THGBMDG5D1LBAIL Toshiba PDF

THGBMDG5D1LBAIL Toshiba PDF

Uploaded by

linCopyright:

Available Formats

THGBMDG5D1LBAIL Toshiba PDF

THGBMDG5D1LBAIL Toshiba PDF

Uploaded by

linOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

THGBMDG5D1LBAIL Toshiba PDF

THGBMDG5D1LBAIL Toshiba PDF

Uploaded by

linCopyright:

Available Formats

THGBMDG5D1LBAIL

TOSHIBA e-MMC Module

4GB THGBMDG5D1LBAIL

INTRODUCTION

THGBMDG5D1LBAIL is 4GB density of e-MMC Module product housed in 153 ball BGA package. This unit is utilized

advanced TOSHIBA NAND flash device(s) and controller chip assembled as Multi Chip Module. THGBMDG5D1LBAIL

has an industry standard MMC protocol for easy use.

FEATURES

THGBMDG5D1LBAIL Interface

THGBMDG5D1LBAIL has the JEDEC/MMCA Version 5.0 interface with 1-I/O, 4-I/O and 8-I/O mode.

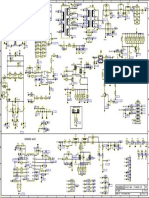

Pin Connection

P-WFBGA153-1113-0.50 (11.5mm x 13mm, H0.8mm max. package)

14 NC NC NC NC NC NC NC NC NC NC NC NC NC NC

13 NC NC NC NC NC NC NC NC NC NC NC NC NC NC

12 NC NC NC NC NC NC NC NC NC NC NC NC NC NC

11 NC NC NC NC NC NC

10 NC NC NC VSF VSF RFU Vss Vcc RFU NC NC RFU

9 NC NC NC VSF Vcc NC NC NC

8 NC NC NC RFU Vss NC NC NC

Top View

7 RFU NC NC Vss RFU NC NC RFU

6 Vss DAT7 VccQ Vcc RFU CLK NC VssQ

5 DAT2 DAT6 NC RFU Vcc Vss DS Vss RST_n CMD VssQ VccQ

4 DAT1 DAT5 VssQ NC index VccQ VccQ VssQ

3 DAT0 DAT4 NC NC NC NC RFU NC NC NC NC NC NC VccQ

2 NC DAT3 VDDi NC NC NC NC NC NC NC NC NC VssQ NC

1 NC NC NC NC NC NC NC NC NC NC NC NC NC NC

A B C D E F G H J K L M N P

Pin Number Name Pin Number Name Pin Number Name Pin Number Name

A3 DAT0 C2 VDDi J5 Vss N4 VccQ

A4 DAT1 C4 VssQ J10 Vcc N5 VssQ

A5 DAT2 C6 VccQ K5 RST_n P3 VccQ

A6 Vss E6 Vcc K8 Vss P4 VssQ

B2 DAT3 E7 Vss K9 Vcc P5 VccQ

B3 DAT4 F5 Vcc M4 VccQ P6 VssQ

B4 DAT5 G5 Vss M5 CMD

B5 DAT6 H5 DS M6 CLK

B6 DAT7 H10 Vss N2 VssQ

NC: No Connect, shall be connected to ground or left floating.

RFU: Reserved for Future Use, shall be left floating for future use.

VSF: Vendor Specific Function, shall be left floating.

1 Dec. 1st, 2015

THGBMDG5D1LBAIL

Part Numbers

Available e-MMC Module Products – Part Numbers

TOSHIBA Part Number Density Package Size NAND Flash Type Weight

THGBMDG5D1LBAIL 4GB 11.5mm x 13mm x 0.8mm(max) 1 x 32Gbit 15nm 0.18g typ

Operating Temperature and Humidity Conditions

-25°C to +85°C, and 0%RH to 95%RH non-condensing

Storage Temperature and Humidity Conditions

-40°C to +85°C, and 0%RH to 95%RH non-condensing

Performance

X8 mode/ Sequential access

Typ. Performance

Interleave Frequency [MB/sec]

TOSHIBA Part Number Density NAND Flash Type VccQ

Operation /Mode

Read Write

1.8V 46 14

52MHz/SDR

3.3V 46 14

Non 1.8V 88 14

THGBMDG5D1LBAIL 4GB 1 x 32Gbit 15nm 52MHz/DDR

Interleave 3.3V 88 14

HS200 1.8V 152 14

HS400 1.8V 152 14

Power Supply

Vcc = 2.7V to 3.6V

VccQ = 1.7V to 1.95V / 2.7V to 3.6V

Operating Current (RMS)

The measurement for max RMS current is done as average RMS current consumption over a period of 100ms

Max Operating

TOSHIBA Part Interleave Frequency Current [mA]

Density NAND Flash Type VccQ

Number Operation /Mode

Iccq Icc

1.8V 60 25

52MHz/SDR

3.3V 70 25

Non 1.8V 70 30

THGBMDG5D1LBAIL 4GB 1 x 32Gbit 15nm 52MHz/DDR

Interleave 3.3V 85 30

HS200 1.8V 90 30

HS400 1.8V 100 30

2 Dec. 1st, 2015

THGBMDG5D1LBAIL

Sleep Mode Current

Iccqs [μA] Iccqs+Iccs [μA]

Interleave

TOSHIBA Part Number Density NAND Flash Type

Operation

Typ. *1 Max. *2 Typ. *1 Max. *2

Non

THGBMDG5D1LBAIL 4GB 1 x 32Gbit 15nm 100 510 120 560

Interleave

*1 : The conditions of typical values are 25°C and VccQ = 3.3V or 1.8V.

*2 : The conditions of maximum values are 85°C and VccQ = 3.6V or 1.95V.

3 Dec. 1st, 2015

THGBMDG5D1LBAIL

Product Architecture

The diagram in Figure 1 illustrates the main functional blocks of the THGBMDG5D1LBAIL.

Specification of the CREG and recommended values of the CVCC, and CVCCQ in the Figure 1 are as follows.

Parameter Symbol Unit Min. Typ. Max. Remark

μF 0.10 - 2.2* Except HS400

VDDi capacitor value CREG

μF 1.00 - 2.2* HS400

VCC capacitor value CVCC μF - 2.2 + 0.1 -

VCCQ capacitor value CVCCQ μF - 2.2 + 0.1 -

* Toshiba recommends that the value should be usually applied as the value of CREG.

Package

Vcc(3.3V)

CVCC

VccQ(1.8V/3.3V)

CVCCQ NAND

REGULATOR Control signal

NAND I/O BLOCK

MMC I/O BLOCK

VDDi

I/O BLOCK

CREG

CORE LOGIC NAND

x11 NAND I/O

MMC I/F(1.8V/3.3V)

Figure 1 THGBMDG5D1LBAIL Block Diagram

4 Dec. 1st, 2015

THGBMDG5D1LBAIL

PRODUCT SPECIFICATIONS

Package Dimensions

P-WFBGA153-1113-0.50 (11.5mm x 13mm, H0.8mm max. package) Unit: mm

5 Dec. 1st, 2015

THGBMDG5D1LBAIL

Density Specifications

Interleave User Area Density SEC_COUNT in

Density Part Number

Operation [Bytes] Extended CSD

4GB THGBMDG5D1LBAIL Non Interleave 3,959,422,976 0x00760000

1) User area density shall be reduced if enhanced user data area is defined.

Register Informations

OCR Register

OCR bit VDD Voltage window Value

[6:0] Reserved 000 0000b

[7] 1.70-1.95 1b

[14:8] 2.0-2.6 000 0000b

[23:15] 2.7-3.6 1 1111 1111b

[28:24] Reserved 0 0000b

[30:29] Access Mode 10b

[31] ( card power up status bit (busy) )1

1) This bit is set to LOW if the Device has not finished the power up routine.

CID Register

CID-slice Name Field Width Value

[127:120] Manufacturer ID MID 8 0001 0001b

[119:114] Reserved - 6 0b

[113:112] Device/BGA CBX 2 01b

[111:104] OEM/Application ID OID 8 0b

[103:56] Product name PNM 48 0x30 30 34 47 36 30 (004G60)

[55:48] Product revision PRV 8 0x02

[47:16] Product serial PSN 32 Serial number

[15:8] Manufacturing date MDT 8 see-JEDEC Specification

[7:1] CRC7 checksum CRC 7 CRC7

[0] Not used, always ‘1’ - 1 1b

6 Dec. 1st, 2015

THGBMDG5D1LBAIL

CSD Register

CSD-slice Name Field Width Cell Type Value

[127:126] CSD structure CSD_STRUCTURE 2 R 0x3

[125:122] System specification version SPEC_VERS 4 R 0x4

[121:120] Reserved - 2 R 0x0

[119:112] Data read access-time 1 TAAC 8 R 0x5E

Data read access-time 2 in CLK cycles

[111:104] NSAC 8 R 0x00

(NSAC * 100)

[103:96] Max. bus clock frequency TRAN_SPEED 8 R 0x32

[95:84] Device command classes CCC 12 R 0x0F5

[83:80] Max. read data block length READ_BL_LEN 4 R 0x9

[79:79] Partial blocks for read allowed READ_BL_PARTIAL 1 R 0x0

[78:78] Write block misalignment WRITE_BLK_MISALIGN 1 R 0x0

[77:77] Read block misalignment READ_BLK_MISALIGN 1 R 0x0

[76:76] DSR implemented DSR_IMP 1 R 0x0

[75:74] Reserved - 2 R 0x0

[73:62] Device size C_SIZE 12 R 0xFFF

[61:59] Max. read current @ VDD min. VDD_R_CURR_MIN 3 R 0x7

[58:56] Max. read current @ VDD max. VDD_R_CURR_MAX 3 R 0x7

[55:53] Max. write current @ VDD min. VDD_W_CURR_MIN 3 R 0x7

[52:50] Max. write current @ VDD max. VDD_W_CURR_MAX 3 R 0x7

[49:47] Device size multiplier C_SIZE_MULT 3 R 0x7

[46:42] Erase group size ERASE_GRP_SIZE 5 R 0x1F

[41:37] Erase group size multiplier ERASE_GRP_MULT 5 R 0x1F

[36:32] Write protect group size WP_GRP_SIZE 5 R 0x07

[31:31] Write protect group enable WP_GRP_ENABLE 1 R 0x1

[30:29] Manufacturer default ECC DEFAULT_ECC 2 R 0x0

[28:26] Write speed factor R2W_FACTOR 3 R 0x4

[25:22] Max. write data block length WRITE_BL_LEN 4 R 0x9

[21:21] Partial blocks for write allowed WRITE_BL_PARTIAL 1 R 0x0

[20:17] Reserved - 4 R 0x0

[16:16] Content protection application CONTENT_PROT_APP 1 R 0x0

[15:15] File format group FILE_FORMAT_GRP 1 R/W 0x0

[14:14] Copy flag (OTP) COPY 1 R/W 0x0

[13:13] Permanent write protection PERM_WRITE_PROTECT 1 R/W 0x0

[12:12] Temporary write protection TMP_WRITE_PROTECT 1 R/W/E 0x0

[11:10] File format FILE_FORMAT 2 R/W 0x0

[9:8] ECC code ECC 2 R/W/E 0x0

[7:1] CRC CRC 7 R/W/E CRC

[0] Not used, always ‘1’ - 1 - 0x1

7 Dec. 1st, 2015

THGBMDG5D1LBAIL

Extended CSD Register

Size Cell

CSD-slice Name Field Value

(Bytes) Type

[511:506] Reserved - 6 - All ‘0’

[505] Extended Security Commands Error EXT_SECURITY_ERR 1 R 0x00

[504] Supported Command Sets S_CMD_SET 1 R 0x01

[503] HPI features HPI_FEATURES 1 R 0x01

[502] Background operations support BKOPS_SUPPORT 1 R 0x01

[501] Max_packed read commands MAX_PACKED_READS 1 R 0x3F

[500] Max_packed write commands MAX_PACKED_WRITES 1 R 0x3F

[499] Data Tag Support DATA_TAG_SUPPORT 1 R 0x01

[498] Tag Unit Size TAG_UNIT_SIZE 1 R 0x03

[497] Tag Resource Size TAG_RES_SIZE 1 R 0x00

[496] Context management capabilities CONTEXT_CAPABILITIES 1 R 0x7F

[495] Large Unit size LARGE_UNIT_SIZE_M1 1 R 0x00

[494] Extended partitions attribute support EXT_SUPPORT 1 R 0x03

[493] Supported modes SUPPORTED_MODES 1 R 0x01

[492] FFU features FFU_FEATURES 1 R 0x00

[491] Operation codes timeout OPERATION_CODES_TIMEOUT 1 R 0x00

[490:487] FFU Argument FFU_ARG 4 R 0xFFFFFFFF

[486] Barrier support BARRIER_SUPPORT 1 R 0x00

[485:309] Reserved - 177 - All ‘0’

[308] CMD Queuing Support CMDQ_SUPPORT 1 R 0x00

[307] CMD Queuing Depth CMDQ_DEPTH 1 R 0x00

[306] Reserved - 1 - 0x00

NUMBER_OF_FW_SECTORS_C

[305:302] Number of FW sectors correctly programmed 4 R All ‘0’

ORRECTLY_PROGRAMMED

VENDOR_PROPRIETARY

[301:270] Vendor proprietary health report 32 R All ‘0’

_HEALTH_REPORT

[269] Device life time estimation type B DEVICE_LIFE_TIME_EST_TYP_B 1 R 0x00

[268] Device life time estimation type A DEVICE_LIFE_TIME_EST_TYP_A 1 R 0x01

[267] Pre EOL information PRE_EOL_INFO 1 R 0x01

[266] Optimal read size OPTIMAL_READ_SIZE 1 R 0x04

[265] Optimal write size OPTIMAL_WRITE_SIZE 1 R 0x04

[264] Optimal trim unit size OPTIMAL_TRIM_UNIT_SIZE 1 R 0x01

[263:262] Device version DEVICE_VERSION 2 R 0x00

[261:254] Firmware version FIRMWARE_VERSION 8 R 0x01

[253] Power class for 200MHz, DDR at VCC=3.6V PWR_CL_DDR_200_360 1 R 0xAA

[252:249] Cache size CACHE_SIZE 4 R 0x00001000

[248] Generic CMD6 timeout GENERIC_CMD6_TIME 1 R 0x05

[247] Power off notification(long) timeout POWER_OFF_LONG_TIME 1 R 0x32

[246] Background operations status BKOPS_STATUS 1 R 0x00

CORRECTLY

[245:242] Number of correctly programmed sectors 4 R 0x00000000

_PRG_SECTORS_NUM

[241] 1st initialization time after partitioning INI_TIMEOUT_AP 1 R 0x1E

8 Dec. 1st, 2015

THGBMDG5D1LBAIL

Size Cell

CSD-slice Name Field Value

(Bytes) Type

[240] Cache Flushing Policy CACHE_FLUSH_POLICY 1 R 0x00

[239] Power class for 52MHz, DDR @ 3.6V PWR_CL_DDR_52_360 1 R 0x22

[238] Power class for 52MHz, DDR @ 1.95V PWR_CL_DDR_52_195 1 R 0x77

Power class for 200MHz,

[237] PWR_CL_200_195 1 R 0x88

@ VCCQ =1.95V, VCC = 3.6V

Power class for 200MHz,

[236] PWR_CL_200_130 1 R 0x88

@ VCCQ=1.3V, VCC = 3.6V

Minimum Write Performance for 8bit

[235] MIN_PERF_DDR_W_8_52 1 R 0x00

@ 52MHz in DDR mode

Minimum Read Performance for 8bit

[234] MIN_PERF_DDR_R_8_52 1 R 0x50

@ 52MHz in DDR mode

[233] Reserved - 1 - 0x00

[232] TRIM Multiplier TRIM_MULT 1 R 0x01

[231] Secure Feature support SEC_FEATURE_SUPPORT 1 R 0x55

[230] Secure Erase Multiplier SEC_ERASE_MULT 1 R 0XDC

[229] Secure TRIM Multiplier SEC_TRIM_MULT 1 R 0xFF

[228] Boot information BOOT_INFO 1 R 0x07

[227] Reserved - 1 R 0x00

[226] Boot partition size BOOT_SIZE_MULTI 1 R 0x10

[225] Access size ACC_SIZE 1 R 0x08

[224] High-capacity erase unit size HC_ERASE_GRP_SIZE 1 R 0x08

[223] High-capacity erase timeout ERASE_TIMEOUT_MULT 1 R 0x07

[222] Reliable write sector count REL_WR_SEC_C 1 R 0x01

[221] High-capacity write protect group size HC_WP_GRP_SIZE 1 R 0x01

[220] Sleep current (Vcc) S_C_VCC 1 R 0x06

[219] Sleep current (VccQ) S_C_VCCQ 1 R 0x0A

PRODUCTION_STATE 0x0A

[218] Production state awareness timeout 1 R

_AWARENESS_TIMEOUT

[217] Sleep/awake timeout S_A_TIMEOUT 1 R 0x10

[216] Sleep Notification Timeout SLEEP_NOTIFICATION_TIME 1 R 0x10

[215:212] Sector Count SEC_COUNT 4 R 0x00760000

[211] Secure Write Protection Information SECURE_WP_INFO 1 R 0x00

Minimum Write Performance for 8bit

[210] MIN_PERF_W_8_52 1 R 0x00

@ 52MHz

Minimum Read Performance 8bit

[209] MIN_PERF_R_8_52 1 R 0x64

@ 52MHz

Minimum Write Performance for 8bit R

[208] MIN_PERF_W_8_26_4_52 1 0x00

@ 26MHz, for 4bit at 52MHz

Minimum Read Performance for 8 bit

[207] MIN_PERF_R_8_26_4_52 1 R 0x3C

@ 26MHz, for 4bit at 52MHz

Minimum Write Performance for 4bit

[206] MIN_PERF_W_4_26 1 R 0x00

@ 26MHz

Minimum Read Performance for 4bit

[205] MIN_PERF_R_4_26 1 R 0x1E

@ 26MHz

9 Dec. 1st, 2015

THGBMDG5D1LBAIL

Size Cell

CSD-slice Name Field Value

(Bytes) Type

[204] Reserved - 1 - 0x00

[203] Power class for 26MHz @ 3.6V PWR_CL_26_360 1 R 0x22

[202] Power class for 52MHz @ 3.6V PWR_CL_52_360 1 R 0x22

[201] Power class for 26MHz @ 1.95V PWR_CL_26_195 1 R 0x66

[200] Power class for 52MHz @ 1.95V PWR_CL_52_195 1 R 0x66

[199] Partition switching timing PARTITION_SWITCH_TIME 1 R 0x01

[198] Out-of-interrupt busy timing OUT_OF_INTERRUPT_TIME 1 R 0x0A

[197] I/O Driver Strength DRIVER_STRENGTH 1 R 0x1F

[196] Device Type DEVICE_TYPE 1 R 0x57

[195] Reserved - 1 - 0x00

[194] CSD structure CSD_STRUCTURE 1 R 0x02

[193] Reserved - 1 - 0x00

[192] Extended CSD revision EXT_CSD_REV 1 R 0x07

[191] Command Set CMD_SET 1 R/W/E_P 0x00

[190] Reserved - 1 - 0x00

[189] Command set revision CMD_SET_REV 1 R 0x00

[188] Reserved - 1 - 0x00

1

[187] Power class POWER_CLASS 1 R/W/E_P 0x00

[186] Reserved - 1 - 0x00

[185] High-speed interface timing HS_TIMING 1 R/W/E_P 0x00

[184] Strobe Support STROBE_SUPPORT 1 R 0x00

[183] Bus width mode BUS_WIDTH 1 W/E_P 0x00

[182] Reserved - 1 - 0x00

[181] Erased memory content ERASED_MEM_CONT 1 R 0x00

[180] Reserved - 1 - 0x00

R/W/E &

[179] Partition configuration PARTITION_CONFIG 1 0x00

R/W/E_P

R/W &

[178] Boot config protection BOOT_CONFIG_PROT 1 R/W/C_ 0x00

P

[177] Boot bus Conditions BOOT_BUS_CONDITIONS 1 R/W/E 0x00

[176] Reserved - 1 - 0x00

[175] High-density erase group definition ERASE_GROUP_DEF 1 R/W/E_P 0x00

[174] Boot write protection status registers BOOT_WP_STATUS 1 R 0x00

R/W &

[173] Boot area write protection register BOOT_WP 1 R/W/C_ 0x00

P

[172] Reserved - 1 - 0x00

R/W,

R/W/C_

[171] User area write protection register USER_WP 1 0x00

P&

R/W/E_P

[170] Reserved - 1 - 0x00

[169] FW configuration FW_CONFIG 1 R/W 0x00

10 Dec. 1st, 2015

THGBMDG5D1LBAIL

Size Cell

CSD-slice Name Field Value

(Bytes) Type

[168] RPMB Size RPMB_SIZE_MULT 1 R 0x04

[167] Write reliability setting register WR_REL_SET 1 R/W 0x1F

[166] Write reliability parameter register WR_REL_PARAM 1 R 0x05

[165] Start Sanitize operation SANITIZE_START 1 W/E_P 0x00

[164] Manually start background operations BKOPS_START 1 W/E_P 0x00

R/W

[163] Enable background operations handshake BKOPS_EN 1 & 0x00

R/W/E

[162] H/W reset function RST_n_FUNCTION 1 R/W 0x00

[161] HPI management HPI_MGMT 1 R/W/E_P 0x00

[160] Partitioning Support PARTITIONING_SUPPORT 1 R 0x07

[159:157] Max Enhanced Area Size 2 MAX_ENH_SIZE_MULT 3 R 0x0001D8

[156] Partitions attribute PARTITIONS_ATTRIBUTE 1 R/W 0x00

PARTITION_SETTING_COMPLET

[155] Partitioning Setting 1 R/W 0x00

ED

[154:143] General Purpose Partition Size 3 GP_SIZE_MULT 12 R/W 0x00

[142:140] Enhanced User Data Area Size 4 ENH_SIZE_MULT 3 R/W 0x00

[139:136] Enhanced User Data Start Address ENH_START_ADDR 4 R/W 0x00

[135] Reserved - 1 - 0x00

[134] Bad Block Management mode SEC_BAD_BLK_MGMNT 1 R/W 0x00

PRODUCTION_STATE

[133] Production state awareness5 1 R/W/E 0x00

_AWARENESS

[132] Package Case Temperature is controlled1 TCASE_SUPPORT 1 W/E_P 0x00

[131] Periodic Wake-up1 PERIODIC_WAKEUP 1 R/W/E 0x00

PROGRAM_CID_CSD_DDR_SUP

[130] Program CID/CSD in DDR mode support 1 R 0x01

PORT

[129:128] Reserved - 2 - All ‘0’

[127:64] Vendor Specific Fields VENDOR_SPECIFIC_FIELD 64 - -

[63] Native sector size NATIVE_SECTOR_SIZE 1 R 0x01

[62] Sector size emulation USE_NATIVE_SECTOR 1 R/W 0x00

[61] Sector size DATA_SECTOR_SIZE 1 R 0x00

1st initialization

[60] after disabling sector size emulation INI_TIMEOUT_EMU 1 R 0x0A

[59] Class 6 commands control CLASS_6_CTRL 1 R/W/E_P 0x00

[58] Number of addressed group to be Released DYNCAP_NEEDED 1 R 0x00

[57:56] Exception events control EXCEPTION_EVENTS_CTRL 2 R/W/E_P 0x0000

[55:54] Exception events status EXCEPTION_EVENTS_STATUS 2 R 0x0000

[53:52] Extended partitions attribute1 EXT_PARTITIONS_ATTRIBUTE 2 R/W 0x0000

[51:37] Context configuration CONTEXT_CONF 15 R/W/E_P 0x00

[36] Packed command status PACKED_COMMAND_STATUS 1 R 0x00

[35] Packed command failure index PACKED_FAILURE_INDEX 1 R 0x00

5

[34] Power Off Notification POWER_OFF_NOTIFICATION 1 R/W/E_P 0x00

[33] Control to turn the Cache ON/OFF CACHE_CTRL 1 R/W/E_P 0x00

11 Dec. 1st, 2015

THGBMDG5D1LBAIL

Size Cell

CSD-slice Name Field Value

(Bytes) Type

[32] Flushing of the cache FLUSH_CACHE 1 W/E_P 0x00

[31] Control to turn the Barrier ON/OFF BARRIER_CTRL 1 R/W 0x00

[30] Mode config MODE_CONFIG 1 R/W/E_P 0x00

[29] Mode operation codes MODE_OPERATION_CODES 1 W/E_P 0x00

[28:27] Reserved - 2 - All ‘0’

[26] FFU status FFU_STATUS 1 R 0x00

6

[25:22] Pre loading data size PRE_LOADING_DATA_SIZE 4 R/W/E_P 0x00760000

MAX_PRE_LOADING_DATA

[21:18] Max pre loading data size 4 R 0x00760000

_SIZE

PRODUCT_STATE R/W/E

[17] Product state awareness enablement5 1 0x03

_AWARENESS_ENABLEMENT &R

[16] Secure Removal Type SECURE_REMOVAL_TYPE 1 R/W & R 0x09

[15] Command Queue Mode Enable CMDQ_MODE_EN 1 R/W/E_P 0x00

[14:0] Reserved - 15 - All ‘0’

1 Although these fields can be re-written by host, TOSHIBA e-MMC does not support.

2 Max Enhanced Area Size (MAX_ENH_SIZE_MULT [159:157]) has to be calculated by following formula.

Max Enhanced Area = MAX_ENH_SIZE_MULT x HC_WP_GRP_SIZE x HC_ERASE_GRP_SIZE x 512kBytes

4

∑ Enhanced general partition size(i) + Enhanced user data area ≤ Max enhanced area

i=1

3 General Purpose Partition Size (GP_SIZE_MULT_GP0 - GP_SIZE_MULT_GP3 [154:143]) has to be calculated

by following formula.

General_Purpose_Partition_X Size = (GP_SIZE_MULT_X_2 x 216 + GP_SIZE_MULT_X_1 x 28

+ GP_SIZE_MULT_X_0 x 20 ) x HC_WP_GRP_SIZE

x HC_ERASE_GRP_SIZE x 512kBytes

4 Enhanced User Data Area Size (ENH_SIZE_MULT [142:140]) has to be calculated by following formula.

Enhanced User Data Area x Size = (ENH_SIZE_MULT_2 x 216 + ENH_SIZE_MULT_1 x 28

+ ENH_SIZE_MULT_0 x 20 ) x HC_WP_GRP_SIZE

x HC_ERASE_GRP_SIZE x 512kBytes

5 Toshiba recommends to issue the Power Off Notification before turning off the device, especially when cache is

on or AUTO_EN(BKOPS_EN[163]:bit1) is set to ‘1b’.

12 Dec. 1st, 2015

THGBMDG5D1LBAIL

6 - Pre loading data size = PRE_LOADING_DATA_SIZE x Sector Size

Pre-loading data size should be multiple of 4KB and the pre-loading data should be written by multiple of 4KB

chunk size, aligned with 4KB address. This is because the valid data size will be treated as 4KB when host

writes data less than 4KB.

- If the host continues to write data in Normal state (after it wrote PRE_LOADING_DATA_SIZE amount

of data) and before soldering, the pre-loading data might be corrupted after soldering.

- If a power cycle is occurred during the data transfer, the amount of data written to device is not clear.

Therefore in this case, host should erase the entire pre-loaded data and set again

PRE_LOADING_DATA_SIZE[25:22], PRODUCTION_STATE_AWARENESS[133], and

PRODUCT_STATE_AWARENESS_ENABLEMENT[17].

13 Dec. 1st, 2015

THGBMDG5D1LBAIL

ELECTRICAL CHARACTERISTICS

DC Characteristics

Absolute Maximum Ratings

The absolute maximum ratings of a semiconductor device are a set of specified parameter values, which must

not be exceeded during operation, even for an instant.

If any of these rating would be exceeded during operation, the device electrical characteristics may be irreparably

altered and the reliability and lifetime of the device can no longer be guaranteed. Moreover, these operations with

exceeded ratings may cause break down, damage, and/or degradation to any other equipment. Applications using

the device should be designed such that each maximum rating will never be exceeded in any operating conditions.

Before using, creating, and/or producing designs, refer to and comply with the precautions and conditions set forth

in this document.

Parameter Symbol Test Conditions Min Max Unit

Supply voltage 1 VCC -0.5 4.1 V

Supply voltage 2 VCCQ -0.5 4.1 V

Voltage Input VIO -0.5 VCCQ+0.5(≤4.1) V

General

Parameter Symbol Test Conditions Min Max Unit

Peak voltage on all lines -0.5 VCCQ+0.5 V

All Inputs

Input Leakage Current (before initialization sequence1

-100 100 μA

and/or the internal pull up resistors connected)

Input Leakage Current (after initialization sequence and

-2 2 μA

the internal pull up resistors disconnected)

All Outputs

Output Leakage Current (before initialization sequence) -100 100 μA

Output Leakage Current (after initialization sequence) -2 2 μA

1) Initialization sequence is defined in Power-Up chapter of JEDEC/MMCA Standard

Power Supply Voltage

Parameter Symbol Test Conditions Min Max Unit

Supply voltage 1 VCC 2.7 3.6 V

1.7 1.95 V

Supply voltage 2 VCCQ

2.7 3.6 V

1) Once the power supply VCC or VCCQ falls below the minimum guaranteed voltage (for example, upon sudden power fail),

the voltage level of VCC or VCCQ shall be kept less than 0.5 V for at least 1ms before it goes beyond 0.5 V again.

14 Dec. 1st, 2015

THGBMDG5D1LBAIL

Supply Current

Interleave Frequency Min Max

Parameter Symbol VccQ Unit

Operation /Mode Iccq Icc Iccq Icc

1.8V 60 10

52MHz/SDR mA

3.3V 70 15

1.8V 70 20

Read IROP Non Interleave 52MHz/DDR mA

3.3V 85 20

HS200 1.8V 90 30 mA

Operation HS400 1.8V 100 30 mA

(RMS) 1.8V 50 25

52MHz/SDR mA

3.3V 55 25

1.8V 50 30

Write IWOP Non Interleave 52MHz/DDR mA

3.3V 55 30

HS200 1.8V 55 30 mA

HS400 1.8V 60 30 mA

15 Dec. 1st, 2015

THGBMDG5D1LBAIL

Internal resistance and Device capacitance

Parameter Symbol Test Conditions Min Max Unit

Single device capacitance CDEVICE 6 pF

Internal pull up resistance DAT1 – DAT7 RINT 10 150 kΩ

Bus Signal Levels

Open-Drain Mode Bus Signal Level

Parameter Symbol Min Max Unit Conditions

Output HIGH voltage VOH VCCQ - 0.2 V NOTE 1

Output LOW voltage VOL 0.3 V IOL = 2 mA

NOTE 1: Because VOH depends on external resistance value (including outside the package), this value does not apply as device

specification. Host is responsible to choose the external pull-up and open drain resistance value to meet VOH Min value.

Push-Pull Mode Bus Signal Level (High-Voltage)

Parameter Symbol Min Max Unit Conditions

Output HIGH voltage VOH 0.75 * VCCQ V IOH = -100 μA @ VCCQ min

Output LOW voltage VOL 0.125 * VCCQ V IOL = 100 μA @ VCCQ min

Input HIGH voltage VIH 0.625 * VCCQ VCCQ + 0.3 V

Input LOW voltage VIL VSS - 0.3 0.25 * VCCQ V

Push-Pull Mode Bus Signal Level (Dual-Voltage)

Parameter Symbol Min Max Unit Conditions

Output HIGH voltage VOH VCCQ - 0.45 V IOH = -2mA

Output LOW voltage VOL 0.45 V IOL = 2mA

Input HIGH voltage VIH 0.65 * VCCQ VCCQ + 0.3 V

Input LOW voltage VIL VSS - 0.3 0.35 * VCCQ V

16 Dec. 1st, 2015

THGBMDG5D1LBAIL

Driver Types Definition

In JEDEC, Driver Type-0 is defined as mandatory for e-MMC HS200&HS400 Device. While four additional Driver

Types (1, 2, 3 and 4) are defined as optional, to allow the support of wider Host loads. The Host may select the most

appropriate Driver Type of the Device (if supported) to achieve optimal signal integrity performance.

Driver Type-0 is targeted for transmission line, based distributed system with 50Ω nominal line impedance.

Therefore, it is defined as 50Ω nominal driver. The nominal line impedance should be kept as 50Ω even if Driver Type

would be changed.

For HS200, when tested with CL = 15pF Driver Type-0 shall meet all AC characteristics and HS200 Device output

timing requirements. The test circuit defined in section 10.5.4.3 of JEDEC/MMCA Standard 5.0 is used for testing of

Driver Type-0.

For HS400, when tested with the reference load defined in page 28 HS400 reference load figure, Driver Type-0 or

Driver Type-1 or Driver Type-4 shall meet all AC characteristics and HS400 Device output timing requirements.

Driver TOSHIBA Nominal Impedance Approximated driving capability

Remark

Type e-MMC (Driver strength) compared to Type-0

0 Supported 50 Ω (18mA) x1 Default Driver Type

Recommendation at HS400 under the

1 Supported 33 Ω (27mA) x1.5 condition of JEDEC standard

reference load.

2 Supported 66 Ω (14mA) x0.75

3 Supported 100 Ω (9mA) x0.5

Recommendation at HS400 under the

4 Supported 40 Ω (23mA) X1.2 condition of JEDEC standard

reference load.

1) Nominal impedance is defined by I-V characteristics of output driver at 0.9V when VCCQ = 1.8V.

*The most suitable setting for user’s operating environment should be selected.

At HS400, Toshiba recommends Driver Type-1 and Type-4. This is because they meet all AC characteristics and

Device output timing requirements under the condition of JEDEC standard reference load.

17 Dec. 1st, 2015

THGBMDG5D1LBAIL

Bus Timing

Device Interface Timings (High-speed interface timing)

Parameter Symbol Min Max Unit Remark

Clock CLK(1)

CL ≤ 30pF

Clock frequency Data Transfer Mode (PP)(2) fpp 0 52(3) MHz

Tolerance: +100kHz

Clock frequency Identification Mode (OD) fOD 0 400 kHz Tolerance: +20kHz

Clock high time tWH 6.5 ns CL ≤ 30pF

Clock low time tWL 6.5 ns CL ≤ 30pF

Clock rise time(4) tTLH 3 ns CL ≤ 30pF

Clock fall time tTHL 3 ns CL ≤ 30pF

Inputs CMD, DAT (referenced to CLK)

Input set-up time tISU 3 ns CL ≤ 30pF

Input hold time tIH 3 ns CL ≤ 30pF

Outputs CMD, DAT (referenced to CLK)

Output Delay time during Data Transfer tODLY 13.7 ns CL ≤ 30pF

Output hold time tOH 2.5 ns CL ≤ 30pF

Signal rise time (5)

trise 3 ns CL ≤ 30pF

Signal fall time tfall 3 ns CL ≤ 30pF

1) CLK timing is measured at 50% of VCCQ

2) This product shall support the full frequency range from 0 MHz - 26 MHz, or 0 MHz - 52 MHz

3) Device can operate as high-speed interface timing at 26MHz clock frequency.

4) CLK rise and fall times are measured by min (VIH) and max (VIL).

5) Inputs CMD, DAT rise and fall times area measured by min (VIH) and max (VIL), and outputs CMD, DAT rise and fall times

are measured by min (VOH) and max (VOL).

18 Dec. 1st, 2015

THGBMDG5D1LBAIL

Device Interface Timings (Backward-compatible interface timing)

Parameter Symbol Min Max Unit Remark(1)

Clock CLK(2)

Clock frequency Data Transfer Mode (PP)(3) fpp 0 26 MHz CL ≤ 30pF

Clock frequency Identification Mode (OD) fOD 0 400 kHz

Clock high time tWH 10 ns CL ≤ 30pF

Clock low time tWL 10 ns CL ≤ 30pF

Clock rise time(4) tTLH 10 ns CL ≤ 30pF

Clock fall time tTHL 10 ns CL ≤ 30pF

Inputs CMD,DAT (referenced to CLK)

Input set-up time tISU 3 ns CL ≤ 30pF

Input hold time tIH 3 ns CL ≤ 30pF

Outputs CMD,DAT (referenced to CLK)

Output set-up time(5) tOSU 11.7 ns CL ≤ 30pF

Output hold time(5) tOH 8.3 ns CL ≤ 30pF

1) The e-MMC must always start with the backward-compatible interface timing. The timing mode can be switched to

high-speed interface timing by the host sending the SWITCH command (CMD6) with the argument for high-speed

interface select.

2) CLK timing is measured at 50% of VCCQ

3) For compatibility with e-MMCs that support the v4.2 standard or earlier, host should not use >26MHz before switching to

high-speed interface timing.

4) CLK rise and fall times are measured by min (VIH) and max (VIL).

5) tOSU and tOH are defined as values from clock rising edge. However, the e-MMC device will utilize clock falling edge to

output data in backward compatibility mode. Therefore, it is recommended for hosts either to set tWL value as long as

possible within the range which will not go over tCK - tOHmin) in the system or to use slow clock frequency, so that host

could have data set up margin for the device.

Toshiba e-MMC device utilize clock falling edge to output data in backward compatibility mode.

Host should optimize the timing in order to have data set up margin as follows.

tWL

CLK

tODLY tOSU tOH

Output Invalid Data

tOSU (min) = tWL(min) - tODLY(max 8ns)

Figure 2 Output timing

19 Dec. 1st, 2015

THGBMDG5D1LBAIL

Bus Timing for DAT signals for during 2x data rate operation

These timings applies to the DAT[7:0] signals only when the device is configured for dual data mode operation. In

this dual data mode, the DAT signals operates synchronously of both the rising and the falling edges of CLK. The

CMD signal still operates synchronously of the rising edge of CLK and therefore complies with the bus timing

specified in High-speed interface timing or Backward-compatible interface timing.

High-speed dual data rate interface timings

Parameter Symbol Min Max Unit Remark

Input CLK (1)

Clock duty cycle 45 55 % Includes jitter, phase noise

Clock rise time tTLH 3 ns CL ≤ 30pF

Clock fall time tTHL 3 ns CL ≤ 30pF

Input CMD(referenced to CLK-SDR mode)

Input set-up time tISUddr 3 ns CL ≤ 20pF

Input hold time tIHddr 3 ns CL ≤ 20pF

Output CMD(referenced to CLK-SDR mode)

Output delay time during data transfer tODLY 13.7 ns CL ≤ 20pF

Output hold time tOH 2.5 ns CL ≤ 20pF

Signal rise time tRISE 3 ns CL ≤ 20pF

Signal fall time tFALL 3 ns CL ≤ 20pF

20 Dec. 1st, 2015

THGBMDG5D1LBAIL

Parameter Symbol Min Max Unit Remark

Input DAT (referenced to CLK-DDR mode)

Input set-up time tISUddr 2.5 ns CL ≤ 20pF

Input hold time tIHddr 2.5 ns CL ≤ 20pF

Output DAT (referenced to CLK-DDR mode)

Output delay time during data transfer tODLYddr 1.5 7 ns CL ≤ 20pF

Signal rise time (all signals) (2) tRISE 2 ns CL ≤ 20pF

Signal fall time (all signals) tFALL 2 ns CL ≤ 20pF

1) CLK timing is measured at 50% of VCCQ.

2) Inputs DAT rise and fall times are measured by min (VIH) and max (VIL), and outputs DAT rise and fall times are measured

by min (VOH) and max (VOL).

21 Dec. 1st, 2015

THGBMDG5D1LBAIL

Bus Timing Specification in HS200 mode

HS200 Clock Timing

Host CLK Timing in HS200 mode shall conform to the timing specified in following figure and Table. CLK input shall

satisfy the clock timing over all possible operation and environment conditions. CLK input parameters should be

measured while CMD and DAT lines are stable high or low, as close as possible to the Device. The maximum

frequency of HS200 is 200MHz. Hosts can use any frequency up to the maximum that HS200 mode allows.

tPERIOD

VCCQ

VIH

CLOCK

VT

INPUT

VIL

VSS tTLH tTHL

NOTE 1 VIH denote VIH(min.) and VIL denotes VIL(max.).

NOTE 2 VT = 50% of VCCQ, indicates clock reference point for timing measurements.

Symbol Min Max Unit Remark

tPERIOD 5 ns 200MHz (Max.), between rising edges

tTLH, tTHL < 1ns (max.) at 200MHz, CDEVICE=6pF,

tTLH, tTHL 0.2 * tPERIOD ns The absolute maximum value of tTLH, tTHL is 10ns regardless of

clock frequency.

Duty Cycle 30 70 %

HS200 Device Input Timing

tPERIOD

VCCQ

CLOCK

VT

INPUT

VSS

VCCQ tISU tIH

VIH VIH

CMD.DAT[7-0] VALID

INPUT WINDOW

VIL VIL

VSS

NOTE 1 tISU and tIH are measured at VIL(max) and VIH(min).

NOTE 2 VIH denote VIH(min) and VIL denotes VIL(max).

Symbol Min Max Unit Remark

tISU 1.40 ns CDEVICE ≤ 6pF

tIH 0.8 ns CDEVICE ≤ 6pF

22 Dec. 1st, 2015

THGBMDG5D1LBAIL

HS200 Device Output Timing

tPH parameter is defined to allow device output delay to be longer than tPERIOD. After initialization, the tPH may have

random phase relation to the clock. The Host is responsible to find the optimal sampling point for the Device outputs,

while switching to the HS200 mode.

While setting the sampling point of data, a long term drift, which mainly depends on temperature drift, should be

considered. The temperature drift is expressed by ΔTPH. Output valid data window (tVW) is available regardless of the

drift (ΔTPH) but position of data window varies by the drift.

tPERIOD

VCCQ

CLOCK

VT

INPUT

VSS

tPH tVW VCCQ

VOH VOH

CMD.DAT[7-0] VALID

OUTPUT WINDOW

VOL VOL

VSS

NOTE VOH denotes VOH(min) and VOL denotes VOL(max).

Symbol Min Max Unit Remark 1

Device output momentary phase from CLK input to CMD

tPH 0 2 UI or DAT lines output.

Does not include a long term temperature drift.

Delay variation due to temperature change after tuning.

-350 +1550 Total allowable shift of output valid window (TVW ) from last

ΔTPH ps system Tuning procedure

(ΔT = -20 °C) (ΔT = 90 °C ) ΔTPH is 2600ps for ΔT from -25 °C to 125 °C during

operation.

tVW =2.88ns at 200MHz

Using test circuit in following figure including skew

tVW 0.575 UI among CMD and DAT lines created by the Device.

Host path may add Signal Integrity induced noise, skews,

etc. Expected tVW at Host input is larger than 0.475UI.

NOTE Unit Interval (UI) is one bit nominal time. For example, UI=5ns at 200 MHz.

23 Dec. 1st, 2015

THGBMDG5D1LBAIL

ΔTPH consideration

Implementation Guide:

Host should design to avoid sampling errors that may be caused by the ΔTPH drift.

It is recommended to perform tuning procedure while Device wakes up, after sleep.

One simple way to overcome the ΔTPH drift is by reduction of operating frequency.

24 Dec. 1st, 2015

THGBMDG5D1LBAIL

Bus Timing Specification in HS400 mode

HS400 Input Timing

The CMD input timing for HS400 mode is the same as CMD input timing for HS200 mode.

NOTE VT = 50% of VCCQ, indicates clock reference point for timing measurements.

Parameter Symbol Min Max Unit Remark

Input CLK

Cycle time data transfer tPERIOD 5 ns 200 MHz(Max), between rising edges

mode With respect to VT

Slew rate SR 1.125 V/ns With respect to VIH /VIL

Duty cycle distortion tCKDCD 0.0 0.3 ns Allowable deviation from an ideal 50% duty cycle.

With respect to VT

Includes jitter, phase noise

Minimum pulse width tCKMPW 2.2 ns With respect to VT

Input DAT(referenced to CLK)

Input set-up time tISUddr 0.4 ns CDEVICE ≤ 6 pF

With respect to VIH /VIL

Input hold time tIHddr 0.4 ns CDEVICE ≤ 6 pF

With respect to VIH /VIL

Slew rate SR 1.125 V/ns With respect to VIH /VIL

25 Dec. 1st, 2015

THGBMDG5D1LBAIL

HS400 Device Output Timing

The Data Strobe is used to read data in HS400 mode. The Data Strobe is toggled only during data read or CRC status response.

NOTE VT = 50% of VCCQ, indicates clock reference point for timing measurements.

Parameter Symbol Min Max Unit Remark

Data Strobe

Cycle time data transfer tPERIOD 5 ns 200 MHz(Max), between rising edges

mode With respect to VT

Slew rate SR 1.125 V/ns With respect to VOH/VOL and HS400 reference load

Duty cycle distortion tDSDCD 0.0 0.2 ns Allowable deviation from the input CLK duty cycle

distortion(tCKDCD)

With respect to VT

Includes jitter, phase noise

Minimum pulse width tDSMPW 2.0 ns With respect to VT

Output DAT(referenced to Data Strobe)

Output skew tRQ 0.4 ns With respect to VOH /VOL and HS400 reference load

Output hold skew tRQH 0.4 ns With respect to VOH /VOL and HS400 reference load

Slew rate SR 1.125 V/ns With respect to VOH /VOL and HS400 reference load

26 Dec. 1st, 2015

THGBMDG5D1LBAIL

HS400 Device Command Output Timing

The Data Strobe is used to response of any command in HS400 mode.

Note : VT = 50% of VCCQ, indicates clock reference point for timing measurements.

Parameter Symbol Min Max Unit Remark

Data Strobe

Cycle time data transfer tPERIOD 5 ns 200 MHz(Max), between rising edges

mode With respect to VT

Slew rate SR 1.125 V/ns With respect to VOH/VOL and HS400 reference load

Duty cycle distortion tDSDCD 0.0 0.2 ns Allowable deviation from the input CLK duty cycle

distortion(tCKDCD)

With respect to VT

Includes jitter, phase noise

Minimum pulse width tDSMPW 2.0 ns With respect to VT

CMD Response (referenced to Data Strobe)

Output skew(CMD) tRQ_CMD 0.4 ns With respect to VOH /VOL and HS400 reference load

Output hold skew(CMD) tRQH_CMD 0.4 ns With respect to VOH /VOL and HS400 reference load

Slew rate SR 1.125 V/ns With respect to VOH /VOL and HS400 reference load

27 Dec. 1st, 2015

THGBMDG5D1LBAIL

Driver

Device I/O Measurement Point

Z0 = 50 Ohm

Td = 350 ps

CREFERENCE = 4pF

Reference Load

Figure 3 HS400 reference load

HS400 Capacitance

The Data Strobe is used to read data in HS400 mode. The Data Strobe is toggled only during data read or CRC status response.

Parameter Symbol Min Typ. Max Unit Remark

(1)

Pull-up resistance for CMD RCMD 4.7 100 kΩ

Pull-up resistance for DAT0-7 RDAT 10 100 (1)

kΩ

Pull-down resistance for Data Strobe RDS 10 100 (1)

kΩ

Internal pull up resistance DAT1-DAT7 Rint 10 150 kΩ

Single Device capacitance CDevice 6 pF

NOTE 1 Recommended maximum value is 50 kΩ for 1.8 V interface supply voltages.

28 Dec. 1st, 2015

THGBMDG5D1LBAIL

Overshoot/Undershoot Specification

VCCQ Unit

1.70V - 1.95V

Maximum peak amplitude allowed for overshoot area. Max 0.9 V

(See Figure Overshoot/Undershoot definition)

Maximum peak amplitude allowed for undershoot area. Max 0.9 V

(See Figure Overshoot/Undershoot definition)

Maximum area above VCCQ Max 1.5 V-ns

(See Figure Overshoot/Undershoot definition)

Maximum area below VSSQ Max 1.5 V-ns

(See Figure Overshoot/Undershoot definition)

Figure 4 Overshoot/Undershoot definition

H/W Reset Operation

Note *1: Device will detect the rising edge of RST_n signal to trigger internal reset sequence

H/W Reset Timings

Symbol Parameter Min Max Unit

tRSTW RST_n pulse width 1 μs

tRSCA RST_n to Command time 200 (1)

μs

tRSTH RST_n high period (interval time) 1 μs

1) 74 cycles of clock signal required before issuing CMD1 or CMD0 with argument 0xFFFFFFFA

2) During the device internal initialization sequence right after power on, device may not be able to detect RST_n signal,

because the device may not complete loading RST_n_ENABLE bits of the extended CSD register into the controller yet.

29 Dec. 1st, 2015

THGBMDG5D1LBAIL

Power-up sequence

Supply voltage

Vcc max

Vcc min

VccQ max

VccQ min

0.5V

time

Vccq Power up time Vcc Power up time Vccq Power up time

tPRUL tPRUH tPRUL

Figure 3 Power up sequence

Power-up parameter

Parameter Symbol Min Max Remark

Supply power-up for 3.3V tPRUH 5 μs 35 ms

Supply power-up for 1.8V tPRUL 5 μs 25 ms

30 Dec. 1st, 2015

THGBMDG5D1LBAIL

Functional restrictions

- Pre loading data size is limited to MAX_PRE_LOADING_DATA_SIZE[21-18] regardless of using Production

State Awareness function.

- MAX_PRE_LOADING_DATA_SIZE[21-18] value will change when host sets Enhanced User area Partition.

Reliability Guidance

This reliability guidance is intended to notify some guidance related to using raw NAND flash. Although random

bit errors may occur during use, it does not necessarily mean that a block is bad. Generally, a block should be

marked as bad when a program status failure or erase status failure is detected. The other failure modes may be

recovered by a block erase. ECC treatment for read data is mandatory due to the following Data Retention and

Read Disturb failures.

-Write/Erase Endurance

Write/Erase endurance failures may occur in a cell, page, or block, and are detected by doing a status read after

either an auto program or auto block erase operation. The cumulative bad block count will increase along with the

number of write/erase cycles.

-Data Retention

The data in memory may change after a certain amount of storage time. This is due to charge loss or charge gain.

After block erasure and reprogramming, the block may become usable again. Also write/erase endurance

deteriorates data retention capability. The figure below shows a generic trend of relationship between write/erase

endurance and data retention.

-Read Disturb

A read operation may disturb the data in memory. The data may change due to charge gain. Usually, bit errors

occur on other pages in the block, not the page being read. After a large number of read cycles (between block

erases), a tiny charge may build up and can cause a cell to be soft programmed to another state. After block erasure

and reprogramming, the block may become usable again.

Considering the above failure modes, TOSHIBA recommends following usage:

- Please avoid any excessive iteration of resets and initialization sequences (Device identification mode) as far as

possible after power-on, which may result in read disturb failure. The resets include hardware resets and software

resets.

e.g.1) Iteration of the following command sequence, CMD0 - CMD1 ---

The assertion of CMD1 implies a count of internal read operation in Raw NAND.

CMD0: Reset command, CMD1: Send operation command

e.g.2) Iteration of the following commands, CMD30 and/or CMD31

CMD30: Send status of write protection bits, CMD31: Send type of write protection

31 Dec. 1st, 2015

THGBMDG5D1LBAIL

Document Revision History

Rev0.1 Sep. 30th, 2015 - Released as preliminary revision

Rev0.2 Oct. 19th, 2015 - Added register values

Rev1.0 Dec. 1st, 2015 - Fixed values of Performance.

- Fixed values of Operating Current and Sleep Mode Current.

- Fixed values of Extended-CSD value.

- Released as final revision.

32 Dec. 1st, 2015

THGBMDG5D1LBAIL

RESTRICTIONS ON PRODUCT USE

• Toshiba Corporation, and its subsidiaries and affiliates (collectively "TOSHIBA"), reserve the right to make changes to the information

in this document, and related hardware, software and systems (collectively "Product") without notice.

• This document and any information herein may not be reproduced without prior written permission from TOSHIBA. Even with

TOSHIBA's written permission, reproduction is permissible only if reproduction is without alteration/omission.

• Though TOSHIBA works continually to improve Product's quality and reliability, Product can malfunction or fail. Customers are

responsible for complying with safety standards and for providing adequate designs and safeguards for their hardware, software and

systems which minimize risk and avoid situations in which a malfunction or failure of Product could cause loss of human life, bodily

injury or damage to property, including data loss or corruption. Before customers use the Product, create designs including the

Product, or incorporate the Product into their own applications, customers must also refer to and comply with (a) the latest versions of

all relevant TOSHIBA information, including without limitation, this document, the specifications, the data sheets and application notes

for Product and the precautions and conditions set forth in the "TOSHIBA Semiconductor Reliability Handbook" and (b) the

instructions for the application with which the Product will be used with or for. Customers are solely responsible for all aspects of their

own product design or applications, including but not limited to (a) determining the appropriateness of the use of this Product in such

design or applications; (b) evaluating and determining the applicability of any information contained in this document, or in charts,

diagrams, programs, algorithms, sample application circuits, or any other referenced documents; and (c) validating all operating

parameters for such designs and applications. TOSHIBA ASSUMES NO LIABILITY FOR CUSTOMERS' PRODUCT DESIGN OR

APPLICATIONS.

• PRODUCT IS NEITHER INTENDED NOR WARRANTED FOR USE IN EQUIPMENTS OR SYSTEMS THAT REQUIRE

EXTRAORDINARILY HIGH LEVELS OF QUALITY AND/OR RELIABILITY, AND/OR A MALFUNCTION OR FAILURE OF WHICH

MAY CAUSE LOSS OF HUMAN LIFE, BODILY INJURY, SERIOUS PROPERTY DAMAGE AND/OR SERIOUS PUBLIC IMPACT

("UNINTENDED USE"). Except for specific applications as expressly stated in this document, Unintended Use includes, without

limitation, equipment used in nuclear facilities, equipment used in the aerospace industry, medical equipment, equipment used for

automobiles, trains, ships and other transportation, traffic signaling equipment, equipment used to control combustions or explosions,

safety devices, elevators and escalators, devices related to electric power, and equipment used in finance-related fields. IF YOU USE

PRODUCT FOR UNINTENDED USE, TOSHIBA ASSUMES NO LIABILITY FOR PRODUCT. For details, please contact your

TOSHIBA sales representative.

• Do not disassemble, analyze, reverse-engineer, alter, modify, translate or copy Product, whether in whole or in part.

• Product shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any

applicable laws or regulations.

• The information contained herein is presented only as guidance for Product use. No responsibility is assumed by TOSHIBA for any

infringement of patents or any other intellectual property rights of third parties that may result from the use of Product. No license to

any intellectual property right is granted by this document, whether express or implied, by estoppel or otherwise.

• ABSENT A WRITTEN SIGNED AGREEMENT, EXCEPT AS PROVIDED IN THE RELEVANT TERMS AND CONDITIONS OF SALE

FOR PRODUCT, AND TO THE MAXIMUM EXTENT ALLOWABLE BY LAW, TOSHIBA (1) ASSUMES NO LIABILITY

WHATSOEVER, INCLUDING WITHOUT LIMITATION, INDIRECT, CONSEQUENTIAL, SPECIAL, OR INCIDENTAL DAMAGES OR

LOSS, INCLUDING WITHOUT LIMITATION, LOSS OF PROFITS, LOSS OF OPPORTUNITIES, BUSINESS INTERRUPTION AND

LOSS OF DATA, AND (2) DISCLAIMS ANY AND ALL EXPRESS OR IMPLIED WARRANTIES AND CONDITIONS RELATED TO

SALE, USE OF PRODUCT, OR INFORMATION, INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, ACCURACY OF INFORMATION, OR NONINFRINGEMENT.

• Do not use or otherwise make available Product or related software or technology for any military purposes, including without

limitation, for the design, development, use, stockpiling or manufacturing of nuclear, chemical, or biological weapons or missile

technology products (mass destruction weapons). Product and related software and technology may be controlled under the

applicable export laws and regulations including, without limitation, the Japanese Foreign Exchange and Foreign Trade Law and the

U.S. Export Administration Regulations. Export and re-export of Product or related software or technology are strictly prohibited

except in compliance with all applicable export laws and regulations.

• Please contact your TOSHIBA sales representative for details as to environmental matters such as the RoHS compatibility of

Product. Please use Product in compliance with all applicable laws and regulations that regulate the inclusion or use of controlled

substances, including without limitation, the EU RoHS Directive. TOSHIBA ASSUMES NO LIABILITY FOR DAMAGES OR LOSSES

OCCURRING AS A RESULT OF NONCOMPLIANCE WITH APPLICABLE LAWS AND REGULATIONS.

33 Dec. 1st, 2015

You might also like

- Samsung Bn41-02079a Bn41-02295a Ua32f4088ar Ua32f4088aj Power Pus SCHDocument1 pageSamsung Bn41-02079a Bn41-02295a Ua32f4088ar Ua32f4088aj Power Pus SCHgrigor-yuraNo ratings yet

- Handbook of Acoustics by Crocker, Malcolm J. PDFDocument1,398 pagesHandbook of Acoustics by Crocker, Malcolm J. PDFExrtra Terrestrial100% (1)

- De ImaginibusDocument62 pagesDe ImaginibusTalal A.80% (5)

- Capital Med in BriefDocument4 pagesCapital Med in BriefE BNo ratings yet

- LC 32D30MDocument92 pagesLC 32D30Mloc_jvc282575% (4)

- Sony CCD TRV Service ManualDocument23 pagesSony CCD TRV Service ManualPratik GurungNo ratings yet

- HCD N455Document72 pagesHCD N455Rodrigo Cieza0% (1)

- Sharp LCD TV LC-42SB45U Service Manual PDFDocument110 pagesSharp LCD TV LC-42SB45U Service Manual PDFGiancarloNo ratings yet

- Diagrama cfd-rg880cpDocument14 pagesDiagrama cfd-rg880cpMarvin Leon Alegria100% (1)

- Emcee Script JsDocument10 pagesEmcee Script JsRon Styx88% (24)

- Air Compressor NotesDocument10 pagesAir Compressor NotesIrfan Shaikh0% (1)

- JazmineDocument280 pagesJazmineRaven Nicole Morales100% (5)

- Vestel 17ips62-R4 Psu SCHDocument1 pageVestel 17ips62-R4 Psu SCHNick Fachin gomez100% (1)

- BGH3299A Manual Servicio PDFDocument36 pagesBGH3299A Manual Servicio PDFaldoNo ratings yet

- Th32a400g PDFDocument11 pagesTh32a400g PDFManage Don GnanathilakaNo ratings yet

- RT9025 25GSP RichtekDocument12 pagesRT9025 25GSP RichtekBengkel Kompu7erNo ratings yet

- CDH l32fd10 Service ManualDocument42 pagesCDH l32fd10 Service Manualtravieso112No ratings yet

- JBL scs-138 178 V2.ce SubwooferDocument13 pagesJBL scs-138 178 V2.ce SubwooferIstván GerencsérNo ratings yet

- CECL08D Datasheet Mp3-PlayerDocument1 pageCECL08D Datasheet Mp3-PlayerGlauber CostaNo ratings yet

- Current Mode LED Driver: General Description FeaturesDocument1 pageCurrent Mode LED Driver: General Description FeaturesEnrique LandraNo ratings yet

- TPS65198RUYTDocument4 pagesTPS65198RUYTАлександр АндриановNo ratings yet

- 5800 P32alb W000Document3 pages5800 P32alb W000autrera100% (1)

- (Codientu - Org) - (Codientu - Org) - AV 21F7 mn1873287 nn5198kDocument10 pages(Codientu - Org) - (Codientu - Org) - AV 21F7 mn1873287 nn5198kGioVoTamNo ratings yet

- DVD Daewoo Dm-k40Document44 pagesDVD Daewoo Dm-k40Fernando Guamán SimbañaNo ratings yet

- Oscilador Booster Led Sony BD9397EFVDocument30 pagesOscilador Booster Led Sony BD9397EFVAntonio Chavez100% (1)

- Daewoo HC-6120 6220 Home Teather Con DVD Diagramas PCBDocument27 pagesDaewoo HC-6120 6220 Home Teather Con DVD Diagramas PCBJavier Silva Alanis100% (1)

- 2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pages2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGioVoTamNo ratings yet

- Placa Sanyo 1LG410Y04400 FuenteDocument7 pagesPlaca Sanyo 1LG410Y04400 FuenteCristian JaramilloNo ratings yet

- Aoc 1619swa+Service+ManualDocument51 pagesAoc 1619swa+Service+ManualGarotinho Latino AmericanoNo ratings yet

- Jiuzhou dtt1609 Service Manual PDFDocument44 pagesJiuzhou dtt1609 Service Manual PDFVishu JoshiNo ratings yet

- LP154WX4 TlabDocument31 pagesLP154WX4 TlabsuzukkNo ratings yet

- C96GH C96GH-3670683: Part Number: Worldway Part: Category: Manufacturer: ApplicationsDocument3 pagesC96GH C96GH-3670683: Part Number: Worldway Part: Category: Manufacturer: ApplicationsAlfa alfaNo ratings yet

- LSC400HM03 SamsungDocument26 pagesLSC400HM03 Samsungikakumon100% (1)

- HozignDocument3 pagesHozignRodolfoNo ratings yet

- Fortune HunterDocument16 pagesFortune HunterKeith WarlickNo ratings yet

- Silicon PNP Power Transistor: INCHANGE Semiconductor Product SpecificationDocument2 pagesSilicon PNP Power Transistor: INCHANGE Semiconductor Product SpecificationElton De Souza CouraNo ratings yet

- BFDX Waterproof Walkie Talkie BF-390 USER'S MANUAL PDFDocument10 pagesBFDX Waterproof Walkie Talkie BF-390 USER'S MANUAL PDFtracy linNo ratings yet

- Philips - QV14.1E - LADocument244 pagesPhilips - QV14.1E - LALuca JohnNo ratings yet

- Panasonic TX-25lk1p TX-28lk1p Chassis z8Document22 pagesPanasonic TX-25lk1p TX-28lk1p Chassis z8drrebyNo ratings yet

- Part Number: Worldway Part: Category: Manufacturer: ApplicationsDocument3 pagesPart Number: Worldway Part: Category: Manufacturer: ApplicationsDonizete Gomes soaresNo ratings yet

- General Description Features: Cost Effective LED ControllerDocument10 pagesGeneral Description Features: Cost Effective LED ControlleranilNo ratings yet

- LG Plde-P008a - gl-Psl40-2 - Chassis Q552.2lla Psu & Led Driver SchematicDocument3 pagesLG Plde-P008a - gl-Psl40-2 - Chassis Q552.2lla Psu & Led Driver Schematiczigoto_2n100% (1)

- 2 Panasonic 2015 OLED TVDocument23 pages2 Panasonic 2015 OLED TVRamalingam Rathinasabapathy EllappanNo ratings yet

- Step-Up Converter As LED DriverDocument7 pagesStep-Up Converter As LED DriverInder100% (1)

- Sl601p Service ManualDocument60 pagesSl601p Service Manualvovan15No ratings yet

- S 2Document14 pagesS 2Sumit BhatiaNo ratings yet

- Sony Hdr-Xr500, Xr520 Service ManualDocument59 pagesSony Hdr-Xr500, Xr520 Service Manualbkhid159No ratings yet

- DVD Toshiba Sd-3990su, Sd-3990sc Service ManualDocument30 pagesDVD Toshiba Sd-3990su, Sd-3990sc Service Manualmaldo7No ratings yet

- Service Manual: HCD-V818Document92 pagesService Manual: HCD-V818Vitorio LogoNo ratings yet

- Philips FWM 3500 Service ManualDocument38 pagesPhilips FWM 3500 Service ManualSebastian Correa100% (1)

- Hi Fi Aiwa Cs Naj54u CX nbl54lh PDFDocument28 pagesHi Fi Aiwa Cs Naj54u CX nbl54lh PDFpitomoyaNo ratings yet

- LM2SA Service ManualDocument40 pagesLM2SA Service Manualraipedri100% (5)

- thx203h PDFDocument21 pagesthx203h PDFabdoNo ratings yet

- Mahindra Cie - Soft Ferrite CoresDocument42 pagesMahindra Cie - Soft Ferrite CoresSatishNo ratings yet

- Mini Hi-Fi System: Service ManualDocument85 pagesMini Hi-Fi System: Service Manualsaul64100% (1)

- Cube Schematic PDFDocument1 pageCube Schematic PDFCarlos ParraNo ratings yet

- Panasonic kxtg3411bxh Service ManualDocument83 pagesPanasonic kxtg3411bxh Service ManualAman100% (1)

- Small Signal Transistors: Reference GuideDocument8 pagesSmall Signal Transistors: Reference GuideJuan RamírezNo ratings yet

- Noblex: SERVICE MANUAL Colour TelevisionDocument29 pagesNoblex: SERVICE MANUAL Colour Televisionjose4445No ratings yet

- Kioxia-Thgbmhg6c1lbail C391257Document33 pagesKioxia-Thgbmhg6c1lbail C391257Павел СлободянюкNo ratings yet

- THGBMBG5D1KBAIL ToshibaDocument32 pagesTHGBMBG5D1KBAIL Toshibap4727No ratings yet

- THGBMHG7C1LBAIL ToshibaDocument33 pagesTHGBMHG7C1LBAIL ToshibaCube7 GeronimoNo ratings yet

- Thgbmbg5d1kbail A19nm 4gb E-Mmc Ver5.0 - e - Rev1.0 - 140807 - Pre-Loading Data ...Document32 pagesThgbmbg5d1kbail A19nm 4gb E-Mmc Ver5.0 - e - Rev1.0 - 140807 - Pre-Loading Data ...Rahmat HidayatNo ratings yet

- Kioxia Thgbmtg5d1lbail 15nm 4gb E-Mmc Ver5.0 e Rev.1.0 20211007Document30 pagesKioxia Thgbmtg5d1lbail 15nm 4gb E-Mmc Ver5.0 e Rev.1.0 20211007Duc Nguyen TruongNo ratings yet

- Kioxia Thgbmug8c2lbail 15nm 32gb E-Mmc Ver 5.1 Rev.1.0 20211007Document31 pagesKioxia Thgbmug8c2lbail 15nm 32gb E-Mmc Ver 5.1 Rev.1.0 20211007Duc Nguyen TruongNo ratings yet

- đề cuối kì 2 (viẹtack)Document4 pagesđề cuối kì 2 (viẹtack)trannhi13052004No ratings yet

- Satellite Communications System Design: Presented To: Engr. Vincent Ronquillo Presented By: Group 3Document13 pagesSatellite Communications System Design: Presented To: Engr. Vincent Ronquillo Presented By: Group 3Caleb BañaresNo ratings yet

- mmf2 Develop HelpDocument187 pagesmmf2 Develop HelpStelios LafazanisNo ratings yet

- Infosys Test PaperDocument31 pagesInfosys Test PaperShreya ShettyNo ratings yet

- Soal Simple Past Tense Kelas XDocument4 pagesSoal Simple Past Tense Kelas XJURIT RATMOKONo ratings yet

- CFD Modelling Approaches Against Single Wind Turbine Wake Measurements Using RANSDocument17 pagesCFD Modelling Approaches Against Single Wind Turbine Wake Measurements Using RANSTareq Abdussalam KhamllagNo ratings yet

- Wise Duplicate Finder (WDF) - How To Use - To Find and Remove Duplicate Files From Your Disk EasilyDocument5 pagesWise Duplicate Finder (WDF) - How To Use - To Find and Remove Duplicate Files From Your Disk EasilyambrosiofdmNo ratings yet

- Parkin 13ge Econ IMDocument10 pagesParkin 13ge Econ IMDina SamirNo ratings yet

- DvdavkjkDocument82 pagesDvdavkjkNajeebuddin AhmedNo ratings yet

- D.C.-D.C. Conversion (1) : Buck Converter 6.1 Operation: in This LectureDocument4 pagesD.C.-D.C. Conversion (1) : Buck Converter 6.1 Operation: in This LectureHassan FarssiNo ratings yet

- XMLSpear 3.1 ReadmeDocument2 pagesXMLSpear 3.1 ReadmeMacadoshisNo ratings yet

- 1st Prelim EconDocument3 pages1st Prelim Econmharjun lampaNo ratings yet

- 3planesoft Haunted House 3d Screensaver Serial PDFDocument3 pages3planesoft Haunted House 3d Screensaver Serial PDFReneNo ratings yet

- Hive Metastore HA - MySQL Replication For Failover Protection - HortonworksDocument18 pagesHive Metastore HA - MySQL Replication For Failover Protection - HortonworksHarsh100% (2)

- Pre Intermediate 1 Welcome Letter EF3 PDFDocument1 pagePre Intermediate 1 Welcome Letter EF3 PDFJackson PradaNo ratings yet

- Physics Experiment Report (Iv) Basic Physics "Oscillation Mathematics"Document8 pagesPhysics Experiment Report (Iv) Basic Physics "Oscillation Mathematics"JkanthNo ratings yet

- LPJ PPDB 2018/2019: SMK Insan TazakkaDocument2 pagesLPJ PPDB 2018/2019: SMK Insan TazakkaSMK INSAN TAZAKKANo ratings yet

- Electromagnetic Compatibility by Felicito S Caluyo PDFDocument40 pagesElectromagnetic Compatibility by Felicito S Caluyo PDFmjpadz100% (2)

- Caged SystemDocument12 pagesCaged SystemGayan GuruNo ratings yet

- Mid-Course Test B: (Sample Answer: 150 Words)Document2 pagesMid-Course Test B: (Sample Answer: 150 Words)AlexAlmacheNo ratings yet

- Research Methods in ManagementDocument71 pagesResearch Methods in ManagementArohi ChaturvediNo ratings yet

- Yocto DevDay Advanced Class PortlandDocument145 pagesYocto DevDay Advanced Class Portlandebbys89No ratings yet

- Pass Leader DumpsDocument30 pagesPass Leader DumpsHyder BasetNo ratings yet

- Solar Cell Losses and Design: Arno SmetsDocument17 pagesSolar Cell Losses and Design: Arno SmetsGianmarco PeñaNo ratings yet