Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)

Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)

Uploaded by

Gaurav SinghCopyright:

Available Formats

Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)

Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)

Uploaded by

Gaurav SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)

Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)

Uploaded by

Gaurav SinghCopyright:

Available Formats

Report on

Major Overhaul of LP Turbine

and Generator

Unit-4,(250 MW) OPJSTPP

JPL Tamnar-Raigarh

(15/07/2012 to 31/07/2012)

Bharat Heavy Electricals Limited

PSWR-SAS-SERVICES NAGPUR

Report on

Major Overhaul of LP

Turbine and Generator

Unit-4,(250 MW) OPJSTPP JPL Tamnar-Raigarh

(15/07/2012 to 31/07/2012)

Customer Service Order No.4400002853 Dt.03.07.2012

BHEL Job Order No. 120017

Prepared by

V.Veerapandi

Dy. General Manager/ ser

Bharat Heavy Electricals Limited

PSWR-SAS-SERVICES NAGPUR

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

Contents

1. Introduction

2. Brief History of Machine

3. Brief Scope of work

4. BHEL – JPL Team associated

5. Major activities carried out

6. Observations & Action Taken

7. Spares consumed

8. Commissioning

9. Turbovisory Parameters

10. Conclusion

11. Recommendations

12. Log Sheets

13. Reports

Bearings Ultrasonic Test

LP Free standing blades MPI Test.

Stator overhang NFT

Generator Rotor RSO.

Bharat Heavy Electricals Limited 1

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

1.0 INTRODUCTION

JPL-OPJSTPP Tamanr-Raigarh has four (4) units of 250MW KWU design TG set. These units

were commissioned during the year 2007-2008.

JPL awarded the work of LP Turbine & Generator along with TG Bearing inspection, HP-IP

casing centering and overhauling of valves & strainers.

Unit was withdrawn on 15.07.12 at 01.45 hrs for the present overhaul and LP-Generator

was decoupled in hot condition on 16.07.12 to speed up the Generator overhauling work.

Barring gear was stopped on 19.07.12 for TG bearing inspection & other associated work.

TG Bearing inspection, Overhauling of LP Turbine, MPI testing of free standing blades ,

overhauling of valves & strainers and Generator & Exciter was completed within 10.5 days

(Barring stop to Barring start) 17 days bar to bar.

After completion of all works, TG set was put on Barring gear on 30.07.12 at 02.00 Hrs. Unit

was rolled and machine was synchronized after electrical testing on 31.07.12 at 20.00 hrs.

All turbovisory parameters including bearings temperature & vibration were found well

within limits.

This report embodies the details of various activities carried out during this overhaul and

performance of the machine after overhauling.

Bharat Heavy Electricals Limited 2

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

2.0 BRIEF HISTORY OF MACHINE

Sl.No Description Period

1. First commissioning 17.06.2008

2. Total Running hours since commissioning 29977

3. Bearing inspection and Exciter Inspection 16.07.2010 to 01.08.2010

LP Turbine, Generator & Exciter overhauling

4. along with Bearing inspection and Valves & 15.07.2012 to 31.07.2012

strainer (present overhauling)

Bharat Heavy Electricals Limited 3

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

2.1 Major event

1. Unit shut down 15.07.12

2. LP-Gen decoupled 16.07.12

3. Generator rotor threaded out 18.07.12

4. Barring Gear stopped 19.07.12

5. LP Turbine dismantled 20.07.12

6. Generator rotor threaded in 23.07.12

7. LP Turbine boxed up 24.0712

8. Oil flushing 29.07.12

9. TG put on barring gear 30.07.12

10. Machine rolled 31.07.12

11. Machine synchronized 31.07.12

Bharat Heavy Electricals Limited 4

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

3.0 BRIEF SCOPE OF WORK

1. Bearing Inspection 1 To 7,

2. OH of Main oil Pump

3. OH of LP Turbine

4. Overhauling of Generator

5. Overhauling of Exciter

6. Inspection of MS/HRH Strainers

7. Inspection of Turbine valves HPSV, IPSV, HPCV, IPCV

8. Inspection of servomotors of HPSV, IPSV, HPCV,IPCV.

9. Stator & rotor testing

NFT test of generator stator winding overhangs

RSO test of rotor

LP Free standing blades in-situ MPI Test

Bharat Heavy Electricals Limited 5

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

4.0. BHEL TEAM ASSOCIATED :

4.1 BHEL SERVICES PS WR NAGPUR

Sl.No Name Designation Area of work

1. Shri.V.Veerapandi Dy. General Manager Site In charge

2. Shri.V.B.Sha Sr. Manager Generator

3. Shri.N.P.Khuntey Engineer Turbine

4. Shri.S.P.Kulkarni Asst.Engineer Generator

5. Shri.R.D.Yadav Asst.Engineer Generator

6. Shri.N.P.Gupta Asst Engineer Valves

7. Shri.Y.P.Singh Asst Engineer/HWR Generator

8. Shri.S.K.Khare Asst Engineer/HWR Generator

4.2. JPL TMD TEAM ASSOCIATED :

1. Shri. S.L.Prabhu Sr.GM.

2. Shri. Saikat Nandy AGM

3. Shri. Santosh Pal Manager

4. Shri. Subash Behera Asst.Mgr

5. Shri. Anit Kumar Asst.Mgr

4.3. JPL EMD TEAM ASSOCIATED :

1. Shri. Naresh Punjabi Sr.GM

2. Shri Kapil Dev Dupey AGM

3. Shri Gaurav Gaur Asst.Mgr.

4. Shri.M.Amit GET

Bharat Heavy Electricals Limited 6

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

5.0 MAJOR ACTIVITIES CARRIED OUT

5.10 BEARING & GENERAL WORK

5.11 Bearing no.1-7 were visually checked. All bearings were found OK.

5.12 Brg.2 thrust float was checked & found OK.

5.13 UT& DP test was carried out in all the bearings. All bearings were found in order.

5.14 HP/IP,IP/LP,LP/Gen & Gen/Exciter alignment was checked and minor correction

was made in bearing 1,2,3 & 4.

5.15 HP/MOP alignment was disturbed and same was corrected.

5.16 Gland box re-centering done on both side by adjusting keys.

5.17 HP-IP-LP casing roll check was carried out and minor correction was done for

centering the casing.

5.18 HP-IP casing Bump & Horn drop checks were carried out.

5.19 All casing & pedestal clamp clearances were adjusted as per design.

5.20 Final JOP lift was checked & Journal lift was kept as per design value.

5.20 MOP

MOP was dismantled for inspection. Impellor, wear ring & gear coupling were visually

inspected and found in order. Governor impeller & wear ring (FS) and Thrust bearing

found damaged. Damaged components were replaced by new one. MOP Shaft run out &

clearances were checked and found OK. DP test was carried out in all the components and

found in order. MOP float was checked after final assembly & was found OK.

Damaged thrust bearing

Bharat Heavy Electricals Limited 7

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

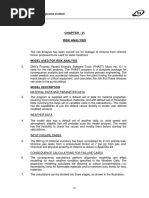

5.30 LP TURBINE INSPECTION:

LP Turbine was opened for first inspection after erection. Visual inspection was carried out

in all the stages of moving & guide blades and found in order. Heavy deposit found in

moving & guide blades of stage no.1 to 6 and it was thoroughly cleaned by alumina blasting.

Deposits on Moving blades

MPI testing was carried out on last three stages of free standing blades at both sides in

position (without removal of blades from rotor). MPI test revealed that the all free standing

blades are in healthy condition. LP steam path radial clearances recorded and clearances

found less in few stages of stationary & moving blades. Those stages were grounded off to

improve the radial clearances. Inner-inner casing ovality checked and measurement was

recorded.

LP rotor was placed in zero position and final steam flow path clearances were recorded. LP

inner-inner and inner-outer, outer casing were boxed up on 24.07.12 after joint inspection

of BHEL & JPL. No loose items & No foreign material was observed during the inspection.

LP roll check was carried out after final box up and minor correction was carried out on

top/bottom and Left/Right. Final roll check was carried out after correction & found ok. LP

outer boxed up on 27.07.12 after removal of all scaffolding materials.

LP extraction compensators bellows were DP Tested and found ok. Compensator bellows

and their supports and steam space were thoroughly inspected and found in order. LP

gland box centering checked and minor correction done at both side.

Bharat Heavy Electricals Limited 8

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

5.50 EXCITER & GENERATOR INSPECTION

Generator was dismantled for planned schedule of first inspection. Visual inspection and

various electrical tests were carried out on stator and rotor after rotor threaded out.

Electrical tests revealed that the Stator, Rotor and Exciter ware found in good and healthy

condition. Generator air leak test was carried out after complete assembly of generator and

was found ok.

Exciter:

Exciter was dismantled for inspection. Visual inspection and electrical tests were carried out

on Exciter stator, rotor, PMG and rectifier wheels.

Stator:

Powder formation was observed in the stator end winding EE at few locations and same was

removed by proper cleaning. NFT of stator end winding joints at both EE and TE was carried

out, all the joints were found in good condition.

Rotor:

The RSO (Recurrent Surge Oscillograph) test was carried on rotor and result found

satisfactory. After CC bolt O-ring was replacement, Rotor air leak test was carried out N2 gas

and no leakage & no pressure drop was observed during the test. DP test was carried out

on Retaining ring and it was found ok.

Bharat Heavy Electricals Limited 9

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

Hydrogen seal rings:

Hydrogen seal rings were dismantled and thorough inspection was carried out. UT & DP

tests on both the seal rings were carried out and both seal rings were found ok. However,

both the seal rings were replaced by the new ones as a precautionary measure.

Hydrogen & Exciter Coolers :

All Hydrogen coolers and Exciter coolers were dismantled for servicing. After thorough

inspection & cleaning, Hydraulic test was carried out as per design value. No leakage & no

pressure drop were observed.

Valves & Strainers:

HPSV1, HPCV1&2 and IPSV1 & IPCV1 and servomotor of HP SV1&CV1 and IPSV1&CV1 were

opened for inspection. HPCV 1&2 servomotor disc spring 12 nos (each 6 Nos) found crack

and same were replaced by new one. HP CV 1&2 seat found dent mark. MS strainer (LHS) &

HRH strainer (RHS) were dismantled for inspection & found OK.

Bharat Heavy Electricals Limited 10

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

6.0 OBSERVATION & ACTION TAKEN

Sl.No Abnormalities Corrective action taken

01 Powder formation & paste Removed by proper cleaning and

formation was observed in the Insulating varnishing done.

stator end winding at EE at few

locations.

02 HPCV-1&2 Servomotor disc springs Replaced by new one

found crack.

03 MOP Thrust bearing & GOP impellor & Replaced by new one

wear ring found damage

04 IP SV 1&2 spindle seat and IP SV 2 Lapping done and 100% blue contact

body seat found dent mark achieved.

05 HP CV 1&2 seat found dent mark Left as it is

Bharat Heavy Electricals Limited 11

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

7.0 SPARES CONSUMED

1. JOP hose for Bearing No.1 to 7

2. Hydrogen seal rings -2 (Nos.)

3. Generator rotor CC bolt O-ring set

4. HPCV servomotor disc springs -12 nos

5. MOP Thrust bearing-1 no

6. Governor oil pump impeller-1 no

7. Governor oil pump impeller wear ring-1 no

8. Pedestal oil guards fins complete set.

Bharat Heavy Electricals Limited 12

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

8.0 COMMISSIONING:

1.0 Oil flushing carried out on 29.07.12.

2.0 Machine was put on Barring gear on 30.07.12

3.0 Machine first rolled on 31.07.12 at 13.30 hrs.

4.0 Electrical testing carried out on 31.07.12.

5.0 Oil injection test was carried out before synchronization and both over speed

tripping device were found operated.

6.0 Machine synchronized on 31.07.12 at 20.00 hrs

Bharat Heavy Electricals Limited 13

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

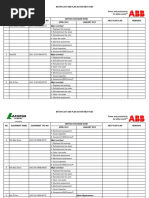

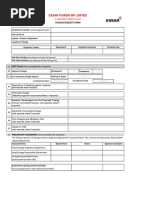

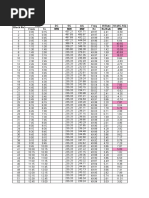

9.0. TURBOVISORY PARAMENTERS :

Bharat Heavy Electricals Limited 14

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

Bharat Heavy Electricals Limited 15

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

10.0 CONCLUSION

The unit was withdrawn on 15.07.12 at 01.45 hrs for overhauling of LP Turbine, Generator

and Exciter overhaul ,TG Bearing inspection, HP-IP casing centering, overhauling of valves &

strainers along with MPI Testing of LP free standing blades. All work was completed within

10.5 days (Barring Stop to Barring Start).

Machine was rolled and synchronized on 31.07.12 after completion of electrical test.

Machine’s performance after overhauling was found smooth and the vibrations &

Turbovisory readings found normal.

Bharat Heavy Electricals Limited 16

U#4 (250MW) OPJSTPP –JPL-Tamnar Raigarh

11.0 RECOMMENDATIONS

11.10 One no MS strainer element may be procured and kept as emergency spares.

11.11 One set of HPCV servomotor spring discs complete set may be procured and kept as

emergency spares.

11.12 Complete set of Clamping pieces for LP free standing blades (3L/3R,2L/2R AND

1L/1R) may be procured and kept as spares.

11.13 LP free standing blades MPI & NFT test may be carried out during the next planned

LP turbine overhaul.

11.14 One set of HP/IP SV&CV valve & servomotor fasteners are to be procured and kept

as spares for future overhauling.

11.15 Complete set of O-rings for TG valve servomotor may be procured.

11.16 Hydrogen cooler pipe line flange O-rings are to be procured and kept as spares.

11.17 One set of HPCV seat to be procured and kept as spares.

Bharat Heavy Electricals Limited 17

You might also like

- High Pressure Turbine Governing System PDFDocument28 pagesHigh Pressure Turbine Governing System PDFAnonymous ZnuMEWN1100% (7)

- Generator OverhaulingDocument26 pagesGenerator Overhaulinglrpatra100% (2)

- Report EHTC HuntingDocument10 pagesReport EHTC HuntingOTPC POWER100% (1)

- 500 MW Simhadri O&M ManualDocument412 pages500 MW Simhadri O&M ManualLasit Mittal100% (4)

- BHEL Turbine ManualDocument58 pagesBHEL Turbine Manualnivasssv86% (7)

- Turbine Pressure SurveyDocument9 pagesTurbine Pressure SurveyManinder Cheema100% (1)

- Jindal Power Limited, Tamnar: JPL/OPN-250/SOP/.. 01/29.07.2019 00/00Document4 pagesJindal Power Limited, Tamnar: JPL/OPN-250/SOP/.. 01/29.07.2019 00/00Chandramani PatelNo ratings yet

- Turbine FundamentalDocument18 pagesTurbine FundamentalHamid Ariz100% (1)

- BHEL Haridwar Tarining Report Block IV Electrical EngineeringDocument37 pagesBHEL Haridwar Tarining Report Block IV Electrical EngineeringAnimesh Verma100% (8)

- Jindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning DepartmentDocument9 pagesJindal Power Limited O.P.J.S.T.P.P, Tamnar, Raigarh: Commissioning Departmentjp mishraNo ratings yet

- Power Plant C&I Systems: Coordinated Master ControlDocument30 pagesPower Plant C&I Systems: Coordinated Master ControlStage2 C&I Shift100% (1)

- 600 MW Turbogenerator: Rating Plate Data For GeneratorDocument5 pages600 MW Turbogenerator: Rating Plate Data For Generatorjaaduscribd50% (2)

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (6)

- A Presentation On Turbine Rolling Atrs Final 2Document59 pagesA Presentation On Turbine Rolling Atrs Final 2Ramakrishna83% (6)

- Generator AuxDocument85 pagesGenerator Auxjp mishra100% (1)

- Generator Manual Rihand 500 MWDocument416 pagesGenerator Manual Rihand 500 MWGautamupadhyay100% (2)

- TAKNIKI DARPAN - Issue 6Document40 pagesTAKNIKI DARPAN - Issue 6Rajarsi Ray100% (1)

- ORT-Aug R1Document67 pagesORT-Aug R1Vishal Kumar LaddhaNo ratings yet

- Presentation On VibrationDocument24 pagesPresentation On VibrationSethuRamalingamNo ratings yet

- Condenser Ball Cleaning SystemDocument6 pagesCondenser Ball Cleaning SystemSonrat100% (2)

- L-06 Erection Guide Line of 500 MW Turbine Anp-4Document20 pagesL-06 Erection Guide Line of 500 MW Turbine Anp-4Sam100% (4)

- Rakesh Kumar: BHEL HaridwarDocument25 pagesRakesh Kumar: BHEL Haridwarparth038100% (3)

- Turbine Stress Evaluator: 17 February 2018 PMI Revision 00 1Document23 pagesTurbine Stress Evaluator: 17 February 2018 PMI Revision 00 1NILESH100% (1)

- Generator Erection Manual THW 210 2A 2BDocument213 pagesGenerator Erection Manual THW 210 2A 2Bkrishkar2010100% (1)

- Valves&Soot BlowersDocument29 pagesValves&Soot BlowersSarah FrazierNo ratings yet

- Turbine Trip LogicDocument2 pagesTurbine Trip Logicdilbagh_scribd75% (4)

- Gen-Seal&cool-New - 500 MWDocument98 pagesGen-Seal&cool-New - 500 MWharisankar100% (5)

- Trip Analysis Recommendation For The FY 2020-21 (660 MW Units)Document45 pagesTrip Analysis Recommendation For The FY 2020-21 (660 MW Units)sudhakarautomatic9940100% (2)

- Seal Oil System (Presentation)Document16 pagesSeal Oil System (Presentation)ToniMelo100% (5)

- Turbogenerator O M ManualDocument440 pagesTurbogenerator O M ManualDreamsinfinite100% (2)

- Esp Charging SopDocument3 pagesEsp Charging SopvikramshounNo ratings yet

- Governing System of 210mw KwuDocument21 pagesGoverning System of 210mw KwuAshok RasekarNo ratings yet

- Updated Boiler and Auxiliaries2Document105 pagesUpdated Boiler and Auxiliaries2Gaurav kumar100% (1)

- Turbine Over Hauling Procedure Siemens Recommendsbirkosit 111019222302 Phpapp01 PDFDocument75 pagesTurbine Over Hauling Procedure Siemens Recommendsbirkosit 111019222302 Phpapp01 PDFAnonymous wIPMQ5rh100% (3)

- Bhel Bearing ErectionDocument39 pagesBhel Bearing ErectionASHUTOSH KUMAR100% (4)

- 500 MW Generator, Salient FeaturesDocument10 pages500 MW Generator, Salient FeaturesSandeep MishraNo ratings yet

- Standard Operating Procedure FOR BCP FlushingDocument6 pagesStandard Operating Procedure FOR BCP FlushingsambhuNo ratings yet

- AC Supply System For Thermal Power PlantDocument21 pagesAC Supply System For Thermal Power PlantAshwani Dogra100% (2)

- Plant Islanding OperationDocument14 pagesPlant Islanding OperationSeshadri Rajendranath100% (3)

- Generator ProtectionDocument24 pagesGenerator ProtectionSantoshkumar Gupta100% (2)

- LP Turbine Assembly ProcedureDocument8 pagesLP Turbine Assembly Procedurebhushanbharat_843298No ratings yet

- DATA SHEET Generator Sagardighi 01 (HW-DC-373-4044-512rev01)Document24 pagesDATA SHEET Generator Sagardighi 01 (HW-DC-373-4044-512rev01)Parthasarathi PaulNo ratings yet

- On GeneratorDocument55 pagesOn GeneratorDileep Reddy91% (11)

- Generator AuxiliariesDocument37 pagesGenerator AuxiliariesAshwani Dogra100% (2)

- To System & Barring GearDocument22 pagesTo System & Barring GearPrudhvi Raj100% (2)

- BCP Installation & CommissioningDocument18 pagesBCP Installation & CommissioningKrishnan Santhanaraj100% (3)

- 500 MW Generator, Salient Features: SpecificationsDocument11 pages500 MW Generator, Salient Features: SpecificationsAhemadNo ratings yet

- Governing SystemDocument70 pagesGoverning SystemPraveen Peethambaran100% (5)

- Electrical Testing On Turbogenerator (TG2Document40 pagesElectrical Testing On Turbogenerator (TG2rkc100% (1)

- Ehtc JharliDocument38 pagesEhtc JharliRakesh Bagri100% (2)

- Float Valve CheckingDocument3 pagesFloat Valve Checkingsprotkar100% (2)

- 660 Generator Protection SchemesDocument9 pages660 Generator Protection Schemesshashank100% (2)

- Automatic Turbine Run Up System Gyanendra Sharma Npti DelhiDocument47 pagesAutomatic Turbine Run Up System Gyanendra Sharma Npti DelhiNPTI80% (5)

- Seal Oil System-ClassDocument39 pagesSeal Oil System-ClassRaja Ramachandran100% (2)

- Turbo GeneratorsDocument26 pagesTurbo Generatorsmani_sne100% (1)

- Turbine Rolling and SynchronizationDocument54 pagesTurbine Rolling and Synchronizationsanjeev kushwaha83% (6)

- Final AOH Report - TMD 060818Document15 pagesFinal AOH Report - TMD 060818sanmukhaNo ratings yet

- 0: 7 Station: Date: FEB ?0t5Document2 pages0: 7 Station: Date: FEB ?0t5SE ESTNo ratings yet

- Mapping MotorDocument6 pagesMapping MotorAkhson SupxNo ratings yet

- Daily Activities: Kamis, 28 Agust 2014 Jumat, 29 Agust 2014 Senin, 1 Sept 2014Document2 pagesDaily Activities: Kamis, 28 Agust 2014 Jumat, 29 Agust 2014 Senin, 1 Sept 2014James GuthrieNo ratings yet

- EPMPL Unit-2 Heat Rate Test: Summary SheetDocument2 pagesEPMPL Unit-2 Heat Rate Test: Summary SheetGaurav SinghNo ratings yet

- 8-CH Vi &vii - 070607Document15 pages8-CH Vi &vii - 070607Gaurav SinghNo ratings yet

- PT 11 EC - Compliance Report - Sep'2019Document5 pagesPT 11 EC - Compliance Report - Sep'2019Gaurav SinghNo ratings yet

- Pt-6.2 SC Order 01072019Document3 pagesPt-6.2 SC Order 01072019Gaurav SinghNo ratings yet

- Pt-6.1 SC Order NCL 22-Apr-2019Document1 pagePt-6.1 SC Order NCL 22-Apr-2019Gaurav SinghNo ratings yet

- Environment Management Plan PDFDocument8 pagesEnvironment Management Plan PDFGaurav SinghNo ratings yet

- EPMPL Unit-2 Heat Rate Test: Summary SheetDocument2 pagesEPMPL Unit-2 Heat Rate Test: Summary SheetGaurav SinghNo ratings yet

- Best Practices in O&M of Thermal Power Stations: Tutorial Course OnDocument4 pagesBest Practices in O&M of Thermal Power Stations: Tutorial Course OnGaurav Singh33% (3)

- Essar Power MP Limited: Yes NoDocument2 pagesEssar Power MP Limited: Yes NoGaurav SinghNo ratings yet

- Essar Power MP Limited: Change Request FormDocument2 pagesEssar Power MP Limited: Change Request FormGaurav SinghNo ratings yet

- Block No Time DC SG AG Freq UI Rate UI (AG-SG) From To MW MW MW HZ RS/KWH MWDocument26 pagesBlock No Time DC SG AG Freq UI Rate UI (AG-SG) From To MW MW MW HZ RS/KWH MWGaurav SinghNo ratings yet

- Se in Blade AngleDocument2 pagesSe in Blade AngleGaurav SinghNo ratings yet

- PAT Target Achievement: Strategies and Practices: EEC Conference 31 August, 2015Document23 pagesPAT Target Achievement: Strategies and Practices: EEC Conference 31 August, 2015Gaurav SinghNo ratings yet

- EM DSM (5th Amendment)Document12 pagesEM DSM (5th Amendment)Gaurav SinghNo ratings yet

- TNI Format Rev 01Document2 pagesTNI Format Rev 01Gaurav SinghNo ratings yet

- (SESSION 2010-2011) : A Major Project Report ONDocument4 pages(SESSION 2010-2011) : A Major Project Report ONGaurav SinghNo ratings yet

- Condenser & Heater PerformanceDocument116 pagesCondenser & Heater PerformanceGaurav Singh100% (5)

- AIEEE 2011 - Provisional Admit Card InformationDocument1 pageAIEEE 2011 - Provisional Admit Card InformationGaurav SinghNo ratings yet

- Labsheet 1Document5 pagesLabsheet 1raidahNo ratings yet

- Atomic Structure Grade 12Document16 pagesAtomic Structure Grade 12jmaeNo ratings yet

- TSP JRM 44742Document11 pagesTSP JRM 44742clau.santiagorNo ratings yet

- Stage Separation of Space Launch VehiclesDocument12 pagesStage Separation of Space Launch Vehiclesvasanraja100% (1)

- 9 Cast Aluminum Alloys - EXEMPLO 20Document7 pages9 Cast Aluminum Alloys - EXEMPLO 20AlexandreinspetorNo ratings yet

- Structural: Properties of ForcesDocument17 pagesStructural: Properties of ForcesPam GarciaNo ratings yet

- High Shear MixerDocument8 pagesHigh Shear MixerantiquekNo ratings yet

- Quick Quiz 31Document23 pagesQuick Quiz 3122146060No ratings yet

- Notes of Chapter Force and Laws of MotionDocument7 pagesNotes of Chapter Force and Laws of MotionppfcyiqiiNo ratings yet

- BROCHURE Lowara CO-series enDocument4 pagesBROCHURE Lowara CO-series enLuis E. RodríguezNo ratings yet

- Hot Air OvenDocument13 pagesHot Air OvenDevanandDongreNo ratings yet

- Part 32 Welding RelatedDocument8 pagesPart 32 Welding Relatedravindra_jivaniNo ratings yet

- Chapter 2 Molecular Orbital Theory EditedDocument42 pagesChapter 2 Molecular Orbital Theory EditedDanial JuniorNo ratings yet

- 4th ChapterDocument25 pages4th ChapterMOHAMMAD SHOHEL RANANo ratings yet

- As Levs Paper 2 CompilationDocument360 pagesAs Levs Paper 2 CompilationFahad Hameed AhmadNo ratings yet

- Second Generation Solar CellsDocument4 pagesSecond Generation Solar CellsAboothahir AfzalNo ratings yet

- PA Probe Catalog en 201308Document24 pagesPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaNo ratings yet

- Electrochemistry Lect Notes CambridgeDocument4 pagesElectrochemistry Lect Notes Cambridgeavatar_75No ratings yet

- Cross Reference Valvoline USADocument22 pagesCross Reference Valvoline USAPatricia Olaya Marchan100% (1)

- Cau Thang TC EurocodeDocument7 pagesCau Thang TC EurocodeNguyễn Văn LêNo ratings yet

- Viscometer-Group 7Document25 pagesViscometer-Group 7Camille Millondaga100% (1)

- Class 8 Revision 2024-25Document2 pagesClass 8 Revision 2024-25George PhilipsNo ratings yet

- USE of Evans & Duncans ChartDocument39 pagesUSE of Evans & Duncans ChartAsif Mostafa AnikNo ratings yet

- H2 PSA SlidesDocument16 pagesH2 PSA SlidesCristian TorrezNo ratings yet

- Solid State StabilityDocument35 pagesSolid State StabilityAisya Amalia Muslima100% (1)

- Binary QuestionsDocument2 pagesBinary QuestionsJuvy Lyka CapulNo ratings yet

- CE6008-Groundwater Engineering PDFDocument13 pagesCE6008-Groundwater Engineering PDFramgharia sameerNo ratings yet

- Apply As Paint... BUT Zinga Is Not PaintDocument4 pagesApply As Paint... BUT Zinga Is Not Paintsathish_iyengarNo ratings yet

- 9781444123166Document7 pages9781444123166eibsource100% (1)

- Concrete Shear Wall Presentation PDFDocument26 pagesConcrete Shear Wall Presentation PDFWenzhuo DingNo ratings yet