Road Wheels & Tires: Section

Road Wheels & Tires: Section

Uploaded by

Wilmer QuiñonezCopyright:

Available Formats

Road Wheels & Tires: Section

Road Wheels & Tires: Section

Uploaded by

Wilmer QuiñonezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Road Wheels & Tires: Section

Road Wheels & Tires: Section

Uploaded by

Wilmer QuiñonezCopyright:

Available Formats

SUSPENSION

WT

A

B

SECTION

ROAD WHEELS & TIRES C

WT

CONTENTS

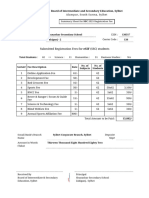

SERVICE INFORMATION ............................ 2 CONSULT-III Function (BCM) .................................14 F

How to Perform Trouble Diagnosis for Quick and

PRECAUTIONS ................................................... 2 Accurate Repair .......................................................15

Precaution for Supplemental Restraint System Preliminary Check ...................................................16 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Self-Diagnosis (With CONSULT-III) ........................16

SIONER" ................................................................... 2 Self-Diagnosis (Without CONSULT-III) ...................17

Precaution Necessary for Steering Wheel Rota-

TROUBLE DIAGNOSIS FOR SELF-DIAG- H

tion After Battery Disconnect ..................................... 2

NOSTIC ITEMS ................................................. 20

PREPARATION ................................................... 4 Data from Transmitter Not Being Received .............20

Special Service Tool ................................................. 4 Transmitter Malfunction ...........................................20 I

Commercial Service Tool .......................................... 4 Transmitter Pressure Malfunction ............................21

Vehicle Speed Signal ..............................................21

NOISE, VIBRATION AND HARSHNESS Vehicle Ignition Signal .............................................22

(NVH) TROUBLESHOOTING ............................. 5 J

NVH Troubleshooting Chart ...................................... 5 TROUBLE DIAGNOSIS FOR SYMPTOMS ...... 23

Low Tire Pressure Warning Lamp Does Not Come

ROAD WHEEL .................................................... 6 On When Ignition Switch Is Turned On ...................23 K

Inspection .................................................................. 6 Low Tire Pressure Warning Lamp Stays On When

ROAD WHEEL TIRE ASSEMBLY ...................... 7 Ignition Switch Is Turned On ...................................23

Adjustment ................................................................ 7 Low Tire Pressure Warning Lamp Flashes When L

Ignition Switch Is Turned On ...................................24

TIRE PRESSURE MONITORING SYSTEM ........ 9 Hazard Warning Lamps Flash When Ignition

System Component ................................................... 9 Switch Is Turned On ................................................25

M

System Description ................................................... 9 ID Registration Cannot Be Completed ....................25

CAN COMMUNICATION ....................................11 REMOVAL AND INSTALLATION ..................... 26

System Description ................................................. 11 Transmitter (Pressure Sensor) ................................26 N

TROUBLE DIAGNOSES ....................................12 SERVICE DATA AND SPECIFICATIONS

Wiring Diagram- T/WARN - ..................................... 12 (SDS) ................................................................. 28

O

Terminal and Reference Value for BCM ................. 12 Road Wheel .............................................................28

ID Registration Procedure ....................................... 13 Tire ..........................................................................28

Transmitter Wake Up Operation ............................. 14

P

Revision: January 2010 WT-1 2010 Versa

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005397085

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005397086

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 2010 WT-2 2010 Versa

PRECAUTIONS

< SERVICE INFORMATION >

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.) A

6. Perform a self-diagnosis check of all control units using CONSULT-III.

WT

Revision: January 2010 WT-3 2010 Versa

PREPARATION

< SERVICE INFORMATION >

PREPARATION

Special Service Tool INFOID:0000000005397087

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number Description

(Kent-Moore No.)

Tool name

KV991B1000 • Transmitter wake up operation

(J-45295) • ID registration procedure

Transmitter activation tool

WEIA0144E

Commercial Service Tool INFOID:0000000005397088

Tool name Description

Power tool Removing wheel nuts

PIIB1407E

Revision: January 2010 WT-4 2010 Versa

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

A

NVH Troubleshooting Chart INFOID:0000000005397089

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts. B

RAX-5, "NVH Troubleshooting Chart",

Refer to ROAD WHEELS in this chart

FAX-5, "NVH Troubleshooting Chart",

RSU-5, "NVH Troubleshooting Chart"

FSU-6, "NVH Troubleshooting Chart"

FAX-5, "NVH Troubleshooting Chart"

BR-5, "NVH Troubleshooting Chart"

PS-5, "NVH Troubleshooting Chart"

C

Refer to TIRES in this chart

D

WT-28

WT-28

WT-28

FAX-6

WT-6

WT-7

WT-6

WT-6

Reference page

WT

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

G

Improper installation, looseness

H

Deformation or damage

Possible cause and SUSPECTED PARTS

Incorrect tire pressure

Incorrect tire size

Uneven tire wear

ROAD WHEELS

I

DRIVE SHAFT

Non-uniformity

Out-of-round

STEERING

Imbalance

BRAKE

TIRES

J

Noise × × × × × × × × × × × × ×

Shake × × × × × × × × × × × × × K

Vibration × × × × × ×

TIRES Shimmy × × × × × × × × × × × × ×

L

Shudder × × × × × × × × × × × ×

Poor quality ride

Symptom × × × × × × × × × ×

or handling

M

Noise × × × × × × × × × ×

Shake × × × × × × × × × ×

ROAD WHEELS Shimmy, Shud- N

× × × × × × × × ×

der

Poor quality ride

× × × × × × ×

or handling O

×: Applicable

Revision: January 2010 WT-5 2010 Versa

ROAD WHEEL

< SERVICE INFORMATION >

ROAD WHEEL

Inspection INFOID:0000000005397090

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from aluminum wheel and mount on a tire balance machine.

b. Set dial indicator as shown.

Wheel runout : Refer to WT-28, "Road Wheel".

(Dial indicator value)

SFA975B

STEEL WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from steel wheel and mount on a tire balance machine.

b. Set two dial indicators as shown.

c. Set each dial indicator to 0.

d. Rotate wheel and check dial indicators at several points around

the circumference of the wheel.

e. Calculate runout at each point as shown.

Radial runout = (A+B)/2

Lateral runout = (C+D)/2

f. Select maximum positive runout value and the maximum nega-

tive value.

Add the two values to determine total runout. In case a positive

or negative value is not available, use the maximum value (neg-

ative or positive) for total runout. If the total runout value

exceeds the limit, replace steel wheel.

Wheel runout : Refer to WT-28, "Road Wheel".

SEIA0558E

Revision: January 2010 WT-6 2010 Versa

ROAD WHEEL TIRE ASSEMBLY

< SERVICE INFORMATION >

ROAD WHEEL TIRE ASSEMBLY

A

Adjustment INFOID:0000000005714422

BALANCING WHEELS (ADHESIVE WEIGHT TYPE) B

Preparation Before Adjustment

Remove inner and outer balance weights from the road wheel using releasing agent, remove double-faced

adhesive tape from the road wheel. C

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road D

wheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and WT

skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the center hole as a guide. Start the balancer machine. F

2. For tire balance machines that only have a clip-on (rim flange) weight mode setting, follow this step to cal-

culate the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

G

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed H

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value) I

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

J

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

SMA054D

K

3. Install balance weight in the position shown.

CAUTION:

• Do not install the inner balance weight before installing L

the outer balance weight.

• Before installing the balance weight, be sure to clean the

mating surface of the road wheel.

M

• When installing balance weight (1) to road wheel, set it into the

grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight center (B) is aligned with the bal-

ancer machine indication position (angle) (C). N

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace with

O

new ones.

• Do not install more than three sheets of balance weight.

JPEIC0040ZZ

Revision: January 2010 WT-7 2010 Versa

ROAD WHEEL TIRE ASSEMBLY

< SERVICE INFORMATION >

4. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal-

ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual

imbalance values are 5 g (0.17 oz) each or below. PEIA0033E

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable un-

Refer to WT-28, "Road Wheel".

balance

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "General Maintenance".

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the T-type spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

SMA829C

• Use NISSAN genuine wheel nuts for aluminum wheels.

Wheel nut tightening : 113 N·m (12 kg-m, 83 ft-lb)

torque

• Perform the ID registration, after tire rotation. Refer to WT-13, "ID Registration Procedure".

Revision: January 2010 WT-8 2010 Versa

TIRE PRESSURE MONITORING SYSTEM

< SERVICE INFORMATION >

TIRE PRESSURE MONITORING SYSTEM

A

System Component INFOID:0000000005397093

WT

WEIA0185E

I

1. BCM 2. Transmitters 3. Tire pressure warning check connector

M18, M20 M39

4. Combination meter 5. Remote keyless entry receiver J

M24 M23

K

System Description INFOID:0000000005397094

BODY CONTROL MODULE (BCM) L

The BCM is shown with the glove box removed. The BCM reads the

air pressure signal received by the remote keyless entry receiver,

and controls the low tire pressure warning lamp as shown below. It M

also has a self-diagnosis function to detect a system malfunction.

Condition Low tire pressure warning lamp N

System normal On for 1 second after ignition ON

Tire less than 193 kPa (2.0 kg/cm2 , 28 psi) ON

[Flat tire] O

Tire pressure monitoring system malfunc- After key ON, flashes once per sec- WEIA0187E

tion ond for 1 minute, then stays ON

P

TRANSMITTER

Revision: January 2010 WT-9 2010 Versa

TIRE PRESSURE MONITORING SYSTEM

< SERVICE INFORMATION >

A sensor-transmitter integrated with a valve is installed in each

wheel, and transmits a detected air pressure signal in the form of a

radio wave. The radio signal is received by the remote keyless entry

receiver.

WEIA0137E

REMOTE KEYLESS ENTRY RECEIVER

The remote keyless entry receiver is shown with the glove box

removed. The remote keyless entry receiver receives the air pres-

sure signal transmitted by the transmitter in each wheel.

WEIA0186E

COMBINATION METER

The combination meter receives tire pressure status from the BCM

using CAN communication. When a low tire pressure condition is

sensed by the BCM, the combination meter low tire pressure warn-

ing lamp is activated.

LEIA0055E

TIRE PRESSURE WARNING CHECK CONNECTOR

The tire pressure warning check connector can be grounded in order to initiate self-diagnosis without a CON-

SULT-III. Refer to WT-17, "Self-Diagnosis (Without CONSULT-III)". The tire pressure warning check connector

is located behind the lower portion of the instrument panel LH. Refer to PG-39, "Harness Layout".

Revision: January 2010 WT-10 2010 Versa

CAN COMMUNICATION

< SERVICE INFORMATION >

CAN COMMUNICATION

A

System Description INFOID:0000000005397095

Refer to LAN-7. B

WT

Revision: January 2010 WT-11 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

TROUBLE DIAGNOSES

Wiring Diagram- T/WARN - INFOID:0000000005397096

ABEWA0037GB

Terminal and Reference Value for BCM INFOID:0000000005397097

Refer to BCS-12, "Terminal and Reference Value for BCM" .

Revision: January 2010 WT-12 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

ID Registration Procedure INFOID:0000000005397098

A

ID REGISTRATION WITH TRANSMITTER ACTIVATION TOOL

NOTE:

This procedure must be done after replacement of a low tire pressure warning transmitter or BCM. B

New replacement transmitters are provided "asleep" and must first be "woken up" using Transmitter

Activation Tool J-45295 before ID registration can be performed.

1. Connect CONSULT-III. C

2. Select “AIR PRESSURE MONITOR” on "SELECT TEST ITEM" screen.

3. Select “WORK SUPPORT” on "SELECT DIAG MODE" screen, and select "ID REGIST".

4. Push the transmitter activation tool against the tire near the front D

left transmitter. Press the button for 5 seconds.

Tool number : (J-45295) WT

LEIA0036E

G

5. Register the IDs in order from FR LH, FR RH, RR RH and RR LH. When ID registration of each wheel has

been completed, a buzzer sounds and the hazard warning lamps flash.

H

Activation tire position Buzzer Hazard warning lamp CONSULT-III

1 Front LH Once I

2 Front RH 2 times “YET”

2 times flashing ↓

3 Rear RH 3 times “DONE”

4 Rear LH 4 times J

6. After completing all ID registrations, press “END” to complete the procedure.

NOTE: K

Be sure to register the IDs in order from FR LH, FR RH, RR RH, to RR LH, or the self-diagnostic results dis-

play will not function properly.

ID REGISTRATION WITHOUT TRANSMITTER ACTIVATION TOOL L

NOTE:

This procedure must be done after replacement of a low tire pressure warning transmitter or BCM.

New replacement transmitters are provided "asleep" and must first be "woken up" using Transmitter

Activation Tool J-45295 before ID registration can be performed. M

1. Connect CONSULT-III.

2. Select “AIR PRESSURE MONITOR” on “SELECT TEST ITEM" screen.

N

3. Select “WORK SUPPORT” on “SELECT DIAG MODE" screen, and select "ID REGIST".

4. Adjust the tire pressure to the values shown in the table below and drive the vehicle at 15 km/h (9.4 MPH)

or more for a few minutes.

O

Tire position Tire pressure kPa (kg/cm2 , psi) P

Front – Left 250 (2.5, 36)

Front – Right 230 (2.3, 33)

Rear – Right 210 (2.1, 30)

Rear – Left 190 (1.9, 27)

5. After completing all ID registrations, press “END” to complete the procedure.

Revision: January 2010 WT-13 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

Activation tire position CONSULT-III

Front LH

Front RH “YET”

↓

Rear RH “DONE”

Rear LH

6. Inflate all tires to proper pressure. Refer to WT-28, "Tire" .

Transmitter Wake Up Operation INFOID:0000000005397099

NOTE:

This procedure must be done after replacement of a low tire pressure warning transmitter or BCM.

New replacement transmitters are provided "asleep" and must first be "woken up" using Transmitter

Activation Tool J-45295 before ID registration can be performed.

1. Turn ignition switch ON. Push the transmitter activation tool

against the tire near the front left transmitter. Press the button for

5 seconds. The hazard warning lamps flash per the diagram

below.

Tool number : (J-45295)

LEIA0036E

2. Repeat this procedure for each tire in the following order: FL, FR, RR, RL.

3. When the BCM finishes assigning each tire ID, the BCM flashes the hazard warning lamps and sends

flashing indicator status by CAN according to the following time chart.

WEIA0177E

4. After completing wake up of all transmitters, make sure low tire pressure warning lamp goes out.

CONSULT-III Function (BCM) INFOID:0000000005397100

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

Diagnostic mode Description

Supports inspections and adjustments. Commands are transmitted to the BCM for setting

WORK SUPPORT the status suitable for required operation, input/output signals are received from the BCM

and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

Revision: January 2010 WT-14 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

Diagnostic mode Description

A

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. B

ECU IDENTIFICATION BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

C

How to Perform Trouble Diagnosis for Quick and Accurate Repair INFOID:0000000005397101

INTRODUCTION D

• Before troubleshooting, verify customer complaints.

• If a vehicle malfunction is difficult to reproduce, harnesses, harness connectors or terminals may be mal-

functioning. Hold and shake these parts to make sure they are securely connected.

WT

• When using a circuit tester to measure voltage or resistance of each circuit, be careful not to damage or

deform connector terminals.

WORK FLOW F

SEIA0100E

Preliminary check : WT-16 Self-diagnosis : WT-16 Trouble diagnosis for symptoms : WT-23

Revision: January 2010 WT-15 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

Preliminary Check INFOID:0000000005397102

BASIC INSPECTION

1.CHECK ALL TIRE PRESSURES

Check all tire pressures. Refer to WT-28, "Tire" .

OK or NG

OK >> GO TO 2.

NG >> Adjust tire pressure to specified value.

2.CHECK LOW TIRE PRESSURE WARNING LAMP ACTIVATION

Check low tire pressure warning lamp activation.

Does warning lamp activate for 1 second when ignition switch is turned ON?

YES >> GO TO 3.

NO >> GO TO WT-23, "Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is

Turned On" .

3.CHECK BCM CONNECTOR

1. Disconnect BCM harness connector.

2. Check terminals for damage or loose connection.

3. Reconnect harness connector.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK TRANSMITTER ACTIVATION TOOL

Check transmitter activation tool battery.

OK or NG

OK >> Carry out self-diagnosis.

NG >> Replace battery in transmitter activation tool.

Self-Diagnosis (With CONSULT-III) INFOID:0000000005397103

DESCRIPTION

During driving, the tire pressure monitoring system receives the signal transmitted from the transmitter

installed in each wheel, and turns on the low tire pressure warning lamp when the tire pressure becomes low.

The control unit (BCM) for this system has pressure judgement and self-diagnosis functions.

FUNCTION

When the tire pressure monitoring system detects low inflation pressure or an internal malfunction, the low tire

pressure warning lamp in the combination meter comes on. The malfunction location is indicated by the low

tire pressure warning lamp flashing and the buzzer sounding.

CONSULT-III Application to Tire Pressure Monitoring System

ITEM SELF-DIAGNOSTIC RESULTS DATA MONITOR

Front - Left transmitter × ×

Front - Right transmitter × ×

Rear - Left transmitter × ×

Rear - Right transmitter × ×

Warning lamp — ×

Vehicle speed × ×

Buzzer (in combination meter) — ×

CAN Communication × ×

× : Applicable

– : Not applicable

Revision: January 2010 WT-16 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

Self-Diagnostic Results Mode

A

Reference

Diagnostic item Diagnostic item is detected when ···

page

FLAT - TIRE - FL [C1704] B

FLAT - TIRE - FR [C1705] Tire pressure dropped below specified value. Refer to WT-

—

FLAT - TIRE - RR [C1706] 9, "System Description".

FLAT - TIRE - RL [C1707]

C

[NO-DATA] - FL [C1708] Data from FL transmitter cannot be received.

[NO-DATA] - FR [C1709] Data from FR transmitter cannot be received.

WT-20

[NO-DATA] - RR [C1710] Data from RR transmitter cannot be received.

[NO-DATA] - RL [C1711] Data from RL transmitter cannot be received. D

[CHECKSUM- ERR] - FL [C1712] Checksum data from FL transmitter is malfunctioning.

[CHECKSUM- ERR] - FR [C1713] Checksum data from FR transmitter is malfunctioning.

WT-20

[CHECKSUM- ERR] - RR [C1714] Checksum data from RR transmitter is malfunctioning.

[CHECKSUM- ERR] - RL [C1715] Checksum data from RL transmitter is malfunctioning.

WT

[PRESSDATA- ERR] - FL [C1716] Air pressure data from FL transmitter is malfunctioning.

[PRESSDATA- ERR] - FR [C1717] Air pressure data from FR transmitter is malfunctioning.

WT-21

[PRESSDATA- ERR] - RR [C1718] Air pressure data from RR transmitter is malfunctioning. F

[PRESSDATA- ERR] - RL [C1719] Air pressure data from RL transmitter is malfunctioning.

[CODE- ERR] - FL [C1720] Function code data from FL transmitter is malfunctioning.

[CODE- ERR] - FR [C1721] Function code data from FR transmitter is malfunctioning. G

WT-20

[CODE- ERR] - RR [C1722] Function code data from RR transmitter is malfunctioning.

[CODE- ERR] - RL [C1723] Function code data from RL transmitter is malfunctioning.

[BATT - VOLT - LOW] - FL [C1724] Battery voltage of FL transmitter drops.

H

[BATT - VOLT - LOW] - FR [C1725] Battery voltage of FR transmitter drops.

WT-20

[BATT - VOLT - LOW] - RR [C1726] Battery voltage of RR transmitter drops.

[BATT - VOLT - LOW] - RL [C1727] Battery voltage of RL transmitter drops.

VHCL_SPEED_SIG_ERR [C1729] Vehicle speed signal is in error. WT-21 I

IGN_CIRCUIT_OPEN [C1735] Vehicle ignition signal is in error. WT-22

NOTE:

J

Before performing the self-diagnosis, be sure to register the ID or else the actual malfunction location may be different from that dis-

played on CONSULT-III.

Data Monitor Mode K

MONITOR CONDITION SPECIFICATION

VEHICLE SPEED Drive vehicle. Vehicle speed (km/h or MPH) L

• Drive vehicle for a few minutes.

AIR PRESS FL

AIR PRESS FR or

Tire pressure (kPa or psi)

AIR PRESS RR

• Ignition switch ON and activation tool M

AIR PRESS RL

is transmitting activation signals.

ID REGST FL1

ID REGST FR1 Registration ID: DONE N

ID REGST RR1 No registration ID: YET

ID REGST RL1

Ignition switch ON

Low tire pressure warning lamp on: ON O

WARNING LAMP

Low tire pressure warning lamp off: OFF

Buzzer in combination meter on: ON

BUZZER

Buzzer in combination meter off: OFF

P

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or the actual malfunction location may be different from that displayed on

CONSULT-III.

Self-Diagnosis (Without CONSULT-III) INFOID:0000000005397104

SELF DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-III)

Revision: January 2010 WT-17 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

1. Turn ignition switch ON.

2. Ground the tire pressure warning check connector to initiate self diagnosis.

3. Compare the flashing pattern with the flash code chart below.

ALEIA0050GB

NOTE:

The system is normal when the low tire pressure warning lamp flashes 5 times and continues repeating. Self-

diagnosis results are erased automatically by turning the ignition switch “OFF”.

Reference

Flash Code or Symptom Malfunction part

page

15

16 Tire pressure dropped below specified value. Refer to WT-9, "System

—

17 Description".

18

21 Transmitter no data (FL)

22 Transmitter no data (FR)

WT-20

23 Transmitter no data (RR)

24 Transmitter no data (RL)

31 Transmitter checksum error (FL)

32 Transmitter checksum error (FR)

WT-20

33 Transmitter checksum error (RR)

34 Transmitter checksum error (RL)

35 Transmitter pressure data error (FL)

36 Transmitter pressure data error (FR)

WT-21

37 Transmitter pressure data error (RR)

38 Transmitter pressure data error (RL)

41 Transmitter function code error (FL)

42 Transmitter function code error (FR)

WT-20

43 Transmitter function code error (RR)

44 Transmitter function code error (RL)

45 Transmitter battery voltage low (FL)

46 Transmitter battery voltage low (FR)

WT-20

47 Transmitter battery voltage low (RR)

48 Transmitter battery voltage low (RL)

52 Vehicle speed signal WT-21

54 Vehicle ignition signal WT-22

Low tire pressure warning lamp does • Fuse or combination meter

not come on when ignition switch is • BCM connector or circuit WT-23

turned on. • BCM

• Combination meter

Low tire pressure warning lamp stays

• BCM connector or circuit WT-23

on when ignition switch is turned on.

• BCM

• BCM harness connector or circuit

Low tire pressure warning lamp flashes • BCM

WT-24

when ignition switch is turned on. • Transmitter's mode off

• ID registration not completed yet

Revision: January 2010 WT-18 2010 Versa

TROUBLE DIAGNOSES

< SERVICE INFORMATION >

Reference

Flash Code or Symptom Malfunction part

page A

Hazard warning lamps flash when igni- • BCM harness connector or circuit

WT-25

tion switch is turned on. • BCM

• Transmitter B

• Remote keyless entry receiver harness connector or circuit

ID registration cannot be completed. • Remote keyless entry receiver WT-25

• BCM harness connector or circuit

• BCM

C

WT

Revision: January 2010 WT-19 2010 Versa

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Data from Transmitter Not Being Received INFOID:0000000005397105

MALFUNCTION CODE NO. 21, 22, 23 OR 24 (DTC C1708, C1709, C1710 OR C1711)

1.CHECK BCM

Drive for several minutes. Check all tire pressures with CONSULT-III.

Are all tire pressures displayed as 0 kPa?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK REMOTE KEYLESS ENTRY RECEIVER CONNECTOR

Check remote keyless entry receiver connector for damage or loose connections.

OK or NG

OK >> Replace BCM, then GO TO 3. Refer to BCS-19, "Removal and Installation of BCM".

NG >> Repair or replace remote keyless entry receiver connector.

3.PERFORM ID REGISTRATION

Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure".

Is there a tire that cannot register ID?

YES >> Replace transmitter of the tire, then GO TO 5. Refer to WT-26, "Transmitter (Pressure Sensor)".

NO >> GO TO 4.

4.DRIVE VEHICLE

1. Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping.

2. Check all tire pressures with CONSULT-III within 15 minutes after vehicle speed becomes 17 km/h (11

MPH).

Does “DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> Inspection End.

NO >> GO TO 5.

5.ID REGISTRATION AND VEHICLE DRIVING

1. Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure".

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes.

3. Check all tire pressures with CONSULT-III within 5 minutes.

Does “DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> Inspection End.

NO >> GO TO the inspection applicable to DTC.

Transmitter Malfunction INFOID:0000000005397106

MALFUNCTION CODE NO. 31, 32, 33, 34, 41, 42, 43, 44, 45, 46, 47 OR 48 (DTC C1712, C1713,

C1714, C1715, C1720, C1721, C1722, C1723, C1724, C1725, C1726 OR C1727)

1.PERFORM ID REGISTRATION

1. Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure".

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes.

>> GO TO 2.

2.REPLACE TRANSMITTER

1. Check low tire pressure warning lamp again for flashing, replace malfunctioning transmitter. Refer to WT-

26, "Transmitter (Pressure Sensor)".

2. Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure".

Revision: January 2010 WT-20 2010 Versa

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

< SERVICE INFORMATION >

Can ID registration of all transmitters be completed?

YES >> GO TO 3. A

NO >> GO TO WT-20, "Data from Transmitter Not Being Received".

3.DRIVE VEHICLE

B

1. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Check all tire pressures with CONSULT-III within 5 minutes.

C

Does “DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> Inspection End.

NO >> Replace malfunctioning transmitter, and perform Step 3 again. Refer to WT-26, "Transmitter

(Pressure Sensor)". D

Transmitter Pressure Malfunction INFOID:0000000005397107

WT

MALFUNCTION CODE NO. 35, 36, 37 OR 38 (DTC C1716, C1717, C1718 OR C1719)

1.CHECK ALL TIRE PRESSURES

F

Check all tire pressures. Refer to WT-28, "Tire".

Are there any tires with pressure of 64 psi or more?

YES >> Adjust tire pressure to specified value.

G

NO >> GO TO 2.

2.ID REGISTRATION AND VEHICLE DRIVING

1. Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure". H

2. Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping.

3. Check all tire pressures with CONSULT-III within 15 minutes after vehicle speed becomes 17 km/h (11

MPH). I

Does “DATA MONITOR ITEM” display 64 psi or more?

YES >> Replace transmitter. Refer to WT-26, "Transmitter (Pressure Sensor)". GO TO 3.

NO >> GO TO 3. J

3.ID REGISTRATION AND VEHICLE DRIVING

1. Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure".

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for K

10 minutes.

3. Check all tire pressures with CONSULT-III within 5 minutes.

Does “DATA MONITOR ITEM” display tire pressure as normal without any warning lamp? L

YES >> Inspection End.

NO >> GO TO the inspection applicable to DTC.

M

Vehicle Speed Signal INFOID:0000000005397108

MALFUNCTION CODE NO. 52 (DTC C1729)

N

1.SELF-DIAGNOSTIC RESULT CHECK

Using CONSULT-III, check display contents in self-diagnostic results.

Is " CAN COMM CIRCUIT" displayed in the self-diagnosis display items? O

YES >> Malfunction in CAN communication system. GO TO LAN-13, "CAN Diagnosis with CONSULT-III".

NO >> GO TO 2.

2.CHECK BCM P

Perform BCM diagnosis. Refer to BCS-17, "CONSULT-III Function (BCM)".

Inspection results OK?

OK >> Perform Vehicle Speed Sensor Inspection. Refer to EC-342, "Diagnosis Procedure" (HR16DE) or

EC-888, "Diagnosis Procedure" (MR18DE).

NG >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

Revision: January 2010 WT-21 2010 Versa

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

< SERVICE INFORMATION >

Vehicle Ignition Signal INFOID:0000000005397109

MALFUNCTION CODE NO. 54 (DTC C1735)

1.CAN IGNITION SIGNAL

Check BCM IGN RLY signal with CONSULT-III. Refer to BCS-12, "Terminal and Reference Value for BCM".

Are the inspection results normal with the ignition switch ON?

YES >> GO TO 2.

NO >> Check CAN system. Refer to LAN-17, "Trouble Diagnosis Flow Chart".

2.BCM POWER SUPPLY

Check BCM power supply (ignition ON). Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspec-

tion".

Is the power supply with the ignition switch ON normal?

YES >> GO TO 3.

NO >> Repair power supply as necessary.

3.DRIVE VEHICLE

Clear DTC and then test drive the vehicle and check the low tire pressure warning lamp.

Does the vehicle operate without any low tire pressure warning lamp?

YES >> Inspection End.

NO >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

Revision: January 2010 WT-22 2010 Versa

TROUBLE DIAGNOSIS FOR SYMPTOMS

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

A

Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is Turned

On INFOID:0000000005397110

B

DIAGNOSTIC PROCEDURE

1.SELF-DIAGNOSTIC RESULT CHECK C

Using CONSULT-III, check display contents in self-diagnostic results.

Is "CAN COMM CIRCUIT" displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-13, "CAN Diagnosis with CONSULT- D

III".

NO >> GO TO 2.

2.CHECK COMBINATION METER WT

Check combination meter operation. Refer to DI-11, "Self-Diagnosis Mode of Combination Meter".

Inspection results OK?

F

OK >> GO TO 3.

NG >> Replace combination meter. Refer to IP-12, "Removal and Installation".

3.CHECK LOW TIRE PRESSURE WARNING LAMP G

Disconnect BCM harness connector.

Does the low tire pressure warning lamp activate?

YES >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM". H

NO >> Check combination meter operation. Refer to DI-11, "Self-Diagnosis Mode of Combination

Meter".

I

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000005397111

DIAGNOSTIC PROCEDURE J

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF. K

2. Disconnect BCM harness connectors M18 and M20.

3. Check terminals for damage or loose connections.

Inspection results OK? L

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK BCM POWER SUPPLY CIRCUIT (BAT) M

Check voltage between BCM harness connector M20 terminal 70 and ground.

1.

N

Terminals Voltage

(+) (–) (Approx.)

Connector Terminal Battery O

Ground

M20 70 voltage

OK or NG P

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

WEIA0188E

3.CHECK BCM POWER SUPPLY CIRCUIT (IGN)

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector M18 terminal 38 and ground.

Revision: January 2010 WT-23 2010 Versa

TROUBLE DIAGNOSIS FOR SYMPTOMS

< SERVICE INFORMATION >

Terminals Voltage

(+) (–) (Approx.)

Connector Terminal Battery

Ground

M18 38 voltage

OK or NG

OK >> GO TO 4.

NG >> Check BCM power supply circuit for open or short.

WEIA0038E

4.CHECK BCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between BCM harness connector M20 terminal 67 and ground.

Terminals Continuity

(+) (–)

Connector Terminal

Ground Yes

M20 67

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM".

NG >> Repair BCM ground circuit. WEIA0189E

Low Tire Pressure Warning Lamp Flashes When Ignition Switch Is Turned On

INFOID:0000000005397112

NOTE:

If low tire pressure warning lamp flashes as shown, the system is normal.

Flash Mode A

• This mode shows transmitter status is OFF-mode.

Carry out transmitter wake up operation. Refer to WT-14, "Trans-

mitter Wake Up Operation".

SEIA0347E

DIAGNOSTIC PROCEDURE

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors M18 and M20.

3. Check terminals for damage or loose connections.

Inspection results OK?

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK TIRE PRESSURE WARNING CHECK CONNECTOR CIRCUIT

Check continuity between BCM harness connector M18 terminal 15 and check connector M39 terminal 1.

Revision: January 2010 WT-24 2010 Versa

TROUBLE DIAGNOSIS FOR SYMPTOMS

< SERVICE INFORMATION >

Continuity should exist. A

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM". B

NG >> Repair or replace harness connector.

WEIA0127E

D

Hazard Warning Lamps Flash When Ignition Switch Is Turned On INFOID:0000000005397113

DIAGNOSTIC PROCEDURE

WT

1.CHECK BCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM harness connector M20. F

3. Check continuity between BCM harness connector M20 terminal 67 and ground.

Terminals Continuity G

(+) (–)

Connector Terminal H

Ground Yes

M20 67

OK or NG

I

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM".

NG >> Repair BCM ground circuit. WEIA0189E

J

ID Registration Cannot Be Completed INFOID:0000000005397114

DIAGNOSTIC PROCEDURE K

1.PERFORM ID REGISTRATION OF ALL TRANSMITTERS

Carry out ID registration of all transmitters. Refer to WT-13, "ID Registration Procedure".

L

Can ID registration of all transmitters be completed?

YES >> Inspection End.

NO >> GO TO WT-20, "Data from Transmitter Not Being Received".

M

Revision: January 2010 WT-25 2010 Versa

REMOVAL AND INSTALLATION

< SERVICE INFORMATION >

REMOVAL AND INSTALLATION

Transmitter (Pressure Sensor) INFOID:0000000005397115

REMOVAL

1. Remove wheel and tire using power tool.

2. Deflate tire. Unscrew transmitter retaining nut and allow transmitter to fall into tire.

3. Gently bounce tire so that transmitter falls to bottom of tire.

Place wheel and tire assembly on tire changing machine and

break both tire beads. Ensure that the transmitter remains at the

bottom of the tire while breaking the bead.

SEIA0047E

4. Turn tire so that valve hole is at bottom, and gently bounce the

tire to ensure transmitter is near valve hole. Carefully lift tire onto

turntable and position valve hole (and transmitter) 270 degrees

from mounting/dismounting head.

5. Lubricate tire well, and remove top side of tire. Reach inside the

tire and remove the transmitter.

6. Remove the second side of the tire as normal.

WEIA0046E

INSTALLATION

1. Place first side of tire onto rim.

SEIA0049E

2. Apply suitable silicone lubricant to new transmitter seal then install seal on transmitter. Refer to MA-14.

NOTE:

Always replace the seal after every disassembly.

Revision: January 2010 WT-26 2010 Versa

REMOVAL AND INSTALLATION

< SERVICE INFORMATION >

3. Mount transmitter on rim and tighten nut.

NOTE: A

Make sure no burrs exist in the valve stem hole of the wheel.

Transmitter nut : 7.7 N·m (0.79 kg-m, 68 in-lb) B

WEIA0137E

D

4. Place wheel on turntable of tire machine. Ensure that transmitter

is 270 degrees from mounting/dismounting head.

NOTE: WT

Do not touch transmitter with mounting head.

5. Lubricate tire well, and install second side of tire as normal.

Ensure that tire does not rotate relative to rim.

F

6. Inflate tire and balance the wheel and tire assembly. Refer to

WT-7, "Adjustment".

7. Install wheel and tire assembly in appropriate wheel position on

G

vehicle. Refer to WT-7, "Adjustment".

NOTE: WEIA0046E

If replacing the transmitter, then transmitter wake up operation

must be performed. Refer to WT-14, "Transmitter Wake Up Operation". H

Revision: January 2010 WT-27 2010 Versa

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

Road Wheel INFOID:0000000005397116

Allowable

Standard item

Aluminum Steel

Lateral deflection Less than 0.3 mm (0.012 in) Less than 0.5 mm (0.020 in)

Maximum radial runout limit

Radial deflection Less than 0.3 mm (0.012 in) Less than 0.8 mm (0.031 in)

Dynamic

Less than 5 g (0.18 oz) (one side)

(At rim flange)

Maximum allowable imbalance

Static

Less than 10 g (0.35 oz)

(At rim flange)

Tire INFOID:0000000005397117

Unit: kPa (kg/cm2 , psi)

Cold tire pressure

Tire size Conventional tire

Spare tire

Front wheel Rear wheel

P185/65R14 230 (2.3, 33) 230 (2.3, 33) —

P185/65R15 230 (2.3, 33) 230 (2.3, 33) —

P195/55R16 240 (2.4, 35) 240 (2.4, 35) —

T125/70D15 — — 420 (4.2, 60)

Revision: January 2010 WT-28 2010 Versa

You might also like

- 2009-2010 Toyota Corolla Electrical Wiring DiagramsDocument482 pages2009-2010 Toyota Corolla Electrical Wiring Diagramsbarcalle1393% (42)

- Mister Bennett Breanne BergieDocument113 pagesMister Bennett Breanne BergieANA VICTORIA LUNA RODRIGUEZ0% (1)

- Microsoft Testking MS-900 v2020-01-29 by Philip 70qDocument47 pagesMicrosoft Testking MS-900 v2020-01-29 by Philip 70qBogdan ZahariaNo ratings yet

- Lesson 3 - Hominization and HumanizationDocument40 pagesLesson 3 - Hominization and HumanizationJoanna Ruth SeproNo ratings yet

- Road Wheels & Tires: SectionDocument28 pagesRoad Wheels & Tires: SectionHarol CastilloNo ratings yet

- Road Wheels & Tires: SectionDocument30 pagesRoad Wheels & Tires: SectionEdni OropezaNo ratings yet

- Road Wheels & Tires: SectionDocument50 pagesRoad Wheels & Tires: SectionJose luis Lopez mtzNo ratings yet

- Road Wheels & Tires: SectionDocument25 pagesRoad Wheels & Tires: SectionascguateNo ratings yet

- Road Wheels & Tires: SectionDocument38 pagesRoad Wheels & Tires: SectionLino Bello RezamanoNo ratings yet

- WT - Road Wheels & TiresDocument71 pagesWT - Road Wheels & TiresKhalid SaifNo ratings yet

- Road Wheels & Tires: SectionDocument60 pagesRoad Wheels & Tires: Sectiondmitry esaulkovNo ratings yet

- Road Wheels & Tires: SectionDocument47 pagesRoad Wheels & Tires: SectionaunzahahaiiNo ratings yet

- Road Wheels & Tires: SectionDocument75 pagesRoad Wheels & Tires: Sectionjair HernandezNo ratings yet

- 21. WT - КОЛЁСА И ШИНЫDocument71 pages21. WT - КОЛЁСА И ШИНЫНаталья Ч.No ratings yet

- WT PDFDocument55 pagesWT PDFJohancito UrdanetaNo ratings yet

- Road Wheels & Tires: SectionDocument66 pagesRoad Wheels & Tires: SectionАндрей НадточийNo ratings yet

- NissanDocument55 pagesNissanAgustin Borge GarciaNo ratings yet

- WT 2004 350Z Service ManuelDocument36 pagesWT 2004 350Z Service ManueljittuNo ratings yet

- Road Wheels & Tires: SectionDocument40 pagesRoad Wheels & Tires: SectionederengNo ratings yet

- WT PDFDocument50 pagesWT PDFMisha KulibaevNo ratings yet

- Frontier Nissan WTDocument32 pagesFrontier Nissan WTCaxonNo ratings yet

- Road Wheels & Tires: SectionDocument66 pagesRoad Wheels & Tires: SectionALexis IbacetaNo ratings yet

- ST PDFDocument30 pagesST PDFronaldNo ratings yet

- Steering System: SectionDocument34 pagesSteering System: SectionederengNo ratings yet

- WT - FeDocument51 pagesWT - FeIvan A. VelasquezNo ratings yet

- Starting System: SectionDocument42 pagesStarting System: SectionАндрей НадточийNo ratings yet

- Road Wheels & Tires: SectionDocument65 pagesRoad Wheels & Tires: SectionChang ChangNo ratings yet

- Seat Belt Control System: SectionDocument27 pagesSeat Belt Control System: SectionАндрей НадточийNo ratings yet

- Steering System: SectionDocument31 pagesSteering System: SectioncesarNo ratings yet

- Wiper & Washer: SectionDocument71 pagesWiper & Washer: SectionRonald Yucra CadenaNo ratings yet

- Brake System: SectionDocument32 pagesBrake System: SectionAnonymous 64HDY7IiN0No ratings yet

- Wiper & Washer: SectionDocument85 pagesWiper & Washer: SectionMohamed SalamaNo ratings yet

- WW Nissan.Document55 pagesWW Nissan.Agustin Borge GarciaNo ratings yet

- Brake System: SectionDocument48 pagesBrake System: SectionjonathanNo ratings yet

- BR PDFDocument33 pagesBR PDFOscar VillaseñorNo ratings yet

- Road Wheels & Tires: SectionDocument64 pagesRoad Wheels & Tires: SectionNestor RosalesNo ratings yet

- STR PDFDocument24 pagesSTR PDFalex100% (1)

- STR PDFDocument26 pagesSTR PDFronaldNo ratings yet

- Wiper, Washer & Horn: SectionDocument32 pagesWiper, Washer & Horn: SectionCristian CastroNo ratings yet

- Starting Charging SystemDocument30 pagesStarting Charging SystemErickson GarciaNo ratings yet

- WT PDFDocument52 pagesWT PDFalexNo ratings yet

- Brake Control System: SectionDocument54 pagesBrake Control System: SectionYB MOTOR Nissan - Datsun SpecialistNo ratings yet

- Charging System: SectionDocument26 pagesCharging System: SectionKunji ManiNo ratings yet

- Road Wheels & Tires: SectionDocument44 pagesRoad Wheels & Tires: Sectionbifemx3639No ratings yet

- Drive Mode System: SectionDocument36 pagesDrive Mode System: SectionPlatinumNo ratings yet

- Road Wheels & Tires: SectionDocument32 pagesRoad Wheels & Tires: SectionRuhu royNo ratings yet

- Driveline: SectionDocument263 pagesDriveline: SectionАндрей НадточийNo ratings yet

- Section: C Transmission/TransaxleDocument238 pagesSection: C Transmission/TransaxleLaunch Easydiag100% (1)

- Steering Control System: SectionDocument22 pagesSteering Control System: SectionAgustin Borge GarciaNo ratings yet

- Starting System: SectionDocument21 pagesStarting System: SectionjapaxploseNo ratings yet

- Wiper & Washer: SectionDocument62 pagesWiper & Washer: SectionaunzahahaiiNo ratings yet

- Brake Control System: SectionDocument126 pagesBrake Control System: SectionskpppNo ratings yet

- Road Wheels & Tires: SectionDocument53 pagesRoad Wheels & Tires: Sectionleosena23No ratings yet

- Seat Belt Control System: SectionDocument26 pagesSeat Belt Control System: SectionOvidiu EsanuNo ratings yet

- Road Wheels & Tires: SectionDocument26 pagesRoad Wheels & Tires: SectionyokonakagimaNo ratings yet

- STArtDocument37 pagesSTArtefrainaraya69No ratings yet

- DLN 2014 2021 Nissan Xtrail Service ManuDocument263 pagesDLN 2014 2021 Nissan Xtrail Service ManuToon KazaNo ratings yet

- PcsDocument71 pagesPcsgsmsbyNo ratings yet

- Fuel System: SectionDocument63 pagesFuel System: SectionLuis BarriosNo ratings yet

- Section: C Transmission/TransaxleDocument240 pagesSection: C Transmission/TransaxleDavide BinelliNo ratings yet

- TM PDFDocument134 pagesTM PDFMisha KulibaevNo ratings yet

- 2007 Nissan Murano 38Document224 pages2007 Nissan Murano 38RodrigoNo ratings yet

- Road Wheels & Tires: SectionDocument50 pagesRoad Wheels & Tires: SectionMartin petruNo ratings yet

- Ecm (Engine Control Module) : MR - 140Document1 pageEcm (Engine Control Module) : MR - 140Wilmer QuiñonezNo ratings yet

- SM 9Document100 pagesSM 9Wilmer QuiñonezNo ratings yet

- Manual Taller Hyundai MatrixDocument1 pageManual Taller Hyundai MatrixWilmer QuiñonezNo ratings yet

- Manual Transaxle: SectionDocument50 pagesManual Transaxle: SectionWilmer QuiñonezNo ratings yet

- Wiper, Washer & Horn: SectionDocument40 pagesWiper, Washer & Horn: SectionWilmer QuiñonezNo ratings yet

- Acs PDFDocument2 pagesAcs PDFWilmer QuiñonezNo ratings yet

- Wiper, Washer & Horn: SectionDocument48 pagesWiper, Washer & Horn: SectionWilmer QuiñonezNo ratings yet

- CVT 187 358Document172 pagesCVT 187 358Wilmer QuiñonezNo ratings yet

- Automatic Transaxle: SectionDocument384 pagesAutomatic Transaxle: SectionWilmer QuiñonezNo ratings yet

- Brake System: SectionDocument36 pagesBrake System: SectionWilmer QuiñonezNo ratings yet

- Starting System: SectionDocument24 pagesStarting System: SectionWilmer QuiñonezNo ratings yet

- DLKDocument165 pagesDLKWilmer QuiñonezNo ratings yet

- El Eje de CardánDocument12 pagesEl Eje de CardánWilmer QuiñonezNo ratings yet

- Engine Cooling System: SectionDocument26 pagesEngine Cooling System: SectionWilmer QuiñonezNo ratings yet

- Krystof Verner Applied Structural Geology and TectonicsDocument129 pagesKrystof Verner Applied Structural Geology and Tectonicsfriska agustin100% (1)

- Elisha Ongoya - Judicial ReviewDocument17 pagesElisha Ongoya - Judicial ReviewNorayne Lyone100% (2)

- Hafeez Taib Ki Nat GoeDocument11 pagesHafeez Taib Ki Nat GoeChand LalNo ratings yet

- gr12 Life Sciences p2 English Sep 2022 Possible AnswersDocument14 pagesgr12 Life Sciences p2 English Sep 2022 Possible Answersapi-202349222No ratings yet

- Activity 3 in StatDocument13 pagesActivity 3 in StatIanna ManieboNo ratings yet

- Filing 2Document8 pagesFiling 2Kaelan DeeseNo ratings yet

- Frozen StoryDocument4 pagesFrozen Storyedgar jr. suyat100% (1)

- Chapter 1 Overview and Evolution of EntrepreneurshipDocument11 pagesChapter 1 Overview and Evolution of EntrepreneurshipFara HaniNo ratings yet

- Bollas FreeAssociationDocument55 pagesBollas FreeAssociationFAUZI PALIS JUNIORNo ratings yet

- Institución Educativa Centro Social Trabajo, Ciencia y Fe: Actividad de Entrada O InicioDocument3 pagesInstitución Educativa Centro Social Trabajo, Ciencia y Fe: Actividad de Entrada O InicioGuery Ludh Piñeros GutierrezNo ratings yet

- Daz Error LogDocument72 pagesDaz Error LogRyan FogartyNo ratings yet

- Mos Manual PDF VersionDocument91 pagesMos Manual PDF Versionsrik14No ratings yet

- Res Bac 2020Document2,766 pagesRes Bac 2020medhaky1No ratings yet

- Class 9 Reg FinalDocument7 pagesClass 9 Reg Finalexclaimkamrul3No ratings yet

- Maths Formula Pocket Book Maths Formula-Page62Document1 pageMaths Formula Pocket Book Maths Formula-Page62Ernie LahaylahayNo ratings yet

- Use Equals Sign To Determine Missing Numbers Algebra Level 3 Worksheet - Ver - 3Document13 pagesUse Equals Sign To Determine Missing Numbers Algebra Level 3 Worksheet - Ver - 3Fatima AliuNo ratings yet

- Meaning & Importance of BrandingDocument30 pagesMeaning & Importance of BrandingJoseph AdhikariNo ratings yet

- Tony Tan CaktiongDocument12 pagesTony Tan CaktiongKaye MalitNo ratings yet

- The True Sabbath PDFDocument32 pagesThe True Sabbath PDFEugenius Divine LoveNo ratings yet

- The Legend of Sleepy HollowDocument43 pagesThe Legend of Sleepy HollowDavid BartonNo ratings yet

- Confession Under Indian Evidence Act, 1872: Uil, Panjab University Regional Centre, LudhianaDocument32 pagesConfession Under Indian Evidence Act, 1872: Uil, Panjab University Regional Centre, Ludhianagourav bansalNo ratings yet

- ARNISDocument5 pagesARNISDarlene Mae VillafloresNo ratings yet

- UTS Reporting G1 1Document24 pagesUTS Reporting G1 1Angala JackNo ratings yet

- Brosura GI Effects Stool ProfileDocument2 pagesBrosura GI Effects Stool ProfileIonicaNo ratings yet

- Budget of Workgrade 6Document19 pagesBudget of Workgrade 6Michael MacaraegNo ratings yet

- Ecologism and The Politics of Sensibilities: Andrew HeywoodDocument6 pagesEcologism and The Politics of Sensibilities: Andrew HeywoodVer Madrona Jr.No ratings yet

- LABMAN 1-2.1: Management ProcessDocument5 pagesLABMAN 1-2.1: Management ProcessAlondra SagarioNo ratings yet