5S Map Structure Handout 20160108

5S Map Structure Handout 20160108

Uploaded by

Ramesh BabuCopyright:

Available Formats

5S Map Structure Handout 20160108

5S Map Structure Handout 20160108

Uploaded by

Ramesh BabuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

5S Map Structure Handout 20160108

5S Map Structure Handout 20160108

Uploaded by

Ramesh BabuCopyright:

Available Formats

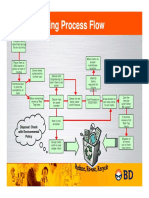

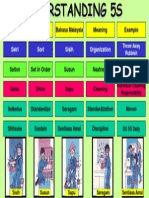

5S

Step)

Step)

Map

Map

Map

5S Area

5S Zone

MAP NAME

(2: Sort Step)

(2: Sort Step)

5S Sub-Area

Standard

Activity Card

(3: Sweep & Wash

(3: Sweep & Wash

A Zone Map identifies a dedicated work zone, There can be as many sub-area map levels as The “Area” is the outer boundary of the 5S Control

(4: Spic & Span Step)

separate from other work zones. needed to make the system work. Zone. One map covers the entire zone.

5S Photo Map &

E

C

3

1

A

Zone

Zone

Sub-Area

Sub-Area

E

E

3. -------------

2. -------------

1. -------------

G

F. ------------

E. ------------

C. ------------

B. ------------

A. ------------

D. ------------

H. ------------

G. ------------

4

2

H

Zone

Zone

ILLUSTRATION

Sub-Area

Sub-Area

Set up the Ideal Condition (standard) Items on the Activity Card match the items from

and take an actual photograph. Label the Zone Map.

the “Photograph Map” so that any The Zone Map shows equipment and other fixtures The lowest level Sub-Area Map is divided into The Area is divided into Sub-Areas.

abnormal condition “Leaps to the Eye.” in the Zone in their correct and relative locations. Work Zones.

Map Structure

5S/Visual Workplace Organization

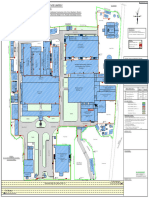

Area Map

Sub-Area Map

1

QC

MAIN

LOBBY

OFFICE

VEHICLE

MAINTENANCE

UNIT QC

ZONE 2 ZONE 1

PAINT

UNIT AXLE

VEHICLE

ZONE 3

ASSEMBLY TRAINING

UNIT ASSEMBLY

Table

Cabinet

Measuring Jig

Sensory Table

Sensory Table

Sensory Table

PLASTICS

Computer Cart

Computer Cart

Torque Wrench

LOGISTICS

UNIT MACHINING

ZONE 4 ZONE 5

UNIT QC AREA

EXAMPLE

(… or No 5S control in this area)

VEHICLE

ZONE 4 STAMPING

WELD TRAINING

& MOLD

TOOL, DIE,

This Zone has 1 Activity Card.

(Gray area: 5S controlled by other organization ...)

The layout in the Zone Map should match the

1 of 5 Photo Maps for this Zone

physical layout of the zone.

All of the items on the Zone Map should be Sub-Areas

addressed on the Activity Card.

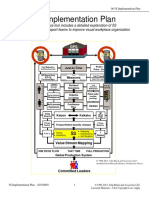

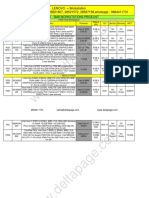

THE AMC

Advanced Manufacturing Center

5S Mapping Structure

STANDARD: Area Map near the Main Entrance

MAIN ENTRANCE

COMPUTER LAB

PLC

MANUFACUTRING

Are

COMPUTER LAB

SIMULATOR

PLC

aM

ZONE ap

MAP

ROBOTS

AMT MANAGEMENT AREA à ZONE

Zon

SAFETY & LOCK-OUT

eM MAP

ap

s

ZONE

MAP

ZONE

MAP

ZONE

MAP

Table Table Table

ZONE 2

Table

Cabinet Cabinet Cabinet Cabinet Cabinet Cabinet

Zon e

Maps

à Photo

Maps

(& Activ

ity Ca

rds)

ZONE

MAP

ZONE

MAP

100% Visual Workplace (5S) control throughout the entire AMC

Implemented and sustained by AMT students in daily practice

You might also like

- Final Fence Set PlanDocument2 pagesFinal Fence Set PlanNnelg Nimsaj Aveunalliv50% (2)

- Accretion Power in Astrophysics PDFDocument400 pagesAccretion Power in Astrophysics PDFAnonymous Di2yBGsNo ratings yet

- The Rainbow Personality Test 2Document3 pagesThe Rainbow Personality Test 2Cj CaoNo ratings yet

- Preparation 19: Iso-Alcoholic Elixir: 3 GttsDocument16 pagesPreparation 19: Iso-Alcoholic Elixir: 3 GttsMikaela LaoNo ratings yet

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work PlacemanishlmehtaNo ratings yet

- 1 - Warehouse Management Tools - The Logistics and Supply Chain Toolkit-HtmDocument40 pages1 - Warehouse Management Tools - The Logistics and Supply Chain Toolkit-HtmNguyenThanhVanNo ratings yet

- 5R Audit FormDocument6 pages5R Audit FormAriefFerdianNo ratings yet

- 5S Red Tag Register 1Document4 pages5S Red Tag Register 187KippenbergerNo ratings yet

- 5S - Excellence Assessment PDFDocument2 pages5S - Excellence Assessment PDFAshokNo ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklistAkhilesh Yadav100% (1)

- Seiri Audit ChecklistDocument4 pagesSeiri Audit Checklistthephaiduong100% (1)

- 5S Audit ChecklistDocument12 pages5S Audit Checklistmogul_hunkNo ratings yet

- 06 5s Implementation Plan and Training Guide v20130618 PDFDocument16 pages06 5s Implementation Plan and Training Guide v20130618 PDFRamesh BabuNo ratings yet

- 6S - 5S - Evaluation and Implementation Tool - LeanDocument8 pages6S - 5S - Evaluation and Implementation Tool - LeanShekhar RaviNo ratings yet

- Sample Procedure - 5S Standard Colour CodeDocument2 pagesSample Procedure - 5S Standard Colour Codesl1828100% (1)

- 5S Implementation Plan UploadDocument21 pages5S Implementation Plan UploadRahul KumarNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- 5S Audit FormDocument1 page5S Audit FormViorel Iosub100% (1)

- Introduction To 5SDocument98 pagesIntroduction To 5SnahomNo ratings yet

- QE (5S) Responsibilities and RolesDocument3 pagesQE (5S) Responsibilities and RolesAdie Caberte0% (1)

- 5S - Check ListDocument3 pages5S - Check ListJayendra RajeshirkeNo ratings yet

- Check SheetDocument14 pagesCheck SheetBalavignesh VenugopalNo ratings yet

- 5s Audit ChecklistDocument22 pages5s Audit ChecklistJeevaAJAnanthanNo ratings yet

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceRamanagiri BharathanNo ratings yet

- Industrial Solutions, Inc: Lean Assessment ScorecardDocument5 pagesIndustrial Solutions, Inc: Lean Assessment Scorecardrgrao85No ratings yet

- 5s Basic TrainingDocument14 pages5s Basic Trainingsachin_bharti92% (13)

- Instructions: 'No' Answers Are To Be Resolved Immediately and DocumentedDocument1 pageInstructions: 'No' Answers Are To Be Resolved Immediately and Documentedrgrao85No ratings yet

- 5S ImplementationDocument35 pages5S ImplementationPrateek Gupta100% (1)

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5S Red Tag ProcessDocument8 pages5S Red Tag ProcessSwj OkeNo ratings yet

- 5S Audit Checklist-NewDocument1 page5S Audit Checklist-NewArun BiswalNo ratings yet

- WF 2012aug 5s Red Tagging Process Flow LEANDocument1 pageWF 2012aug 5s Red Tagging Process Flow LEANGaneshan Mathan RajNo ratings yet

- 5s Audit Check ListDocument2 pages5s Audit Check Listravi.rimc3869100% (2)

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklisttahirNo ratings yet

- Smed Analysis 2Document80 pagesSmed Analysis 2Azaly Buang100% (1)

- A Strategy For Performance ExcellenceDocument31 pagesA Strategy For Performance ExcellenceMahesh KumarNo ratings yet

- What Is 5SDocument13 pagesWhat Is 5SVidya SagarNo ratings yet

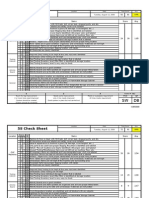

- 5S Check SheetDocument8 pages5S Check SheetDONNo ratings yet

- 5S Guidence PDFDocument28 pages5S Guidence PDFAnonymous llBSa7No ratings yet

- 5S Audit Checklist - SafetyCultureDocument7 pages5S Audit Checklist - SafetyCultureruchitssNo ratings yet

- Submitted By,: Jarzid Alam Alomgir Badsha Saif MahabubDocument26 pagesSubmitted By,: Jarzid Alam Alomgir Badsha Saif MahabubSaif KhanNo ratings yet

- 5S Check List SeiriDocument2 pages5S Check List Seirikyle1991No ratings yet

- Apply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some MovementsDocument13 pagesApply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some MovementsRahul RawatNo ratings yet

- 5S Activity Roadmap 28 June - 2011Document24 pages5S Activity Roadmap 28 June - 2011Navnath TamhaneNo ratings yet

- Standard Work Sheets - v04Document3 pagesStandard Work Sheets - v04Balaji SNo ratings yet

- Calculating Oee WorksheetDocument2 pagesCalculating Oee WorksheetAdriano Tiago EinsfeldNo ratings yet

- Opr # Desc Location M/C Desc Cycle Time (Secs) Manpower Available # of Machines AvailableDocument3 pagesOpr # Desc Location M/C Desc Cycle Time (Secs) Manpower Available # of Machines AvailableSudhaNo ratings yet

- 5S Routine Audit FormDocument8 pages5S Routine Audit Formblackbarby100% (3)

- 5S & TPMDocument19 pages5S & TPMJesus Chi GorosicaNo ratings yet

- NAME OF COMPANY - 5S Audit ChecklistDocument2 pagesNAME OF COMPANY - 5S Audit ChecklistDũng Tây NinhNo ratings yet

- MSE507 Lean Manufacturing: 5S and The Visual WorkplaceDocument85 pagesMSE507 Lean Manufacturing: 5S and The Visual WorkplaceSAYFUDDINSG100% (3)

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work Placebrock100% (24)

- Quality Function Deployment VanLaanen S07Document38 pagesQuality Function Deployment VanLaanen S07shule1No ratings yet

- 5s Training Module by Jayanth, Feb 09Document82 pages5s Training Module by Jayanth, Feb 09Senyum Sehat100% (1)

- Smed Forms For Lean ProjectsDocument11 pagesSmed Forms For Lean ProjectscivanusNo ratings yet

- Japanese English Bahasa Malaysia Meaning Example: Seiri Sort Sisih OrganizationDocument1 pageJapanese English Bahasa Malaysia Meaning Example: Seiri Sort Sisih OrganizationGeddy JeminiNo ratings yet

- 5S Audit SheetDocument3 pages5S Audit SheetRamiro G. J. ChavarriaNo ratings yet

- Uenr7613uenr7613-01 SisDocument6 pagesUenr7613uenr7613-01 SisFabrizio JesúsNo ratings yet

- PRM-DWG-DC-ME-DR-EL-1001-1-1101Document1 pagePRM-DWG-DC-ME-DR-EL-1001-1-1101Arumugam BalamuruganNo ratings yet

- Dindori Area StatementDocument1 pageDindori Area StatementPranav ShewaleNo ratings yet

- Drawing Symbols and SpecsDocument1 pageDrawing Symbols and SpecsHarried EscalonaNo ratings yet

- Charlotte-Mecklenburg Area Plans That Update The District PlansDocument1 pageCharlotte-Mecklenburg Area Plans That Update The District PlansIsabelle WesternNo ratings yet

- CG Key Map - 1Document1 pageCG Key Map - 1Akshay NampalliwarNo ratings yet

- System: Fort Worth Central StationDocument2 pagesSystem: Fort Worth Central StationbenNo ratings yet

- KH (Footwear Div) - Ranipet Site PlanDocument1 pageKH (Footwear Div) - Ranipet Site PlanRamesh BabuNo ratings yet

- Printers PDFDocument5 pagesPrinters PDFRamesh BabuNo ratings yet

- DesktopDocument24 pagesDesktopRamesh BabuNo ratings yet

- Laptop PDFDocument51 pagesLaptop PDFRamesh BabuNo ratings yet

- Projectors PDFDocument8 pagesProjectors PDFRamesh BabuNo ratings yet

- ProjectorsDocument8 pagesProjectorsRamesh BabuNo ratings yet

- Desktop PDFDocument24 pagesDesktop PDFRamesh BabuNo ratings yet

- OSHADocument20 pagesOSHARamesh BabuNo ratings yet

- VOS 8000FTR Installation ManualDocument12 pagesVOS 8000FTR Installation ManualRamesh BabuNo ratings yet

- ServerDocument13 pagesServerRamesh BabuNo ratings yet

- Powering Tamil Nadu'S Progress.... (Subsidiary of TNEB Limited)Document2 pagesPowering Tamil Nadu'S Progress.... (Subsidiary of TNEB Limited)Ramesh BabuNo ratings yet

- MJF Lion M.Mohan Kumar - Dce.,Be. Kewin BuildersDocument1 pageMJF Lion M.Mohan Kumar - Dce.,Be. Kewin BuildersRamesh BabuNo ratings yet

- Camara - Hikvision: - 1 Megapixel Call For Best Price at 28521607, 28521572, 28587158, Whatsapp - 9884411731Document4 pagesCamara - Hikvision: - 1 Megapixel Call For Best Price at 28521607, 28521572, 28587158, Whatsapp - 9884411731Ramesh BabuNo ratings yet

- DrivDocument84 pagesDrivRamesh BabuNo ratings yet

- DP XUSB 14064 DriversDocument72 pagesDP XUSB 14064 DriversRamesh BabuNo ratings yet

- Connection of VDS2100 Sender and VDS2200 Viewer: CCD Camera (Composite Video Out)Document1 pageConnection of VDS2100 Sender and VDS2200 Viewer: CCD Camera (Composite Video Out)Ramesh BabuNo ratings yet

- Lesson Plan IP - Class-XIIDocument13 pagesLesson Plan IP - Class-XIIvirendraNo ratings yet

- DIGITAL PORTFOLIO 3 (Practice)Document2 pagesDIGITAL PORTFOLIO 3 (Practice)amnimusfirah04No ratings yet

- MISRA C v2 UpdateDocument17 pagesMISRA C v2 Updatelu_ondirNo ratings yet

- Use of ArticleDocument7 pagesUse of ArticlesharadNo ratings yet

- 2018shangdong UniversityDocument65 pages2018shangdong UniversityslhippoNo ratings yet

- Mariano Marcos Memorial High School: 4-Strongly Agree 3-Agree 2-Disagree 1-Strongly DisagreeDocument4 pagesMariano Marcos Memorial High School: 4-Strongly Agree 3-Agree 2-Disagree 1-Strongly DisagreeMarkie EspañolaNo ratings yet

- The Impacts of Climate Changes On The Risk of Natural DisastersDocument12 pagesThe Impacts of Climate Changes On The Risk of Natural DisastersProf. dr Vladimir M. Cvetković, Fakultet bezbednosti, Univerzitet u BeograduNo ratings yet

- Crizal 9 Step ProcessDocument2 pagesCrizal 9 Step ProcessŽarko BačakNo ratings yet

- Classroom Interaction AnalysisDocument20 pagesClassroom Interaction AnalysisDon Zian EncarnacionNo ratings yet

- Weinberg Cosmology ErrataDocument10 pagesWeinberg Cosmology Erratashekhar_deodharNo ratings yet

- Title of The Project "Plato's Ideal State "Document22 pagesTitle of The Project "Plato's Ideal State "vishnudeepakNo ratings yet

- NetChart Presentation - September 2015Document33 pagesNetChart Presentation - September 2015sinansarmedNo ratings yet

- Hybrid Driver Safety, Vigilance and Security System For VehicleDocument6 pagesHybrid Driver Safety, Vigilance and Security System For VehicleRajeevan ArunNo ratings yet

- Thesis Tilbrook PDFDocument467 pagesThesis Tilbrook PDFalfierelorNo ratings yet

- Thomas BiodataDocument6 pagesThomas BiodataThomas SebastianNo ratings yet

- Relay Setting Editing Through HMI ABBDocument28 pagesRelay Setting Editing Through HMI ABBSasiKumar SivathangaveluNo ratings yet

- Silo - Tips - Board of Intermediate Secondary Education LahoreDocument71 pagesSilo - Tips - Board of Intermediate Secondary Education LahoreUsama SohailNo ratings yet

- Peer Evaluation FormDocument3 pagesPeer Evaluation FormAlaksamNo ratings yet

- Olbers ParadoxDocument4 pagesOlbers ParadoxPrakash SankerNo ratings yet

- 2017C MKTG754002 4d8f6218Document13 pages2017C MKTG754002 4d8f6218srinivasa raoNo ratings yet

- Light Mirror and LensesDocument11 pagesLight Mirror and LensesDanbert TaopaNo ratings yet

- Kì 1 Unit 1Document13 pagesKì 1 Unit 1hau.tranminhNo ratings yet

- Rubrics For Quantitative ResearchDocument1 pageRubrics For Quantitative ResearchakhieyhukieNo ratings yet

- Love in The Time of CapitalDocument7 pagesLove in The Time of Capitalzizek100% (2)

- AssignmentDocument3 pagesAssignmentHANA WORLDNo ratings yet

- Bneo BGPMSDocument26 pagesBneo BGPMSCarlo TorresNo ratings yet

- Cara Install Bentley Autoplant PDFDocument4 pagesCara Install Bentley Autoplant PDFZoebairNo ratings yet