Thioflex 600

Thioflex 600

Uploaded by

mangjitCopyright:

Available Formats

Thioflex 600

Thioflex 600

Uploaded by

mangjitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Thioflex 600

Thioflex 600

Uploaded by

mangjitCopyright:

Available Formats

Fosroc Thioflex 600 constructive solutions

Multi-component, gun and pouring grade, polysulphide

sealant

Uses Thioflex 600 is particularly recommended for use in high rise

buildings and other applications where access for

Sealing movement joints in building and civil engineering

subsequent maintenance will be difficult and the risk of early

structures, including superstructures, reservoirs, floors,

movement failure must be minimised. It is also suitable for

basements and subways.

sealing joints in brickwork, retaining walls, reservoirs,

basements and subways.Thioflex 600 pouring grade is

Advantages

recommended for sealing expansion joints and stress relief

A high quality product meeting key international standards joints in floors or other horizontal surfaces.

Forms a tough, elastic rubber-like seal

Specification

Acts as an acoustic sealant

Accommodates continuous and cyclic movement Joints shall be sealed using Fosroc Thioflex 600, two part,

polysulphide sealant, manufactured by Fosroc to BS 4254

Excellent adhesion to most common substrates

1983, and ASTM C 920 -87. Joints shall be prepared and the

High resistance to ageing reduces physical damage due

sealant mixed and applied in accordance with the

to climatic extremes

manufacturer’s current data sheet.

Standards compliance

Design criteria

British Standard BS 4254: 1983.

Thioflex 600 may be applied to joints between 5 and 50 mm

British Standard BS 6920: 1988 (gun grade grey).

wide. Joints which are expected to experience cyclic

U.S. Federal Specification TT-S-00227E November 1969

movements should be designed to an optimum width:depth

(amended 1970).

ratio of 2:1, subject to the overriding recommended minimum

Water Byelaws Scheme – Approved Product.

sealant depths set out below:

DTp specification for Highway Works Dec 1991 series

1000 clause 1017. 5 mm for metals, glass and other non-porous surfaces;

ASTM C 920-87, Type M, Class 25.

10 mm for all porous surfaces;

Description 20 mm for trafficked joints and those subject to hydrostatic

pressures.

Thioflex 600 is a multi-component joint sealant, based on a

liquid polysulphide polymer, which when mixed and applied, To ensure that the sealant remains within its stated movement

cures to form a tough, rubber-like seal. The cured sealant capacity (25% MAF), sealing slot widths should be designed

exhibits excellent adhesion to most surfaces including in accordance with the recommendations of BS 6093.

primed concrete, glass, aluminium and stainless steel.

The use of a surface primer is always required on porous

Thioflex 600 is available in gun and pouring grades. The gun surfaces. On non-porous surfaces a primer is not normally

grade is ideal for general application. It is packed in ready to required except where glass or glazed surfaces are to be

mix, 2.5 litre & 4 litre tins containing the base and curing permanently immersed in water.

agent in the correct proportions. The pouring grade for joints

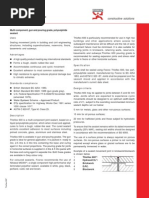

Example of a sealed movement joint in brickwork/blockwork

in horizontal surfaces is supplied in 4 litre & 5 litre packs with

is shown below

the base and curing agent in separate tins. Both these grades

1 Thioflex 600*‡

are available in Grey colour only.

2 Hydrocell XL*‡

For coloured sealants, Fosroc recommends the use of 3 Brickwork

Nitoseal MS300*‡, a single component high performance silyl 4 D.P.C.

terminated polyether sealant, available in white, grey, black, 5 Blockwork

portland, rustic red and brown.

Thioflex 600

Fosroc Thioflex 600

Example of a sealed subway expansion joint is shown below: Chemical resistance to

occasional spillage :

Dilute acids resistant

Dilute alkalis resistant

Petrol resistant

Aviation fuels resistant

Diesel fuel resistant

1 Thioflex 600 Kerosene resistant

2 Bond breaking tape Lubricating oils resistant

3 Supercast Rearguard ‘S’ waterstop Skydrol resistant

4 Blinding concrete White spirit resistant

5 Membrane Chlorinated solvents not resistant

6 Bitucell*‡ Aromatic solvents not resistant

Dilute oxidising acids not resistant

Properties

Instructions for use

Form : Grey colour, multi-part,

paste compound Joint preparation

Movement accommodation

The joint surfaces must be thoroughly dry, clean and frost

factor (BS 6093) : 25% butt joints

free. Remove all dust and laitance by rigorous wire brushing,

50% lap joints

grinding or grit blasting. Remove all rust, scale and protective

Physical or

lacquers from metal surfaces. Remove any oil or grease with

chemical change : Chemical cure

Fosroc Joint Cleaner.

Pot life : 2 hours @ 25°C

1 hour @ 35°C Any expansion joint filler must be checked to ensure it is

Setting time : 36 hours @ 15°C tightly packed and no gaps or voids exist at the base of the

18 hours @ 25°C sealing slot before positioning a bond breaker.

12 hours @ 35°C

Note: The use of a bond breaker is not required in expansion

Cure time : 2 weeks @ 15°C

joints containing Fosroc Hydrocell XL* ‡ or Expandafoam*‡

1 week @ 25°C

cellular polyethylene expansion joint fillers. For construction

4 days @ 35°C

or contraction joints a bond breaker tape or back-up strip

Application temperature : 5 to 50°C

should be used. Where hydrostatic pressure exists, only bond

Hardness shore 'A' 25°C : 15 to 23

breaking tapes must be used, not foamed back-up strips.

Water immersion : Thioflex 600 must be fully

cured before permanent Where a particularly neat finish is required, mask the face

immersion in water. edges of the joint before priming and remove immediately

Biological resistance : Thioflex 600 has been after tooling is completed.

evaluated in

Priming

microbiologically active

situations and has been Non-porous surfaces

shown to have resistance to

Use Primer MS2 on glass, ceramics and metals. The two

aerobic conditions.

part chemically active clear liquid is to be applied by brush or

Solids content : 100%

pad. One thin coat should be applied and allowed to dry for

Density : 1.62 to 1.73 kg/litre

10 to 30 minutes prior to sealant application.

according to colour.

Flash point : Over 65°C Porous surfaces

Flammability : Burns but does not readily

Primer 7E: It is a two part high performance chemically active

support combustion.

non-toxic liquid for brush application to prime all concrete,

stone, brickwork, timber and unglazed edges of ceramic tiles.

Add component A of Primer 7E to component B and mix

throughly until a homogeneuos dispersion is achieved. Apply

one thin coat using a clean, dry brush, ensuring complete

Thioflex 600 - Page 2 of 4

Fosroc Thioflex 600

coverage. Avoid over priming resulting in an excess of primer - Thioflex 600 should not be used in direct contact with

in the base of the joint or application beyond faces. The mixed materials containing pitch or bitumen.

Thioflex 600 must be applied when the primer is tack free, that

- Only Thioflex 600 Gun Grade should be used in vertical or

is after the evaporation of the solvent but before the primer film

horizontal joints in reservoirs or other water retaining

has completely reacted. After 6 hours @ 20oC, or 3 hours @

structures.

35 oC the surfaces must be re-primed before applying the

sealant. - Thioflex 600 is not recommended for use in highly

chlorinated water. If in doubt, contact your local Fosroc

Steel surfaces

technical services department.

Iron and steel must be protected with an anti-corrosion primer

prior to sealing. Estimating

Mixing Supply

Thioflex 600 GG : 2.5 litre & 4 litre packs

Gun Grade

Thioflex 600 PG : 4 litre & 5 litre packs

The base component and curing agent are supplied ready for Primer MS2 : 500 ml cans

mixing in a single tin. Mix thoroughly using a slow speed drill Primer 7E : 500 ml cans

(300-500 rpm) fitted with a Fosroc Mixing Paddle (MR2) for Fosroc solvent 102 : 5 litre containers

5 minutes. Only thorough mixing, including material right at

Coverage

the bottom of the tin, will result in proper curing. In cold weather

Thioflex 600 mixes more easily if stored overnight at room Primer MS2 : 8-10 m2/litre

temperature. Primer 7E : 8-10 m2/litre

Immediately after mixing, load the sealant into a Fosroc ‘G’ Note: Coverege figures given are theoretical due to wastage

Gun using the follower plate, and apply to the joint. factors and the variety amd the nature of substrates,

practical coverage figures maybe reduced, this will

Pouring Grade vary with site and application conditions.

Thioflex 600 Pouring Grade is supplied in two separate Guide to sealant quantities

containers. The small container contents should be transferred Joint Litres Metre run Metre run Metre run

to the other tin, and mixed as per the gun grade instructions. size per per per per

The pouring grade may be poured directly into horizontal joints in mm Metre run 2.5 ltr pack 4ltr pack 5 ltr pack

or for application to horizontal joints less than 15 mm wide 5x5 0.025 100.00 160.00 200.00

loaded into a Fosroc ‘G’ Gun. For quantity application, a Fosroc 5 x 10 0.050 50.00 80.00 100.00

1.5 litre gun is available. 10 x 5 0.050 50.00 80.00 100.00

Finishing 10 x 10 0.100 25.00 40.00 50.00

20 x 10 0.200 12.50 20.00 25.00

Thioflex 600 should be tooled to a smooth finish. A minimum 20 x 15 0.300 8.30 13.30 16.60

of surface lubricant such as dilute detergent solution may be 20 x 20 0.400 6.20 10.00 12.50

used to assist the process. Any masking tape should be 40 x 20 0.800 3.10 5.00 6.20

removed immediately after tooling. 40 x 25 1.000 2.50 4.00 5.00

Cleaning 40 x 30 1.200 2.00 3.30 4.10

40 x 40 1.600 1.50 2.50 3.10

Clean equipment immediately after use with Fosroc Solvent 102. 50 x 25 1.250 2.00 3.20 4.00

50 x 30 1.500 1.60 2.64 3.30

Limitations 50 x 40 2.000 1.25 2.00 2.50

- Over-painting of sealants is not recommended because 50 x 50 2.500 1.00 1.60 2.00

of the inability of paint films to accept movement. However, 0.5 litre of Primer MS2 will be sufficient for 60 meters of joint.

if required, trials should be carried out to determine

compatibility. 1.5 litre of Primer 7E to 150m length of 10 x 20mm joint.

These are theoretical yields. No allowance has been made

for variation in joint width or wastage.

Thioflex 600 - Page 3 of 4

Fosroc Thioflex 600

Storage Additional Information

Thioflex 600, Primer 7E and Primer MS2 have a storage life Fosroc manufactures a wide range of complementary

of 12 months when kept in original containers and stored in products which include :

dry conditions between 5°C and 27°C.

waterproofing membranes & waterstops

Precautions joint sealants & filler boards

Health and safety cementitious & epoxy grouts

Thioflex 600, Primer MS2 and Primer 7E should not come in specialised flooring materials

contact with skin and eyes or be swallowed. Avoid breathing

Fosroc additionally offers a comprehensive package of

of vapour. Splashes must be washed off immediately. Wear

products specifically designed for the repair and

impervious rubber or PVC gloves and eye protection. Hands

refurbishment of damaged concrete. Fosroc’s ‘Systematic

should be thoroughly washed with soap and water before

Approach’ to concrete repair features the following :

eating or smoking. In the case of eye contact seek medical

attention immediately. hand-placed repair mortars

Thioflex 600 curing agent consists of a heavy metal based spray grade repair mortars

oxide. Cured sealant should not be burned off due to the

fluid micro-concretes

generation of toxic fumes. Empty containers must be

collected for careful disposal and not left lying about. chemically resistant epoxy mortars

Fire anti-carbonation/anti-chloride protective coatings

Fosroc Solvent 102 is flammable. Primer MS2 and primer chemical and abrasion resistant coatings

7E are highly flammable, store away from heat. Do not use

For further information on any of the above, please consult

near naked flames or other sources of ignition. No smoking.

your local Fosroc office - as below.

Use in well ventilated surroundings. In the event of fire,

extinguish with CO2 foam.

Flash point

Primer MS2 : 23°C

Primer 7E : 23°C

For further information, refer to the Product Material Safety

Data Sheet.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the recent version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4432365 fax: 4419517 email: qatar@fosroc.com

UAE/0300/10/G

You might also like

- Concrete Used For Fireproofing: NIOEC-SP-10-04No ratings yetConcrete Used For Fireproofing: NIOEC-SP-10-049 pages

- Fosroc Thioflex 600: Multi-Component, Gun and Pouring Grade, Polysulphide Sealant UsesNo ratings yetFosroc Thioflex 600: Multi-Component, Gun and Pouring Grade, Polysulphide Sealant Uses4 pages

- Thioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureNo ratings yetThioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & Infrastructure5 pages

- Fosroc Thioflex 600 Gun Grade: Technical Data SheetNo ratings yetFosroc Thioflex 600 Gun Grade: Technical Data Sheet3 pages

- Thioflex 600: Two-Part Polysulphide SealantNo ratings yetThioflex 600: Two-Part Polysulphide Sealant4 pages

- Thioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceNo ratings yetThioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards Compliance5 pages

- Nitoflor Hardtop - Technical Submittal - 8 Apr 2020No ratings yetNitoflor Hardtop - Technical Submittal - 8 Apr 202030 pages

- Fosroc Conbextra EP75: Constructive SolutionsNo ratings yetFosroc Conbextra EP75: Constructive Solutions2 pages

- Fosroc Nitoproof 800HT System: Liquid Applied Waterproofing SystemNo ratings yetFosroc Nitoproof 800HT System: Liquid Applied Waterproofing System5 pages

- Conbextra EP120: High Strength, Epoxy Resin GroutNo ratings yetConbextra EP120: High Strength, Epoxy Resin Grout2 pages

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutNo ratings yetFosroc Conbextra EP40: Free Flowing, Epoxy Resin Grout2 pages

- Fosroc Conbextra EP10: Constructive SolutionsNo ratings yetFosroc Conbextra EP10: Constructive Solutions2 pages

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Water-based Acrylic Dispersions: Applications in Architectural CoatingsFrom EverandWater-based Acrylic Dispersions: Applications in Architectural CoatingsNo ratings yet

- Pages From Equipment Manual SN 21870-2 3No ratings yetPages From Equipment Manual SN 21870-2 31 page

- Corporate Social Responsibility Policy (CSR Policy) : 1. Title and ApplicabilityNo ratings yetCorporate Social Responsibility Policy (CSR Policy) : 1. Title and Applicability1 page

- Fosroc Nitoproof 10: Constructive SolutionsNo ratings yetFosroc Nitoproof 10: Constructive Solutions2 pages

- Tadano Tr-500ex Rough Terrain Crane Network PDFNo ratings yetTadano Tr-500ex Rough Terrain Crane Network PDF6 pages

- Fatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, GermanyNo ratings yetFatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, Germany6 pages

- Flexural Performance of The Integrated Steel Truss Reinforced 3D Printed Concrete Beams Experimental and Numerical AnalysisNo ratings yetFlexural Performance of The Integrated Steel Truss Reinforced 3D Printed Concrete Beams Experimental and Numerical Analysis17 pages

- Props and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The ProductsNo ratings yetProps and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The Products38 pages

- Response of Concrete Liquid Containing Structures in Different Seismic ZonesNo ratings yetResponse of Concrete Liquid Containing Structures in Different Seismic Zones13 pages

- Basilisk Brochure - Liquid Repair System ER7 EN - v2022cNo ratings yetBasilisk Brochure - Liquid Repair System ER7 EN - v2022c4 pages

- UNIT-1 Advanced Structural System: GroupNo ratings yetUNIT-1 Advanced Structural System: Group19 pages

- U.S. Army Explosives and Demolitions HandbookFrom EverandU.S. Army Explosives and Demolitions Handbook

- Fosroc Thioflex 600: Multi-Component, Gun and Pouring Grade, Polysulphide Sealant UsesFosroc Thioflex 600: Multi-Component, Gun and Pouring Grade, Polysulphide Sealant Uses

- Thioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureThioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & Infrastructure

- Fosroc Thioflex 600 Gun Grade: Technical Data SheetFosroc Thioflex 600 Gun Grade: Technical Data Sheet

- Thioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceThioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards Compliance

- Nitoflor Hardtop - Technical Submittal - 8 Apr 2020Nitoflor Hardtop - Technical Submittal - 8 Apr 2020

- Fosroc Nitoproof 800HT System: Liquid Applied Waterproofing SystemFosroc Nitoproof 800HT System: Liquid Applied Waterproofing System

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutFosroc Conbextra EP40: Free Flowing, Epoxy Resin Grout

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and Secco

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and Applications

- Turf Wall Architecture and Turf Furniture Assembly GuideFrom EverandTurf Wall Architecture and Turf Furniture Assembly Guide

- Water-based Acrylic Dispersions: Applications in Architectural CoatingsFrom EverandWater-based Acrylic Dispersions: Applications in Architectural Coatings

- Corporate Social Responsibility Policy (CSR Policy) : 1. Title and ApplicabilityCorporate Social Responsibility Policy (CSR Policy) : 1. Title and Applicability

- Fatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, GermanyFatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, Germany

- Flexural Performance of The Integrated Steel Truss Reinforced 3D Printed Concrete Beams Experimental and Numerical AnalysisFlexural Performance of The Integrated Steel Truss Reinforced 3D Printed Concrete Beams Experimental and Numerical Analysis

- Props and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The ProductsProps and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The Products

- Response of Concrete Liquid Containing Structures in Different Seismic ZonesResponse of Concrete Liquid Containing Structures in Different Seismic Zones

- Basilisk Brochure - Liquid Repair System ER7 EN - v2022cBasilisk Brochure - Liquid Repair System ER7 EN - v2022c