Dts

Dts

Uploaded by

Fadua HarbiCopyright:

Available Formats

Dts

Dts

Uploaded by

Fadua HarbiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Dts

Dts

Uploaded by

Fadua HarbiCopyright:

Available Formats

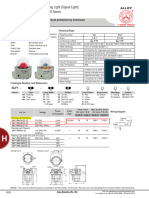

ABB DTS TUBUL A R FIT TINGS - XEL TUBUL A R LED FIT TING - ZONES 1 , 2, 2 1 & 2 2 55

—

Tubular fittings

XEL Self-contained or slave emergency lighting - zones 1, 2, 21 & 22

Features

• Emergency lighting suitable for zones 1, 2, 21, 22

• Two-in-one product: lighting and signage

• Self contained and Slave version

• 800000 Operating life at 25°C

• Glass diffuser

• Offshore grade painting

• 1h battery life (3h depending on reference)

LED

—

XEL Tubular LED fitting

Approvals & certifications Specifications Standards

Marine grade copper-free Approved to: EN 60079-0: General requirements

aluminum alloy EN 60079-1: Flameproof enclosure “d”

Borosilicate glass - thickness 7mm EN 60079-7: increased safety "e"

Rating: 4x1W LED EN 60079-31: Enclosure “t”

Exde Exd Extb Supplied with pictogram stickers

ATEX Directive INERIS 13 ATEX 0050X

Rated voltage 230Vac 50/60Hz 2014/34/EU INERIS 13 ATEX 0051X (Only for XEL400VLSI)

G D II 2 GD

Wiring configuration: 3 wires

IIC IIIC 2x entries 3/4“NPT Ex de IIC T6 Gb (XEL400VLSI)

or 1 x entry M20 Ex d IIC T6 Gb (all other)

GROUP

Ex tb IIIC T80°C Db IP66

II

T° amb: see table on next page

ZONE ZONE ZONE ZONE EMC Directive EN 55015: Conducted emission test and radiated

1 2 21 22 (2014/30/EU) emission test

EN61547: CEM immunity

EN61000-3-2 Harmonic current emissions class C

IP66 IK07 EN61000-3-3 Limitation of voltage changes

and flickers

Low voltage EN 60598-1: Luminaire general requirements

Directive and tests, including dielectric strength

(2014/35/EU) and isolation resistance

Glow wire test 960oC

IP test: IEC 60529: IP66

Impact protection IEC 62262: IK 07

index:

56 ABB DTS LIG HT FIT TI NGS , BOXE S & CUSTOM BU I LT CONTROL PAN E L S FOR E XPLOSI V E ATMOSPHERES

—

Tubular fittings

XEL Self-contained or slave emergency lighting - zones 1, 2 & 21, 22

XEL Tubular LED fitting

• 3 wires

• Glass Diffuser

• Equipped with 1 cable gland & 1 plug

• Suitable for use in Zones 1, 2, 21, 22

—

Dimensions

—

XEL 3 wires: Glass Diffuser Equipped with 1 cable gland & 1 plug

Lumen output Operating

Function: Battery M/ without / with life at Weight

Type Non maintained Testing type H NM pictogram 25°C h T amb. Gas Dust kg

Self contained

XEL400VLAK-00000 Lighting /Escape route Auto test 1H NM 330 / 100 80000 -20°C to +55°C IIC T80˚C 5.4

XEL400VLSI-00000 Lighting /Escape route Addressable + Auto test 1H NM 330 / 100 80000 -20°C to +55°C IIC T80˚C 5.4

XEL4001VSI-00000 Lighting /Escape route Addressable 3H NM 150 / NA 80000 -20°C to +55°C IIC T80˚C 5.4

XEL4001VA-00000 Lighting /Escape route Auto test 3H NM 150 / NA 80000 -20°C to +55°C IIC T80˚C 5.4

XEL400VLPA-00000 Lighting /Escape route Auto test 1H M 330 / 100 80000 -20°C to +55°C IIC T80˚C 5.4

XEL400VLPSI-00000 Lighting /Escape route Addressable 1H M 330 / 100 80000 -20°C to +55°C IIC T80˚C 5.4

XEL400VLPAB-00000 Lighting /Escape route Module LB400 1H M 330 / 100 80000 -20°C to +55°C IIC T80˚C 5.4

Slave:

XEL3008VLBU-00000 Lighting /Escape route Module LTC NA 200 / NA 80000 0°C to +40°C IIC T80˚C 5.3

XEL3008VL-00000 Lighting /Escape route NA 200 / NA 80000 -20°C to +55°C IIC T80˚C 5.3

XEL3008VLBG-00000 Lighting /Escape route Module FLX NA 200 / NA 80000 -10°C to +55°C IIC T80˚C 5.3

XEL3008VLB-00000 Lighting /Escape route Module LBS NA 200 / NA 80000 -10°C to +55°C IIC T80˚C 5.3

XEL3008VL-0K000 Lighting /Escape route NA 200 / NA 80000 -20°C to +55°C IIC T80˚C 5.3

Note: Spacing table available page 183.

—

Technical information

General data General data

Lamps LED 4x1W External grounding lug Screw M4x20 (stainless steel 316L)

Photometric curve See page 182 (nearby cable gland)

Terminal block (screws 2.5mm² rigid or flexible

Rated voltages Electronic ballast: 230Vac 50/60Hz or 24V

plug in terminal block)

Power NM 0.5W Terminals supplied L1, L2, L3, N, PE (looping

24V(only for XEL3008VL-0K000) possible with one additional cable gland)

Over-current protection The power supply shall be self-recovery Cable entries XEL400VLSI : One entry M20

when the fault condition is removed

All other: 2 entries 3/4"NPT

Power factor 0.4 Included: one stopping plug 3/4"NPT nickel

CRI Minimum 70 plated brass (EXN/075/SP) and one cable

gland for non armoured cable, diameter

Wiring Configuration 3 wires + 2 remote control unit 6-12mm (EX05ASC3)

Dielectrical class I Casting Marine grade aluminum alloy according to

Grounding system TNS, TNC, TT, IT neutral system standard EN1706.

Borosilicate glass thickness 7mm.

Battery Battery NiMh 3.6V 1.1Ah

Average life time of battery 4 years Colour of casting (std) l XEL****-00000 - Yellow offshore, RAL 1003

Upload charge cycle 100% 25°C - 24h Colour option: l XEL****-B0000 - Grey, RAL 7035

Pictogram 4 adhesive pictograms (included) Fixing D023- 2x zinc plated steel articulated

(included with product) brackets for ceiling mounting

ABB DTS TUBUL A R FIT TINGS - XEL TECHNIC A L INFORM ATION & ACCESSORIES - ZONES 1 , 2, 2 1 & 2 2 57

—

Tubular fittings

XEL Self-contained or slave emergency lighting - zones 1, 2, 21 & 22

Technical information & accessories

—

Technical information

General data General data

Lamps LED 4x1W External grounding lug Screw M4x20 (stainless steel 316L)

(nearby cable gland)

Cool White - approximately 4000K

L70/B10 at 25°C (70% lumen output/ 90%

active LED) according to operating life

Photometric curve See page 182

Spare parts Type Specifications

B013B LED Gear tray for XEL400VLAK (includes battery)

B013C LED Gear tray for XEL400VLSI (includes battery)

B013L1SI LED Gear tray for XEL4001VSI (includes battery)

B013L1A LED Gear tray for XEL4001VA (includes battery)

B013LPA LED Gear tray for XEL400VLPA (includes battery)

B013LPSI LED Gear tray for XEL400VLPSI (includes battery)

B013LPAB LED Gear tray for XEL400VLPAB (includes battery)

B013LBU LED Gear tray for XEL3008VLBU

B013L LED Gear tray for XEL3008VL

B013LBG LED Gear tray for XEL3008VLBG

B013LB LED Gear tray for XEL3008VLB

B013LK LED Gear tray for XEL3008VL-0K000 – 24Vac/Vdc

—

Additonal information for XEL400VLAK-00000 and XEL400VLSI-00000

Remote control units for emergency lighting

Order number BT5F BT12V

Type 621500 621201

Power supply 220-240 Vac - 50/60 Hz

Main feature Multi-brand compatibility Standard ON / OFF

ON / OFF offset 230Vac 50/60Hz

Power 0.5W

Testing type Unswitched - Switch off - combined

Size (mm) 82 x 70 x 70

Standard remote control installation (Self contained) Remote control installation with integrated self

Standard

—Standardremote control installation (Self contained) testing control

Remote

— capabilities

installation with integrated self

remote control installation (Self contained) Remote control installation with integrated self

LINE INremote control installation (Self contained)

Standard

Standard remote control installation (Self contained) testing

Remote

Remote capabilities

control

control installation

installation with integrated

with integrated self self testing capabilities

testing capabilities

LINE IN testing

LINE IN LINE INcapabilities

LINE IN Remote control

LINE IN

LINE IN

Remote control

LINE IN Main Remote control

Main Remote control

disconnect

disconnect Main

Main

Main

Main disconnect

disconnect

Main

disconnect

disconnect

Main disconnect

disconnect

Normally open contact

close for SATI report

Normally

Normally open contact

open contact

Sub close

close for

Normally for SATI

SATI

open

report

report

contact

Block n°1 Block n°2 Block n°3 disconnect

Sub

Sub close for SATI report

Block n°1n°1

Block Block

Blockn°2

n°2 Block

Blockn°3

n°3 disconnect

disconnect

Sub

Block n°1 Block n°2 Block n°3 disconnect

Regulations

Regulations

Article EC 12 paragrah 6

Regulations

Regulations

Self-contained emergency lighting installations must have on fit one or

Article EC 1212

Article EC paragrah 66

paragrah

several devices allowing centralised control. The devices must be located

Article EC 12 paragrah

Self-contained

Self-contained 6

emergency

emergency lighting

lightinginstallations

installationsmust

musthave

haveon

onfit

fitone

oneor or

close to the master control unit or one sub-division control units.

Self-contained

several

severaldevicesemergency

allowing

devices allowing lighting

centralised

centralisedinstallations

control. must

control.The

The havemust

devices

devices on fitbe

must one

be or

located

located

several

close todevices

close the

to the allowing

master

master centralised

control

controlunit control.

unitororone The devices

onesub-division

sub-division must

control

control be located

units.

units.

close to the master control unit or one sub-division control units.

BAES LED range | Data sheet DTS

You might also like

- Vol 1Document274 pagesVol 1Marcelo Brigard CarvajalNo ratings yet

- Admit CardDocument2 pagesAdmit CardAnuj KumarNo ratings yet

- Making A New Violin BridgeDocument9 pagesMaking A New Violin BridgefuyberNo ratings yet

- Solarflex - X H1Z2Z2-K: 1500 V DC, EN 50618Document2 pagesSolarflex - X H1Z2Z2-K: 1500 V DC, EN 50618Solar ProjectsNo ratings yet

- Attachment - 4 Technical Documents: Laxxim Internation Pte - LTD (Chalmit Lightings)Document5 pagesAttachment - 4 Technical Documents: Laxxim Internation Pte - LTD (Chalmit Lightings)Budi Putra NasutionNo ratings yet

- Catalog Pages English Atx Feled Series Nonmetallic Led Luminaires en Us 188686Document16 pagesCatalog Pages English Atx Feled Series Nonmetallic Led Luminaires en Us 188686Emiliano MercadoNo ratings yet

- Cooper MEDC LD15DMDCYWBDR Sinalizador de Advertencia Ficha Tecnica Catalogo DatasheetDocument2 pagesCooper MEDC LD15DMDCYWBDR Sinalizador de Advertencia Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- 2019 S KForestFrog J ExDocument8 pages2019 S KForestFrog J ExAgus CandraNo ratings yet

- DLF1-BN, DLF1-OB, DLF1-WN Series - Warning Light (Signal Light)Document1 pageDLF1-BN, DLF1-OB, DLF1-WN Series - Warning Light (Signal Light)hdtNo ratings yet

- Product Data Sheet: EXFS 100 / EXFS 100 KU EXFS 100 (923 100)Document1 pageProduct Data Sheet: EXFS 100 / EXFS 100 KU EXFS 100 (923 100)Alessandro KawanoNo ratings yet

- Olflex Power LV N 2xyry Pg87Document1 pageOlflex Power LV N 2xyry Pg87Hardy FerrysianNo ratings yet

- 35071-En (Web)Document2 pages35071-En (Web)hansidudeNo ratings yet

- ATX PC Series Floodlights: Flameproof. Metal Halide, High Pressure Sodium, Mercury Vapor, HalogenDocument5 pagesATX PC Series Floodlights: Flameproof. Metal Halide, High Pressure Sodium, Mercury Vapor, HalogenLuis CasasNo ratings yet

- D1xB2x05 - Xenon Strobe 5 J - E2SDocument2 pagesD1xB2x05 - Xenon Strobe 5 J - E2SAntonio Chuman MedinaNo ratings yet

- Crouse Hinds VMVL Led 3to13 Catalog PagesDocument7 pagesCrouse Hinds VMVL Led 3to13 Catalog Pageszoraima sulbaran camposNo ratings yet

- Xenon Helideck FloodlightDocument2 pagesXenon Helideck Floodlightluis0% (1)

- Clampco LightsDocument2 pagesClampco LightsZilvinas EzerskisNo ratings yet

- BExBG05 Explosion Proof Xenon Beacon 5 JouleDocument3 pagesBExBG05 Explosion Proof Xenon Beacon 5 Jouleosama omayerNo ratings yet

- ESS Ds EVFG 8 EN GI 01Document3 pagesESS Ds EVFG 8 EN GI 01Bibene MakitaNo ratings yet

- Photovoltaic Cable (Solar) : Solar Energy. Ful Lling The Energy Needs of TomorrowDocument4 pagesPhotovoltaic Cable (Solar) : Solar Energy. Ful Lling The Energy Needs of TomorrowNitinNo ratings yet

- S KGoldenFrog Ex PDFDocument8 pagesS KGoldenFrog Ex PDFRifandi AdityaNo ratings yet

- ATEX Light FixtureDocument3 pagesATEX Light FixtureKartickBakshiNo ratings yet

- Cortem Luminaria EVE-LDocument10 pagesCortem Luminaria EVE-LAlfredoNo ratings yet

- AVN - Exn.pdf اكسبل برووفDocument10 pagesAVN - Exn.pdf اكسبل برووفMowheadAdelNo ratings yet

- CMP Products Cable Gland CatalogueDocument1 pageCMP Products Cable Gland CataloguesubramanyaNo ratings yet

- Cable GlandsDocument13 pagesCable Glandsharry jangNo ratings yet

- Laser Blade Inout: Product Configuration: E886Document2 pagesLaser Blade Inout: Product Configuration: E886UmeshNo ratings yet

- Gamma Floodlight Z1 (ABDS-103 Rev6)Document2 pagesGamma Floodlight Z1 (ABDS-103 Rev6)ytatard042024No ratings yet

- Luminaria LED Areamaster AMLED77YBU1Document5 pagesLuminaria LED Areamaster AMLED77YBU1william barriosNo ratings yet

- Components: For Armoured Cables - Inner and Outer SealingDocument2 pagesComponents: For Armoured Cables - Inner and Outer SealingKarwanNo ratings yet

- TDK CD70 B2GA101KYGS Datasheet PDFDocument2 pagesTDK CD70 B2GA101KYGS Datasheet PDFSebastian ChaileNo ratings yet

- En Trex Data SheetDocument5 pagesEn Trex Data SheetEYplaza- alertsNo ratings yet

- DFDR Series - LED Floodlight (Round Shape)Document1 pageDFDR Series - LED Floodlight (Round Shape)hdtNo ratings yet

- E2S D2xB1X10Document3 pagesE2S D2xB1X10ffNo ratings yet

- Ce 362 BeDocument2 pagesCe 362 BeCRISENTENANo ratings yet

- D 88974043 0 Crouzet 88974043 Automata DocumentaciónDocument5 pagesD 88974043 0 Crouzet 88974043 Automata DocumentaciónRodolfo Antonio Cardenas FernandezNo ratings yet

- S202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereDocument5 pagesS202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereMary RoshmaNo ratings yet

- CHL Protecta III EmergencyDocument4 pagesCHL Protecta III EmergencyWill BuickNo ratings yet

- BExS110 Explosion Proof Alarm Horn SounderDocument3 pagesBExS110 Explosion Proof Alarm Horn Sounderosama omayerNo ratings yet

- TopCable FR N20XA8E AR ENG 900009012204Document1 pageTopCable FR N20XA8E AR ENG 900009012204ISGENo ratings yet

- VY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VDocument8 pagesVY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VheribertosfaNo ratings yet

- 15 AVC INX enDocument4 pages15 AVC INX enARah AtilehNo ratings yet

- Miniature Circuit Breaker - S200 - 2P - C - 32 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200 - 2P - C - 32 Ampere: Product-DetailsAbdullrahim AlastalNo ratings yet

- Arowana-H-Ex-G-V0 Grey Color HousingDocument7 pagesArowana-H-Ex-G-V0 Grey Color HousingAgus CandraNo ratings yet

- BW0 Series, 32 Ampere Frame MCCB: Fuji Molded Case Circuit BreakersDocument4 pagesBW0 Series, 32 Ampere Frame MCCB: Fuji Molded Case Circuit BreakersAutomation Engineering & Controls Ltd.No ratings yet

- S201M-C1 Miniature Circuit Breaker - 1P - C - 1 A: Product-DetailsDocument5 pagesS201M-C1 Miniature Circuit Breaker - 1P - C - 1 A: Product-DetailsrosmawanNo ratings yet

- Safety Relay LC ControllerDocument5 pagesSafety Relay LC ControlleraguilavmNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument3 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- RAC Type CatalogDocument2 pagesRAC Type CatalogAnonymous 9rM4GbfuQKNo ratings yet

- Pg032 - o Power LV (N) YyryDocument1 pagePg032 - o Power LV (N) YyryDolyNo ratings yet

- Miniature Circuit Breaker - S200 - 2P - C - 2 Ampere: Product-DetailsDocument6 pagesMiniature Circuit Breaker - S200 - 2P - C - 2 Ampere: Product-DetailsChristian SarrNo ratings yet

- Zone 2 Explosion LightDocument6 pagesZone 2 Explosion LightSOBHY KHELANo ratings yet

- UntitledDocument4 pagesUntitledjay25No ratings yet

- MS220VA ZIEHL PTC-Resistor-RelayDocument1 pageMS220VA ZIEHL PTC-Resistor-RelayAbdulraheem SalmanNo ratings yet

- CMP Products Cable Gland CatalogueDocument1 pageCMP Products Cable Gland Cataloguesuhaili pedroNo ratings yet

- 13-Exel-L en 2Document10 pages13-Exel-L en 2ladynotezanouNo ratings yet

- NHXCH-FE 180/E 90: Security Cable, Halogen-Free, 0,6/1kV, With Improved Fire CharacteristicsDocument2 pagesNHXCH-FE 180/E 90: Security Cable, Halogen-Free, 0,6/1kV, With Improved Fire CharacteristicsbebeNo ratings yet

- CQY80N, CQY80NG: Vishay SemiconductorsDocument8 pagesCQY80N, CQY80NG: Vishay SemiconductorsHELLOGREGNo ratings yet

- Celdas PrimariasDocument24 pagesCeldas PrimariasMartin CarrascoNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument2 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- Electromagnetic Compatibility (EMC) Design and Test Case AnalysisFrom EverandElectromagnetic Compatibility (EMC) Design and Test Case AnalysisNo ratings yet

- Web Intelligence OverviewDocument35 pagesWeb Intelligence Overviewraja singhNo ratings yet

- Home Security Using Fingerprint Scanner and Keypad Lock With Sms NotificationDocument24 pagesHome Security Using Fingerprint Scanner and Keypad Lock With Sms NotificationBecca AzarconNo ratings yet

- Samil Power Inverter Catalogue BrochureDocument16 pagesSamil Power Inverter Catalogue BrochurevhgiaoNo ratings yet

- LIC AAO Notification 2019Document12 pagesLIC AAO Notification 2019CharulNo ratings yet

- VoLTE KPI Report - 9mobileDocument29 pagesVoLTE KPI Report - 9mobileDee OyeNo ratings yet

- Updating MapsDocument3 pagesUpdating MapsamanggayamNo ratings yet

- History of Cartridge CaseDocument12 pagesHistory of Cartridge CaseHerbert Gongon100% (1)

- Ultrafine PowderDocument90 pagesUltrafine PowderraeggaemanNo ratings yet

- TESAR Installation Use and Maintenance EngDocument20 pagesTESAR Installation Use and Maintenance EngPatran ValentinNo ratings yet

- DigitalSafe User GuideDocument19 pagesDigitalSafe User Guideglobex1No ratings yet

- Instructional Decision MakingDocument5 pagesInstructional Decision Makingapi-267503852No ratings yet

- Mark Hoang: 9999 Mill St. Apt. 8C - San Luis Obispo, CA 93401 - (805) 762-4978 - Mhoang777@calpoly - EduDocument1 pageMark Hoang: 9999 Mill St. Apt. 8C - San Luis Obispo, CA 93401 - (805) 762-4978 - Mhoang777@calpoly - Edubpsharmab1p1No ratings yet

- Occupancy Permit Forms NewDocument12 pagesOccupancy Permit Forms NewaltavanoarNo ratings yet

- The Current Status and The Prospect of E-Banking in BangladeshDocument42 pagesThe Current Status and The Prospect of E-Banking in BangladeshFayaza Rahman Eva85% (20)

- Empowerment in Technology (Final Exam)Document2 pagesEmpowerment in Technology (Final Exam)Praise Rafols PasajeNo ratings yet

- F2474-14 Standard Test Method For Heat Gain To SPDocument17 pagesF2474-14 Standard Test Method For Heat Gain To SPHussein El BeqaiNo ratings yet

- Deh P1yDocument90 pagesDeh P1yPaulo ChagasNo ratings yet

- Nanoelectronics AbstractDocument1 pageNanoelectronics AbstractAmrit PattnaikNo ratings yet

- A Project Report On Consumer Satisfaction of Buying Behavior On Men'S Apparel in Reliance TrendsDocument12 pagesA Project Report On Consumer Satisfaction of Buying Behavior On Men'S Apparel in Reliance TrendsAnutosh DuttaNo ratings yet

- Disease in CoconutDocument28 pagesDisease in CoconutKarthick SunithaNo ratings yet

- High Density Plasma Sources PopovDocument6 pagesHigh Density Plasma Sources Popovbad_mariussNo ratings yet

- Chenanai Circle & BranchesDocument162 pagesChenanai Circle & BranchesSuganthiVasanNo ratings yet

- Pims BriefDocument5 pagesPims BriefPriya ChaudharyNo ratings yet

- IQ41x Series ControllersDocument20 pagesIQ41x Series ControllersZill RafiNo ratings yet

- Task 7 EnglishDocument5 pagesTask 7 EnglishGkusumaNo ratings yet

- Sulphur Hexafluoride (SF6) Circuit BreakerDocument4 pagesSulphur Hexafluoride (SF6) Circuit BreakerVishal BhatNo ratings yet

- Modification of Diffie-Hellman AlgorithmDocument4 pagesModification of Diffie-Hellman AlgorithmAnurag TiwariNo ratings yet