake Capacity Calculation PDF

Mooring Winch Brake Capacity Calculation PDF

Uploaded by

vdevivOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Mooring Winch Brake Capacity Calculation PDF

Mooring Winch Brake Capacity Calculation PDF

Uploaded by

vdevivCopyright:

Available Formats

Brake holding test

The brake secures the drum and thereby the mooring line at the shipboard end. It also acts as a safety device in

case the load in the line becomes excessive, by rendering and allowing the line to shed its load before it breaks

(at MBL or Maximum Breaking Load). For normal operation the recommended (OCIMF) setting on the brake

is 60 % of the MBL of the rope. For new ships this is tested for 80 % of the line's MBL since brakes may

deteriorate in service.

Every ship is supplied with a brake testing kit to test the brake at least once in a year. The break testing kit

simulates the load on the line by means of hydraulic pressure producing a torque on the winch drum.

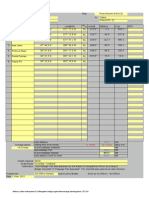

Example:

Winch capacity : 16 T

Mooring line MBL : 51 T

Brake holding force : Po = 40.8 T at first layer (80 % of MBL)

Drum diameter : R = 48 cm

Rope diameter : r = 2.8 cm

Hydraulic jack cylinder diameter: Jc = 6,50 cm

Effective area of hydraulic jack : A = (Jc * 3,1416) /4 = 33.2 cm

Test force moment arm : L = 132.5 cm

Rope PCD : Rpcd = R + r = 50.8 cm

Brake torque : Tb = Po * Rpcd / 2 = 1036.3 T/cm

Force on hydraulic jack : F = Tb / L = 7.8 T = 7800 Kg

Required pressure : P = F / A = 234.9 kg/cm (at 80 % MBL) = 230.5 bar

W

Nominal Pull N kN Carretel MBL r R L Jc A Tb F BT RL

(first layer)

Carga de rotura del cabo/alambre MBL T 1 51 40,80 50,80 48,00 132,50 6,50 33,18 1.036,3 7.821 235,70 230,99

Capacidad del freno (Diseo/Servicio:

80/60% del MBL del cabo/alambre)

W T

Dimetro del cabo r cm

Dimetro del carretel R cm

Distancia desde el eje del gato hidrulico

al centro del carretel

L cm

Dimetro del cilindro hidrulico (cuello) Jc cm

rea efectiva del gato hidrulico A cm2

Torsin del freno Tb T/cm

Fuerza requerida por el gato hidrulico F kgs

Capacidad del freno (Presin requerida) BT kg/cm2

Carga a la que rinde (Presin requerida) RL kg/cm2

Connecting the bracket on drum flanges. Tight the brake turning handle. The pressure is increased in the

hydraulic jack using a manual pump. After the pressure reaches the calculated value (here 230.5 bar), a

marking is made on the brake band. It is held for a minute and the marking is checked to see if there is any slip.

Grfico a ttulo informativo. Los datos no corresponden con los mostrados en el ejemplo.

62

You might also like

- Mooring Winch Brake Capacity CalculationDocument1 pageMooring Winch Brake Capacity CalculationDani Parada60% (10)

- Determining Critical Wind Velocity For Dragging AnchorDocument2 pagesDetermining Critical Wind Velocity For Dragging AnchorOctavianNo ratings yet

- Stability Booklet Check ListDocument3 pagesStability Booklet Check ListReza BabriNo ratings yet

- Grain Stability Calculation Form ExcelDocument4 pagesGrain Stability Calculation Form ExcelAhmad fayez Bayazid33% (3)

- Swirlax BurnerDocument3 pagesSwirlax BurnerSafeer AbbasNo ratings yet

- Stability AHTSDocument18 pagesStability AHTSPrakharNo ratings yet

- DigiMoorX7 Software IntroductionDocument24 pagesDigiMoorX7 Software IntroductionSachin SikkaNo ratings yet

- MOORING WINCH BRAKE HOLDING TEST JAN2017 Report OnlyDocument1 pageMOORING WINCH BRAKE HOLDING TEST JAN2017 Report Onlyvinnileo50% (2)

- Freeboard and Loadline Calculation: Vessel Name M V KALA PANI (Passenger CUM Cargo Ship) Principal ParticularsDocument3 pagesFreeboard and Loadline Calculation: Vessel Name M V KALA PANI (Passenger CUM Cargo Ship) Principal Particularsmanish5lallNo ratings yet

- Winch Brake Holding Capacity TestDocument2 pagesWinch Brake Holding Capacity TestDenis Mihin83% (6)

- Imo Wheelhouse Poster (Musashi Gloria)Document1 pageImo Wheelhouse Poster (Musashi Gloria)Somayajula Suryaram100% (1)

- What Are CATZOC and How To Use It For Passage Planning - MySeaTime PDFDocument25 pagesWhat Are CATZOC and How To Use It For Passage Planning - MySeaTime PDFvdeviv100% (2)

- Risk Assessment Method For EcdisDocument2 pagesRisk Assessment Method For EcdisvdevivNo ratings yet

- Port State Control Fsi.2-Circ.6Document57 pagesPort State Control Fsi.2-Circ.6vdevivNo ratings yet

- En-100-G-Z-0201-00-P5-Without AdsDocument88 pagesEn-100-G-Z-0201-00-P5-Without AdsAbdelkader BOUKHOUSNo ratings yet

- Mooring Winch Tests1Document7 pagesMooring Winch Tests1RachitNo ratings yet

- Barometer Calibration CertificateDocument1 pageBarometer Calibration CertificateARE YOU TECH CRAZYNo ratings yet

- UKC CalculationDocument2 pagesUKC CalculationIrwan Januar0% (1)

- SquatDocument2 pagesSquatRupesh Kumar100% (1)

- DNV Template Biofouling Management Plan Rev1 Tcm4-524330Document14 pagesDNV Template Biofouling Management Plan Rev1 Tcm4-524330Mary Smith100% (1)

- Mooring & Wire RopesDocument14 pagesMooring & Wire RopesAlexNo ratings yet

- Register of Materials Handling Equipment-AMSA357Document10 pagesRegister of Materials Handling Equipment-AMSA357SudheerRawatNo ratings yet

- Garbage MANUALDocument36 pagesGarbage MANUALmouloud miloudNo ratings yet

- SQUAT CALCULATION Huuska-Icorels Formula: Notice: Input Only in Yellow Fields!Document2 pagesSQUAT CALCULATION Huuska-Icorels Formula: Notice: Input Only in Yellow Fields!Aamir Sirohi100% (1)

- Towards Safer ShipsDocument550 pagesTowards Safer ShipsElijah Smelkoff100% (2)

- User's Manual - Synthetic Μooring RopesDocument32 pagesUser's Manual - Synthetic Μooring RopesNikos StratisNo ratings yet

- Deck Cadet SSTP - List of Projects and ActivitiesDocument36 pagesDeck Cadet SSTP - List of Projects and ActivitiesAzim Modak100% (1)

- Navigational EquipmentsDocument26 pagesNavigational EquipmentsParth Sarathi100% (1)

- Bridge8 - Steering GearDocument2 pagesBridge8 - Steering GearDrago Dragic100% (1)

- GRAINCALCNCBDocument8 pagesGRAINCALCNCBwaleedyehia100% (1)

- C 4 FfaDocument35 pagesC 4 Ffaanjuman ara100% (1)

- Sill Height of Watertight Door and HatchesDocument3 pagesSill Height of Watertight Door and HatchesOzata Tersanesi100% (1)

- LashCon Version 9.1 Oct 2004 - tcm48-75125Document4 pagesLashCon Version 9.1 Oct 2004 - tcm48-75125Gary LampenkoNo ratings yet

- Stability Calculation Form For MV MaineborgDocument9 pagesStability Calculation Form For MV MaineborgtrananhnganNo ratings yet

- IOPPDocument6 pagesIOPPSebastian JoshuaNo ratings yet

- Ship Fittings by A NyghDocument12 pagesShip Fittings by A NyghTyasno PrasetyoNo ratings yet

- Appendix E - Rest Hour RecordDocument2 pagesAppendix E - Rest Hour RecordlasithNo ratings yet

- DNV Rules For ShipsDocument134 pagesDNV Rules For ShipsGustavo Heraldo GregoretNo ratings yet

- Cargo PBLMDocument7 pagesCargo PBLMmeghna c binu100% (1)

- HK Flag Req For Lsa Ffa InspectionDocument13 pagesHK Flag Req For Lsa Ffa InspectionMohit S Sodhi100% (1)

- 5 - Cargo Securing ManualDocument87 pages5 - Cargo Securing Manualalxgam75% (4)

- MSC.1-Circ.1175-Rev.1 - Revised Guidance On Shipboard Towing and Mooring Equipment (Secretariat)Document16 pagesMSC.1-Circ.1175-Rev.1 - Revised Guidance On Shipboard Towing and Mooring Equipment (Secretariat)Maksim ZaritskiiNo ratings yet

- 5 International Tonnage Certificate (1969) - LL-115E-152178014Document2 pages5 International Tonnage Certificate (1969) - LL-115E-152178014Ngwe Min TheinNo ratings yet

- 5 Ballast SequenceDocument46 pages5 Ballast Sequenceนัทเดช เรืองสวน100% (1)

- IMO Grain Code Stability RequirementsDocument2 pagesIMO Grain Code Stability RequirementsRakesh EdekkadNo ratings yet

- Stability Calculation BarcazaDocument26 pagesStability Calculation BarcazaRenzo Gonzales EsquenNo ratings yet

- Passage Planning .Dubai To SharjahDocument4 pagesPassage Planning .Dubai To SharjahKunal Singh100% (3)

- Rest Hours STCW & MLCDocument2 pagesRest Hours STCW & MLCsameerNo ratings yet

- AnchoringDocument12 pagesAnchoringDryanmNo ratings yet

- ANNEX - Navigational Audit QuestionnaireDocument24 pagesANNEX - Navigational Audit QuestionnaireАлексей Преподобный 1406No ratings yet

- 8 MooringDocument18 pages8 MooringchNo ratings yet

- TestDocument8 pagesTestGeorge Cristian100% (1)

- Merchant Shipping Act 2007Document189 pagesMerchant Shipping Act 2007twweettybirdNo ratings yet

- 11 International Oil Pollution Prevention (IOPP) & Form ADocument7 pages11 International Oil Pollution Prevention (IOPP) & Form AWILLINTON HINOJOSANo ratings yet

- Voy 038D Callao - TalaraDocument35 pagesVoy 038D Callao - TalaraHendra TambunanNo ratings yet

- Brake Holding Power TestDocument6 pagesBrake Holding Power TestCaptIsqanNo ratings yet

- Optimoor: Mooring Analysis So Ware For Ships & BargesDocument2 pagesOptimoor: Mooring Analysis So Ware For Ships & BargesTam Jun HuiNo ratings yet

- Grain Stability - The Missing LinkDocument5 pagesGrain Stability - The Missing LinkPetar Saydenov100% (3)

- Iacs Ship Structure Access ManualDocument18 pagesIacs Ship Structure Access ManualKordalhs Kyriakos100% (1)

- Primary and Secondary Means of Venting On TankersDocument19 pagesPrimary and Secondary Means of Venting On TankersFlexi100% (1)

- Offshore Vessels Inspection Database (OVID) Oviq2Document16 pagesOffshore Vessels Inspection Database (OVID) Oviq2Elldy FrenkyNo ratings yet

- Mooring Line Management SNAME 1994 PDFDocument8 pagesMooring Line Management SNAME 1994 PDFLe Phuong DongNo ratings yet

- Mooring Winch Brake Capacity Calculation PDFDocument1 pageMooring Winch Brake Capacity Calculation PDFMorozan C Si DNo ratings yet

- MooringWinchBrake Apacity Calculation PDFDocument1 pageMooringWinchBrake Apacity Calculation PDFMorozan C Si DNo ratings yet

- Mooring Winch Brake Capacity Calculation PDFDocument1 pageMooring Winch Brake Capacity Calculation PDFMorozan C Si DNo ratings yet

- Free-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosaDocument2 pagesFree-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosavdevivNo ratings yet

- Rec 85 Rev1 Dec 2018 UlDocument14 pagesRec 85 Rev1 Dec 2018 UlvdevivNo ratings yet

- 2019 Anchoring Guidelines A Risk-Based-Approach PDFDocument57 pages2019 Anchoring Guidelines A Risk-Based-Approach PDFvdeviv100% (4)

- PR 40 Rev1 Apr 2019 UlDocument12 pagesPR 40 Rev1 Apr 2019 UlvdevivNo ratings yet

- 10 Simple Things That Make Seafarers Happy On Board ShipsDocument17 pages10 Simple Things That Make Seafarers Happy On Board ShipsvdevivNo ratings yet

- Navigation Safety Assessment in The Restricted Area With The Use of ECDIS PDFDocument7 pagesNavigation Safety Assessment in The Restricted Area With The Use of ECDIS PDFvdevivNo ratings yet

- A Study On The Factors Influencing The Seafarers' Stress PDFDocument8 pagesA Study On The Factors Influencing The Seafarers' Stress PDFvdevivNo ratings yet

- S-101 Info Paper Jun12 enDocument13 pagesS-101 Info Paper Jun12 envdevivNo ratings yet

- Hatzigrigoris - New Operating Con.2008.SYMPDocument8 pagesHatzigrigoris - New Operating Con.2008.SYMPvdevivNo ratings yet

- Guidelines For Healthy Food Onboard Merchant ShipsDocument8 pagesGuidelines For Healthy Food Onboard Merchant ShipsvdevivNo ratings yet

- Calculating Reel CapacityDocument1 pageCalculating Reel CapacityvdevivNo ratings yet

- OVVP OffshoreVesselVettingProcess Tcm14-41400Document52 pagesOVVP OffshoreVesselVettingProcess Tcm14-41400vdeviv100% (1)

- LNG VESSEL APPROVAL PROCEDURE - DESFA LNG TERMINAL Rev.2 - 2015 1 PDFDocument11 pagesLNG VESSEL APPROVAL PROCEDURE - DESFA LNG TERMINAL Rev.2 - 2015 1 PDFvdevivNo ratings yet

- A Complete Guide of Cargo Sampling On Tankers - MySeaTimeDocument17 pagesA Complete Guide of Cargo Sampling On Tankers - MySeaTimevdeviv67% (3)

- 20 January 2017 Standard Europe Circular Ballast Water Management ConventionDocument5 pages20 January 2017 Standard Europe Circular Ballast Water Management ConventionvdevivNo ratings yet

- WSH Manual Marine IndustriesDocument360 pagesWSH Manual Marine IndustriesluiscremaschiNo ratings yet

- Marine Safety Information Bulletin: Alternate Management Systems (AMS) Program Update, Rev. 1Document2 pagesMarine Safety Information Bulletin: Alternate Management Systems (AMS) Program Update, Rev. 1vdevivNo ratings yet

- Marine Case Studies July2014Document57 pagesMarine Case Studies July2014vdevivNo ratings yet

- Voyage Passage Planning - CompressedDocument38 pagesVoyage Passage Planning - Compressedvdeviv100% (2)

- Ground Joint Unions PDFDocument4 pagesGround Joint Unions PDFAnonymous du4yYem5100% (1)

- DT-Dry Type Data SheetDocument3 pagesDT-Dry Type Data SheetArnold StevenNo ratings yet

- 27 ASL CircularDocument2 pages27 ASL CircularArvind SrivastavaNo ratings yet

- Feminism in India An Eastern PerspectiveDocument7 pagesFeminism in India An Eastern PerspectiveKamal BagNo ratings yet

- Creative Holiday Homework in HindiDocument5 pagesCreative Holiday Homework in Hindig3n75kv3100% (1)

- Top 30 Infrastructure Companies - ConstructionWeekIndiaConstructionWeekIndia PDFDocument9 pagesTop 30 Infrastructure Companies - ConstructionWeekIndiaConstructionWeekIndia PDFMelwin PaulNo ratings yet

- Veritas Cluster File SystemDocument19 pagesVeritas Cluster File SystemSubbarao AppanabhotlaNo ratings yet

- Air Compressor For Scba - Type LW 100 e & LW 100 BDocument55 pagesAir Compressor For Scba - Type LW 100 e & LW 100 BEserNo ratings yet

- CpE646 8v3 PDFDocument41 pagesCpE646 8v3 PDFGurpreet SinghNo ratings yet

- Composing A Strong PHD Dissertation Problem StatementDocument2 pagesComposing A Strong PHD Dissertation Problem StatementSARRA EL KAMOUSNo ratings yet

- SRSDocument4 pagesSRSRifat_D_ver_1422No ratings yet

- Account Statement From 1 Feb 2024 To 29 Feb 2024: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument6 pagesAccount Statement From 1 Feb 2024 To 29 Feb 2024: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceAmar JainNo ratings yet

- Data Sheet, GAD and QAP of Y StrainerDocument13 pagesData Sheet, GAD and QAP of Y StrainerSHABAHATNo ratings yet

- 10.knock Out DrumDocument10 pages10.knock Out DrumZaidatu ImtinanNo ratings yet

- PE PRICE LIST 22.04.2021 RelianceDocument15 pagesPE PRICE LIST 22.04.2021 RelianceKishan SolankeNo ratings yet

- Module 1 Mis VtuDocument14 pagesModule 1 Mis Vtuajay4dudeNo ratings yet

- 04Electrostatic-SenAct 44Document94 pages04Electrostatic-SenAct 44Prashant SinghNo ratings yet

- Compass Accessories PDFDocument9 pagesCompass Accessories PDFAnonymous GKqp4HnNo ratings yet

- Drill Chapter 1: Notre Dame of Midsayap CollegeDocument5 pagesDrill Chapter 1: Notre Dame of Midsayap CollegeMarites AmorsoloNo ratings yet

- Leading Edge Assembly - Avions de Transport Regional - 57-42-11Document74 pagesLeading Edge Assembly - Avions de Transport Regional - 57-42-11Kevin PangilinanNo ratings yet

- Physics Syllubus 2022-2023Document5 pagesPhysics Syllubus 2022-2023api-319028487No ratings yet

- GNED - 500 TxtbookDocument200 pagesGNED - 500 TxtbookInderjit72% (18)

- Pistons and Connecting RodsDocument6 pagesPistons and Connecting Rodsma.powersourceNo ratings yet

- Billet Inspection Control in The Steel Grinding Balls ProductionDocument4 pagesBillet Inspection Control in The Steel Grinding Balls ProductionChouial BilelNo ratings yet

- Engr Navarro - DC Circuits LectureDocument6 pagesEngr Navarro - DC Circuits LectureDodong JhuLz DumalanNo ratings yet

- Oil and Natural Gas Corporation Ltd. Vasai East Development ProjectDocument7 pagesOil and Natural Gas Corporation Ltd. Vasai East Development Projectmathew1965No ratings yet

- ASTM Norms Commonly UsedDocument1 pageASTM Norms Commonly Usedivanov5559No ratings yet

- Learning Outcome 1: Obtain and Convey Workplace Information Contents: Assessment MethodsDocument6 pagesLearning Outcome 1: Obtain and Convey Workplace Information Contents: Assessment MethodsDiane AguilarNo ratings yet