A148 14

A148 14

Uploaded by

عصام السامرائيCopyright:

Available Formats

A148 14

A148 14

Uploaded by

عصام السامرائيOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

A148 14

A148 14

Uploaded by

عصام السامرائيCopyright:

Available Formats

Designation: A148/A148M − 14

Standard Specification for

Steel Castings, High Strength, for Structural Purposes1

This standard is issued under the fixed designation A148/A148M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Specification A781/A781M constitutes nonconformance with

1.1 This specification covers carbon steel, alloy steel, and this specification. In case of conflict between the requirements

martensitic stainless steel castings that are to be subjected to of this specification and Specification A781/A781M, this

higher mechanical stresses than those covered in Specification specification shall prevail.

A27/A27M.

4. Ordering Information

1.2 Several grades of steel castings are covered, having the

chemical composition and mechanical properties prescribed in 4.1 The inquiry and order should include or indicate the

Tables 1 and 2. following:

4.1.1 A description of the casting by pattern number or

1.3 The values stated in either SI units or inch-pound units

--``,````,,,`,,```,```,,`,,``-`-`,,`,,`,`,,`---

drawing (dimensional tolerances shall be included on the

are to be regarded separately as standard. The values stated in casting drawing),

each system may not be exact equivalents; therefore, each

4.1.2 Grade of steel,

system shall be used independently of the other. Combining

4.1.3 Options in the specification, and

values from the two systems may result in non-conformance

4.1.4 The supplementary requirements desired, including

with the standard.

the standards of acceptance.

1.3.1 Within the text, the SI units are shown in brackets.

2. Referenced Documents 5. Heat Treatment

2.1 ASTM Standards: 2 5.1 All castings shall be heat treated either by full annealing,

A27/A27M Specification for Steel Castings, Carbon, for normalizing, normalizing and tempering, or quenching and

General Application tempering. Unless otherwise specified in the inquiry, contract,

A370 Test Methods and Definitions for Mechanical Testing or order, the castings may be heat treated by any of these heat

of Steel Products treatments or combination of these heat treatments at the option

A781/A781M Specification for Castings, Steel and Alloy, of the manufacturer.

Common Requirements, for General Industrial Use 5.2 Heat treatment shall be performed after the castings

E29 Practice for Using Significant Digits in Test Data to have been allowed to cool below the transformation range.

Determine Conformance with Specifications

6. Temperature Control

3. General Conditions for Delivery

6.1 Furnace temperatures for heat-treating shall be regulated

3.1 Material furnished to this specification shall conform to

by the use of pyrometers.

the requirements of Specification A781/A781M, including any

supplementary requirements that are indicated in the purchase

7. Chemical Composition

order. Failure to comply with the general requirements of

7.1 The steel shall conform to sulfur and phosphorus re-

quirements as prescribed in Table 1.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee 7.2 The content of carbon, manganese, silicon, and alloying

A01.18 on Castings. elements may, by agreement, be prescribed by the purchaser. If

Current edition approved Nov. 15, 2014. Published December 2014. Originally not specified, the content may be selected by the manufacturer

approved in 1955. Last previous edition approved in 2008 as A148/A148M – 08.

DOI: 10.1520/A0148_A0148M-14. to obtain the required mechanical properties.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.3 When the analysis of carbon, manganese, silicon, or any

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on intentionally added alloying element is specifically requested

the ASTM website. in the contract or order, it shall be made by the manufacturer

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/04/2015 23:31:37 MST

A148/A148M − 14

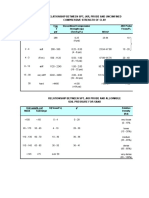

TABLE 1 Chemical Requirements

Grade (UNS No.) Composition, %

Sulfur, max Phospho-

rus, max

80-40 [550-275] (D50400) 0.06 0.05

80-50 [550-345] (D50500) 0.06 0.05

90-60 [620-415] (D50600) 0.06 0.05

105-85 [725-585] (D50850) 0.06 0.05

115-95 [795-655] (D50950) 0.06 0.05

130-115 [895-795] (D51150) 0.06 0.05

135-125 [930-860] (D51250) 0.06 0.05

150-135 [1035-930] (D51350) 0.06 0.05

160-145 [1105-1000] (D51450) 0.06 0.05

165-150 [1140-1035] (D51500) 0.020 0.020

165-150L [1140-1035L] (D51501) 0.020 0.020

210-180 [1450-1240] (D51800) 0.020 0.020

210-180L [1450-1240L] (D51801) 0.020 0.020

260-210 [1795-1450] (D52100) 0.020 0.020

260-210L [1795-1450L] (D52101) 0.020 0.020

TABLE 2 Tensile Requirements

Grade Tensile strength min, Yield point min, Elongation in 2 Reduction of Area, min, %

ksi [MPa] ksi [MPa] in. or 50 mm,

min, %

80-40 [550-275] 80 [550] 40 [275] 18 30

80-50 [550-345] 80 [550] 50 [345] 22 35

90-60 [620-415] 90 [620] 60 [415] 20 40

105-85 [725-585] 105 [725] 85 [585] 17 35

115-95 [795-655] 115 [795] 95 [655] 14 30

130-115 [895-795] 130 [895] 115 [795] 11 25

135-125 [930-860] 135 [930] 125 [860] 9 22

150-135 [1035-930] 150 [1035] 135 [930] 7 18

160-145 [1105-1000] 160 [1105] 145 [1000] 6 12

165-150 [1140-1035] 165 [1140] 150 [1035] 5 20

165-150L [1140-1035L] 165 [1140] 150 [1035] 5 20

210-180 [1450-1240] 210 [1450] 180 [1240] 4 15

210-180L [1450-1240L] 210 [1450] 180 [1240] 4 15

260-210 [1795-1450] 260 [1795] 210 [1450] 3 6

260-210L [1795-1450L] 260 [1795] 210 [1450] 3 6

and reported to the purchaser. The results of these analyses 9. Charpy Impact Requirements

shall not be used as a basis for rejection except by prior 9.1 This section is applicable only to grades 165-150L

agreement. [1140-1035L], 210-180L [1450-1240L], and 260-210L [1795-

1450L].

8. Tension Testing Requirements

NOTE 1—Other grades may be ordered to charpy impact test require-

8.1 One tension test shall be made from each heat and shall ments in accordance with Supplementary Requirement S9 of Specification

conform to the tensile requirements specified in Table 2. A781/A781M.

8.2 The test coupons and specimens shall conform to 9.2 The impact properties of each heat shall be determined

requirements specified in Section 11. by testing one set of three Charpy V-notch impact specimens at

−40° 6 2°F [−40° 6 1°C]. The energy value of the three

8.3 Tension test coupons shall be machined to the form and specimens shall not be less than shown in Table 3.

dimension shown in Fig. 4 of Test Methods and Definitions

A370 and tested in accordance with those test methods with the

TABLE 3 Impact Requirements

ends machined to fit the grips on the tensile testing machine to

be used. Suggested types of ends for standard round tension Grade 165-150L 210-180L 260-210L

[1140- [1450- [1795-

test specimens are shown in Fig. 5 of Test Methods and 1035L] 1240L] 1450L]

Definitions A370. Impact Requirements 20 [27] 15 [20] 6 [8]

Charpy V-notch

8.4 To determine conformance with the tension test Energy value, ft·lbf [J], min value for

requirements, an observed value or calculated value shall be two specimens and minimum aver-

rounded off in accordance with Practice E29 to the nearest 500 age of three specimens

Energy value, ft·lbf [J], min for single 16 [22] 12 [16] 4 [5]

psi [5 MPa] for yield point and tensile strength and to the specimen

nearest 1 % for elongation and reduction of area.

--``,````,,,`,,```,```,,`,,``-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/04/2015 23:31:37 MST

A148/A148M − 14

9.3 Test coupons and specimens shall conform to the 11.3 Test specimens may be cut from heat-treated castings,

requirements specified in Section 11. at the producer’s option, instead of from test bars.

9.4 Impact test specimens shall be machined to the form and 11.4 If any specimen shows defective machining, or exhib-

dimensions shown in Test Methods and Definitions A370, its flaws, it may be discarded and another substituted from the

Charpy V-notch specimen, Fig. 11, and tested in accordance same heat.

with those test methods.

10. Retests 12. Repair by Welding

10.1 If the results of the tensile or charpy tests do not 12.1 Weld repairs shall be inspected to the same quality

conform to the requirements specified, heat-treated castings standards that are used to inspect the castings. When castings

may, at the manufacturer’s option, be reheat treated. Testing are produced with Supplementary Requirement S1 specified,

after reheat treatment shall consist of the full number of weld repairs shall be inspected by magnetic particle examina-

specimens complying with the specification or order. tion to the same standards that are used to inspect the castings.

When castings are produced with Supplementary Requirement

11. Test Coupons and Specimens S2 specified, weld repairs in which the depth of the cavity

11.1 Test bars shall be poured from the same heat as the prepared for repair welding exceeds 20 % of the wall thickness

castings represented. Test coupons may be cast integrally with or 1 in. [25 mm], whichever is smaller, or in which the cavity

2

the castings or as separate blocks similar to those shown in Fig. prepared for welding is greater than approximately 10 in. [65

1 of Specification A781/A781M. cm2], shall be radiographed to the same standards that are used

11.1.1 In the case of quenched and tempered castings where to inspect the castings.

the ruling section of the casting exceeds three inches, supple- 12.2 Welds exceeding 20 % of the wall thickness or 1 in. [25

mentary requirement S15 of Specification A781/A781M shall mm], whichever is smaller, or exceeding approximately 10 in.2

apply. [65 cm 2] in area, shall be given a suitable stress relief or heat

11.2 The bar from which the test piece is taken shall be heat

--``,````,,,`,,```,```,,`,,``-`-`,,`,,`,`,,`---

treatment.

treated in production furnaces with the castings or to the same

procedure as the castings it represents. 13. Rehearing

11.2.1 When the bar from which the test piece is taken is not

heat treated as part of the same heat treatment load as the 13.1 Tested samples representing rejected material shall be

casting(s) it qualifies, the austenitizing (or solution, if appli- held for two weeks from the date of the test report. In case of

cable) temperatures for the bar shall be within 25°F of those for dissatisfaction with the results of the tests, the manufacturer

the casting(s). The tempering temperature for the bar shall be may make claim for a rehearing within that time.

no higher than 25°F above that of the casting(s) and no higher

than permitted by the heat treatment procedure for the material. 14. Keywords

The cycle time at each temperature shall not exceed that for the 14.1 alloy steel; carbon steel; castings; high strength steel;

casting(s). martensitic stainless steel; steel castings; structural castings

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall not apply unless specified in the purchase order. A

list of standardized supplementary requirements for use at the option of the purchaser is included in

Specification A781/A781M. Those which are ordinarily considered suitable for use with this

specification are given below together with additional supplementary requirements that are applicable

only to this specification. Other supplementary requirements enumerated in Specification A781/

A781M may be used with this specification upon agreement between the manufacturer and purchaser.

S1. Magnetic Particle Examination. Definitions A370 and tested at a temperature agreed upon

between the manufacturer and purchaser. The acceptance

S2. Radiographic Examination. requirements shall be either energy absorbed, lateral

S6. Certification. expansion, or percent shear area, or all three, and shall be that

agreed upon by the manufacturer and purchaser. Test speci-

S8. Marking. mens shall be prepared and tested in accordance with Test

Methods and Definitions A370.

S9. Charpy Impact Test

S9.1 Charpy impact test properties shall be determined on

each heat from a set of three Charpy V-notch specimens made

from a test coupon in accordance with Test Methods and

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/04/2015 23:31:37 MST

A148/A148M − 14

S9.2 Absorbed Energy—Average energy value of three S9.4 Percent Shear Area—Percent shear area shall be

specimens shall be not less than specified, with not more than agreed upon between the manufacturer and purchaser.

one value permitted to fall below the minimum specified and

no value permitted below the minimum specified for a single S15. Alternate Tension Test Coupons and Specimen Loca-

specimen. tions for Castings (in lieu of Test Bars Poured from

S9.3 Lateral Expansion—Lateral expansion value shall be Special Blocks).

agreed upon between the manufacturer and purchaser.

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue

(A148/A148M – 08) that may impact the use of this standard (Approved Nov. 15, 2014).

Footnote A, Table 2 deleted. Deleted notched bar from Paragraph 9.2, changed “tested at a

Footnote B, Table 2 deleted. test temperature” to “tested at a temperature” in S9.1.

Changed title of Section 8 from “Tensile Requirements” to

--``,````,,,`,,```,```,,`,,``-`-`,,`,,`,`,,`---

“Tension Testing Requirements.”

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/04/2015 23:31:37 MST

You might also like

- Facon PDFDocument4 pagesFacon PDFmaint.longvan0% (1)

- Astm A 743 PDFDocument8 pagesAstm A 743 PDFWill MottaNo ratings yet

- Geotechnical Capacity of Spun PileDocument5 pagesGeotechnical Capacity of Spun Pileعصام السامرائيNo ratings yet

- Astm A148Document4 pagesAstm A148Leo Aislan100% (1)

- ASTM A 487 (Impeller) PDFDocument6 pagesASTM A 487 (Impeller) PDFnugrohowiwitNo ratings yet

- Astm 487Document6 pagesAstm 487JOSEPH REFUERZO100% (1)

- Astm A890 - A890m - 12Document4 pagesAstm A890 - A890m - 12Nguyen Duc Thanh (EVPC)No ratings yet

- Astm A 297a 297M - 07Document4 pagesAstm A 297a 297M - 07Ramsi AnkziNo ratings yet

- Astm A216Document3 pagesAstm A216guangrizheng84No ratings yet

- Astm A995 A995m 13 2013 PDFDocument4 pagesAstm A995 A995m 13 2013 PDFdelta lab sangli0% (1)

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationVIKAS DAHIYA100% (1)

- Steel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), For High-Temperature ServiceDocument4 pagesSteel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), For High-Temperature ServiceHoem ITNo ratings yet

- A 389 - A 389M - 03 Qtm4os9bmzg5tqDocument3 pagesA 389 - A 389M - 03 Qtm4os9bmzg5tqtruongminhhoangNo ratings yet

- Astm A 447-2011Document4 pagesAstm A 447-2011Vk Rai100% (1)

- Asme Section Ii A Sa-437 Sa-437m PDFDocument6 pagesAsme Section Ii A Sa-437 Sa-437m PDFdavid perezNo ratings yet

- Astm A560 A560m - 12Document3 pagesAstm A560 A560m - 12Leandro Dilkin ConsulNo ratings yet

- A27-A27m Standard Specification For Steel Castings, Carbon, For General ApplicationDocument4 pagesA27-A27m Standard Specification For Steel Castings, Carbon, For General Applicationarmando0212-1No ratings yet

- Astm A320-A320m 2010Document8 pagesAstm A320-A320m 2010Alexandre Amaro VieiraNo ratings yet

- Astm A494 - A494m - 13Document7 pagesAstm A494 - A494m - 13raul100% (1)

- Asme Section Ii B Sa-494Document10 pagesAsme Section Ii B Sa-494Monica SuarezNo ratings yet

- Sa 351Document7 pagesSa 351Pavul RajNo ratings yet

- ASTM - A 27 - Standard Specification For Steel Castings, Carb PDFDocument4 pagesASTM - A 27 - Standard Specification For Steel Castings, Carb PDFMohamed RizkNo ratings yet

- Asme Section II A-2 Sa-638 Sa-638mDocument4 pagesAsme Section II A-2 Sa-638 Sa-638mAnonymous GhPzn1xNo ratings yet

- Specification For Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument6 pagesSpecification For Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature Servicecesar jaramilloNo ratings yet

- Astm A 27 PDFDocument4 pagesAstm A 27 PDFmvalenzuelatNo ratings yet

- Norma Inox-A743.1537974-1 PDFDocument8 pagesNorma Inox-A743.1537974-1 PDFJACKROSI2009No ratings yet

- Structural Steel For ShipsDocument7 pagesStructural Steel For ShipsRICARDONo ratings yet

- ASTM A227 A227M - 06 Steel Spring WireDocument4 pagesASTM A227 A227M - 06 Steel Spring WireLesley EsparzaNo ratings yet

- Din en Iso 9015 1 PDFDocument4 pagesDin en Iso 9015 1 PDFMarcos Verissimo Juca de PaulaNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification ForVIKAS DAHIYANo ratings yet

- A351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsDocument5 pagesA351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsPhong ThanhNo ratings yet

- Astm A351Document6 pagesAstm A351Rahul SinghNo ratings yet

- Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationDocument4 pagesSteel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Applicationعصام السامرائيNo ratings yet

- Asme Section Ii B Sa-494 Sa-494mDocument10 pagesAsme Section Ii B Sa-494 Sa-494mVania Navarro CárdenasNo ratings yet

- ASTM A356 A356M - 07 Steel CastingsDocument6 pagesASTM A356 A356M - 07 Steel CastingsMacario LeyvaNo ratings yet

- Asme Section Ii A-2 Sa-995Document4 pagesAsme Section Ii A-2 Sa-995Anonymous GhPzn1xNo ratings yet

- A958Document5 pagesA958DeepakRajurkarNo ratings yet

- Martensitic Stainless Steel Bars For High-Temperature ServiceDocument4 pagesMartensitic Stainless Steel Bars For High-Temperature ServiceTatan FirmansyahNo ratings yet

- Astm A213Document12 pagesAstm A213hernan grilloNo ratings yet

- Astm A320 Rev ADocument8 pagesAstm A320 Rev AStalin Ayala GaiborNo ratings yet

- Astm 494Document7 pagesAstm 494JOSEPH REFUERZO100% (1)

- Astm A743 PDFDocument6 pagesAstm A743 PDFzafarbadal100% (2)

- ASTM A 351 Standard Specification For Castings, Austenitic, - 2003Document5 pagesASTM A 351 Standard Specification For Castings, Austenitic, - 2003Andres Afanador MuñozNo ratings yet

- Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesCastings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationWin DarNo ratings yet

- A743A743M-13ae1 Standard Specification For Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesA743A743M-13ae1 Standard Specification For Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationAhmed ShakerNo ratings yet

- Astm A743Document6 pagesAstm A743lyricmp100% (1)

- Low and Intermediate Tensile Strength Carbon Steel Plates: Standard Specification ForDocument2 pagesLow and Intermediate Tensile Strength Carbon Steel Plates: Standard Specification ForLeonardo Pellin RigonNo ratings yet

- ASTM A 351 - A 351M - 03 SS CastingsDocument5 pagesASTM A 351 - A 351M - 03 SS CastingsSaravanan VaradarajanNo ratings yet

- Astm A47-99Document5 pagesAstm A47-99romerobernaNo ratings yet

- Astm A213Document11 pagesAstm A213guangrizheng84No ratings yet

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument8 pagesHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNo ratings yet

- Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesDocument12 pagesSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesExel RangelNo ratings yet

- Steel Castings, High Strength, For Structural PurposesDocument4 pagesSteel Castings, High Strength, For Structural PurposesLuis Daniel MadrigalNo ratings yet

- Astm A297Document3 pagesAstm A297rams789No ratings yet

- Astm A 351 - 05Document5 pagesAstm A 351 - 05srihariNo ratings yet

- 297 GR HFDocument4 pages297 GR HFAgustinus KNo ratings yet

- Astm A216-A216m 2008Document4 pagesAstm A216-A216m 2008Guilherme de BarrosNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Analysis and Design of Elastic Beams: Computational MethodsFrom EverandAnalysis and Design of Elastic Beams: Computational MethodsNo ratings yet

- Settlement Limits PDFDocument1 pageSettlement Limits PDFعصام السامرائيNo ratings yet

- Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationDocument4 pagesSteel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Applicationعصام السامرائيNo ratings yet

- Buttress Wall - R1Document110 pagesButtress Wall - R1عصام السامرائيNo ratings yet

- KDC19 Container Concept C Mk3a 17 10 19 Rev E Master S7 - ModelDocument1 pageKDC19 Container Concept C Mk3a 17 10 19 Rev E Master S7 - Modelعصام السامرائيNo ratings yet

- Form F - Application For Registration Renewal 13112019-1 PDFDocument1 pageForm F - Application For Registration Renewal 13112019-1 PDFعصام السامرائيNo ratings yet

- N (Flow/Ft.) Consistency Cqu Uncomfined Compressive JKR Probe 2 Strength (Qu) Flows/Ft. PSF (Ton/Sq - FT.) kN/m2Document8 pagesN (Flow/Ft.) Consistency Cqu Uncomfined Compressive JKR Probe 2 Strength (Qu) Flows/Ft. PSF (Ton/Sq - FT.) kN/m2عصام السامرائيNo ratings yet

- C Geo5Document23 pagesC Geo5عصام السامرائيNo ratings yet

- Geo5 OutputDocument23 pagesGeo5 Outputعصام السامرائيNo ratings yet

- Plaxis ValidationDocument5 pagesPlaxis Validationعصام السامرائيNo ratings yet

- Base Plate DesignMS601a Good MahfuzDocument4 pagesBase Plate DesignMS601a Good MahfuzDavid PuenNo ratings yet

- Mesy Tapak BilDocument2 pagesMesy Tapak Bilعصام السامرائيNo ratings yet

- Design of Raft FoundationDocument9 pagesDesign of Raft FoundationМилош ЈанићијевићNo ratings yet

- Sepakat Setia Perunding SDN BHD: Design Information DimensionsDocument30 pagesSepakat Setia Perunding SDN BHD: Design Information Dimensionsعصام السامرائيNo ratings yet

- Transactionhistory PDFDocument3 pagesTransactionhistory PDFعصام السامرائيNo ratings yet

- Pac Pdpa NoticeDocument1 pagePac Pdpa Noticeعصام السامرائيNo ratings yet

- CL - Ms Premalatha Sukumaran - 17th August 2018Document1 pageCL - Ms Premalatha Sukumaran - 17th August 2018عصام السامرائيNo ratings yet

- Bridge Design v1.1 enDocument186 pagesBridge Design v1.1 enGaurav GhaiNo ratings yet

- Foundry Refractories Wall Chart 1616807444Document1 pageFoundry Refractories Wall Chart 1616807444chemibermudezNo ratings yet

- Basic Principles of Induction Logging. Electromagnetic Methods in Borehole Geophysics Alexander Kaufman and Gregory Itskovich (Auth.)Document54 pagesBasic Principles of Induction Logging. Electromagnetic Methods in Borehole Geophysics Alexander Kaufman and Gregory Itskovich (Auth.)amanda.parker119100% (28)

- Heat Transfer November Am Rr310803Document8 pagesHeat Transfer November Am Rr310803Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Product Information - Tesa® 61325 - enDocument2 pagesProduct Information - Tesa® 61325 - enildefonsodiasNo ratings yet

- Abaqus FormingDocument18 pagesAbaqus Formingdaha333No ratings yet

- Hyperelasticity and Viscoelasticity in AbaqusDocument12 pagesHyperelasticity and Viscoelasticity in AbaqusHéctor Enrique Jaramillo SuárezNo ratings yet

- SPS AN ISO16750 AtAGlance 1209 e 0001Document8 pagesSPS AN ISO16750 AtAGlance 1209 e 0001craigchenhmNo ratings yet

- Determine Material Property (PSG Data Book Page No 1.9 & 1.5)Document28 pagesDetermine Material Property (PSG Data Book Page No 1.9 & 1.5)Sagarias Albus100% (1)

- Pillar in Coal MinesDocument8 pagesPillar in Coal MinesSujit KumarNo ratings yet

- Valve Sizing Hand BookDocument24 pagesValve Sizing Hand Bookพรรษพล เจี่ยปิยะสกุล100% (1)

- MECCOCT18-12586: Determination of The Degradation of A AISI TP321 Stainless Steel TubeDocument7 pagesMECCOCT18-12586: Determination of The Degradation of A AISI TP321 Stainless Steel TubeOwais MalikNo ratings yet

- O Tower Stress CheckDocument12 pagesO Tower Stress CheckVishal TomarNo ratings yet

- Introducing RS: A New 3D Program For Geotechnical AnalysisDocument4 pagesIntroducing RS: A New 3D Program For Geotechnical AnalysisAriel Bustamante100% (1)

- SLG CHEM2 LG 5.2 Galvanic Cells SDJFHSDDocument4 pagesSLG CHEM2 LG 5.2 Galvanic Cells SDJFHSDJoyce AmanteNo ratings yet

- Bolt Preload Calculation: AnswerDocument2 pagesBolt Preload Calculation: AnswerPedja100% (1)

- Thermodynamics Multiple Choice Questions and AnswersDocument21 pagesThermodynamics Multiple Choice Questions and AnswersPadmavathi C50% (2)

- Lightweight ConcreteDocument6 pagesLightweight ConcretediracmoutinhoNo ratings yet

- EEE1302 - Lab No 01Document7 pagesEEE1302 - Lab No 01tithynusrat812No ratings yet

- Liu2020 Article EvaluationOfTheReliabilityOfSi PDFDocument10 pagesLiu2020 Article EvaluationOfTheReliabilityOfSi PDFSimo ZniberNo ratings yet

- Fluid Mechanics: Shandong University AFD EFD CFDDocument84 pagesFluid Mechanics: Shandong University AFD EFD CFDKhurram SherazNo ratings yet

- SKF TIH 030M - 230V SpecificationDocument3 pagesSKF TIH 030M - 230V SpecificationÇAĞATAY ÇALIŞKANNo ratings yet

- Miller Indices ClassDocument35 pagesMiller Indices ClassDhiyaAldeenAl-SerhanyNo ratings yet

- PMMADocument3 pagesPMMANancy DanielNo ratings yet

- Design of Concrete Gravity DamDocument26 pagesDesign of Concrete Gravity DamAdil Javed Chaudhary95% (19)

- Experimental Investigation Into Convective Heat Transfer of Nano Fluids at The Entrance Region Under Laminar Flow ConditionsDocument8 pagesExperimental Investigation Into Convective Heat Transfer of Nano Fluids at The Entrance Region Under Laminar Flow ConditionssachinnigadeNo ratings yet

- Unit - 4Document7 pagesUnit - 4dd3613667No ratings yet

- Dart ImpactDocument2 pagesDart ImpactMd Ali RazuNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Fundamentals of Controlledliving Radical PolymDocument378 pagesFundamentals of Controlledliving Radical PolymElif AlyamacNo ratings yet