Crack Width Check

Crack Width Check

Uploaded by

Anand SoniCopyright:

Available Formats

Crack Width Check

Crack Width Check

Uploaded by

Anand SoniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Crack Width Check

Crack Width Check

Uploaded by

Anand SoniCopyright:

Available Formats

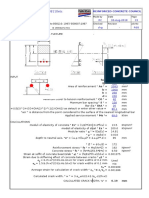

CRACK WIDTH CHECK ( LIMIT STATE METHOD)

1. For Flexure;

STEEL GRADE = 500 N/mm²

CONCRETE GRADE = 30 N/mm²

MEMBER DEPTH (D) = 550 mm

COVER = 50 mm

REINFORCEMENT = 12 mm 100 mm Spacing.

+ 0 mm 100 mm Spacing.

PROVIDED AREA = 1130.973355 mm²

Pt( % ) = 0.228941975 %

SERVICE MOMENT = 151 KNm

EFFECTIVE COVER = 56 mm

SPACING OF REINF. = 50 mm

Ec = 27386.12788 N/mm²

Es = 200000 N/mm²

Limiting strain in tension reinforcement = 0.002

Limiting stress in concrete = 13.5 N/mm²

acr = 55.32699

Ɛm = average strain at the level where cracking is considered

Ɛ1 = strain at the level considered

Ɛ2 = strain due to stiffening effect of concrete between cracks.

Ɛm = Ɛ1 - Ɛ2

For, Strain at the level considered ( Ɛ1 ),

xu = 29.01852829 mm

Effective depth, d = 494 mm

ƒs = 318.51 N/mm2

As stress in steel is greater than 130 N/mm2; crack width check is needed

Ɛ1 = 0.001784367

Strain due to stiffening effect of concrete between cracks. ( Ɛ2 ),

For a limiting design surface rack width of 0.2 mm :

Ɛ2 = 0.000860212

So, Ɛm = 0.000924155

For a limiting design surface rack width of 0.1 mm :

Ɛ2 = 0.001290317

So, Ɛm = 0.000494049

Design Surface Crack Width ( Wcr )

For limiting crack width = 0.2 mm

Wcr = 0.150318213 mm

Crack width is within limit, Hence section is SAFE

CRACK WIDTH CHECK ( LIMIT STATE METHOD)

1. For Flexure;

STEEL GRADE = 500 N/mm²

CONCRETE GRADE = 30 N/mm²

MEMBER DEPTH (D) = 350 mm

COVER = 50 mm

REINFORCEMENT = 12 mm 100 mm Spacing.

+ 0 mm 100 mm Spacing.

PROVIDED AREA = 1130.973355 mm²

Pt( % ) = 0.384684815 %

SERVICE MOMENT = 81 KNm

EFFECTIVE COVER = 56 mm

SPACING OF REINF. = 50 mm

Ec = 27386.12788 N/mm²

Es = 200000 N/mm²

Limiting strain in tension reinforcement = 0.002

Limiting stress in concrete = 13.5 N/mm²

acr = 55.32699

Ɛm = average strain at the level where cracking is considered

Ɛ1 = strain at the level considered

Ɛ2 = strain due to stiffening effect of concrete between cracks.

Ɛm = Ɛ1 - Ɛ2

For, Strain at the level considered ( Ɛ1 ),

xu = 26.51451788 mm

Effective depth, d = 294 mm

ƒs = 291.03 N/mm2

As stress in steel is greater than 130 N/mm2; crack width check is needed

Ɛ1 = 0.001759788

Strain due to stiffening effect of concrete between cracks. ( Ɛ2 ),

For a limiting design surface rack width of 0.2 mm :

Ɛ2 = 0.000576509

So, Ɛm = 0.00118328

For a limiting design surface rack width of 0.1 mm :

Ɛ2 = 0.000864763

So, Ɛm = 0.000895026

Design Surface Crack Width ( Wcr )

For limiting crack width = 0.2 mm

Wcr = 0.190139699 mm

Crack width is within limit, Hence section is SAFE

CRACK WIDTH CHECK ( LIMIT STATE METHOD)

1. For Flexure;

STEEL GRADE = 500 N/mm²

CONCRETE GRADE = 30 N/mm²

MEMBER DEPTH (D) = 350 mm

COVER = 50 mm

REINFORCEMENT = 12 mm 100 mm Spacing.

+ 0 mm 100 mm Spacing.

PROVIDED AREA = 1130.973355 mm²

Pt( % ) = 0.384684815 %

SERVICE MOMENT = 79 KNm

EFFECTIVE COVER = 56 mm

SPACING OF REINF. = 50 mm

Ec = 27386.12788 N/mm²

Es = 200000 N/mm²

Limiting strain in tension reinforcement = 0.002

Limiting stress in concrete = 13.5 N/mm²

acr = 55.32699

Ɛm = average strain at the level where cracking is considered

Ɛ1 = strain at the level considered

Ɛ2 = strain due to stiffening effect of concrete between cracks.

Ɛm = Ɛ1 - Ɛ2

For, Strain at the level considered ( Ɛ1 ),

xu = 25.83372438 mm

Effective depth, d = 294 mm

ƒs = 283.56 N/mm2

As stress in steel is greater than 130 N/mm2; crack width check is needed

Ɛ1 = 0.00171385

Strain due to stiffening effect of concrete between cracks. ( Ɛ2 ),

For a limiting design surface rack width of 0.2 mm :

Ɛ2 = 0.000577468

So, Ɛm = 0.001136382

For a limiting design surface rack width of 0.1 mm :

Ɛ2 = 0.000866202

So, Ɛm = 0.000847648

Design Surface Crack Width ( Wcr )

For limiting crack width = 0.2 mm

Wcr = 0.182615995 mm

Crack width is within limit, Hence section is SAFE

CRACK WIDTH CHECK ( WORKING STRESS METHOD)

1. For Flexure;

STEEL GRADE = 415 N/mm²

CONCRETE GRADE = 30 N/mm²

MEMBER DEPTH (D) = 550 mm

COVER = 50 mm

REINFORCEMENT = 20 mm 400 mm Spacing.

+ 20 mm 400 mm Spacing.

PROVIDED AREA = 1570.7963268 mm²

Pt( % ) = 0.3205706789 %

SERVICE MOMENT = 166.75 KNm

EFFECTIVE COVER = 60 mm

SPACING OF REINF. = 200 mm

Ec = 27386.127875 N/mm² m= 9.3333

Es = 200000 N/mm²

σcbc = 10 σct = 1.5

σcc = 8 σcbt = 2

acr = 106.61904

Ɛm = average strain at the level where cracking is considered

Ɛ1 = strain at the level considered

Ɛ2 = strain due to stiffening effect of concrete between cracks.

Ɛm = Ɛ1 - Ɛ2

For, Strain at the level considered ( Ɛ1 ),

xu = 106.097 mm σcbc = 6.9140054 < 10

Effective depth, d = 490 mm O.K.

Z= d - x/3 = 454.634 mm

ƒs = 233.50 N/mm 2

As stress in steel is greater than 130 N/mm2; crack width check is needed

Ɛ1 = 0.001349958

Strain due to stiffening effect of concrete between cracks. ( Ɛ2 ),

For a limiting design surface rack width of 0.2 mm :

Ɛ2 = 0.000544607

So, Ɛm = 0.000805351

For a limiting design surface rack width of 0.1 mm :

Ɛ2 = 0.000816911

So, Ɛm = 0.000533048

Design Surface Crack Width ( Wcr )

For limiting crack width = 0.2 mm

Wcr = 0.2052410586 mm

Crack width is exceeding the limit hence modify section

2. For Direct Tension;

SERVICE FORCE = 169.9 KN

For a limiting design surface rack width of 0.2 mm :

ƒct = 0.2948732 N/mm2

ƒst = 54.08085 N/mm2

Ɛ2 = 0.0005835681

For a limiting design surface rack width of 0.1 mm :

Ɛ2 = 0.0008753522

Apparent strain Ɛ1 = 0.00027040

For limiting crack width = 0.2 mm

Wcr = -0.100167694 mm

Crack width is within limit, Hence section is SAFE

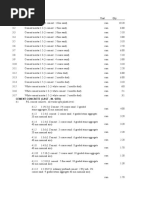

You might also like

- 3.0crack Width Check (Aci)Document48 pages3.0crack Width Check (Aci)klynchelle100% (2)

- Calculation of Crack WidthDocument1 pageCalculation of Crack WidthSerjoe N. Rosal100% (1)

- Crack Width CalculationDocument2 pagesCrack Width CalculationprabhuNo ratings yet

- RC Pilecap Design (Beam Method)Document27 pagesRC Pilecap Design (Beam Method)Thaung Myint OoNo ratings yet

- CorbelDocument4 pagesCorbelAnand SoniNo ratings yet

- BT ReviewerDocument4 pagesBT ReviewerRenee Obligar100% (1)

- Recommendations AFTES Sprayed Concrete PDFDocument35 pagesRecommendations AFTES Sprayed Concrete PDFSanjeev Kr. ThakurNo ratings yet

- Ita Report 16 WG2 BD - P PDFDocument72 pagesIta Report 16 WG2 BD - P PDFmetropodikasNo ratings yet

- Crack Width Check For Water Tank BaseDocument4 pagesCrack Width Check For Water Tank BaseShamim Ahsan ZuberyNo ratings yet

- 5.3 Design of Crash BarrierDocument3 pages5.3 Design of Crash BarrierMd BIN HASANNo ratings yet

- T Beam DesignDocument5 pagesT Beam DesignShuvam Pyakurel100% (1)

- Crack Width L - Steps - 75mm 4.56 MDocument22 pagesCrack Width L - Steps - 75mm 4.56 MpandianNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument2 pagesLarsen & Toubro Limited: ECC Division - EDRCselva100% (1)

- Crack WidthDocument5 pagesCrack WidthchanakyaNo ratings yet

- Base Slab & Crack Width Check - ACI CodeDocument6 pagesBase Slab & Crack Width Check - ACI CodensureshbabuNo ratings yet

- Crash Barrier DesignDocument2 pagesCrash Barrier DesignDevdatta100% (1)

- Corbel DesignDocument107 pagesCorbel DesignMrJanji JohnyNo ratings yet

- Crack Width CalculationsDocument9 pagesCrack Width Calculationsankkeshmundra1No ratings yet

- Sub StructureDocument51 pagesSub StructureamawauceNo ratings yet

- Design of Roof Purlin at Mid Bay: KX 0.995 Ky 0.100Document3 pagesDesign of Roof Purlin at Mid Bay: KX 0.995 Ky 0.100Utkarsh BhardwajNo ratings yet

- Crack Width Calc - BS 8110Document1 pageCrack Width Calc - BS 8110Thomas Crowe100% (2)

- ACI Beam DesignDocument8 pagesACI Beam DesignsujatNo ratings yet

- RC Beam Design To EC2Document3 pagesRC Beam Design To EC2suman_civilNo ratings yet

- Crack Width CalculationDocument8 pagesCrack Width CalculationSM ConsultantsNo ratings yet

- Corbel DesignDocument4 pagesCorbel Designprabhat_iitdNo ratings yet

- Crack Width (ACI 350R)Document1 pageCrack Width (ACI 350R)reyNo ratings yet

- Punching Shear Check For SlabDocument2 pagesPunching Shear Check For SlabArnab Sur50% (2)

- 09 bs8007 CrackwidthDocument11 pages09 bs8007 CrackwidthMUTHUKKUMARAMNo ratings yet

- Beam Design and Control: T U C GDocument3 pagesBeam Design and Control: T U C GmegunNo ratings yet

- Crack Width CalculationDocument3 pagesCrack Width CalculationTarun Sai50% (2)

- 1 - Inputs: Project Name: Title of Report: 180xx R0yy Input Variable Name Units Symbol Value Formula & InformationDocument17 pages1 - Inputs: Project Name: Title of Report: 180xx R0yy Input Variable Name Units Symbol Value Formula & InformationSurya PratapNo ratings yet

- Crack Width Calculation: MaterialsDocument2 pagesCrack Width Calculation: MaterialsIrfan AliNo ratings yet

- Design Slab On Grade Postension (ACI 360R & PTI) : I. Input DataDocument2 pagesDesign Slab On Grade Postension (ACI 360R & PTI) : I. Input DataVandaNo ratings yet

- Circular Section Crack Width Under Tension Plus MomentDocument2 pagesCircular Section Crack Width Under Tension Plus MomentAbinash ModakNo ratings yet

- ACI - Crack CalculationsDocument3 pagesACI - Crack CalculationsLuis Ariel B. MorilloNo ratings yet

- RCC14 Crack WidthDocument3 pagesRCC14 Crack WidthMatumbi NaitoNo ratings yet

- ACI-14 Beam Ledge Design v1.0Document6 pagesACI-14 Beam Ledge Design v1.0Raymund Dale P. BallenasNo ratings yet

- Staad Pro Parameter ListDocument1 pageStaad Pro Parameter ListpawanNo ratings yet

- RC Design Functions5Document90 pagesRC Design Functions5Wr ArNo ratings yet

- Grade Slab ACI-150thkDocument7 pagesGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- Crack Width CalculationsDocument1 pageCrack Width CalculationsdfdgggNo ratings yet

- Beam Torsion CheckDocument9 pagesBeam Torsion CheckSamir PrajapatiNo ratings yet

- CorbelDocument2 pagesCorbelaahtagoNo ratings yet

- 200 THK Grade Slab-50kn Variable Load-With FibreDocument7 pages200 THK Grade Slab-50kn Variable Load-With FibreFazilat Mohammad Zaidi0% (1)

- Tata Consulting Engineers Limited: 1.0.material PropertiesDocument3 pagesTata Consulting Engineers Limited: 1.0.material PropertiesNitesh SinghNo ratings yet

- Waffle Slab DesignDocument26 pagesWaffle Slab DesignMinh ĐứcNo ratings yet

- Curve BeamDocument8 pagesCurve Beamkeat_leong_yeeNo ratings yet

- Design of Pole Foundation Using Broms MethodDocument3 pagesDesign of Pole Foundation Using Broms MethodOmar SalahNo ratings yet

- PBSD Guidelines For Tall Buildings Dec12 2017Document56 pagesPBSD Guidelines For Tall Buildings Dec12 2017Andrés Esteban Garzón RamírezNo ratings yet

- Beam Design (SSB)Document6 pagesBeam Design (SSB)Er Sai KiranNo ratings yet

- Rectangular Beam 1VB27-300x650mm - Sagging: InputDocument4 pagesRectangular Beam 1VB27-300x650mm - Sagging: InputSiti Fatimah MokhtarNo ratings yet

- Check For Uncracked Section by LIMIT STATE METHOD-For SlabDocument10 pagesCheck For Uncracked Section by LIMIT STATE METHOD-For SlabMalviya PravinNo ratings yet

- Rectangular Beam 1VB6-300 X 500mm - Sagging: InputDocument4 pagesRectangular Beam 1VB6-300 X 500mm - Sagging: InputSiti Fatimah MokhtarNo ratings yet

- RCC Slab DesignDocument4 pagesRCC Slab DesignarghyadeepNo ratings yet

- Rectangular Beam 1VB16-300x800mm - Sagging: InputDocument4 pagesRectangular Beam 1VB16-300x800mm - Sagging: InputSiti Fatimah MokhtarNo ratings yet

- Design of Isolated Footing: Given DataDocument7 pagesDesign of Isolated Footing: Given Dataradhi_rads89No ratings yet

- Irrigation Division Chunar, Mirzapur: Design of BeamDocument3 pagesIrrigation Division Chunar, Mirzapur: Design of Beamgovind narayan ShuklaNo ratings yet

- Bridge Design: Tulagan, John Lloyd P. BRIDGE ENG'G 7:30 - 9:00 TTHDocument1 pageBridge Design: Tulagan, John Lloyd P. BRIDGE ENG'G 7:30 - 9:00 TTHJohn Lloyd Palaganas TulaganNo ratings yet

- Circular Section Crack Width X NegativeDocument1 pageCircular Section Crack Width X NegativeAbinash Modak50% (2)

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Slab Design Vehicle MovementDocument21 pagesSlab Design Vehicle MovementsivaNo ratings yet

- DomeDocument2 pagesDomeParshwa ConsultancyNo ratings yet

- Detailed Design Design of SlabDocument4 pagesDetailed Design Design of Slabnandheeswaran rNo ratings yet

- Guideline For Soil Bearingcapacity and Geotechnical Investigation of Buildings 2014Document24 pagesGuideline For Soil Bearingcapacity and Geotechnical Investigation of Buildings 2014Anand SoniNo ratings yet

- Sump Design 10KLDocument30 pagesSump Design 10KLAnand SoniNo ratings yet

- Box Culvert EstimateDocument13 pagesBox Culvert EstimateAnand Soni100% (1)

- Head Wall StabilityDocument8 pagesHead Wall StabilityAnand SoniNo ratings yet

- Pier Cap DesignDocument2 pagesPier Cap DesignAnand SoniNo ratings yet

- Pile CapacityDocument3 pagesPile CapacityAnand SoniNo ratings yet

- Strap Footing: Condition ColoumnDocument11 pagesStrap Footing: Condition ColoumnAnand SoniNo ratings yet

- Class A: Items Computations Materials and Estimated Quantities Quanitity Unit Price TotalDocument5 pagesClass A: Items Computations Materials and Estimated Quantities Quanitity Unit Price TotalCamille RamosNo ratings yet

- Design of Structural Steel BeamsDocument63 pagesDesign of Structural Steel BeamskumuthaNo ratings yet

- Hangzhou Xintiandi Factory H Serie ArchitectsDocument3 pagesHangzhou Xintiandi Factory H Serie ArchitectsAndreea CarabusNo ratings yet

- 2 Properties of Ingredients of ConcreteDocument12 pages2 Properties of Ingredients of Concretekiran sreekumarNo ratings yet

- 306-Advanced Structural DesignDocument5 pages306-Advanced Structural Designsibhathulla mohammed pvNo ratings yet

- Calculation Sheet of SiloDocument26 pagesCalculation Sheet of Siloeye4aneye1989No ratings yet

- Sl. No. Description Unit Qty.: Cement Consumption CoefficientDocument19 pagesSl. No. Description Unit Qty.: Cement Consumption CoefficientDeepak ChandolaNo ratings yet

- 2.channel WallDocument40 pages2.channel WallSIVAKUMARNo ratings yet

- Lecture 10 (Shear and Moment Diagram, EtAl)Document29 pagesLecture 10 (Shear and Moment Diagram, EtAl)francisNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodePre SheetNo ratings yet

- Ieee Paper FormatDocument6 pagesIeee Paper FormatAJAY KUMAR T.MNo ratings yet

- Preliminary Beam Size Calculation: Using NSCPDocument5 pagesPreliminary Beam Size Calculation: Using NSCPKarl VencerNo ratings yet

- Cross-Sectional Frame A (DL&LL Computation)Document1 pageCross-Sectional Frame A (DL&LL Computation)Joshua GonzagaNo ratings yet

- F06BOQ3721 2645BOQ Khel Maidan NirmanDocument3 pagesF06BOQ3721 2645BOQ Khel Maidan NirmanDEEPA BAGNo ratings yet

- Introduction To Concrete Technology: April 2015Document5 pagesIntroduction To Concrete Technology: April 2015Waseem AkramNo ratings yet

- Midas Gen: 1. Design ConditionDocument1 pageMidas Gen: 1. Design Conditionengr.geraldkevincatiponNo ratings yet

- Warehouse Civil WorksDocument10 pagesWarehouse Civil WorksKushal BkNo ratings yet

- 2 Pebs Manual PDFDocument59 pages2 Pebs Manual PDFharishram123456No ratings yet

- ReviewModule24 Steel2Document3 pagesReviewModule24 Steel2JM De Guzman TuzonNo ratings yet

- BS en 1991-1-1 (Na) - 2002Document16 pagesBS en 1991-1-1 (Na) - 2002Meyssa DelleciNo ratings yet

- Sheet PileDocument2 pagesSheet PileAdita Rian PradanaNo ratings yet

- Case Study of Twin CableDocument10 pagesCase Study of Twin Cablebhakti ganatraNo ratings yet

- Widebay Trussed Purlin: Varco Pruden BuildingsDocument2 pagesWidebay Trussed Purlin: Varco Pruden Buildingsnikola050884No ratings yet

- Castellated BeamsDocument16 pagesCastellated BeamsPauloAndresSepulveda100% (3)

- Loads & Codes: The Short Length Beam 2.85mDocument1 pageLoads & Codes: The Short Length Beam 2.85mTharmalingam VijayNo ratings yet

- Concrete Technology DissertationDocument6 pagesConcrete Technology DissertationWriteMyCollegePaperBillings100% (1)

- Seismic Design of Cast in Place Concrete Special Structural Walls and Coupling Beams - MoehleDocument41 pagesSeismic Design of Cast in Place Concrete Special Structural Walls and Coupling Beams - MoehleLuis Pablo Ramirez ZavalaNo ratings yet