Brijesh ERL PDF

Brijesh ERL PDF

Uploaded by

BrajeshCopyright:

Available Formats

Brijesh ERL PDF

Brijesh ERL PDF

Uploaded by

BrajeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Brijesh ERL PDF

Brijesh ERL PDF

Uploaded by

BrajeshCopyright:

Available Formats

International Journal of Advances in Engineering and Emerging Technology (IJAEET), Vol. 7, No.

4, April 2015 220

Stone Dust as Fine Aggregate Replacement

in Concrete: Effect on Compressive Strength

Brajesh Kumar Suman, Amit Kumar Singh and Vikas Srivastava

Abstract--- In present days natural sand of good quality are becoming scarcer and costlier due to non-

accessibility of river during entire year, illegal dredging, rapid growth of construction activities etc. So it is

necessary to search an alternative material to use as natural sand in construction activities. Stone dust is such an

alternative material which can be effectively being used in construction as partial replacement of natural sand.

Hence present study taken a view to verify the suitability and potential use of stone dust in concrete mix as fine

aggregate. To accomplish this an experimental programme was planned for cast specimen cubes at an interval of 10

percent replacement of fine aggregate with stone dust in concrete. Results shows natural sand can be effectively

replace with stone dust and maximum strength attains at 60 percent replacement of natural sand with stone dust

based on compressive strength.

Keywords--- Coarse Aggregate, Compressive Strength, Fine Aggregate, Stone Dust Replacement

I. INTRODUCTION

Concrete is commonly used construction material due to its ease of availability, mouldability, rigidity and

durability. It generally consists of binding material, fine aggregate, coarse aggregate and required quantity of water,

where sand is normally used as fine aggregate. Due to rapid growth of construction activity, the available sources of

natural sand are getting exhausted. Hence conservation of natural resources is great challenge for civil engineers

since construction activities cannot be diminished as it is intimate able. The only way is to search an alternatives

material which can fully or partially replaced naturally available material in construction. Stone dust is such an

alternative material which can be effectively being used in construction as partial replacement of natural sand. This

is a waste product obtained from aggregate crushing plant. Stone dust is well appropriate in terms of strength and

economy over normal sand for medium grade concrete (Mahzuz et al 2011)[1]. 40 percent fine aggregate can be

effectively replaced with stone dust (Franklin et al 2014)[2]. The compressive strength of concrete mix had

increased by 22% with the use of crusher dust at 40% replacement of natural sand (Pofale et al 2013)[3].The present

study aimed to utilizing stone dust as fine aggregate in concrete in place of natural fine aggregate. For that an

experimental programme was carried out to study the suitability and potential use of stone dust as partial

replacement of fine aggregate in concrete. To accomplish this concrete cubes were cast for different replacement

level at an interval of 10 percent to determine compressive strength of concrete at different level of fine aggregate

with stone dust. The study shows that compressive strength of concrete made using stone dust as fine aggregate

replacement having greater value in comparison of conventional concrete.

Brajesh Kumar Suman, Department of Civil Engineering, SHIATS, Allahabad, India. E-mail:bs270790@gmail.com

Amit Kumar Singh, Department of Civil Engineering, SHIATS, Allahabad, India. E-mail:amitsingh15290@gmail.com

Vikas Srivastava, Department of Civil Engineering, SHIATS, Allahabad, India. E-mail:vikas.srivastava@shiats.edu.in

ISSN 2321-452X © 2015 Emerging Research Library

International Journal of Advances in Engineering and Emerging Technology (IJAEET), Vol. 7, No. 4, April 2015 221

II. MATERIALS AND METHODS

A. Cement

Portland Pozzolana Cement (fly ash based) brand name Birla Gold confirming to IS 1489 (Part 1) –1991[4]

single batched used in this investigation. The properties are shown in table 1.

Table 1: Properties of Cement

Standard Consistency 31%

Initial Setting Time 240 minutes

Final Setting Time 315 minutes

7 days Compressive Strength 33 N/mm2

28 days Compressive Strength 44 N/mm2

Specific Gravity 2.72

B. Fine Aggregate

River sand available in Allahabad confirming to IS 383-1997[5], zone II used in this study. It was completely

passed by 4.75 mm sieve. Fineness modulus and specific gravity of this material was 2.76 and 2.3 respectively.

C. Coarse Aggregate

Locally available coarse aggregate having two fraction 20mm and 10mm sizes individually sieved was used in

the present study. One fraction was passed through 20 mm sieve and another through 10 mm sieve. The specific

gravity of coarse aggregate was 2.66 for both fractions. Fineness modulus was 6.9 for 10 mm aggregate and 7.7 for

20 mm aggregate. For concrete mix a proportion of 40:60 of coarse aggregate was used where 40% 10 mm

aggregate and 60% 20 mm aggregate.

D. Stone Dust

Grey colour stone dust was collected from local stone crushing units of Bharatpur, Rewa road, Uttar Pradesh. It

was initially dry in condition and thoroughly retained on IS 150 μ sieve before preparation of mix. The stone dust

also confirmed zone II of IS 383-1997[5].Fineness modulus of stone dust was 2.85 and specific gravity was 2.4.

E. Super Plasticizer

KEM SUPLAST 101 S super plasticizer manufactured by Chembond Chemicals was to be used in the study. It

was synthetic super plasticizer based on sulphonated naphthalene and instantly dispersible in water having specific

gravity 1.2.

M25 grade of concrete is used as bench mark which was designed as per IS 10262 –2009[6] guidelines. The

proportion of materials was 1:1.54:3 with water cement ratio 0.42 and dose of super plasticizerwas 0.65% by weight

of cement. The coarse aggregate used in a combination of 40:60 individually sieved with IS sieve size 10 mm and 20

mm respectively. The particle size distribution of fine aggregate and stone dust was nearly same and confirm same

zone according to IS 383- 1997[5].Total 84 specimen of size 150 X 150 X 150 mm were casted for this

investigation. Initially 18 specimens cube of size 150 mm were casted for mix design calculation contained 380 kg

ISSN 2321-452X © 2015 Emerging Research Library

International Journal of Advances in Engineering and Emerging Technology (IJAEET), Vol. 7, No. 4, April 2015 222

cement per cubic meter of concrete with varying water cement ratios. Then 66 specimen of same size casted for

replacement of fine aggregate with stone dust at different percentage. For a percent replacement 6 cubes were

casted, 3 for 7 days and 3 for 28 days. The cube was filled in two parts with manually mix mixture and vibrated on a

table vibrator. Workability of fresh concrete was measured by slump cone. Uniformity and accuracy was maintained

during mix preparation and test. After 24 hours of casting specimens were demoulded and put in water bath for

curing. The compressive strength of concrete for 7th days and 28th days were tested on analogue compression

testing machine confirm to IS 14858 – 2000[7] of capacity 2000kN. Figure 1 shows a tested specimen in

compression testing machine.

Figure 1: Compression Testing Machine

III. RESULT AND DISCUSSION

The average compressive strength of concrete for 7th days and 28thdayswere tested as per IS 516 – 2004[8]

guidelines and results are tabulated in table 2 and its graphical representation on figure 2. It was observed that the

compressive strength of specimen at all replacement level of natural fine aggregate with stone dust was more than

designed value of conventional concrete which shows suitability of stone dust in concrete as partial or full

replacement of natural fine aggregate from compressive strength point of view. The 7 days compressive strength

variations within 34.3 percent and maximum strength attains on 30 percent replacement of fine aggregate with stone

dust. The 28 days strength gradually increased within variation of 9 percent up to 40 percent replacement level, at 50

percent replacement of natural fine aggregate in concrete the strength slightly (8 percent) decreases with respect to

30 – 40 percent replacement of fine aggregate. At 60 percent replacement of fine aggregate concrete attains

maximum value and then strength decreases or increases within variation of 8 percent. The variation in compressive

strength may be due to different water absorption capacity of stone dust and sand, different dose of super plasticizer

in mix, different angularity of particles etc. For attain good strength in this study the concrete with above 50%

replacement level of natural fine aggregate casted on 1 - 1.5% dose of super plasticizer. Finally it can be stated that

the stone dust is to be used in concrete with partially or fully replacement of fine aggregate.

ISSN 2321-452X © 2015 Emerging Research Library

International Journal of Advances in Engineering and Emerging Technology (IJAEET), Vol. 7, No. 4, April 2015 223

Table 2: Compressive Strength of Cubes with Different Percentage of Stone Dust

Concrete Cube Group % of Stone Dust in Concrete Compressive Strength (N/mm2)

7 days 28 days

B0 0 27.12 38.58

B1 10 26.40 38.80

B2 20 27.20 39.00

B3 30 31.80 41.50

B4 40 26.52 42.12

B5 50 27.56 38.68

B6 60 26.58 45.06

B7 70 28.08 42.22

B8 80 27.46 41.60

B9 90 26.84 44.28

B10 100 23.68 42.20

Compressive Strength of Concrete

50

Compressive Strength

40

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100

% of Stone Dust

Compressive Strength Compressive Strength

Figure 2: Compressive Strength of Concrete Cubes with Varying Percentage of Stone Dust

IV. CONCLUSION

On the basis of above investigation it can be concluded that –

Stone dust is to be used as fine aggregate replacement in concrete as partially or fully.

Use of stone dust as fine aggregate in concrete is beneficial in different manners such as environmental

aspects, non-availability of good quality of fine aggregate, and strength criteria also.

Compressive strength of cubes with stone dust as fine aggregate replacement attains maximum value on 60

percent replacement level of natural sand with stone dust.

It to be used at that place where setting time is not much important because excess dose of super plasticizer

increase the setting time.

ISSN 2321-452X © 2015 Emerging Research Library

International Journal of Advances in Engineering and Emerging Technology (IJAEET), Vol. 7, No. 4, April 2015 224

REFERENCES

[1] Mahzuz, H. M. A. Ahmed, A. A. M. and Yusuf, M. A. (2011) Use of stone powder in concrete and mortar

as an alternative of sand, African Journal of Environmental Science and Technology Volume 5, Issue 5,

pages 381-388.

[2] Kujur, Franklin Eric. Srivastava, Vikas. Agarwal, V.C. Anjelo F. Denis and Ali, Ehsan (2014)Stone Dust as

Partial Replacement of Fine Aggregate in Concrete,Journal of Academia and Industrial Research (JAIR)

Volume 3, Issue 3.

[3] Pofale, A. D. and Quadri, Syed Raziuddin.(2013) Effective utilization of crusher dust in concrete using

portland pozzolona cement, International Journal of Scientific and Research Publications, Volume 3, Issue

8.

[4] IS 1489 (Part 1) - 1991 Specification for Portland Pozzolana cement, Part 1: Flyash based, Bureau of Indian

standards, New Delhi.

[5] IS 383 - 1997 Specification for coarse and fine aggregate from natural sources for concrete, Bureau of

Indian standards, New Delhi.

[6] IS 10262 - 2009 Concrete mix proportioning guidelines, Bureau of Indian standards, New Delhi.

[7] IS 14858 - 2000): Requirements for compression testing machine used for testing of concrete and mortar,

Bureau of Indian standards, New Delhi.

[8] IS 516 - 2004 Method of test for strength of concrete, Bureau of Indian standards, New Delhi.

[9] IS 4031(Part 6)–2005 Method of physical tests of hydraulic cement Part 6 Determination of compressive

strength of hydraulic cement other than the masonry cement, Bureau of Indian standards, New Delhi.

[10] IS 4031(Part 5)–2000 Method of physical tests of hydraulic cement Part 5 Determination of initial and

final setting times, Bureau of Indian standards, New Delhi.

[11] IS 2386–2002 Method of test for aggregate for concrete Part 3 Specific gravity, density, voids, absorption

and bulking, Bureau of Indian standards, New Delhi.

[12] Celik, T. and Marar, K., (1996). Effects of crushed stone dust on some properties of concrete, Cement and

Concrete Research Volume 26, Issue 7, pages 1121-1130.

[13] Ahmed, E. Ahmed. and Kourd., A.E., (1989), Properties of concrete incorporating natural and crushed

stone very fine sand. ACI Material Journal, Volume 86, Issue 4, pages 417-424.

[14] Lohani T. K, Padhi M., Dash K. P. and Jena, S.(2012) Optimum utilization of quarry dust as partial

replacement of sand in concrete. International Journal of Applied Science and Engineering Research,

Volume 1, Issue 2.

[15] Jain, M. E. M, Safiuddin, M. and Yousuf, K.M., (1999). A study on the properties of freshly mixed high

performance concrete, Cement and Concrete Research, Volume 29, Issue 9, pages 1427-1432.

ISSN 2321-452X © 2015 Emerging Research Library

You might also like

- Form Checklist Civil.Document91 pagesForm Checklist Civil.Iki Hendro100% (2)

- Stone Dust in Concrete: Effect On Compressive Strength: Amit Kumar Singh, Vikas Srivastava, V.C. AgarwalDocument4 pagesStone Dust in Concrete: Effect On Compressive Strength: Amit Kumar Singh, Vikas Srivastava, V.C. AgarwalerpublicationNo ratings yet

- Partial Replacement of River Sand With Quarry Rock DustDocument8 pagesPartial Replacement of River Sand With Quarry Rock DustDharma banothuNo ratings yet

- Optimum .FullDocument8 pagesOptimum .FullAbrar Hussain KhanNo ratings yet

- A Study On Strength and Durability Characteristics of Concrete With Partial Replacement of Fine Aggregate by Laterite SandDocument8 pagesA Study On Strength and Durability Characteristics of Concrete With Partial Replacement of Fine Aggregate by Laterite SandIJIRSTNo ratings yet

- Construction and Building Materials: Gurpreet Singh, Rafat SiddiqueDocument6 pagesConstruction and Building Materials: Gurpreet Singh, Rafat SiddiqueharshitNo ratings yet

- Effect of Types of Fine Aggregate On Mechanical Properties of Cement ConcreteDocument4 pagesEffect of Types of Fine Aggregate On Mechanical Properties of Cement ConcreteKiranSDNo ratings yet

- Influence of Stone Dust On Compressive Strength and Embodied Energy of MortarDocument9 pagesInfluence of Stone Dust On Compressive Strength and Embodied Energy of MortarInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Muhit Et Al.Document6 pagesMuhit Et Al.Test SeriesNo ratings yet

- Effects of Manufactured Sand On Compressive Strength and Workability of ConcreteDocument5 pagesEffects of Manufactured Sand On Compressive Strength and Workability of Concretenught surNo ratings yet

- Msand Research PaperDocument10 pagesMsand Research PaperPandianKalaimaniNo ratings yet

- 3IJCSEIERDJUN20193Document6 pages3IJCSEIERDJUN20193TJPRC PublicationsNo ratings yet

- Research Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustDocument3 pagesResearch Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustjasimabdNo ratings yet

- Stone Dust & RubberDocument64 pagesStone Dust & RubberSyed Mohd Mehdi100% (1)

- Eijcse3157 PDFDocument8 pagesEijcse3157 PDFPritam MangoreNo ratings yet

- Experimental Study On Blended Concrete in R.C.C Beam and Its Behaviour Phase-Ii Review-1Document17 pagesExperimental Study On Blended Concrete in R.C.C Beam and Its Behaviour Phase-Ii Review-1HemapriyaNo ratings yet

- Replacement of Fine Aggregate by Mixture of Ceramic and Surkhi Powder in Concrete IJERTV6IS040780Document9 pagesReplacement of Fine Aggregate by Mixture of Ceramic and Surkhi Powder in Concrete IJERTV6IS040780Abdullah Al-MamunNo ratings yet

- Study On Behaviour of Concrete Partially Replacing Quartz Sand As Fine AggregateDocument8 pagesStudy On Behaviour of Concrete Partially Replacing Quartz Sand As Fine AggregateShaikKhanNo ratings yet

- FYP PresentationDocument21 pagesFYP PresentationalihassanNo ratings yet

- IJTSEV2I504Document3 pagesIJTSEV2I504Alamgir kabirNo ratings yet

- 45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFDocument4 pages45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFArunkumar AKNo ratings yet

- Utilization of Aggregate Quarry Waste in Construction IndustryDocument7 pagesUtilization of Aggregate Quarry Waste in Construction IndustryJanine Rose MendozaNo ratings yet

- Experimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureDocument9 pagesExperimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureEditor IJTSRDNo ratings yet

- 1 To Study The Properties of Concrete Mix On Partial Replacement of Coarse Aggregate With Burnt BricksDocument4 pages1 To Study The Properties of Concrete Mix On Partial Replacement of Coarse Aggregate With Burnt BrickssadatdeshmukhNo ratings yet

- Partial Replacement of Laterite As A CoaDocument7 pagesPartial Replacement of Laterite As A Coaslalitha.613No ratings yet

- High Performance of Concrete With Robo SandDocument3 pagesHigh Performance of Concrete With Robo Sandpenta63No ratings yet

- Comprehensive Literature Review On Use of Waste Product in ConcreteDocument8 pagesComprehensive Literature Review On Use of Waste Product in ConcreteInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Study On Glass Fiber Reinforced Concrete With Steel Slag and M-Sand As Replacement of Natural AggregatesDocument6 pagesExperimental Study On Glass Fiber Reinforced Concrete With Steel Slag and M-Sand As Replacement of Natural AggregatesthirumalNo ratings yet

- Experimental Investigation On Partial Replacement of Fine Aggregate With Sabbath (Cuddapah Stone) StoneDocument8 pagesExperimental Investigation On Partial Replacement of Fine Aggregate With Sabbath (Cuddapah Stone) StoneAnonymous kw8Yrp0R5rNo ratings yet

- Major Project JournalDocument8 pagesMajor Project Journalalwinr89No ratings yet

- JETIR2205718Document8 pagesJETIR2205718Faisal manzoorNo ratings yet

- A Review of Evaluation of Cement Concrete by Partial Replacement of Natural SandDocument6 pagesA Review of Evaluation of Cement Concrete by Partial Replacement of Natural SandIJRASETPublicationsNo ratings yet

- Comparative Study On The Strength and Durability Properties of Concrete With Manufactured SandDocument7 pagesComparative Study On The Strength and Durability Properties of Concrete With Manufactured SandyoussefNo ratings yet

- Conference Paper. Final - AnkieDocument5 pagesConference Paper. Final - AnkieAnkieNo ratings yet

- Use of M Sand As A Replacement ofDocument7 pagesUse of M Sand As A Replacement ofbasanth babuNo ratings yet

- Effect of Fly Ash and Quarry Dust On Properties of ConcreteDocument8 pagesEffect of Fly Ash and Quarry Dust On Properties of ConcreteDinesh RamoNo ratings yet

- Waste Tyre Crumb Rubber Particle As A Partial Replacement To Fine Aggregate in Concrete IJERTV3IS061161Document4 pagesWaste Tyre Crumb Rubber Particle As A Partial Replacement To Fine Aggregate in Concrete IJERTV3IS061161220Ranjeet PatilNo ratings yet

- Experimental Investigation On High Performance Concrete With Partial Replacement of Fine Aggregate by Foundry Sand With Cement by Mineral AdmixturesDocument6 pagesExperimental Investigation On High Performance Concrete With Partial Replacement of Fine Aggregate by Foundry Sand With Cement by Mineral Admixturesபுருஷோத்தமன் சரவணன்No ratings yet

- Chapter-1 1.1.1 GENERALDocument45 pagesChapter-1 1.1.1 GENERALVishNo ratings yet

- Utilization of Waste Plastics As A Fiber in Concrete: January 2017Document6 pagesUtilization of Waste Plastics As A Fiber in Concrete: January 2017Excel MigsNo ratings yet

- Study of Partial Replacement of Fine Aggregate by Using Quarry DustDocument8 pagesStudy of Partial Replacement of Fine Aggregate by Using Quarry DustramakrishnaNo ratings yet

- An Experimental Investigation On Rubberized ConcreteDocument7 pagesAn Experimental Investigation On Rubberized ConcreteIJIRSTNo ratings yet

- Construction and Building MaterialsDocument10 pagesConstruction and Building MaterialsharshitNo ratings yet

- Utilisation of Waste Marble Dust As Fine AggregateDocument7 pagesUtilisation of Waste Marble Dust As Fine AggregatePoporok SantiagoNo ratings yet

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Document6 pagesExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156kishor150688No ratings yet

- 11 PDFDocument7 pages11 PDFSuraj DubeyNo ratings yet

- Group No 18Document47 pagesGroup No 18Amey KadulkarNo ratings yet

- Effect On Compressive Strength of Concrete With Addition of Solid Waste AshDocument6 pagesEffect On Compressive Strength of Concrete With Addition of Solid Waste AshIJAR JOURNALNo ratings yet

- Stone Crusher Dust As A Fine Aggregate in Concrete For Paving BlocksDocument8 pagesStone Crusher Dust As A Fine Aggregate in Concrete For Paving Blocksaswaths007No ratings yet

- Ijsrdv3i110384 PDFDocument5 pagesIjsrdv3i110384 PDFtonydisojaNo ratings yet

- Ijsrdv3i110384 PDFDocument5 pagesIjsrdv3i110384 PDFtonydisojaNo ratings yet

- Effect of Quarry Dust On High Performance ConcreteDocument5 pagesEffect of Quarry Dust On High Performance ConcreteMark EliasNo ratings yet

- Assessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsDocument6 pagesAssessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsIJRASETPublicationsNo ratings yet

- Study On Partial Replacement of Cement and Coarse Aggregate by Egg Shell Powder and Steel Slag in ConcreteDocument8 pagesStudy On Partial Replacement of Cement and Coarse Aggregate by Egg Shell Powder and Steel Slag in ConcreteIJRASETPublicationsNo ratings yet

- A Review and Study On Stabilization of Expansive Soil Using Brick DustDocument8 pagesA Review and Study On Stabilization of Expansive Soil Using Brick DustalibuxjatoiNo ratings yet

- Replacing Query Dust Instead of Sand in Concrete MixDocument43 pagesReplacing Query Dust Instead of Sand in Concrete MixudayashankarNo ratings yet

- Abrasion ResistanceDocument5 pagesAbrasion ResistanceHafiz Zain AkramNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Reinforced Concrete FoundationsDocument25 pagesReinforced Concrete FoundationsDiether AguilarNo ratings yet

- Daily Report Proforma-CIVIL - 01-03-2018Document6 pagesDaily Report Proforma-CIVIL - 01-03-2018rajupetalokeshNo ratings yet

- Technical Service Bulletin: Reverse Osmosis and Nanofiltration Membrane Element PrecautionsDocument6 pagesTechnical Service Bulletin: Reverse Osmosis and Nanofiltration Membrane Element PrecautionsTalukder RifatNo ratings yet

- KCC SiliconeDocument15 pagesKCC Siliconerendra syamNo ratings yet

- Wash ClothesDocument12 pagesWash ClothespradeepvohraNo ratings yet

- D6378 10 (Reapproved 2016)Document14 pagesD6378 10 (Reapproved 2016)Cristhian Emmanuel Garrido100% (2)

- Udyam Registration Certificate: TradingDocument1 pageUdyam Registration Certificate: TradingGAURAV BHARDWAJNo ratings yet

- Aluminium IsopropoxideDocument12 pagesAluminium IsopropoxidepradipNo ratings yet

- B.tech Seminar Report FormatDocument9 pagesB.tech Seminar Report FormatBiswa vijayee GarnaikNo ratings yet

- Beal Roy E.eds. Engine Coolant Testing Volum PDFDocument317 pagesBeal Roy E.eds. Engine Coolant Testing Volum PDFCorina StanculescuNo ratings yet

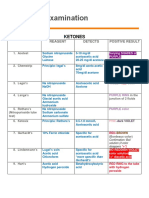

- KetonesDocument3 pagesKetonespixiedustNo ratings yet

- Compressive Strength TestDocument6 pagesCompressive Strength TestjejojuNo ratings yet

- A Review On Design and Development of Semi-Automated Colour Painitng Machine PDFDocument4 pagesA Review On Design and Development of Semi-Automated Colour Painitng Machine PDFHussain MuslimNo ratings yet

- Hotline Numbers:: Select LanguageDocument38 pagesHotline Numbers:: Select LanguageIndrajit Shorcar100% (1)

- 10 Stainless Steel PDFDocument86 pages10 Stainless Steel PDFPopovici PaulNo ratings yet

- Of Copper: Colorimetric Determination AmmoniaDocument3 pagesOf Copper: Colorimetric Determination AmmoniaMithran R TIPSNo ratings yet

- Balinox Aisi 316L With 304 BraidDocument1 pageBalinox Aisi 316L With 304 BraidshyamNo ratings yet

- Counter Rust 6655 TDSDocument1 pageCounter Rust 6655 TDSFadhli KusumaNo ratings yet

- Organic Chemistry: Course Code: SKO 3033 Semester 2 Sessions 2020/2021 Id Number and NameDocument6 pagesOrganic Chemistry: Course Code: SKO 3033 Semester 2 Sessions 2020/2021 Id Number and NameSITI HUMAIRAH BINTI HAMZAHNo ratings yet

- Rising Opportunity in Technical Textiles 2020-2026Document19 pagesRising Opportunity in Technical Textiles 2020-2026Savan GajjarNo ratings yet

- RestofIndiaMRP priceListJune2007Document10 pagesRestofIndiaMRP priceListJune2007Braj PalNo ratings yet

- Cable Tray CalculationsDocument33 pagesCable Tray CalculationsأحمدساسيNo ratings yet

- Final - Constitutive Behaviour of Bond in RC Structures Based On Pull Out Strength PDFDocument25 pagesFinal - Constitutive Behaviour of Bond in RC Structures Based On Pull Out Strength PDFRakesh SiempuNo ratings yet

- Lesson Plan Elements Comp MixDocument4 pagesLesson Plan Elements Comp Mixloralie tolentinoNo ratings yet

- TRL 611 - Ground Investigation and Ground Investigation and Road PavementDocument54 pagesTRL 611 - Ground Investigation and Ground Investigation and Road PavementAu Yong Thean SengNo ratings yet

- Rough CostDocument1 pageRough CostKannanNo ratings yet

- 23 Fabric Defects To Look Out For During Fabric InspectionDocument22 pages23 Fabric Defects To Look Out For During Fabric InspectionMayan DynastyNo ratings yet

- P E Q PVC W and D P: Technical CatalogueDocument24 pagesP E Q PVC W and D P: Technical CatalogueWaqas FareedNo ratings yet

- VWR Chemical Resistance Gloves ChartDocument8 pagesVWR Chemical Resistance Gloves ChartBruno MenezesNo ratings yet