A320-X Introduction Guide

Uploaded by

carlosjricoA320-X Introduction Guide

Uploaded by

carlosjricoA320-X Introduction Guide

Configuration – Usage – Help

1. Introduction ----------------------------------------------- 3

2. Loading the A320-X ------------------------------------- 5

Setting-up the Aircraft --------------------------------- 5

Loading and Saving a Panel State --------------------- 6

3. A320-X Configuration ------------------------------------ 7

MCDU Option Pages ----------------------------------- 7

Recommended ActiveSky Settings -------------------- 9

4. Hardware Controls Setup ----------------------------- 10

Thrust Lever and Thrust Detent Configuration -------- 10

Steering Tiller ----------------------------------------- 11

Flight Controls ---------------------------------------- 12

5. Using the A320-X -------------------------------------- 13

Panel States ------------------------------------------ 13

Doors ------------------------------------------------- 13

Mouse Button Usage ---------------------------------- 13

2D-Panel Navigation ----------------------------------- 15

Thrust Lever Operation -------------------------------- 16

Failure Simulation ------------------------------------- 17

Weather Radar ---------------------------------------- 19

MCDU Keyboard Entry ------------------------------- 19

Walk-Around ------------------------------------------ 20

Payload Settings -------------------------------------- 20

Fuel Load Settings ------------------------------------ 21

Remote MCDU ---------------------------------------- 22

Flight- and Fuel-Planning ----------------------------- 23

Route Saving and Loading ---------------------------- 24

Weather Information via Datalink --------------------- 25

Hints from A320-rated Pilots -------------------------- 27

6. Help & Support ----------------------------------------- 29

Questions & Answers --------------------------------- 29

Manuals & Documents -------------------------------- 29

Good Memory (VAS) Management -------------------- 29

Credits ------------------------------------------------ 31

Appendix A --------------------------------------------- 32

How to link PFPX to the FMGC ----------------------- 32

Last revision: 19-JAN-17 Page 2 of 37

A320-X Introduction Guide

Configuration – Usage – Help

1. INTRODUCTION

Welcome to the Flight Sim Labs A320-X desktop flight simulation of the A320. The aircraft you have just purchased is one of

the most complex and accurate simulations of a commercial passenger aircraft ever offered to the flight simulation enthusiast.

Whether your interests lie in simply recreating real world A320 flight operations or an in-depth study of the multiple systems

that make up this modern jet airliner, we think you will thoroughly enjoy the A320-X.

According to aviation historians, the A320 aircraft was first conceived in June 1977 as an unnamed single-aisle passenger jet

capable of carrying 130 to 188 passengers and flying at a cruise speed of Mach .84. It would take four more years before the

aircraft was given the A320 designation and another seven years to receive certification by European aviation authorities.

Work on the FSLabs A320-X began in March 2010 right after the very successful launch of the Concorde-X product. Much like

its real-world counterpart, the FSLabs A320-X would undergo a long development process which exceeded six years and

consisted of three major and countless minor design overhauls before it could finally be ”delivered” to its first customers.

You may wonder why the development process for this simulation took so long. The answer is simple. The real-world A320 is

a very complex aircraft.

The A320 utilises a revolutionary fly-by-wire concept that is primarily driven by a side-stick (as opposed to a traditional yoke)

which sends commands as electrical signals to the various components that move the aircraft’s control surfaces. To

accomplish this, there is a need for multiple computers to not only control the flight surfaces but also to continuously check

that pilot inputs do not jeopardise the aircraft, its crew or its passengers by taking it outside a safe flight control envelope. In

addition to the primary computers, the introduction of a glass cockpit concept into this dynamic environment necessitated

adding secondary and even tertiary computers, all communicating with each other via a network of thousands of wires which

are interconnected via terminal blocks and wiring modules. These computers are powered from several different electrical

sources with multiple redundancies built-in to protect against single or multiple equipment failures.

The FSLabs A320-X manages to simulate its real-world counterpart very reliably because it models this wiring connectivity

with extreme accuracy and fidelity, right down to a given aircraft component’s individual wiring connections. In the same

fashion, hydraulic fluids travel the simulated hydraulic piping network with manifold pressures, temperatures and flow control

that allows each component to work (or fail) in the same way as the real-world version.

Relays, switches, diodes, fuses, inverters, pressure switches, fuel, air valves, pumps, filters, generators - even individual circuit

breakers are all modelled and simulated. Voltages, currents and their effects are propagated through the system to blend with

the digital signals transmitted and received, all utilising the same ARINC protocols found in the real aircraft.

In the real A320, all these signals - analogue and digital together - are inputted into and used by over fifty different on-board

computers as part of the fly-by-wire concept. All of these computers are modelled accurately by the FSLabs A320-X to produce

a simulation of the A320 for a desktop computer that is unrivalled in its complexity, depth of systems recreation and accuracy.

Last revision: 19-JAN-17 Page 3 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Airline pilots have always complained that a desktop simulator version of any passenger jet would never be able to accurately

model how the actual aircraft flies. The FSLabs A320-X now makes this possible. A sampling of some of innovations modelled

in the A320-X includes:

• Recreating the “system behind the systems” that simulates the data flow/connections utilising networks in the same

way as the real A320.

• Recreating the real wiring, connectors, relays, switches and servos from the real A320.

• Custom coding of the A320’s Fly-By-Wire (“FBW”) system, utilising complex control loops for maximum accuracy and

realism.

• Complete recreation of the Electronic Flight Control System (“EFCS”).

• Complete recreation of Normal, Alternate and Direct Laws and Mechanical Backup.

• New rolling and sliding coefficients, dynamically loaded when using the A320-X, allowing a realistic handling of the

aircraft in all situations. This allows for realistic breakaway thrust from a stop, realistic single engine taxi operations and

accurate stopping distances on dry, wet, snow and iced surfaces.

These and many other performance characteristics and idiosyncrasies of the real world aircraft have all been faithfully

recreated in the FSLabs A320-X. How was this accomplished?

Engine and Aerodynamics External Modelling

In the early stages of development FSLabs spent considerable time to understand how FS models work so as to identify

strengths and weaknesses of the Prepar3D flight and engine modelling. We found that while the rendering performance of low

and slow subsonic aircraft like GA aircraft was modelled quite accurately, things started to drift with airliners and jet aircraft.

With our previous experience in developing the Concorde-X, we turned into external engine and aerodynamics models,

dividing the work into three different sections, one each for engines, aerodynamics and ground modelling.

For our engine modelling, we used various papers available in literature describing gas turbines performance evaluation. Each

modelling phase is linked to the behaviour of its respective component (compressors, burner, turbines, etc.) and described by

its mapped characteristics. Data collected on their real counterparts were used to fine-tune the overall model via an iterative

process.

For our aerodynamic modelling, we divided the wings into discrete sections and ran various Computational Fluid Dynamics

calculations to establish moment, lift and drag coefficients. Combined with documented tables and data collected on the real

aircraft, this allowed highly accurate aircraft aerodynamics renditions.

The ground model represents the interaction between the wheel system and ground. Other more simplistic approaches try to

do this by fake-adjusting engine parameters to the default P3D friction model, but we were able to model real longitudinal

frictions of the wheels in various runway conditions instead. This was critical to render accurate taxi behaviour with accurate

idle engine thrust which are different and typical for each engine version. While IAE

engine variants accelerate gently around 60T with engine idle, the CFM counterparts

just maintain its taxi speed.

Lateral frictions were also calculated to accurately render single engine taxi and cross

wind landing: now the pilot has to properly de-crab the aircraft before touch down!

Based on real aircraft numbers, we also adapted brake friction coefficients to allow

stop distances under pure wheel braking action to be spot on in dry, wet, snowy and

iced runway.

Last, but not least, brake temperatures were accurately modelled as a result of energy

balancing calculations between energy income given by braking action and thermal

dissipation based on various parameters including temperature difference between

air and discs, chill effect due to relative wind, etc.

These engine and aerodynamics models run in separate threads while you fly the

A320-X. They are continuously computing all necessary parameters so that the overall

result very closely matches actual aircraft performance over a wide array of flight

conditions, including changes relative to International Standard Atmosphere (Delta

ISA), Mach number, pressure altitude and runway conditions. The real beauty of it,

though, is that all this is accomplished with a minimal CPU and VAS footprint, thereby

ensuring a fluid simulation for any of the modern computer system setups.

Last revision: 19-JAN-17 Page 4 of 37

A320-X Introduction Guide

Configuration – Usage – Help

2. LOADING THE A320-X

Use the following two methods to load the A320-X into P3D:

CREATE A NEW FLIGHT

When you create a new flight, you first must decide whether you want the aircraft to be loaded with engines running, or with a

cold & dark cockpit (no power).

• If you want the engines to be running upon loading the A320-X, select the A320 livery of your choice and continue with

creating the desired scenario.

• If you want the A320-X to be completely powerless (cold & dark), choose the Piper Cub as your aircraft on the scenario

setup screen. Then continue with the desired location, date and other settings for the scenario. Press ‘OK’ when done.

As soon as the scenario is loaded, shut down the Piper Cub’s engine (if it is running) and switch to the desired A320-

X livery. The A320-X will then load in a powerless state with both engines off. You will not be able to do anything further

until you energise the aircraft by connecting it to an external power source. For more information, see the section on

“Setting up the Aircraft” below.

LOAD A SAVED FLIGHT

Launch P3D, choose “Load…” from the scenario setup menu and select a flight you have saved which uses the A320-X. The

panel state and the livery you were using when you saved the flight will be loaded.

Note: It is not recommended to switch from one A320-X livery to another within the same flight. You should instead close P3D

and create or load a new flight.

It is also recommended to turn off the P3D internal crash detection. The high aircraft system complexity will make the

automated reload after a detected crash unreliable for further flight.

Setting-Up the Aircraft

After the A320-X is loaded into P3D, you will have either the engines running or a completely cold and dark cockpit.

To get some external power while the aircraft is still cold and dark, you may use the captain’s MCDU (SHIFT+6) to simulate

contacting the ground crew:

Press and hold the ‘BRT’-key on the MCDU until you see text being displayed.

Select ‘OPTIONS>’, then ‘<EXT CTRLS’ to get to the external connections menu providing the following options:

• GPU (Ground Power Unit) - Supplies the aircraft with

ground power without the need to start and run the APU

while parked.

• Air Starter – Provides external pressurised air to enable an

engine start without the APU.

• GND A/C – Provides conditioned external air to the aircraft

to control cabin temperature while parked at the gate.

• GND Chocks – Places chocks around the nose- and main

gear to prevent aircraft movement. Chocks are always used

independent of the parking brake.

Last revision: 19-JAN-17 Page 5 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Loading and Saving a Panel State

The A320-X offers a panel state loading and saving functionality, which means settings and states for aircraft systems and

cockpit switches can be saved, and loaded again later.

You can either save and load a panel state manually, or load a panel state that was automatically saved after using the P3D

“save flight” functionality. Each time you save a flight in P3D using the A320-X, the software will create a saved panel state

file.

SAVING A PANEL STATE

Locate the “Add-Ons” tab on the P3D menu

bar. Within that menu you will see the

“FSLabs” entry, containing the saving function

“*Save…”.

First press the “NEW” button, enter a name

and description for the panel state, then press

“OK”.

Press “OK” a second time to close the

window.

1 5

LOADING A PANEL STATE

Access the “FSLabs” menu mentioned above via the P3D menu bar. Press “*Load…” and then choose the desired panel state.

Last revision: 19-JAN-17 Page 6 of 37

A320-X Introduction Guide

Configuration – Usage – Help

3. A320-X CONFIGURATION

MCDU Option Pages

The Master Control Display Unit (MCDU) can be used to change

various aircraft specific settings, to enable or arm system failures

and to perform various tasks such as opening doors, fuelling or

loading the aircraft.

To access the configuration option pages, use either the

pop-up MCDU in the 2D panel or the MCDU within the

virtual cockpit.

• If the display of the Captain’s MCDU is blank, press and

hold the “BRT” button (1) to turn the unit on.

• On the MCDU press the “MCDU MENU” button (2), then

“OPTIONS >” to get the options page:

1

2

Page 1 / 2

MAINT UNITS

Perform maintenance actions such as re- Set the units of measurement for:

stowing a deployed Ram Air Turbine, re-filling • Air temperature (Degrees °F / °C)

engine oil or resetting electrical system • Weight (Imperial / Metric)

components. • Liquid volume (Litres / Quarts)

This can only be done on ground. • Barometric pressure (inHg / hPa)

EFIS FWC/SDAC

Optional synchronisation of the barometric • See the FWC flight phase

pressure switches between Captain and First • Adjust height callouts

Officer. • V ONE INST – Provides a system-generated callout when

This can be used to simulate the other reaching the V1 decision speed.

crewmember setting the same QNH as you do. • PR MON INST – If inactive: Supresses ADR system faults

caused by sudden air pressure changes due to

unrealistic weather data.

• PIN PROG – Enables or disables a new “cabin ready”

memo logic that integrates the message into the take-off

or landing config tests.

FIRE FMGC

Refill any fire suppression agent bottle using A couple of options for the Flight Management and Guidance

this menu. Computer:

• Pause at T/D – Triggers a pause in the simulation at the

start point of the descent.

• Max Routes – Sets the max. number of routes that can be

stored in the FMGC.

• ARPT RWY Limit – Sets the min. RWY length required to

display an airport on the Navigation Display (in metres).

FUEL ADIRUS

Quickly add or remove fuel in various fuel tanks Allows you to influence the time it takes to align the inertial

or as a total fuel amount. platforms and sensors.

For details, see chapter 5. Default option is set to “Realistic”, meaning the alignment time will

vary depending on latitude. “Fast” will accelerate the alignment

process considerably.

PAYLOAD ENGINES

Sets the payload of the aircraft. Check the engine running hours or re-connect a disconnected IDG

For details, see chapter 5. (Integrated Drive Generator). This can only be done on ground

with engines off.

Last revision: 19-JAN-17 Page 7 of 37

A320-X Introduction Guide

Configuration – Usage – Help

EXT CTRLS DOORS

Offers external services and connections Open and close doors on the main deck and the lower deck.

performed by the ground crew. For details, see chapter 5.

For details, see chapter 2.

Page 2 / 3

EFCS CIDS

Allows to adjust the tolerance for flight control Different options to set conditions to be met in order to display the

movement before the autopilot disconnects. “Cabin Ready” message.

A value of 0 means no tolerance, 1 equals the The setting “AUTO” will take the passenger load and other factors

full movement before a disconnect happens. into account, before the cabin crew will send the ready message.

Using the setting “READY”, the cabin will always be ready.

AEVC

Enable or disable the self test performed for the

blower fans on start-up from a cold and dark

state.

Page 3 / 3

SEAT SELECTION

Set this selection to F/O if you intend to fly sitting on the first officer side. Note that this will not automatically switch

the viewpoint in the virtual cockpit. It will however set which of the two sidesticks gets animated.

SOUNDS

Adjust all custom FSLabs ambient sound

levels. Engine sound levels remain unaffected.

CONTROLS DISPLAYS

Configure thrust control and nose wheel Change the refresh rate of the display units. Lower values may

steering. See chapter 4 for more information. help to improve the overall framerate of P3D.

You may also change the time required for the DU self-test upon

powering up the aircraft.

HTTP SVR DEBUG

Allows you to change the port setting used for Used for troubleshooting and support purposes only.

the remote MCDU and Fuel Panel.

You may also turn off this connectivity if

desired.

Last revision: 19-JAN-17 Page 8 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Recommended Active Sky Settings

For a realistic weather experience, FSLabs encourages users to fly using a programme that provides real-time weather

information to the simulation. However, we strongly recommend that you adjust the turbulence settings on any of these

programmes.

Turbulence effects within P3D and the various aftermarket weather programmes tend to be stronger and interact with the

airframe unrealistically when compared to real aircraft. This has the undesired result of negatively affecting the autopilot that

has been programmed to real-world specifications.

Active Sky Next and Active Sky 16 are FSLabs preferred weather programmes as they deliver precipitation data to the A320-

X’s weather radar.

RECOMMENDED SETTINGS FOR ACTIVE SKY

Active Sky Next

Turbulence Scale: 30%

Enhanced Turbulence: Off

Active Sky 16

Max Cloud Turbulence: 20%

Max Wind Turbulence: 20%

Turbulence Scale Effect: 10%

Enhanced Turbulence: Off

Last revision: 19-JAN-17 Page 9 of 37

A320-X Introduction Guide

Configuration – Usage – Help

4. HARDWARE CONTROLS SETUP

Thrust Lever and Thrust Detent Configuration

The default thrust lever configuration is set for a single joystick axis that controls both throttle levers simultaneously. If this is

the configuration you have and you do not wish to alter the position of the thrust detents, then you may skip this thrust lever

configuration chapter.

If, however, you use one hardware lever per engine or you utilise your hardware to command reverse thrust, then use the

following MCDU setup functions to configure the A320 thrust levers:

1. Navigate to the option pages as described in the previous chapter.

2. Press the left or right pointing arrow key to go to the second options page.

3. Press the LSK next to ‘< CONTROLS’

4. Select ‘<THRUST LEVERS’ to access the thrust lever control settings.

The following settings are available:

Number of throttle levers – (1)

Select the number of joystick throttle levers you use for the

engines, one or two levers.

1

Enable reverse range – (2)

Enables you to use your joystick engine levers for reverse 2

thrust by setting a range.

3

Visual cues for thrust detents – (3)

Enables or disables a visual text prompt at the top of the 4

simulator screen indicating in which throttle detent the levers

have been placed. 5

Set detent zones – (4)

Allows for fine-tuning of the throttle detents along your thrust Note: Standard detent settings should be fine for most

lever(s) axis (or axes). users. Try them out first before you adjust any values.

Reset to default settings – (5)

Reverts to standard detent settings.

HOW TO SET CUSTOM DETENT ZONES:

1 2

Note: In this particular example, the forward idle detent is adjusted, to

make the detent larger so that more of the available movement range

of the joystick lever is used.

1. Select the “SET DETENT ZONES” option as described

above.

2. If using two throttle levers, decide which one you want

to adjust (1)

3. Move your joystick lever to the position you wish to set

as the “beginning” of the detent you want to change.

4. Press the Line Select Key 1R (2) to copy this position 3

into the scratch pad (3).

5. Move the joystick lever forward to the desired “end” of

the detent.

6. Again press the LSK 1R to copy this value into the 4

scratchpad behind the first one (4).

7. Press the LSK 4L to change the values for the detent 5

(5).

Last revision: 19-JAN-17 Page 10 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Steering Tiller

The A320-X has the ability to simulate the use of a small hand operated steering wheel called a “tiller” to steer the aircraft

while taxiing on the ground (“Nose Wheel Steering” or “NWS”). You can use the Options page in the MCDU to set this

functionality based on your hardware setup. The real A320 can be steered by either the rudder pedals or the tiller. While the

tiller offers the pilots full deflection (left to right movement) of the nose wheel, the rudder pedals are limited to turning the nose

wheel only 6° to either side. Pilots use the tiller to steer the aircraft during taxi and the rudder pedals to steer the aircraft down

the runway on the take-off roll.

For maximum realism, the rudder and the tiller should each have their own axis assigned. A popular way to do this is to utilise

the twist axis of a joystick (assuming your hardware has such an axis) to control the tiller and your rudder pedals to control the

rudder axis. However, if only a single axis is available for steering on ground, then the A320-X offers a configuration option for

that scenario as well.

To access the steering options, select the MCDU option page as described in chapter 3.

Select ‘<CONTROLS’, then ‘RUDDER PEDALS>’

SINGLE AXIS SETUP

"I only have rudder pedals - I cannot assign any separate joystick

axis for the steering tiller"

If you only have a rudder axis (either on the joystick or through the

rudder pedals) which you have assigned to control rudders in P3D,

then set Pedals Control NWS to “ON” using LSK 2L on the Rudder

Pedals Option Page (1). This results in the rudder pedals controlling

the rudder the same way you are used to in the simulator. They will 1

also control NWS but their effect is limited to +/- 6 degrees turn, just

like the real A320. However, by pressing the PEDAL DISC key (by 2

default, this is the "comma" key), the rudder pedals stop controlling

the rudder axis and instead act as the steering tiller. The rudder

pedals will provide full NWS. You can see the tiller turning in the

Virtual Cockpit as you move your rudder pedals. When you release Single axis setup for rudder pedals and tiller control.

the PEDAL DISC key, the rudder pedals will go back to moving the

rudder and will be limited to the +/- 6 degrees for the nose wheel.

Choose whether you need to keep the PEDALS DISC button

depressed to act as tiller (2), or if it works as an on/off-switch.

DUAL AXIS SETUP

"I have rudder pedals and I can assign a separate steering tiller axis

through FSUIPC"

If you have rudder pedals and you can assign a different joystick

axis (through FSUIPC’s "Steering Set" functionality) to act as a

tiller, then set Pedals Control NWS to “OFF” using LSK 2L on the

Rudder Pedal Option Page (3). This results in the rudder pedals

only controlling the rudder axis and NWS to that +/- 6 degree limit. 3

The joystick axis that you set up in FSUIPC will now serve as your

steering tiller while on the ground, providing full deflection of the Dual axis setup for rudder pedals and tiller control.

NWS. In other words, you will have two axes set up in P3D, one for

the rudder and one for the tiller.

In addition, you will still have the PEDAL DISC functionality (the

“comma” key), only under this setup, it will serve to disconnect the

rudder pedals from the +/- 6° limit. This means that while the

PEDAL DISC button is depressed, moving the rudder pedal axis

will have no effect on the NWS and will only cause the rudder of the

aircraft to move. This is useful to test the rudder control while taxiing

and not having the NWS move. When you release the PEDAL DISC

button, the rudder pedals will go back to moving the NWS.

Note: If you need to re-assign the ‘PEDAL DISC’ button to a different key, you may do so via the P3D menu bar. Select the

‘Add-Ons’ tab, then ‘FSLabs’, followed by ‘Keyboard Commands’.

Last revision: 19-JAN-17 Page 11 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Flight Controls

To get the flight control response to resemble the real aircraft as close as possible, use these recommended settings either in

P3D or within FSUIPC. The null zones are of special importance, because the flight control computers need an uninterrupted

“neutral” setting of the flight stick to perform their magic flawlessly.

P3D SETTINGS

Use these P3D sensitivity and null zone settings if you are not using FSUIPC to set up your stick and throttle:

FSUIPC SETTINGS

Use these recommended settings for null zones if you use FSUIPC to configure your stick axes:

Ailerons: 12% of the full movement range number.

Elevator: 16% of the full movement range number.

It will look like this, if your flight controls feature the same number (16384) for

full movement to one side. If that number differs, then adjust the null zones

accordingly.

Last revision: 19-JAN-17 Page 12 of 37

A320-X Introduction Guide

Configuration – Usage – Help

5. USING THE A320-X

Panel States

The A320-X will save the current panel state whenever you save a flight. If you then reload a saved flight, the panel state at

the time of the save will load along with it. This is possible on both ground as well as while airborne.

Doors

You may wish to open or close cabin or cargo doors.

Select ‘DOORS>’ on the MCDU option page to get to the door control options.

Note: The blue text below the door label always describes the action after the key next to it is pressed. This means if the blue

text says “OPEN”, then the door is currently closed and vice versa.

Mouse Button Usage

In order to provide for easy manipulation of the many pushbuttons, rotating switches and handles you will find in the A320-X’s

panels, the mouse handling has received some changes compared to the default P3D aircraft.

LEFT / RIGHT

Knobs which allow to be rotated to the left and right, can be moved accordingly using the left and right mouse buttons or the

scroll wheel.

Knobs that can be rotated AND pushed or pulled, have dedicated clickspots to allow rotating them left or right with mouse

button clicks using the 2D panel. However, these clickspots are not available in the Virtual Cockpit. In VC mode these knobs

can only be rotated using the scroll wheel.

PUSH / PULL

Whenever a knob can be pushed or pulled, pushing is always accomplished with a left-click, and pulling with a right-click.

LIFT / MOVE

Certain switches need to be lifted before they can be moved to a different position. This is done to prevent unintentional

movement by accidently hitting the switch. One example is the two fuel cutoff switches, one for each engine.

To move these switches, you must first right-click to lift the switch (and keep the mouse button pressed), then left-click to move

it.

GUARDED PUSHBUTTON SWITCH

Certain switches have protective covers to

prevent them from being accidentally pressed.

These are referred to as guarded switches. In

order to access these switches, the guards

must first be lifted up out of the way.

First click and hold the guard with your right

mouse button. While continuing to hold the

right button, click once with the left mouse

button. The guard will move back to its original

position as soon as the right mouse button is

Left: Guarded pushbutton in normal (off) state.

released.

Right: Guarded pushbutton with the guard lifted and the button pressed.

Last revision: 19-JAN-17 Page 13 of 37

A320-X Introduction Guide

Configuration – Usage – Help

FLIGHT CONTROL UNIT (FCU) – 2D PANEL

There are four large rotating knobs, or “selectors” as they are also called, on the A320’s Flight Control Unit (FCU) that are

used to manually select or change the aircraft’s speed, heading, altitude and vertical speed. FSLabs have designed specific

mouse actions which allow you to easily manipulate these selectors for efficient use during the flight. In the figure below, the

numbered red boxes show the various mouse click areas around the selectors.

6

1 2 8

5

1 3 1 2 4 2 5 7 5 8 9 8

1 2 5 8

(1) Select speed by rotating the selector (5) Select altitude by rotating the selector (8) Select vertical speed by

with left or right click, or using the with left or right click, or by using the rotating the selector with left-

mouse wheel mouse wheel. or right-click, or by using the

(2) Select heading by rotating the selector (6) Right or left click to switch between mouse wheel

with left- or right-click, or using the 100ft and 1000ft altitude increments. (9) Select vertical speed mode:

mouse wheel (7) Select open climb/descend: Right-click to pull the selector.

(3) Selected speed: Right-click to pull the Right-click to pull the selector. Select level-off:

selector. Select managed climb/descend: Left-click to push the selector

Managed speed: Left-click to push the Left-click to push the selector. and level-off the aircraft.

selector.

(4) Select heading mode: Right-click to pull

Select NAV mode: Left-click to push to

follow the flightplan.

FLIGHT CONTROL UNIT (FCU) – VIRTUAL COCKPIT

While the function of the selectors is the same as in the 2D cockpit, the mouse actions are slightly different. You must use the

mouse wheel in the Virtual Cockpit to rotate the selectors (i.e. left and right clicking will not rotate the selector). In the figure

below, the numbered red boxes show the various mouse areas around the selectors.

5

3

2

1

(1) Select speed by rotating the selector (3) Select altitude by rotating the selector (5) Select vertical speed by

using the mouse wheel. using the mouse wheel. rotating the selector using the

Selected speed mode: Select open climb/descend: mouse wheel.

Right click to pull the selector. Right click to pull the selector. Select vertical speed mode:

Managed speed mode: Select managed climb/descend: Right click to pull the selector.

Left click to push the selector. Left click to push the selector. Select level-off:

(2) Select heading by rotating the selector (4) Right or left click the outer ring of the Left click to push the selector

using the mouse wheel. selector to switch between 100ft and and level-off the aircraft.

Select heading mode: Right click to pull 1000ft altitude increments.

the selector.

Select NAV mode: Left click to push

the selector.

Last revision: 19-JAN-17 Page 14 of 37

A320-X Introduction Guide

Configuration – Usage – Help

2D-Panel Navigation

The main 2D-panel provides various mouse click-spots for easy access to sub-panels. Some of these click-spots have different

actions for the left and right mouse buttons. All of the sub-panels, once opened, may be undocked and moved around the

screen and/or to additional monitors.

3

8 8 8 5

2

6 4

(1) Left-click to open the overhead (4) Left-click to open the lower ECAM (6) Left-click to move the entire panel

panel. display and the ECAM control upwards.

(2) Left-click to open the left panel. (7) Left-click to switch to the F/O

(Captain’s) MCDU. (5) Left-click to open the upper gear panel.

Right-click to open the right (First panel and the clock. (8) Left-click to enlarge the display.

Officer’s) MCDU. Right-click to open the entire gear

(3) Left-click to open the centre panel.

pedestal.

CLOSING A POP-UP PANEL

Find the X-symbol on any pop-up

panel to close it.

Last revision: 19-JAN-17 Page 15 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Thrust Lever Operation

The thrust levers are the main interface between the Flight Management Guidance Computer (FMGC), the Full Authority

Digital Engine Control System (FADEC) and the flight crew.

The A320 provides two thrust levers to control engine thrust, one per engine, as any other twin-engine aircraft. The range

goes from full reverse thrust to maximum take-off thrust.

In addition, the A320’s thrust levers feature various thrust “detents”. A detent is a pre-set position along the thrust lever’s

movement range that sets a particular thrust during a specific phase or condition of flight. The flight crew interacts with the

A320’s auto thrust system by moving the thrust levers through the various detents.

WHAT ARE THESE DETENTS?

The following detents are available:

Go Around / Max T.O. (TOGA) – (1)

This thrust setting commands maximum go around or take-

off power at all times.

1

Max Cont (MCT) / Flex T.O. (FLX) – (2)

The flex setting is used for reduced thrust take-off, called

flex take-off (FLX). When airborne this setting is also used 2

in case of a one-engine-out situation to get the maximum

thrust allowed for the remaining engine during climb and

cruise (MCT). 3

Max Climb (CL) – (3)

This is the climb thrust setting. The thrust levers remain in

this detent during the entire flight under normal conditions,

whenever the autothrust system commands thrust and the

flight crew does not need to interfere with auto thrust

system.

Idle Thrust (0) – (4)

The auto thrust system is ALWAYS disconnected when the 4

thrust levers are moved into the idle detent.

Rev Idle (REV) – (5) 5

Reverse doors open with the engines at idle thrust. If in

landing phase, this will also extend ground spoilers if they

have not been armed before touchdown.

Note: There is a maximum reverse setting, but this is simply

the physical stop for the thrust levers. This commands

maximum reverse thrust only without any other system

connections.

ADJUSTING THRUST USING A HARDWARE THROTTLE LEVER (JOYSTICK)

Using a USB joystick lever to control thrust, the thrust levers will move through the entire thrust range including the thrust

detents. Each detent will be clearly audible as soon as the levers snap into it.

If you wish to use one joystick lever per engine or use the same axis to control reverse thrust, adjust the thrust lever settings

as described in chapter 3.

ADJUSTING THRUST USING THE KEYBOARD

You may also use your keyboard to move the thrust levers, utilising the F1 – F4 keys.

• F1 and F4: Use these two keys to move the thrust levers from one detent to the next

• F2 and F3: Use these two keys to move the thrust levers between the detents.

Example: For take-off press F3 repeatedly to move the thrust levers to 50% N1. When the engines have stabilised, press F4

twice to move the levers to the FLX detent for a reduced thrust take-off.

Last revision: 19-JAN-17 Page 16 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Failure Simulation

The A320-X offers the possibility to experience and deal with system failures in various system categories. This chapter

describes how they can be armed or activated. Failures will not take place unless you specifically activate them. The A320 will

perform flawlessly unless and until you decide to allow for failures to take place via the MCDU.

To access the failure menu:

1. On the MCDU press the ‘MCDU MENU’ button.

2. Select ‘FAILURES>’ using the LSK 4R.

3. The MCDU then let’s you choose to list the armed failures, as well as the already active ones. The latter obviously

shows nothing if you haven’t set any failures.

CREATE A NEW SYSTEM FAILURE

Once you are in the MCDU failure menu:

1. Select ‘<ARMED’ to create a new failure condition.

2. Since there’s no armed failure present, the MCDU will automatically present to the ‘New Condition’-page.

From this page, you can set a new failure and its activation conditions:

• First, select the empty brackets on the left with the LSK 1L

to get a list of available failures (1).

• Next, choose one or more of the conditions for this failure to

1

activate:

• SPD (2) – Enter a value for knots IAS. Precede the value

with a + symbol to create “at or above”, or a – symbol for

“at or below”.

Valid range: 0 -399 (kts)

• ALT (3) – Enter a value for altitude in feet MSL. Precede

the value with a + symbol to create “at or above”, or a –

2

symbol for “at or below”.

3

Valid range: 0 – 41000 (ft)

• TIME DELAY (4) – Enter a value for seconds. Precede 4

the value with a + symbol to create “at or after”, or a –

symbol for “at or before”.

5

Valid range: 0 – 3600000 (seconds)

• Hit ‘INSERT*’ to add this failure to the ‘ARMED’ list.

• Or hit ‘ACTIVATE NOW’ (5) to immediately activate the

selected failure.

Further options:

• You can also create a random time at which the failure will occur by inserting a time delay condition. To do this, use

the ‘OVFY’-key (located at the bottom right of the MCDU keyboard) to insert the OVFY-symbol instead of a number

value. This will create a random time delay between 0 seconds and 8 hours at which the failure will be triggered.

• The systems are categorised using the industry standard ATA numbering system. You may enter a chapter number

into the empty brackets on the left side, which will display just the failures for that chapter.

• Up to 5 failures can be associated with each condition or set of conditions.

• If you wish to get a randomly chosen system to fail with the condition you set, you may do so by placing the ‘OVFY’-

symbol into the empty brackets on the left side. This will then display as ‘RANDOM FAILURE’.

• Use the ‘OVFLY’-symbol followed by any number from 1 to 5 to choose the number of random systems to fail.

• You may also choose a random system within a specific chapter by specifying the ATA chapter number:

Example: D2ATA 24

This will choose 2 random systems within the electrical power category (ATA24). Note that there is a space required

before the chapter number.

Last revision: 19-JAN-17 Page 17 of 37

A320-X Introduction Guide

Configuration – Usage – Help

CLEARING A FAILURE

• To clear an armed or an active failure, display either the armed or active list and use the ‘CLR’-button to delete the

desired failure.

• A ‘CLEAR ALL’ command is provided to clear all failures on the armed OR active list.

DEALING WITH A SYSTEM FAILURE

The A320 provides for a convenient method to

work through system failures. “ECAM Action”

messages are shown on the upper ECAM

display when a system failure occurs. These

procedures allow for troubleshooting the

problem.

2

1

(1) All fault messages are displayed on this

part of the upper ECAM display. It contains

the fault message itself in amber followed

by a list of immediate actions to perform in

blue. If there are multiple faults, each one

will have its own section listing the fault and

the action list.

(2) This section shows a summary of the

system categories affected by the fault. 3

(3) On the right side of the “Status” page (on

the lower ECAM display), you will find a list 4

of all inoperative systems.

(4) On the left side of the Status page, a list

appears which advises you of actions

which should be taken and any

consequences resulting from inoperative

systems.

(5) The ECAM Control Panel (ECP) is used to

switch between system pages and to work

through the system failures:

STS – Press this button to access the

Status-Page.

CLR – Press the clear-button to clear a

fault message and proceed to the next

one(if there are multiple faults).

Last revision: 19-JAN-17 Page 18 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Weather Radar

Weather radar is functional in the FSLabs A320-X when P3D is run in conjunction with ActiveSky Next or ActiveSky 2016 by

HiFi-Sim.

For more information including buying options, please go to the HiFi Sim website at: www.hifisimtech.com

When coupled with ActiveSky Next, the A320-X will display weather radar returns on its Navigation Display indicating

precipitation intensity. The radar will also provide you with information on turbulence as well as predictive wind shear

avoidance. The radar system can be adjusted for Gain (sensitivity) as well as Tilt (position of the radar antenna up or down).

The weather radar panel is located on the centre pedestal

right next to the captain’s seat. It offers the following

settings:

7

SYS – (1) 3

6

Turns on the radar by moving the switch to either position

1 or 2.

4 5

MODE – (2)

Selects the mode of operation: 2

WX – Displays precipitation information

WX+T – Displays precipitation and turbulence information 1

TURB – Displays turbulence areas only

MAP – Ground mapping function (not implemented) The weather radar panel located on the centre pedestal.

TILT – (3)

Adjusts the radar antenna’s tilt. MULTISCAN – (6)

When set to AUTO the radar will adjust gain and tilt

GAIN – (4) automatically. With this setting the GAIN and TILT selectors

Adjusts the receiver’s sensitivity. have no effect.

PWS – (5) GCS – (7)

Activates the Predictive Windshear System. Turns ground clutter suppression off or sets it to auto. (not

implemented)

MCDU Keyboard Entry

Text can be entered into the MCDU by using your PC’s 1

hardware keyboard. To enable the keyboard entry method,

click the white dot at the top left of the MCDU (1). The

white dot will turn yellow, which enables you to write into

the scratchpad (2) using your keyboard.

Click the same (now yellow) dot again to disable keyboard

entry.

Last revision: 19-JAN-17 Page 19 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Walk-Around

While it is unnecessary to perform a walk around as the types of abnormal conditions a pilot is looking for are not simulated,

if you decide to venture outside the aircraft before the flight, you will discover more of the depth of the FSLabs A320-X’s

external visual and aural modelling.

TEXT LABELS

All text labels on the outside of the aircraft are designed to be legible from various distances. You will find accurate labelling

around equipment, on access panels, on nose wheel and cargo doors and engines.

Text detail on the engine cowling doors

SOUNDS

The FSLabs A320-X provides an innovative 3D sound design that lets you experience sounds spatially. This means that how

you hear various sounds will be dependent on what your proximity is to those sounds. For example, the sound of a running

APU will be much louder if you are underneath the A320-X’s tail than it will be under the nose. As you move left and right or

front and back from the source, the sound will change. This is so realistic that if you have the brake fans running while checking

the main gear, you will wish you had brought ear protection!

This aural experience is also carried into the cabin. Sounds will be heard wherever they are audible in the real aircraft.

Payload Settings

This option page allows for dynamic adjustment of the

aircraft’s payload, by either adjusting the ZFW entry, or by

making separate adjustments for each cabin section and

cargo compartment. 1 4

The following functions are available: 2

Zero Fuel Weight (ZFW) – (1)

Set the desired ZFW. The load will be distributed 5

automatically. 3

Crew Complement – (2)

Sets the number of crewmembers. 2 is the minimum value.

Gross weight, ZFW CG and current CG are also displayed.

Passenger Compartments – (3)

The total number of passengers is 168.

GW/CG – (4) Cargo Compartments – (5)

Displays gross weight and current Centre of Gravity (CG). For cargo loading the A320 features 4 compartments. CP1 is

The CG is calculated by the FMGC by utilising the fuel load located forward of the wing while CP3, 4 and 5 are located aft

and payload distribution. of the wing.

Last revision: 19-JAN-17 Page 20 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Fuel Load Settings

VIA MCDU PAGE

The easiest way to change the fuel load is by using the

refuelling options page in the MCDU.

You may set any desired fuel amount, either by entering a value

at the individual fuel tanks (1), or by setting the total amount (2).

Enter the amount of fuel via the MCDU’s numeric keypad. The

amount will be displayed on the MCDU’s scratchpad. To enter 1

the amount of fuel to an individual tank, click the appropriate

1

Line Select Key next to the fuel tank. If you are entering a total

fuel amount, click the 6L LSK. The total fuel will automatically

be distributed between all five of the A320-X’s fuel tanks.

Note: These settings are fully dynamic and may even be

changed while airborne. 2

REMOTE REFUELLING PANEL

On the real A320, a refuelling panel is located on the fuselage beneath the right wing. The FSLabs A320-X includes an exact

replication of this refuelling panel that is fully functional and can simulate the fuelling or de-fuelling procedure.

The refuelling panel is only accessible through a web browser. Currently, FSLabs supports the following browsers: Microsoft

Internet Explorer, Edge, Mozilla Firefox and Google Chrome. Apple iPad, iPhone and OSX users may download the Google

Chrome browser from the App Store. The browser can be located on the same computer as P3D or any PC, tablet or phone

that is connected to the same network as the computer running P3D.

Use one of the following addresses to display the panel:

• If the browser is located on the same computer as

P3D:

localhost:8080/Panels/800VU/800VU.html

• If the browser is located on a remote PC or tablet:

192.168.1.1:8080/Panels/800VU/800VU.html

Note: You must replace the IP address in bold

print with your P3D computer’s IP address. 4 4 4

The following functions are available: 3 3 3

Fuel Quantity Selection – (1)

Set the desired fuel amount by toggling the switch

between ‘DEC’ (decrease) and ‘INC’ (increase).

2 5

Mode Select – (2)

Lift the guard on the mode switch up for refuelling or down

for defueling. This will start the fuel flow in the selected

direction.

Refuel Valves – (3) 1

The ‘NORM’ setting is sufficient for normal refuelling

operation. You can opt to manually open and close the

three refuel valves.

Screenshot of the Remote Refuelling Panel taken on an iPad

High Level Lights and Test using the Chrome browser

These lights will light up as soon as a tank has reached

maximum capacity (4). Use the test switch to test these

lights for proper indication (5).

Note: In order for the refuelling to work, the aircraft’s engines must be turned off and external or APU power established.

Last revision: 19-JAN-17 Page 21 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Remote MCDU

The FSLabs A320-X offers you the ability to run the MCDU remotely as well. As the Remote Refuelling Panel described above,

the remote MCDU unit is only accessible through a web browser that can be on the same computer as P3D or on a networked

PC, tablet or other device. Currently, FSLabs supports the following browsers: Microsoft Internet Explorer, Edge, Mozilla

Firefox and Google Chrome. Apple iPad, iPhone and OSX users may download the Google Chrome browser from the App

Store.

Use one of the following addresses to display the

MCDU:

• If the browser is located on the same computer

as P3D, enter the following address:

localhost:8080/mcdu/mcdu.html

• If the browser is located on a remote PC or

other device which is on the same network as

the computer running P3D, enter the following

address:

192.168.1.1:8080/mcdu/mcdu.html

Note: You must replace the IP address in bold

print with your P3D computer’s IP address.

You may switch between the Captain’s and First

Officer’s MCDUs by clicking the white round buttons at

the top. The button then turns green and indicates

whether the left or right MCDU is displayed.

Note: The brightness control buttons on the remote

MCDU are not functional. Use your device’s screen

brightness settings instead.

Screenshot of the MCDU taken on an iPad using the Chrome browser

Last revision: 19-JAN-17 Page 22 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Flight- and Fuel-Planning

The A320-X offers you several convenient methods to perform flight- and fuel planning. For flight planning, the MCDU can be

linked to an external flight planning software (such as Professional Flight Planner X (“PFPX”). Generating a route this way

simulates a flight dispatch service sending a flightplan directly to the aircraft via datalink. A second, similar method is to utilise

the MCDU to search for suitable flight plans on the internet and online ATC networks. Generating a route this way simulates

accessing externally stored company flightplans via datalink. For fuel planning, the FMGC is capable of calculating the fuel

required for flight plans entered utilising either method.

These functions (called “AOC” functions) are available on the actual A320 aircraft and are replicated in FSLabs’ A320-X to

provide the user with an easy way of generating a realistic flight plan along with the possibility to do fuel planning.

FLIGHTPLAN REQUEST UTILISING ONLINE SEARCH

There are three different methods to utilise the online search method described above for acquiring a flight plan on the INIT A

page of the FMGC:

(1) Entering the Identifiers for the Departure and

Destination Aerodromes. Enter the ICAO identifiers

into the scratchpad for the departure and arrival

airports. The identifiers should be separated by a 3 1

slash and there should be no spaces (for example,

LGAV/LOWW). Press LSK 1R (1) to enter into the 4

FROM/TO field (Note: You should NOT enter

anything into the CO RTE or FLT NBR fields). 2

Press the LSK 2R at ‘INIT REQUEST’ (4) to initiate

the flight plan request. If a route is found, the CO RTE

field in the upper left of the display will be populated

with a route name and “AOC ACT F-PLN UPLINK” will

appear in the MCDU’s scratchpad. This will indicate

that a flightplan has been loaded into the MCDU

(without runway, SID or STAR information which you

may still insert).

(2) Entering a Flight Number. This will look for a pre- (3) Entering a Company Route Designator. This will load

filed or filed flightplan on the VATSIM or IVAO a previously saved flightplan using its corresponding CO

network servers. Enter the exact flight number ROUTE designator.

including the airline identifier for a filed or pre-filed

flight on VATSIM or IVAO into the scratchpad (for

example AEE880). Press LSK 3L to enter it into the

FLT NBR field (Note: You should NOT enter anything

into the CO RTE or FROM/TO fields).

Select ‘INIT REQUEST’ (4) to initiate the flight plan

request. You’ll see the same message as described

in option 1.

RECEIVING A FLIGHTPLAN FROM PFPX

The A320-X can load flight plans created with the flight planning tool “Professional Flight Planner X”, developed by

FlightSimSoft. This is implemented in a way which simulates a ground station sending a flightplan to the aircraft using a satellite

datalink.

You may use this service if PFPX is installed on the same computer as P3D, or on another computer within your network.

Check the tutorial at the end of this document to learn how to transfer

a flightplan from PFPX to the A320-X.

PFPX can be purchased directly at the FlightSimSoft website:

www.flightsimsoft.com

Last revision: 19-JAN-17 Page 23 of 37

A320-X Introduction Guide

Configuration – Usage – Help

FMGC FUEL PLANNING

If you do not own any flight planning software, you may use the built-in fuel planning function the A320’s FMGC provides. It

will calculate fuel requirements according to the active flightplan.

Access the fuel planning function on the INIT B page of the

FMGC. You will see the corresponding prompt next to the

LSK 3R (1) after Zero Fuel Weight and ZFW Centre of

Gravity have been entered at LSK 1R.

Note: Engines need to be off for this to work. Also make sure that

you enter the route as complete as possible including the SID and

expected STAR and approach. This will allow for a precise 1

calculation.

Using the Fuel Planning function only computes the required fuel

estimates.

You must separately load the fuel as in the real aircraft! See

Chapter 5 for detailed instructions.

Route Saving and Loading

DATA PAGE

The FMGC contains a function to save pilot-generated routes.

Use the MCDU to access the DATA INDEX page:

1. Press the ‘DATA’ key on the MCDU.

nd

2. Use the left or right arrow key to go to the 2 page.

3. Select the LSK next to ‘PILOTS ROUTES’ to access the NEW ROUTE page:

(4) Type in a name for the route you want to save.

(5) Press the LSK 2L to store the route presently 4

being the active flightplan.

5

(6) To load a previously saved route, use the ‘INIT’

page’s ‘CO ROUTE’ entry.

Type in the name under which you saved the

6

route into the scratchpad and press LSK 1L.

Note: To increase the number of possible stored routes, go to the FMGC options page. For details see chapter 4.

Last revision: 19-JAN-17 Page 24 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Weather Information via Datalink

As was mentioned in the previous chapter about fuel planning, the A320’s systems include datalink functionality, which allow

for data to be sent and received during flight. A good amount of this data is related to weather information.

The A320-X allows you to use two of these weather-related datalink functions, ATIS and METAR information.

METAR REQUEST

Note:

For this to work, P3D needs to be connected to any tool or network 1

providing real weather to P3D. The A320-X will look for the weather in

the following order: 1. Active Sky 2016, 2. Active Sky Next, 3. VATSIM,

4. IVAO, 5. NOAA weather.

1. Select “ATSU” within the MCDU MENU page. 2

2. Select “AOC MENU”.

3. Select “WEATHER REQ”.

4. Enter the weather station designator, like LSGG for

Geneva airport. Up to 3 stations can be requested with

one message.

5. Press the LSK 6R to send the request. 3

The real Airbus would then print the received weather reports 7

via the on-board printer. To avoid excessive paper usage, the

A320-X sends the messages (after a short delay) to the

MCDU:

4

6. Return to the “AOC MENU” page.

7. Select “RCVD MSGS” to display all messages.

8. Select the desired message.

6 5

Last revision: 19-JAN-17 Page 25 of 37

A320-X Introduction Guide

Configuration – Usage – Help

ATIS REQUEST

Note:

For this to work, P3D needs to be connected to either VATSIM or

IVAO. Furthermore, there needs to be an active ATIS on the airports

you intend to receive data from. 1

The ATIS request function is similar to the METAR request

function described on the previous page:

1. Select “ATC MENU” within the ATSU DATALINK page.

3

2. Confirm that the correct ATC data provider (VATSIM or

IVAO) is selected.

3. Select “ATIS”.

4. The ATIS menu is pre-filled with your active point of

departure, destination and alternate aerodrome. You

may add to or modify this selection.

5. Press the LSK next to “SEND” to send a request.

6. The ATIS info will be received and displayed straight

away, if available. 2

4 5

Last revision: 19-JAN-17 Page 26 of 37

A320-X Introduction Guide

Configuration – Usage – Help

Hints from A320-rated Pilots

The team behind the A320-X includes many A320-rated pilots currently flying with various airlines around the world.

They share some of their insights and hints about flying the A320 in their own words.

MANAGING DESCENTS

by X24 (Christopher Allan)

60T GW is a convenient median value, above which we know we're starting to feel the weight more and all that implies. We

make a point of mentioning that fact during the arrival briefing - gets harder to slow down if you have a tailwind at the top of

the ILS for instance, which is pretty typical around Melbourne. Vls can be a problem if you haven't anticipated this - she won't

go down and slow down so you have to get in early. Then there's short runways = hot brakes, etc.

Conversely, below 60T, lighter, don't mind so much when ATC asks you maintain 180 kts till 6 miles, clattery landings, cooler

brakes, quicker to turn around 'cos not so many passengers so the cabin crew are a little less frazzled, and it means the

weather's good 'cos we have less fuel remaining.

Because you only get half speed brake with the autopilot engaged, you can disengage the AP, use full speed brake, then re-

engage the AP. Done that a few times. Here are some numbers most of my colleagues seem to use to assess how the descent

profile is looking. Once you get used to this you can tell quite quickly if you're starting to get high or low or it looks like you're

going to. We don't necessarily always trust the flight guidance implicitly, and these are really useful raw data gross error cross-

checks.

In round figures, 1000/IAS = miles per thousand feet. So at 300 knots, very close to 3 miles per thousand (3.3), at 250 knots

- 4 miles per thousand, and 200 knots - 5 miles per thousand. Those are easy to do in your head. That's clean - 200 will be

pretty close to green dot at medium weights. As you slow down, the glide flattens out. Green dot is best lift/drag speed. They

say it takes a mile in level flight to lose 10 knots, bit less if you're light.

From 10,000 ft, a 4x profile works really well for the A320, i.e. 4 x the alt in 1000's of feet, so at 5000' you want to be at 20

miles, 4000 at 16, 3000 at 12-13 and aim for green dot at 13 miles.

This makes it easy to see if you're getting high or low. If low, we might VS it to match the blue bottom of descent arrow with

the white continue descent arrow. If high, so OP DES, tweak the speed up a few knots, bit of speed brake, watching the blue

arrow to see where bottom of descent will be so as to try and have a bit of a level segment to wash the speed off rather than

try to do it while descending. In rare cases, getting slowed down and held up because of traffic, I've had flaps 1 out at 7000

feet.

We'll be around 17 miles out doing 230, when ATC tells us to reduce to 190. As soon as the brakes are out (and remember

you only get half deflection with the AP engaged), the Vls begins to climb and as it reaches our indicated speed of 230 we

back the brakes off a bit to control the Vls, and once below 230 knots, select flaps 1 which then causes Vls to quickly reduce.

- Part 2 -

To comply with ATC speed requirements, I generally select the speed (rather than MACH), especially below the Mach/SPD

crossover altitude. SPD rather than MACH also makes it easier to achieve RTAs accurately.

Once the winds have been put in, it gives the FMGS a forecast cross-section of the atmosphere for predictions - the operative

word being "forecast". A managed descent out of a 160kt tailwind that suddenly drops off can result in an over-speed if you're

not ready for it, and the aeroplane will quite happily allow this. Surprisingly given that it is fly-by-wire, i.e. software-driven, there

are noticeable differences between airframes when it comes to speed handling. If high on profile with speed and descent

managed, some aircraft will put their heads down and allow the speed to overshoot the top end of the buffer and get right up

to the bottom of the "bricks", still accelerating. Speed-brake is usually enough to prevent an over-speed and cause the nose

to pitch up and the speed to decay if you get in early. Otherwise, I've seen people have to disconnect, close the thrust levers

and manually level off. This can all happen very quickly, particularly at higher altitudes, especially descending out of a strong

tailwind that reduces rapidly with altitude. I typically start descent 5-10 miles early, which starts off nice and gentle at 1000 fpm

and with no surprises.

Also, being within 2-300' of an altitude restriction on a STAR is considered satisfactory by the aircraft. Accordingly, to meet a

limiting STAR requirement of at or below 9000', I put in -8700. Murphy's Law states that if you don't amend the altitude, it will

go through at 9300 feet, and if you do, it will go through at 8700 feet!

Last revision: 19-JAN-17 Page 27 of 37

A320-X Introduction Guide

Configuration – Usage – Help

- Part 3 -

Fuel is a huge cost to us, so we operate at CI 15, and depending on weight and wind, the FMGS will often program a descent

speed of .76 - .77/270 - 280. If less than 280 knots, company policy is to enter /280 on the DES PERF page. Descending

early, say 5 - 10 miles, initiates a descent at 1000 fpm. The behaviour of the thrust depends on whether the descent winds

have been entered and how the actual winds compare to the entered winds. The FM uses this to decide if it is high or low and

adjusts thrust and/or pitch accordingly. If low, the speed will tend to reduce to the bottom of the speed bracket - target minus

20 - but because ATC expects us to maintain a certain speed, we generally then select 280, or 250 if below 10,000'.

Initially, when commencing the descent, thrust will reduce to idle to stop the aircraft accelerating, but once the FM has had a

chance to evaluate the profile, thrust may well increase again. In a managed descent, the FMA quite often flickers between

THR IDLE and SPEED as it tries to maintain the profile and the programmed speed.

MANAGING DESCENTS

by Flyingspanner

On the A320, when managed descent is initiated before the calculated descent point, the aircraft will put you into a 1000ft/min

descent until the calculated rate meets the current profile for the descent. The aircraft will then adjust its thrust for the descent

mode. The FMA call for this on the A320 is "THR IDLE" - HOWEVER, this is not actually a true statement. Actually, some

thrust is kept on to maintain the descent profile and keep the green profile dot in the middle. This can cause speed to build up

to almost reaching the descent speed +20 upper band (around the +15-17 mark). it is only then that the the engines actually

go back to an idle setting, confirmed by the flashing IDLE on the Upper ECAM in-between the 2 engine EPR displays. Once

it reaches this point, the aircraft then tries to slow down and maintain the calculated profile, slowing down to the target airspeed,

sometimes with varying degrees of accuracy depending on the descent winds etc.

Lastly, in the airline I work for, we are using a variable cost index, which alters the descent speed. For example, a CI of 50

gives a descent speed of around 320kts. If you are kept high (by ATC), this does not give much speed allowance to make a

fast descent to regain the profile. I generally like to use a descent speed of around 290kts. That way if kept high, I can go fast

to get down and then slow down (my old instructor used to say: "its easier to go down, then slow down than to slow down and

go down!" We also use an Idle Performance percentage to reduce the computed track miles for descent on the profile by

about 15 miles to try and maintain a higher altitude for longer before the descent.

MANAGING DESCENTS

by Aerlingus231

Managed descents are a quite inconsistent to be honest. As a rough guide, it responds slowly initially to deviations but then

will progressively reduce the pitch up to the point where it'll quite happily put you in a dive of death in excess of -4500 fpm with

no qualms to try and regain the computed profile. Descents are quite the dark art in the A320, In most jets to be fair, the

computer will only roughly put you in the ball park and will quite often need intervention in the form of VS/Op Des and manually

adjusting the speed to accurately manage your profile.

Entering the actual spot winds on the way down can help, particularly in the case of tailwinds on the descent. But invariably,

most of the time, the winds we have are spaced in gaps of 8,000' +, and the computer will consider that the wind changes

evenly across those 8000' from the first level to the next. In reality, the swing tends to happen across 2,000-3,000', meaning

the computer gets a bit of a surprise, and in turn, gives us a bit of a surprise with its attempts to regain the profile. I agree with

the general concept though that it does reduce the severity of its inconsistencies and does better plan the track millage required

for the descent.

MANAGING CROSSWIND LANDINGS

by Bus_Driver

I keep the crab all the way until about 30 feet, then kick it straight with rudder (if it's really strong leaving 5 degrees crab on

touchdown) simultaneously when bringing out the crab applying enough sidestick to prevent the wing lifting. Again, if the wind

is really strong, I keep about 5 degrees drift and a small amount of wing down at touchdown.

Once on the ground the aircraft tends to track down the runway pretty easily, and is easily controlled with the peddles. The

autobrake makes our life easier (particularly in the simulator); in real life it seems to want to stay straight better than in the

simulator.

PS: you see a lot of people saying the airbus is tricky in a crosswind, personally I have not found this to be the case - even

in a maximum crosswind (38kt)

Last revision: 19-JAN-17 Page 28 of 37

A320-X Introduction Guide

Configuration – Usage – Help

6. HELP & SUPPORT

Questions & Answers

To help you with issues and answer questions you might have, head over to the Flight Sim Labs support forum which features

an up-to-date Q&A section:

http://forums.flightsimlabs.com

Manuals & Documents

The following documents are available to help you get flying easily, as well as using the correct procedures and workflows:

• Introduction Guide

The document you are reading right now. Contains information on how to install, configure and use the A320-X.

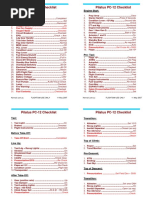

• Flight Checklist

Use this checklist on every flight you do. You will notice that it is a very slim checklist. This is because many items

are handled or displayed by the avionics and therefore do not need to be on paper anymore.

The backside offers many limitation figures helping you during the operation of the aircraft. Other limitations are either

displayed on the screens or printed right onto the main panel.

Should you have access to a paper lamination device, this would be the perfect document for that. It gets tossed

around quite a bit during daily operations but needs to be readily available at any time.

• Normal Procedures

Follow these procedures to fly the A320 exactly the same way as the airline pilots do.

Note that the ultimate goal would be to know all content of this document by heart. The more you fly the A320, the

easier this will be.

• Basic Tutorial

A tutorial flight covering a short flight across Europe from Vienna (LOWW) to Copenhagen (EKCH).

Good Memory (VAS) Management

Since P3D is a 32 bit-application, it has a hard limit on how much memory it is allowed to use. This so called VAS (Virtual

Address Space) is limited to 4 GB for the P3D-process if you are running a 64-bit operating system. If you are running a 32 bit

operating system, P3D will be even more limited and have access to just 2 GB (or 3GB with a “3GB Switch Option” enabled).

This means that no matter how much physical memory you have installed in your system, P3D processes will be limited to

between 2GB and 4GB of memory. P3D processes include not only the sim itself but the complexity levels you have set within

the sim as well as all add-on aircraft and sceneries (of any kind) you have installed. Once you reach that VAS limit, the

simulator will simply crash.

Current generation PCs have become fast enough to handle much more complex aircraft and high definition textures utilised

in today’s modern scenery. However, while new hardware allows P3D to remain smooth and perfectly flyable with good frame

rates, the memory restrictions remain in place. This results in limiting the amount of complexity and texture resolution you can

load into the simulator to avoid memory issues.

Since the FSLabs A320-X is one of the most sophisticated and highly complex add-on aircraft available today, it too needs its

fair share of memory to run. In order to prevent you from suffering out of memory-errors (OOM), you will find some helpful

recommendations below on how to configure your simulator in order to ensure the best experience with the A320-X.

P3D LEVEL OF DETAIL (LOD) SETTING

P3D offers a setting which increases the level of detail radius (LOD) around the user aircraft. However, increasing the LOD

value results in using much more VAS. For this reason, it is recommended that when flying the A320-X, make sure the setting

for “Level of detail radius” in your P3D scenery settings is set to no higher than “high”.

Last revision: 19-JAN-17 Page 29 of 37

A320-X Introduction Guide

Configuration – Usage – Help

CLOUD TEXTURES

There are texture replacement add-ons on the market that improve the visual quality of cloud textures. Many of them give the

option to install “ultra high resolution” textures, or in other words a cloud texture size of 4096x4096 pixels.

Using these texture resolutions will have a huge impact on available VAS, especially if used together with a sophisticated

weather tool injecting numerous layers of different clouds.

In addition to the VAS demand, larger texture sizes often give clouds an over-sharpened appearance with edges and contours

much more defined than real clouds. FSLabs recommends a cloud texture size of 512x512 pixels for cirrus clouds. We think

that this setting offers an optimal balance between visual appeal and utilization of a minimal amount of memory resources.

Note that it is not enough to simply limit the “Texture Resolution” setting in your P3D settings to 1024. You must go into the

settings of your texture replacement program and select the lower texture size. If you don’t, then the 4096 pixel textures will

still be read and loaded into memory before being displayed.

SCENERY TEXTURES

Another trend for ultra-high resolution textures is sceneries. Developers tend to use them as a marketing tool and to be able

to show stunning screenshots of areas no one will ever fly or taxi the aircraft into.

Larger (4096 pixels) scenery textures can make sense with some parts of an airport, such as aprons and runways. However

it has been proven that textures this large on buildings will only be visible in full detail when the user is right in front of the

building. This is something that is not possible while taxing or even parking an aircraft. While the highest level of detail is

invisible to the user, it is still loaded into P3D, consuming valuable VAS.

It is therefore recommended to avoid using 4096 pixels (and even 2048 pixels, if possible) textures with airport sceneries as

this level of resolution will not always provide a visible difference which justifies the increased memory usage. If an airport

scenery developer offers a “light” texture package with lower resolution, you should always try it and see if you are satisfied

with the visuals before opting for the higher resolution textures and the increased VAS usage it will entail.

AI TRAFFIC

AI Traffic has become more detailed over the years, offering more complex visual models and numbers of aircraft, often

matching real world traffic and schedules into major airports. Therefore, AI traffic has evolved into another consumer of

valuable VAS.

Recently, some AI Traffic models have been made available with optional 4096-pixel textures offering an incredible amount

of detail. As is the case with scenery textures above, it is recommended to stick to a maximum of 2048 pixels with AI Traffic

textures.

P3D RESTART

P3D is not very good at flushing data that has accumulated during a flight or from a previously loaded aircraft. When you

switch aircraft or even change the livery of the current aircraft in the same session, P3D does not release all memory that has

already been used. By loading the new aircraft (or changing livery) you are actually using up even more of the limited VAS

memory.

This insufficient clearing of used data may also require you to restart P3D between flights. While you might be able to fly from

point “A” to point “B” and then back to point “A” (or on to point “C”) without issue, this will be highly dependent on your settings

and the scenery you are using. For example, you may use a good amount of memory flying between two highly detailed add-