Astm c470

Astm c470

Uploaded by

jem guiCopyright:

Available Formats

Astm c470

Astm c470

Uploaded by

jem guiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Astm c470

Astm c470

Uploaded by

jem guiCopyright:

Available Formats

Designation: C470/C470M – 09

Standard Specification for

Molds for Forming Concrete Test Cylinders Vertically 1

This standard is issued under the fixed designation C470/C470M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revis

revision.

ion. A number in parentheses

parentheses indicates the year of last reapproval.

reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Sco

Scope*

pe* C192/C192M Practi

Practice

ce for Mak

Making

ing and Cur

Curing

ing Con

Concre

crete

te

1.1 Th

1.1 This

is sp

spec

ecifi

ificat

catio

ion

n co

cove

vers

rs mo

mold

ldss fo

forr us

usee in fo

form

rmin

ing

g Test Specimens in the Laboratory

cylindrical concrete specimens. The provisions of this specifi- C1077 Practice for Laboratories Testing Concrete and Con-

cation include the requirements for both reusable and single- crete Aggregates for Use in Construction and Criteria for

use molds. Laboratory Evaluation

D256 Test

Test Met

Method

hodss for Det

Determ

ermini

ining

ng the Izo

Izod

d Pen

Pendul

dulum

um

NOTE 1—Sizes included are molds having diameters from 50 mm [2 Impact Resistance of Plastics

in.] to 900 mm [36 in.].

D570 Test Method for Water Absorption of Plastics

1.2 The values stated in either SI units or inch-pound

inch-pound units

are to be regarded separately as standard. The values stated in 3. General Requirements

Requirements

each system may not be exa exact

ct equ

equiva

ivalen

lents;

ts; the

theref

refore

ore,, each 3.1 The fol

follow

lowing

ing pro

provis

vision

ionss app

apply

ly to bot

bothh reu

reusab

sable

le and

system shall be used independently of the other. Combining single-use molds:

values from the two systems may result in non-conformance 3.1.1 Molds shall

shall be constructed

constructed in the form of right circular

circular

with the standard. The inch-pound units are shown in brackets. cylinders

cylind ers which stand with the cylind

cylindrical

rical axis vertic

vertical

al and the

1.3 The following

following safety hazards

hazards caveat pertains only to the top

top op

open

en to re

recei

ceive

ve ththee co

conc

ncre

rete.

te. They shshall

all be mad

madee of

test method described in this specification: This standard does materials that do not react with concrete containing portland or

nott pu

no purp

rpor

ortt to ad

addr

dres

esss alalll of th

thee sa

safet

fetyy co

conc

ncern

erns,

s, if an

anyy, other hydraulic cements. They shall be watertight and suffi-

associated

associ ated with its use. It is the responsibili

responsibilityty of the user of this ciently strong and tough to permit their use without tearing,

standard to establish appropriate safety and health practices crushing, or deforming.

and determine the appli

applicabilit

cabilityy of reg

regulato

ulatory

ry limitat

limitations

ions prior

NOTE 2—Reu

2—Reusable

sable lids may be used on molds to reduce moisture

moisture loss.

to use.

1.4 The text of this standard

standard references

references notes and footnotes 3.1.2 Mol

3.1.2 Molds

ds sha

shall

ll hav

havee a nom

nominal

inal inside

inside hei

height

ght equal to

which provide explanatory material. These notes and footnotes twice the nominal inside diameter. The diameter of a mold,

(excluding those in tables and figures) shall not be considered consisting of the average of two measurements taken at right

as requirements of the standard. angles to each other at the top of the mold, shall not differ from

the nominal diameter by more than 1 %. The height, deter-

2. Referenc

Referenced

ed Documents

Documents mined by averaging two measurements taken 180° apart, shall

2.1 ASTM Standards: 2 not differ

differ from the nominal

nominal hei

height

ght by mor

moree tha

than

n 2 %. The

C31/C31M Practice for Making and Curing Concrete Test planes of the top rim of the mold and the bottom shall be

Specimens in the Field perpen

perpendic

dicula

ularr to the axi

axiss of the mold with

within

in 0.5 degrees—

degrees—

C33 Specification for Concrete Aggregates approximately equivalent to 3 mm in 300 mm [ ⁄ 8 in. in 12 in.].

1

No diameter of a mold shall differ from any other diameter of

the same mold by more than 2 % except that molds that fail to

1

This specification

specification is under the jurisd

jurisdiction

iction of ASTM Committee

Committee C09 on

meet this requirement may be used when the user is able to

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.61 on Testing for Strength. demonstrate that no diameter of hardened concrete specimen

Current edition approved Oct. 1, 2009. Published November 2009. Originally produced in a similar mold differs from any other diameter on

approved in 1961. Last previous edition approved in 2008 as C470/C470M-08. DOI: the same specimen by more than 2 % (see Note 3). 3).

10.1520/C0470_C0470M-09.

2

For refere

referenced

nced ASTM stand

standards,

ards, visit the ASTM websi

website,

te, www

www.astm

.astm.org

.org,, or NOTE 3—Certain single-use molds may require the use of a special

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM device such as a tub

device tubee of heavy-gag

heavy-gagee met

metal

al aro

around

und the mol

moldd durduring

ing

Standards volume information, refer to the standard’s Document Summary page on molding to maintain the dimensional tolerances specified in 3.1.2

in 3.1.2..

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright. (C) ASTM International. 100 Barr Harbor Dr., P.O. box C-700, West Conshohocken PA. United States

Copyright by ASTM Int'l (all rights reserved); 1

C470/C470M – 09

3.1.3 The bottom inside surface of the mold shall not depart 5.3 Single-use Plastic Molds—Molds shall conform to the

from a plane by more than 2 mm in 150 mm [ 1 ⁄ 16 in. in 6 in.] following additional requirements when plastic is the predomi-

(1 % of the diameter of the mold). nant material used in construction:

5.3.1 Wall Thickness—The side walls shall be of sufficient

4. Reusable Molds stiffness to meet the requirements of 3.1 (See Note 5).

4.1 Reusable molds are those which are designed to be used NOTE 5—This can be achieved through sufficient side wall thickness

more than a single time. Reusable molds shall be made of alone, or in combination with a stiffened top.

nonabsorptive materials, and constructed as either one piece or 5.3.2 Bottom Design—The bottom shall be designed so that

several pieces (see Note 4). it will be flush with the bottom of the sidewall within a

4.2 Reusable molds shall be provided with a closure or base tolerance of 2 mm [ 1 ⁄ 16 in.]. An inside fillet, if any, at the

on the lower end at right angles to the axis of the cylinder. bottom of the sidewall shall have an indentation around the

Molds may be single piece molds or made from castings with circumference no more than 4 mm [1 ⁄ 8 in.] in the vertical

a separate detachable base plate or a base that is an integral part direction or no more than 5 mm [ 3 ⁄ 16 in.] in the radial direction.

of the sidewall. The mold shall be either coated or made of a The bottom shall be of adequate rigidity to prevent permanent

material that will prevent adherence to the concrete. At the time deformation when specimens are molded in accordance with

of use, molds shall not leak water. An inside fillet, if any, at the the applicable provisions of Practice C31/C31M or C192/

bottom of the side wall shall have an indentation around the C192M.

circumference no more than 3 mm [1 ⁄ 8 in.] in the vertical 5.3.3 Material—The mold manufacturer shall certify that:

direction or no more than 5 mm [ 3 ⁄ 16 in.] in the horizontal (1) the plastic material used in molds has a maximum water

direction. absorption of less than 0.5 % in 24 h when tested in accordance

4.3 Reusable molds shall be tested for water leakage as with Test Method D570; (2) the plastic has an Izod impact

described in 6.4, for resistance to damage as described in 6.3.1, toughness of at least 117 J/m [2.2 ft lb/in.] of notch for a 4 mm

and for dimensional stability in accordance with 3.1.2 and 3.1.3 [1 ⁄ 8 in.] thick specimen tested in accordance with Test Methods

initially and after every 50 uses or every six months, whichever D256; and (3) after being held at 12 °C [10 °F] for 24 h, the

comes first. plastic shall not fracture when subject to tapping and jarring

NOTE 4—Satisfactory molds can be made from lengths of steel tubing that is judged to be typical of what occurs when specimens are

or pipe that is slit on one side parallel to the axis and fitted with a means molded in accordance with the applicable provisions of Prac-

of closing the vertical slit as well as a means of attaching a base plate. The tice C31/C31M or C192/C192M.

required dimensional tolerances must be maintained after slitting, clamp- 5.4 Paper Molds—When paper or other potentially absorp-

ing, and attaching the base plate. Other nonabsorptive materials which

tive fiber material is used as the primary structural material in

have been used include iron, brass, steel, and various plastics. Although

aluminum and magnesium alloys have been used, some of these alloys

the construction of the side walls or bottom of the mold, the

may be reactive with cement constituents and are therefore unacceptable. mold shall conform to the following additional requirements:

5.4.1 Side Walls—The side walls of paper molds shall be

5. Single-Use Molds made with a minimum of three plies having a combined

5.1 Single-use molds are molds designed to be used once thickness of not less than 2 mm [0.070 in.]. Seams on the inside

and discarded. They are permitted to be made of sheet metal, of the mold shall not be open by more than 2 mm [ 1 ⁄ 16 in.].

plastic, suitably treated paper products, or other materials and NOTE 6—The minimum thickness of material used in side walls and

shall conform to the requirements of this specification. bottoms is considered adequate for cylinders up to 150 mm [6 in.] in

5.2 Physical Requirements—The molds as prepared for use diameter. For larger cylinders thicker material may be required to meet

shall comply with the following: requirements of 3.1.

5.2.1 Water Leakage—When tested as described in Section 5.4.2 Bottom Caps —The bottom cap of the mold shall be

6, there shall be no visible leakage. made of either metal or paper. If metal, it shall not be less than

5.2.2 Absorptivity—When tested as described in Section 6, 0.23 mm [0.009 in.] in thickness and coated to prevent

the absorption shall not exceed the values given in Table 1. corrosion (Note 6). It shall be designed so that it will be flush

Intermediate values are proportional to the square of the height. with the bottom edge of the side wall within a tolerance of 2

5.2.3 Elongation—When tested as described in Section 6, mm [1 ⁄ 16 in.] and the inside crimp, if any, shall produce an

the elongation after test shall not exceed 0.2 % of height. indentation around the circumference of the cylinder no more

than 5 mm [ 3 ⁄ 16 in.] in the radial, and no more than 4 mm [ 1 ⁄ 8

in.] in the vertical direction. If made of paper, the bottom cap

TABLE 1 Limits for Absorption and Elongation of the mold shall be of parchment-lined cap stock not less than

Nominal Mold Height,

Absorption, max g

Elongation, max 0.7 mm [0.028 in.] thick (Note 6). It shall be glued to the

mm [in.] mm [in.]

outside of the walls by means of a flange not less than 19 mm

100 [4] 2.7 0.2 [0.008] [3 ⁄ 4 in.] high. The glue shall be water-insoluble adhesive of the

150 [6] 6.0 0.3 [0.012]

200 [8] 11 0.4 [0.016] resin type that will not react with fresh concrete. Only the

300 [12] 24 0.6 [0.024] practicable minimum amount of adhesive shall be exposed on

450 [18] 54 0.9 [0.036] the inner side of the bottom of the mold.

600 [24] 96 1.2 [0.048]

900 [36] 216 1.8 [0.072] 5.4.3 Waterproofing—The mold made from paper or fiber

shall be completely coated on inside and outside, side walls,

Copyright by ASTM Int'l (all rights reserved); 2

C470/C470M – 09

and bottom with a suitable waterproofing medium (Note 7). mold, the indentation produced in the concrete cylinder shall

The top edge shall be waterproofed, or coated, to limit not exceed 4 mm [1 ⁄ 8 in.] in either a radial or vertical direction.

absorption. The surfaces of metal bottoms, which must comply 5.5.4 Coating—If the mold is made of material which will

with 5.4.2, need not be coated. Any waterproofing coating used rust, corrode, react, or adhere to the freshly mixed or hardened

in this application shall have a melting point not less than 49 °C concrete, it must be coated with a protective coating of lacquer

[120 °F] (Note 8). The coating shall provide a film over the or other suitable material.

inside that will minimize adherence of the concrete to the side

walls and the bottom. 6. Test Methods for Elongation, Absorption, and Water

Leakage

NOTE 7—Paraffin coating for this use may be of the grade known to the

trade as crude scale wax or of any superior grade. In general, a film of

6.1 Apparatus—The assembly used for the absorption-

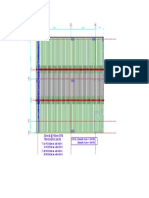

paraffin of sufficient thickness to accomplish the intended purposes will elongation test shall follow the principles illustrated in Fig. 1.

permit one to raise a curl of paraffin with the thumbnail. 6.2 Specimens—Molds shall be selected as described in

NOTE 8—Such coatings may be unsuitable for molds that are subjected Section 2. Single-use molds shall not be reused nor the same

to temperatures above 49 °C [120 °F], either before or after filling with mold retested.

concrete. 6.3 Test Procedure for Molds:

5.5 Single-Use Sheet Metal Molds—Molds shall conform to 6.3.1 Samples of all types of single-use molds and reusable

the following additional requirements when light-gage sheet plastic molds shall be subjected to the dry rodded coarse

metal is the predominant material used in their construction: aggregate test as described in 6.3.2 to evaluate their resistance

5.5.1 Metal Thickness—The side wall of steel sheet metal to damage under use and to the water leakage test described in

molds shall be manufactured from sheet metal not thinner than 6.3.3 and 6.3.4. Paper or other potentially absorptive molds

can-making quality blackplate and shall have a minimum metal shall additionally be tested for absorptivity and elongation

thickness corresponding to that of 48.5-kg [107-lb] blackplate, described in 6.3.5. Plastic and sheet metal molds need not be

which is approximately 0.300 mm [0.0118 in.] thick or 30 1 ⁄ 2 tested for elongation and absorption, but should be tested for

gage. The metal for the bottom of the mold shall have a water leakage. Dimensional requirements for all molds shall be

minimum thickness of 0.23 mm [0.009 in.] (Note 6). verified.

5.5.2 Bottom Design—The bottom shall be so designed that 6.3.2 Prepare the mold for test by filling with dry crushed

it will be flush with the bottom of the side wall within a stone coarse aggregate meeting the grading requirements of

tolerance of 2 mm [1 ⁄ 16 in.]. An inside crimp, if used, shall Specification C33 size No. 57, 25.0 to 4.75 mm [1 in. to No. 4]

produce an indentation around the circumference of the cylin- or No. 67, 19.0 to 4.75 mm [ 3 ⁄ 4 in. to No. 4]. Fill and compact

der no more than 4 mm [ 1 ⁄ 8 in.] in the vertical or 5 mm [ 3 ⁄ 16 the mold by the rodding procedure specified in Practice

in.] in the radial direction. C192/C192M for compression test specimens using the tamp-

5.5.3 Top Edge—The top edge of the side wall shall be ing rod, number of layers and number of strokes per layer

curled or beaded to strengthen the mold and protect the user specified. It will generally not be possible to obtain the

from sharp edges. If such bead protrudes to the inside of the penetration of the tamping rod specified in Practice C192/

FIG. 1 Apparatus for Absorption-Elongation Test of Paper Molds

Copyright by ASTM Int'l (all rights reserved); 3

C470/C470M – 09

C192M. After rodding the final layer, empty the coarse 8. Record to be Prepared by the Purchaser

aggregate, wipe lightly with a dry cloth and examine the mold 8.1 Where applicable for the type of mold tested, record and

for physical damage. retain in accordance with Practice C1077 the following infor-

6.3.3 After completion of 6.3.2, determine the mass of the mation for each mold tested:

mold and record to the nearest 0.004 g/mm [0.1 g/in.] of mold

8.1.1 Brand or source of molds,

height. Place the mold on a firm, flat surface and fill with water

8.1.2 Shipment or lot from which the mold was taken,

at room temperature to a depth of 90 to 95 % of the mold

8.1.3 Date sampled and date tested,

height. Then place the mold on the dial stand, cover with the

glass or metal plate and record the initial length by dial 8.1.4 Brief general description of the mold including nomi-

micrometer to the nearest 0.025 mm [0.001 in.]. nal dimensions, type of mold, and materials of which it is

6.3.4 Allow the mold to stand for 3 h and take a final made,

reading of the micrometer. Examine and record any visible 8.1.5 Total absorption, g, if specified,

leakage. Empty water from the mold, dry lightly with a towel 8.1.6 Total expansion, mm [in.], if specified, and

and record the final mass to the nearest 0.04 g/cm [0.1 g/in.] of 8.1.7 Water leakage reported in terms of compliance, or

mold height. failure by leakage.

6.3.5 Calculate the elongation as the difference between the 8.2 Where applicable for the type of mold tested, record and

final length and initial length. Calculate the absorption as the retain the following information for samples which do not meet

difference between the final mass and initial mass of the mold. the requirements of the specification:

6.3.6 Verify all dimensional requirements. 8.2.1 Average diameter or height, mm [in.],

6.4 Water Leakage Test for Reusable Molds: 8.2.2 Maximum and minimum diameters or heights, mm

6.4.1 Prepare reusable molds with the sealant to be used, if [in.],

required. Fill molds with water to a depth of 90 to 95 % of the 8.2.3 Nonconformance with required perpendicularity of

nominal height. Subject the mold to tapping and jarring which rim or base to the axis of the mold,

is judged to be typical of what occurs when specimens are 8.2.4 Apparent reaction between mold materials and con-

molded in accordance with the applicable provisions of Prac- crete or mortar or corrosion of metal in contact with concrete,

tice C31/C31M or C192/C192M.

8.2.5 Melting point less than 49 °C [120 °F],

6.4.2 One hour after tapping, examine for visible leakage.

8.2.6 Minimum thickness of materials in side walls or

7. Sampling and Rejection bottom, and

7.1 At least three single-use and reusable molds shall be 8.2.7 Dimension of crimp in bottom, top edge or construc-

selected at random from each shipment by the purchaser to tion of paper bottom.

ensure that the molds are in compliance with this specification.

7.2 Failure of any one of the three molds to comply with this 9. Keywords

specification shall be basis for rejection of the shipment. 9.1 concrete; molds; test cylinders

SUMMARY OF CHANGES

Committee C09 has identified the location of selected changes to this specification since the last issue,

C470/C470M – 08, that may impact the use of this specification. (Approved October 1, 2009)

(1) Revised 4.3 to require initial compliance testing of reusable (2) Replaced “report” with “record and retain” in Section 8.

molds before being placed in service. (3) Added Practice C1077 to 8.1 and Referenced Documents.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright by ASTM Int'l (all rights reserved); 4

You might also like

- Draft Plan For Construction and Pre-CommissioningDocument77 pagesDraft Plan For Construction and Pre-Commissioningwangrui50% (2)

- Astm DesignationDocument16 pagesAstm DesignationLawrence John AntonioNo ratings yet

- Mathprint PDFDocument53 pagesMathprint PDFjem gui100% (1)

- Mathprint PDFDocument53 pagesMathprint PDFjem gui100% (1)

- C309 Hlja5316Document4 pagesC309 Hlja5316Brisa Yuliet100% (1)

- Sampling Bituminous Paving Mixtures: Standard Practice ForDocument4 pagesSampling Bituminous Paving Mixtures: Standard Practice ForAnonymous x7VY8VF7No ratings yet

- Astm C192Document8 pagesAstm C192gustavo aguilarNo ratings yet

- Staad Advanced Concrete Design RCDC 63 PhilippinesDocument2 pagesStaad Advanced Concrete Design RCDC 63 Philippinesjem guiNo ratings yet

- Understanding Stresses and Modular Ratio - RCC Structures - Civil Engineering ProjectsDocument2 pagesUnderstanding Stresses and Modular Ratio - RCC Structures - Civil Engineering ProjectslearnafrenNo ratings yet

- TR 066 Design Post Installed Shear Connection 2concrete Layer 2019 04Document15 pagesTR 066 Design Post Installed Shear Connection 2concrete Layer 2019 04phamducquangNo ratings yet

- BOQ of Proposed Bungalow For Providing Approximate CostDocument13 pagesBOQ of Proposed Bungalow For Providing Approximate CostA.k. Mishra100% (1)

- Comparison of Cost of Foundation in Kerala, IndiaDocument20 pagesComparison of Cost of Foundation in Kerala, IndiaBijoy AVNo ratings yet

- Astm D-5361Document3 pagesAstm D-5361mohammad sahmoud100% (2)

- C231 Air Content of Freshly Mixed Concrete by The Pressure MethodDocument10 pagesC231 Air Content of Freshly Mixed Concrete by The Pressure MethodLuis AlvarezNo ratings yet

- Air Content (ASTM-C185)Document21 pagesAir Content (ASTM-C185)John LusterioNo ratings yet

- Sampling Aggregates: Standard Practice ForDocument7 pagesSampling Aggregates: Standard Practice Formuqeem khanNo ratings yet

- Ready-Mixed Concrete: Standard Specification ForDocument13 pagesReady-Mixed Concrete: Standard Specification ForJesús Luis Arce GuillermoNo ratings yet

- Astm C116-15 PDFDocument7 pagesAstm C116-15 PDFDanny LiangNo ratings yet

- Astm D6938 NuclearDocument3 pagesAstm D6938 NuclearRey Rapay100% (1)

- Aashto T89-22Document12 pagesAashto T89-22jaheshfarhad100% (1)

- C188.5653 ASTM StandardTestMethodforDensityofHydraulicCementDocument3 pagesC188.5653 ASTM StandardTestMethodforDensityofHydraulicCementJUAN M100% (1)

- Astm C143 C143MDocument4 pagesAstm C143 C143Mhaval100% (1)

- ASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsDocument10 pagesASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsMohammad Raihan MukhlisNo ratings yet

- Astm C87 (2005)Document4 pagesAstm C87 (2005)Stuar TencioNo ratings yet

- Astm C129-22Document3 pagesAstm C129-22Earlle John Nicoli IbañezNo ratings yet

- ASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing Concretebenedick barquinNo ratings yet

- ASTM C1116-10aDocument8 pagesASTM C1116-10aViết DuyNo ratings yet

- Astm C 87Document4 pagesAstm C 87mickyfelixNo ratings yet

- Astm d412 Testing FixtureDocument6 pagesAstm d412 Testing FixturePallab Jyoti DasNo ratings yet

- ASTM - Standard Test - Cement MortarsDocument10 pagesASTM - Standard Test - Cement Mortarstigani brigdar100% (1)

- Astm C185 - 20Document4 pagesAstm C185 - 20Maricel NgaganNo ratings yet

- Astm d2172Document10 pagesAstm d2172radhaNo ratings yet

- M 29-03 Fine Aggregate For Bituminous Paving Mix PDFDocument3 pagesM 29-03 Fine Aggregate For Bituminous Paving Mix PDFWalticoZegarraHerreraNo ratings yet

- ACES Riyadh-Co - Profile 2022-23-REV0 PDFDocument74 pagesACES Riyadh-Co - Profile 2022-23-REV0 PDFOmar O Fili SalehNo ratings yet

- ASTM C 39 Standard Test Method For Compressive Strength of Cylindrical Concrete SpecimensDocument8 pagesASTM C 39 Standard Test Method For Compressive Strength of Cylindrical Concrete SpecimensMohamed HunaisNo ratings yet

- ASTM D 3203 Percent Air Voids in Compacted Dense and Open Bituminous Paving MixturesDocument2 pagesASTM D 3203 Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixturesiel84749No ratings yet

- M 195-06 Lightweight Aggregates PDFDocument6 pagesM 195-06 Lightweight Aggregates PDFWalticoZegarraHerreraNo ratings yet

- Lanko 764 - Shotcrete PHDocument2 pagesLanko 764 - Shotcrete PHJet ToledoNo ratings yet

- Fedspec Ss-S-200e Joint Sealant, Oil & Jet Blast Resistant, For Concrete PavementDocument24 pagesFedspec Ss-S-200e Joint Sealant, Oil & Jet Blast Resistant, For Concrete PavementAlex BeldnerNo ratings yet

- C87-C87M - 10Document4 pagesC87-C87M - 10Jesus Luis Arce GuillermoNo ratings yet

- C1611C1611M 14371Document6 pagesC1611C1611M 14371josueNo ratings yet

- Mix Design SubmittalDocument140 pagesMix Design SubmittalWaleedMareyNo ratings yet

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDocument7 pagesStandard Test Procedures Manual: 1. Scope 1.1. Description of TestMuhsin KhanNo ratings yet

- C150C150M-15 Standard Specification For Portland Cement PDFDocument9 pagesC150C150M-15 Standard Specification For Portland Cement PDFPrafulla PatilNo ratings yet

- Marshal Test: Marshal Test Is Extensively Used in Routine Test Programs For The Paving Jobs. TheDocument3 pagesMarshal Test: Marshal Test Is Extensively Used in Routine Test Programs For The Paving Jobs. TheSnehashish BasuNo ratings yet

- D560D560M 15.PDF (EngPedia - Ir)Document6 pagesD560D560M 15.PDF (EngPedia - Ir)Dastaggir KarimiNo ratings yet

- ACI JTA Concrete Strength Technician PDFDocument3 pagesACI JTA Concrete Strength Technician PDFjerin sam kurianNo ratings yet

- Laboratory Soils TestingDocument5 pagesLaboratory Soils TestingNavam NanthanNo ratings yet

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument6 pagesDensity (Unit Weight), Yield, and Air Content (Gravimetric) of Concreteminhhuan0101100% (1)

- Astm C109 C109M 21Document7 pagesAstm C109 C109M 21ahmadfaathir100% (1)

- Standard Test Method For Slump Flow of SCCDocument6 pagesStandard Test Method For Slump Flow of SCCPris Twins TobingNo ratings yet

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document2 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)mjgutierrezperaltaNo ratings yet

- Astm C618 19Document2 pagesAstm C618 19maniharimeenaNo ratings yet

- Aci 211.2 - 1998 PDFDocument18 pagesAci 211.2 - 1998 PDFBhavanishankar ShettyNo ratings yet

- Astm C702 C702M 11Document12 pagesAstm C702 C702M 11Jhaiiler ZlatanNo ratings yet

- C 138Document4 pagesC 138Kevin Castillo IbarraNo ratings yet

- Aggregate For Masonry MortarDocument2 pagesAggregate For Masonry MortarNada Khlif100% (1)

- Astm c140 - 20aDocument27 pagesAstm c140 - 20aMaritza Cordova Salgado100% (1)

- Astm C1107-02 Hydraulic-Cement Non-Shrink GroutDocument5 pagesAstm C1107-02 Hydraulic-Cement Non-Shrink GroutCharwin PicaoNo ratings yet

- Astm c-192 PDFDocument8 pagesAstm c-192 PDFProbo100% (2)

- Astm D2172 95Document6 pagesAstm D2172 95Raj BalasubramaniamNo ratings yet

- ASTM D2939 2003 Emulsified Bitumens Protective CoatingsDocument7 pagesASTM D2939 2003 Emulsified Bitumens Protective CoatingstsalemnoushNo ratings yet

- Density, Absorption, and Voids in Hardened Concrete: Standard Test Method ForDocument3 pagesDensity, Absorption, and Voids in Hardened Concrete: Standard Test Method ForMohamed BelmokaddemNo ratings yet

- Astma615 615MDocument6 pagesAstma615 615MRahul Bhardwaj100% (1)

- Chemical Admixtures For ConcreteDocument15 pagesChemical Admixtures For ConcreteKMNo ratings yet

- Astm c94 Mixed ConcreteDocument13 pagesAstm c94 Mixed ConcreteasdNo ratings yet

- Astm C76M-14Document11 pagesAstm C76M-14Wen ZhuNo ratings yet

- ASTM C76-14 Standard Specification For Reinforced Concrete Culvert, Storm Drain, and Sewer PipeDocument11 pagesASTM C76-14 Standard Specification For Reinforced Concrete Culvert, Storm Drain, and Sewer Pipebenedick barquinNo ratings yet

- Splices, Development and STD - HooksDocument6 pagesSplices, Development and STD - Hooksjem guiNo ratings yet

- Checklist For Masonry: Project: Doc. No.: Client: Project LocationDocument4 pagesChecklist For Masonry: Project: Doc. No.: Client: Project Locationjem guiNo ratings yet

- Jobhazard Analysis SampleDocument6 pagesJobhazard Analysis Samplejem guiNo ratings yet

- Cutting List of RebarDocument1 pageCutting List of Rebarjem guiNo ratings yet

- 4 PDFDocument1 page4 PDFjem guiNo ratings yet

- 4 PDFDocument1 page4 PDFjem guiNo ratings yet

- 25mmø at 150Mm BTM Transverse Bars 1. 2Document1 page25mmø at 150Mm BTM Transverse Bars 1. 2jem guiNo ratings yet

- 4 PDFDocument1 page4 PDFjem guiNo ratings yet

- MF 33Document1 pageMF 33jem guiNo ratings yet

- Column Rebar ModelDocument1 pageColumn Rebar Modeljem guiNo ratings yet

- Method of Making and Curing Concrete Test Specimens in FLDDocument8 pagesMethod of Making and Curing Concrete Test Specimens in FLDjem guiNo ratings yet

- Chapter 7 (MORTARNEW)Document24 pagesChapter 7 (MORTARNEW)Mitiku AregieNo ratings yet

- Wall Modular Block Mechanically Stabilized Earth (Structure), Item SPV.0165.XXDocument16 pagesWall Modular Block Mechanically Stabilized Earth (Structure), Item SPV.0165.XXCekinNo ratings yet

- Compressive Strength of Concrete With Partial Replacement of Cement by Fly AshDocument6 pagesCompressive Strength of Concrete With Partial Replacement of Cement by Fly AshEditor IJTSRDNo ratings yet

- Sikament-520 BADocument3 pagesSikament-520 BAShahbaz AkramNo ratings yet

- The Experimental Investigation of Concrete Carbonation DepthDocument8 pagesThe Experimental Investigation of Concrete Carbonation DepthasdfghNo ratings yet

- Types of CementDocument5 pagesTypes of CementPeniel LuzonNo ratings yet

- Testing FormatDocument8 pagesTesting FormatJATINBHAI TRIVEDINo ratings yet

- Damage Limit State MasonryDocument7 pagesDamage Limit State MasonryDaniel Ortega CotrinaNo ratings yet

- Proceso Constructivo de Tanques PostensadosDocument8 pagesProceso Constructivo de Tanques PostensadosGrecia FloresNo ratings yet

- Pilefoundations 180502041727Document60 pagesPilefoundations 180502041727Kiprono VincentNo ratings yet

- CRSI-PILECAP (Full Version)Document228 pagesCRSI-PILECAP (Full Version)xhq08No ratings yet

- How To Build An A-Frame House (Tiny House, Cabin) - TheDIYPlanDocument59 pagesHow To Build An A-Frame House (Tiny House, Cabin) - TheDIYPlanccm.participacoes50% (2)

- CMT Lab ManualDocument38 pagesCMT Lab ManualAlliahkherzteen LagoNo ratings yet

- City of Dallas, Texas: Front Elevation at Curb FaceDocument9 pagesCity of Dallas, Texas: Front Elevation at Curb FaceardabiliNo ratings yet

- Concrete in Sea WaterDocument17 pagesConcrete in Sea Watersabareesan09No ratings yet

- Abstract Post TensionDocument4 pagesAbstract Post TensionDe Silva ShmapkNo ratings yet

- SMNR-RPRT Ballastless TrackDocument19 pagesSMNR-RPRT Ballastless Trackgreeshma cNo ratings yet

- ASTM C33. Standard Specification For Concrete AggregateDocument11 pagesASTM C33. Standard Specification For Concrete AggregateENGYA2007No ratings yet

- Project On Partial Replacement of Cement With Marble PowderDocument8 pagesProject On Partial Replacement of Cement With Marble PowderYu Paing HanNo ratings yet

- A Study of Cost Comparison of Precast Concrete vs. Cast-In-PlaceDocument4 pagesA Study of Cost Comparison of Precast Concrete vs. Cast-In-PlaceEditor IJRITCC100% (1)

- Keepers AreaDocument162 pagesKeepers Areadimuthu lasinthaNo ratings yet

- Installation Procedure For Pressure VesselDocument8 pagesInstallation Procedure For Pressure VesselSamuel Babu100% (1)

- (WWW - Entrance-Exam - Net) - B.tech in Civil Engineering 7th Sem - Estimation, Costing & Valuation Sample Paper 4Document4 pages(WWW - Entrance-Exam - Net) - B.tech in Civil Engineering 7th Sem - Estimation, Costing & Valuation Sample Paper 4Lakshmi PrasadNo ratings yet

- Highway Construction BasicsDocument4 pagesHighway Construction Basicsqadiradnan7177No ratings yet

- 14464Document125 pages14464Bui Tat ThanhNo ratings yet