Tata Consulting Engineers Design Guide For Auxiliary Steam Header

Tata Consulting Engineers Design Guide For Auxiliary Steam Header

Uploaded by

vijayanmksCopyright:

Available Formats

Tata Consulting Engineers Design Guide For Auxiliary Steam Header

Tata Consulting Engineers Design Guide For Auxiliary Steam Header

Uploaded by

vijayanmksOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Tata Consulting Engineers Design Guide For Auxiliary Steam Header

Tata Consulting Engineers Design Guide For Auxiliary Steam Header

Uploaded by

vijayanmksCopyright:

Available Formats

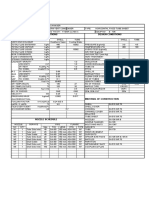

TATA CONSULTING ENGINEERS SECTION: TITLE

TCE.M6-ME-590-416 SHEET i OF iii

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

DESIGN GUIDE

FOR

AUXILIARY STEAM HEADER

FLOPPY NO :

FILE NAME : M6590416.DOC

REV.NO R0 R1 ISSUE

INITIALS SIGN INITIALS SIGN INITIALS SIGN INITIALS SIGN

PPD.BY RS Sd/- VS

CKD.BY BVR Sd/- DP

R1

APP.BY GS Sd/- MLN/RL

DATE 86-06-24 2000-03-31

FORM NO. 020R2

TATA CONSULTING ENGINEERS SECTION:CONTENTS

TCE.M6-ME-590-416 SHEET ii OF iii

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

CONTENTS

SL.NO. TITLE SH.NO.

1.0 INTRODUCTION 1

2.0 HEADER SIZE 1

3.0 HEADER FABRICATION 1

4.0 HEADER DRAINAGE 2

5.0 ISOLATING VALVES 2

6.0 SPACING BETWEEN BRANCHES 2

7.0 SUPPORT OF HEADER 3

8.0 PIPE REACTIONS 3

FIGURES

FIGURE - 1 - STEAM HEADER 4

FIGURE - 2A - DRAIN POT WITH TRAP STATION 5

FIGURE - 2B - DRAIN POT WITH M.O VALVE 5

FIGURE - 3 - ANCHOR ON CONCRETE PEDESTAL 6

FIGURE - 4 - SLIDING SUPPORTS ON CONCRETE 7

PEDESTALS

FIGURE - 5 - ANCHOR ON STRUCTURAL STEEL 8

FIGURE - 6 - SLIDING SUPPORT ON STRUCTURAL STEEL 8

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:REV.STATUS

TCE.M6-ME-590-416 SHEET iii OF iii

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

REVISION STATUS

REV.NO DATE DESCRIPTION

R0 86-06-24 -

R1 2000-03-31 Generally revised

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:WRITE-UP

TCE.M6-ME-590-416 SHEET 1 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

1.0 INTRODUCTION

The distribution of auxiliary steam to various consumers should preferably be

through a header (distributor) which is a short length of adequately-sized pipe

and to which the supply sources and consumer points are connected. Branch

connections are provided on top of the header for all incoming and outgoing

pipelines. The header itself is located just above the floor or platform level.

The arrangement of the auxiliary steam header in a typical power plant is

shown in Fig.1. The principal design features of the auxiliary steam header

are discussed in the following paragraphs. Though power plant applications

are discussed, the principles involved are applicable to other types of plants

as well.

2.0 HEADER SIZE

The header should be sized for the maximum flow to be handled by it. In a

power plant, the design flow of the header is either the capacity of the

auxiliary PRDS connected to it or the maximum flow that can be imported into

the unit from another unit or package boiler through the interconnecting line,

whichever is greater. Generally, headers are designed for lower velocities

than pipelines in order to permit future expansion and / or effect trapping of

moisture / condensate entrained in steam.

3.0 HEADER FABRICATION

3.1 The header with its nozzles can be fabricated in one of the following ways :

a) By welding a series of tees with spool pieces, as required, in between

b) By welding stubs of the required sizes to the header in which the

openings have already been made. The joints are secured through

intersection welds.

c) By using “Weldolets” or “Sockolets” depending on the branch size.

3.2 The first method is to have auxiliary steam header using standard wrought

steel tees with spool pieces.

3.3 The second method employs intersection of joints. The openings in the

header weaken it and additional wall thickness has to be provided on the

header by way of reinforcement. The need for additional wall thickness for the

branch lines should also be examined. In short, reinforcement calculations

have to be carried out for the header. Refer BS : 806 / ASME B 31.1 / IBR for

performing reinforcement calculations.

3.4 In the third method, weldolet type fittings are used alongwith openings made

in the header. These provide full strength joints without the need for

additional reinforcement. It is suggested that preference is given to the use of

weldolets as the amount of welding on the header is substantially reduced.

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:WRITE-UP

TCE.M6-ME-590-416 SHEET 2 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

4.0 HEADER DRAINAGE

4.1 The header being at floor level is a receptacle for condensate formed in the

branch lines. A drain pot should be provided on the header near one end with

a size as per guidelines given in Note-1 of Fig-1. The header should be

sloped towards the drain pot. All branch lines should be sloped towards the

header. The condensate collected in the drain pot is drained either through a

trap or though a motor operated valve, actuated by level switch. Refer Figs.

2A and 2B. The scheme depends on system requirements, operating

pressure and temperature and the quantity of drain to be handled. Traps are

adequate to handle small drain quantities at relatively low pressure and

temperature.

4.2 Motor operated valve actuated with level switch is recommended when the

operating temperature is greater than 400oC or at places where spray water is

introduced into steam piping (e.g. downstream of desuperheater, downstream

of HP Bypass valves).

5.0 ISOLATING VALVES

Isolating valves on branch lines should be located close to the header.

The centre line elevations of the valves should be uniform and should be

1300–1500 mm above the floor. Valves may be staggered to reduce the

centre distances between branch lines. This arrangement presents a neat

appearance renders the operation of valves convenient and ensures quick

and ready identification of the service of the valves. This arrangement implies

that the length of the stubs on the header, upto the valves, may not be

uniform for all branch lines due to differences in end-to-end lengths of valves.

This is however of little consequence.

6.0 SPACING BETWEEN BRANCHES

The spacing between the branch pipes on the header is governed by the

following two requirements.

a) The clear spacing between two branches should be equal to or greater

than the sum of the outside diameter of the two branch pipes in order

to avoid the influence of one branch on the other and thus minimise

reinforcement requirements. This will not be applicable if weldolets

are used.

b) The hand wheels of the isolating valves on adjacent branch lines

should have adequate clearance in between for ease of operation.

The minimum clearance between the outer edges of the valves should

not be less than 150MM.

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:WRITE-UP

TCE.M6-ME-590-416 SHEET 3 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

7.0 SUPPORT OF HEADER

The header should be supported from the floor through bottom pipe supports.

As the steam piping is hot and calls for thermal analysis, the header at one of

the support points should be anchored so as to split the piping connected in

to individual systems for purpose of stress analysis and to minimise the effect

of one branch on the other. Individual systems stress analysis shall be

carried out with header anchor as the anchor. Figures 3 to 6 indicate typical

arrangement for support of anchor and restraints.

8.0 PIPE REACTIONS

As each pipeline connected to the header is being stress analysed

individually, the combined effect of all the pipe reactions at the various take-

off points should be studied and the header stress computed. Similarly, the

anchor and restraints on the header should be designed for the combined

effect of pipe reactions. Here it should be borne in mind that it is not

necessary for all the pipe lines to be hot or cold simultaneously. While

computing the combined reactions, the worst possible combination of the

individual reactions should be considered. The effect due to the reaction

forces of safety relief valves that are mounted on the steam header also need

to be considered while designing the anchors & restraints. Safety valves

should preferably be located near one of the supports of the header.

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:FIGURES

TCE.M6-ME-590-416 SHEET 4 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

BETWEEN UNIT HEADERS

INTER CONNECTING LINE

STEAM TO BOILER FUEL

STEAM TO DEAERATOR

STEAM TO EJECTORS

OIL SYSTEM & SCAPH

SPARE CONNECTION

STEAM TO TURBINE

GLAND SEALS

STEAM FROM

AUX. PRDS.

SPARE

TI SAFETY PI

RELIEF VALVE

1300 TO 1500 mm

STEAM HEADER

SLOPE

FLOOR LEVEL

PIPE SUPPORT DRAIN POT

PIPE ANCHOR

WELD CAP(TYP) SEE FIG-4 SEE FIG-2A & 2B

SEE FIG-3 & 5

FOR DETAILS FOR DETAILS

FOR DETAILS

ELEVATION

TI PI

.

IN

M )

0 P

15 TY

(

PLAN

FIGURE.-1

STEAM HEADER

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:FIGURES

TCE.M6-ME-590-416 SHEET 5 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

SLOPE C OF HEADER

L

DRAIN POT TRAP STATION

(REF. NOTE-1)

NB 25

T TO FLASH TANK OR WASTE

AS SHOWN IN FLOW DIAGRAM

DRAIN PLUG

(THREADED / WELDED

HALF COUPLING WITH PLUG)

FIGURE-2A

DRAIN POT WITH TRAP STATION

SLOPE C OF HEADER

L

LEGEND

HHLVL

HHLVL HIGH HIGH LEVEL PROBE TYPE

HLVL HIGH LEVEL LEVEL SWITCH

HLVL

M

DRAIN POT

(REF. NOTE-1) NB50

TO FLASH

TANK

(REF. NOTE-2)

DRAIN PLUG

(THREADED / WELDED

HALF COUPLING WITH PLUG)

FIGURE-2B

DRAIN POT WITH M.O VALVE

NOTES:

1. DRAIN POT SIZE SHALL BE AS FOLLOWS

HEADER < 150 mm SAME AS HEADER SIZE

HEADER > 200 mm HALF THE HEADER SIZE

OR 150 mm WHICH EVER IS GREATER.

2. WITH HIGH HIGH LEVEL THE MOTOR OPERATED VALVE WILL OPEN AND

CLOSE AT HIGH LEVEL

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:FIGURES

TCE.M6-ME-590-416 SHEET 6 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

DO NOT DRILL HOLE

THICKNESS +

INSULATION

25mm(TYP)

OR 100 mm

STUB

D

A A

(MIN)

2 mm PLATE 10THK.

VENT HOLE

PF

LEGEND

CC

25 GROUT(MIN.)

PF : PIPE FABRICATOR

CC : CIVIL CONTRACTOR

POCKET SIZE

50 S.Q. x 300 LONG

100 FOR b < 300

125 FOR b = 301 TO 400

STUB SIZE DIM. IN mm.

ELEVATION

NB OD(D) a b

b

50 60.3 75 120

a

65 73.0 90 140

80 88.9 110 160

b

100 114.3 140 190

150 168.3 190 240

200 219.1 240 300

250 273 300 350

SECTION A-A

300 323.9 340 400

FIGURE-3

ANCHOR ON CONCRETE PEDESTAL

ERECTION NOTES:

1. THE GROUTING SHOULD BE DONE AFTER SETTING THE PIPE LINE FOR SLOPE

2. HEIGHT OF FOUNDATION SHOULD BE CALCULATED CONSIDERING THE ACTUAL PIPE

ELEVATION AFTER SLOPE AT THE POINT OF SUPPORT

3. PIPE STUB IS NORMALLY ONE OR TWO SIZES SMALLER THAN HEADER SIZE

4. PIPE STUB WALL THICKNESS SHOULD BE CHECKED FOR WORST POSSIBLE COMBINED

PIPE REACTIONS AT ANCHOR. THE REACTIONS FORCES MUST BE INDICATED ON THE

PIPING DRAWING TO ENABLE THE PIPING FABRICATOR TO DESIGN WELD JOINTS.

ISSUE

R1

FORM NO. 120 R1

TATA CONSULTING ENGINEERS SECTION:FIGURES

TCE.M6-ME-590-416 SHEET 7 OF 8

DESIGN GUIDE FOR AUXILIARY STEAM HEADER

DO NOT DRILL HOLE

THICKNESS +

INSULATION

25mm(TYP)

OR 100 mm

A D

2 mm STUB A

(MIN)

PLATE 10THK.

VENT HOLE

PF

25 GROUT(MIN.)

CC

2 mm

(TYP)

POCKET SIZE

50 S.Q. x 300 LONG

100 FOR b < 300

125 FOR b = 301 TO 400

ELEVATION

PIPE MVT.

b = a + PIPE MOVEMENT IN

THE DIRECTION + 100mm.

a c = a + 200mm.

d = b + 100mm

a = SAME AS IN FIG. 3

b

d

c & d COULD BE MADE EQUAL

IF THERE IS NOT MUCH

DIFFERENCE.

LEGEND

100 FOR b < 300 PF : PIPE FABRICATOR

125 FOR b > 301 TO 400 CC : CIVIL CONTRACTOR

c

SECTION A-A

FIGURE-4

SLIDING SUPPORTS ON CONCRETE PEDASTALS

ERECTION NOTES:

SAME AS NOTES 1 & 3 OF FIGURE - 3

ISSUE

R1

FORM NO. 120 R1

You might also like

- Hello Kitty - Crochelandia - Rose Nogueira - ENG - CompDocument6 pagesHello Kitty - Crochelandia - Rose Nogueira - ENG - CompGiovanna Schenkel70% (10)

- 225-002 - Piping Hydraulics and Specification - Book 1Document114 pages225-002 - Piping Hydraulics and Specification - Book 1antemio hernandez100% (1)

- Service Manual: Precision SeriesDocument32 pagesService Manual: Precision SeriesMoises ShenteNo ratings yet

- Mep Concept ReportDocument22 pagesMep Concept ReportMIMR67% (3)

- TATA Consulting Engineers Limited: Design Guide On Air Chamber For Pumping PlantsDocument17 pagesTATA Consulting Engineers Limited: Design Guide On Air Chamber For Pumping PlantsksshashidharNo ratings yet

- Steam HeaderDocument9 pagesSteam Headervijayanmks100% (1)

- Tce Consulting Engineers Limited Design Guide For Line SizingDocument27 pagesTce Consulting Engineers Limited Design Guide For Line SizingKaliya PerumalNo ratings yet

- Excerpt - Mihir's Handbook and Adv Course v3.0Document88 pagesExcerpt - Mihir's Handbook and Adv Course v3.0Jayaseelan GNo ratings yet

- Datasheet ClarifierDocument1 pageDatasheet ClarifierMuhammad GhaziNo ratings yet

- Centrifugal Pump Piping Design LayoutDocument16 pagesCentrifugal Pump Piping Design LayoutCustodio SantosNo ratings yet

- Piping Boq Phase-2Document151 pagesPiping Boq Phase-2Bagadi AvinashNo ratings yet

- Slurry Piping Systems, Its Design and Instrumentation - PIPING GUIDEDocument8 pagesSlurry Piping Systems, Its Design and Instrumentation - PIPING GUIDESriramShraffNo ratings yet

- Removal of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuDocument20 pagesRemoval of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuChuah Chong YangNo ratings yet

- Calculation Sheet Pipe SupportDocument33 pagesCalculation Sheet Pipe SupportKhamal Rachmanda AdamNo ratings yet

- PFD & P&idDocument70 pagesPFD & P&idashir100% (1)

- Estimation of TanksDocument1 pageEstimation of TanksHgagselim SelimNo ratings yet

- Att594 0 PFD-P&IDDocument431 pagesAtt594 0 PFD-P&IDnvmohankumarNo ratings yet

- Pi Ups 1004Document39 pagesPi Ups 1004JOEL ARNAO CORTEGANANo ratings yet

- TC-M Series 2017.compressedDocument8 pagesTC-M Series 2017.compressedFredrik SihombingNo ratings yet

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 pagesBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNo ratings yet

- Steam Pipe SizingDocument2 pagesSteam Pipe SizingONLY PHYSICSNo ratings yet

- CCIVALVE Desuper HeaterDocument4 pagesCCIVALVE Desuper Heaterhappale2002No ratings yet

- 1 Inlet 1 Outlet 2 Inlet 2 Outlet 3 Inlet 3 Outlet 12333 11 184 0Document1 page1 Inlet 1 Outlet 2 Inlet 2 Outlet 3 Inlet 3 Outlet 12333 11 184 0AbdulNo ratings yet

- Achieving Zero Discharge Panipat Refinery and Petrochemical Complex-Indian OilDocument86 pagesAchieving Zero Discharge Panipat Refinery and Petrochemical Complex-Indian OilWalter GuttlerNo ratings yet

- Dowtherm Vent CondenserDocument1 pageDowtherm Vent Condensersushant_jhawerNo ratings yet

- Dowtherm BookDocument30 pagesDowtherm BookMeghnad M GavitNo ratings yet

- Steam Tracing SpecificationDocument14 pagesSteam Tracing SpecificationPankaj SahuNo ratings yet

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- Resistance Equivalent Length FittingsDocument3 pagesResistance Equivalent Length FittingsRicardo DaclanNo ratings yet

- LCF-RFQ-MC-007 Compressed Air System R.03Document24 pagesLCF-RFQ-MC-007 Compressed Air System R.03Anonymous mZEUquNo ratings yet

- KLM Hydraulic Program OverviewDocument50 pagesKLM Hydraulic Program Overviewjoshimanan01No ratings yet

- Volume Calculation For BlowdownDocument6 pagesVolume Calculation For BlowdownrohitkushNo ratings yet

- Buttweld Fittings Accesorios SoldadosDocument5 pagesButtweld Fittings Accesorios SoldadosJuan CadenaNo ratings yet

- Fuel Oil Pump Calculation 26-05-2017R4 PDFDocument19 pagesFuel Oil Pump Calculation 26-05-2017R4 PDFArdian20No ratings yet

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshNo ratings yet

- Tower Tray Oil and Gas IndustryDocument11 pagesTower Tray Oil and Gas IndustryHeet PatelNo ratings yet

- Data Sheet P-0560 - Hot Oil Drain Tank Sump PumpDocument2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pumpcygnus marine panamaNo ratings yet

- Pressure DropDocument4 pagesPressure Dropsrishanthi82No ratings yet

- Condensate GuidelinesDocument54 pagesCondensate GuidelinesMajid Hamidi DadgarNo ratings yet

- Helical Coil Length - UpdDocument2 pagesHelical Coil Length - UpdNaqqash SajidNo ratings yet

- Piping SpecificationDocument3 pagesPiping SpecificationArun KumarNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Flowline Piping DesignDocument6 pagesFlowline Piping DesignHua Tien DungNo ratings yet

- PF-0002-01Z-ME-985-0022-A-Diesel Storage TankDocument7 pagesPF-0002-01Z-ME-985-0022-A-Diesel Storage Tankpavan kumarNo ratings yet

- BAC - Technical ResourcesDocument66 pagesBAC - Technical Resourcesmihdragos100% (1)

- Penstock Surge ConsiderationDocument29 pagesPenstock Surge ConsiderationoctatheweelNo ratings yet

- Air CompressorDocument51 pagesAir CompressorInaam Ur Rehman100% (1)

- Production Pump Sizing P. 0920 A, B, C: CalculationDocument5 pagesProduction Pump Sizing P. 0920 A, B, C: CalculationElias EliasNo ratings yet

- NPSH Calculator For Process EngineerDocument14 pagesNPSH Calculator For Process Engineerlutfi awnNo ratings yet

- Basic Piping Data For P&IDDocument5 pagesBasic Piping Data For P&ID심판자100% (1)

- Sand Filter Design GuideDocument2 pagesSand Filter Design Guideoanzar100% (2)

- Kirloskar Kos Openwell Submersible Pumps PDFDocument1 pageKirloskar Kos Openwell Submersible Pumps PDFSuraj SNo ratings yet

- CSAP Department Training Series - HRSG and Balance of Plant Foundations-R0Document82 pagesCSAP Department Training Series - HRSG and Balance of Plant Foundations-R0sreenivasulu chenchugariNo ratings yet

- Limpet With Jacket Nozzle OrientationDocument1 pageLimpet With Jacket Nozzle OrientationArunkumar Myakala100% (1)

- Boiler Feed Pump Sizing CalculationDocument18 pagesBoiler Feed Pump Sizing CalculationArun Kumar Dey100% (2)

- Pressure Drop in Steam Lines CalculatorDocument7 pagesPressure Drop in Steam Lines CalculatorHiranthaNo ratings yet

- Work Instruction Per Diesel Transfer Air Compressor P&IDDocument1 pageWork Instruction Per Diesel Transfer Air Compressor P&IDjoeripaNo ratings yet

- Tce Consulting Engineers Limited Design Guide For Auxiliary Steam HeaderDocument12 pagesTce Consulting Engineers Limited Design Guide For Auxiliary Steam HeaderbandithaguruNo ratings yet

- m6-730-206-R1-Design Check List For SwitchyardDocument9 pagesm6-730-206-R1-Design Check List For SwitchyardMunusamyKarthikeyanNo ratings yet

- Dub 00 Yh Ta Iem 002 - 0 251 424Document174 pagesDub 00 Yh Ta Iem 002 - 0 251 424con.sup.amchfcNo ratings yet

- Control StasDocument16 pagesControl StasSobe ThapaNo ratings yet

- 028120-SPL-001 Shop Fabrication Bend Rev. CDocument12 pages028120-SPL-001 Shop Fabrication Bend Rev. CRokan PipelineNo ratings yet

- ET-3010.00-1500-270-PKY-001-FLANGESPARAROV-REV-03 - INGLÊSDocument8 pagesET-3010.00-1500-270-PKY-001-FLANGESPARAROV-REV-03 - INGLÊSLuan OliveiraNo ratings yet

- AXIAL and Lateral Stifness BellowsDocument9 pagesAXIAL and Lateral Stifness BellowsvijayanmksNo ratings yet

- LNG Stress AnalysisDocument22 pagesLNG Stress Analysisvijayanmks100% (1)

- Pressure Equipment Directive 97 23Document260 pagesPressure Equipment Directive 97 23vijayanmksNo ratings yet

- Calculation Bellows DisplacementDocument10 pagesCalculation Bellows Displacementvijayanmks100% (1)

- TF Expansion Joints DetailsDocument34 pagesTF Expansion Joints DetailsvijayanmksNo ratings yet

- Rubber Expansion Joint - Notes PDFDocument9 pagesRubber Expansion Joint - Notes PDFvijayanmksNo ratings yet

- Structural Hollow SectionsDocument187 pagesStructural Hollow SectionsvijayanmksNo ratings yet

- Knife Gate ValvesDocument25 pagesKnife Gate ValvesvijayanmksNo ratings yet

- Anchor Block For PipeLinesDocument24 pagesAnchor Block For PipeLinesvijayanmksNo ratings yet

- Cambridge Material Data BookDocument40 pagesCambridge Material Data Bookvijayanmks0% (1)

- HDPE For OG Vs SteelDocument40 pagesHDPE For OG Vs SteelvijayanmksNo ratings yet

- Titanium AlloysDocument77 pagesTitanium Alloysvijayanmks100% (1)

- WRC Stress Analysis - NozzleDocument14 pagesWRC Stress Analysis - NozzlevijayanmksNo ratings yet

- Fire WorksDocument12 pagesFire WorksvijayanmksNo ratings yet

- AMET Mechanical PDFDocument43 pagesAMET Mechanical PDFvijayanmksNo ratings yet

- Span Limits For Elevated Temperature PipingDocument4 pagesSpan Limits For Elevated Temperature PipingDushyant Varshney100% (3)

- CAESAR Load CaseDocument15 pagesCAESAR Load Casevijayanmks100% (2)

- Vastu For House EbookDocument30 pagesVastu For House EbookpankgargNo ratings yet

- PDILDocument15 pagesPDILvijayanmksNo ratings yet

- TM-9-2320-279-34-3 M977 HemttDocument851 pagesTM-9-2320-279-34-3 M977 HemttАлександр МоскалевNo ratings yet

- HVAC Approved Manufacturers ListDocument2 pagesHVAC Approved Manufacturers ListJoshua100% (1)

- Anamorphic Lenses: Hawk V-Lite Anamorphics Hawk V-Lite Vintage 74 AnamorphicsDocument1 pageAnamorphic Lenses: Hawk V-Lite Anamorphics Hawk V-Lite Vintage 74 AnamorphicsFelix YungNo ratings yet

- Rayasandra Lake LandDocument9 pagesRayasandra Lake LandkulupsNo ratings yet

- CS1 AntibioticsDocument4 pagesCS1 AntibioticsTaraKyleUyNo ratings yet

- Topaire Cassete Aircond CatelogDocument6 pagesTopaire Cassete Aircond CatelogBina Integrated Technology Terengganu Sdn BhdNo ratings yet

- BSSHGC PPT ProposalDocument12 pagesBSSHGC PPT ProposalSin Za DolaNo ratings yet

- Ravenloft - Gazetteer ZherisiaDocument140 pagesRavenloft - Gazetteer ZherisiaDanielBelardini100% (4)

- Cambridge IGCSE ™: Information and Communication TechnologyDocument21 pagesCambridge IGCSE ™: Information and Communication Technologykiaan.0615No ratings yet

- Dr. Booth Report On Cell Tower at SchoolDocument6 pagesDr. Booth Report On Cell Tower at SchoolSafe Tech For SchoolsNo ratings yet

- 07 Tig SparesDocument14 pages07 Tig SparesWeldingSupply.com.auNo ratings yet

- Safal 5 - AssesmentDocument45 pagesSafal 5 - AssesmentSatyam KanwarNo ratings yet

- Lebanese International University School of EngineeringDocument12 pagesLebanese International University School of EngineeringHassan RashedNo ratings yet

- Archery MaintenanceDocument15 pagesArchery Maintenanceslaiyfershin100% (1)

- Read Me RSCDocument66 pagesRead Me RSCokij1209No ratings yet

- The MedTrak ProgramDocument11 pagesThe MedTrak ProgramInBalanceNo ratings yet

- (Effective From January 1, 2021) : NAAS Score of Science JournalsDocument64 pages(Effective From January 1, 2021) : NAAS Score of Science JournalsShridevi VNo ratings yet

- Master Service Manual (MSM) Product Family RT: Part Number: 146575-040 © BT Industries AB Issued: 1998-01-28 SSDDocument468 pagesMaster Service Manual (MSM) Product Family RT: Part Number: 146575-040 © BT Industries AB Issued: 1998-01-28 SSDVrshtyr100% (1)

- SSTP Deck Complete-UnprotectedDocument230 pagesSSTP Deck Complete-Unprotectedpokshyt67% (3)

- Method of Statement For Reinforced Cement Concrete WorkDocument8 pagesMethod of Statement For Reinforced Cement Concrete Workbatayi9833No ratings yet

- 2008 OliveOil Awards by CountryDocument27 pages2008 OliveOil Awards by CountrycostasthegreekNo ratings yet

- Uras26 NDIR Photometer: Z263e - Web-Based Training (External Version)Document1 pageUras26 NDIR Photometer: Z263e - Web-Based Training (External Version)isctomaslopezNo ratings yet

- SpinozaDocument5 pagesSpinozaNazirNo ratings yet

- 4610V206 - 01gb Camshaft BearingDocument1 page4610V206 - 01gb Camshaft BearingBertan ChirimNo ratings yet

- General Physics 1 Lecture Notes Kinematics Motion in One DimensionDocument11 pagesGeneral Physics 1 Lecture Notes Kinematics Motion in One DimensionJasmine DelgadoNo ratings yet

- Bubble Coral FactsDocument4 pagesBubble Coral FactsSeok WilliamsNo ratings yet

- VANETfinalDocument47 pagesVANETfinalMeenakshi MuthuramanNo ratings yet