Site Safety Inspection

Site Safety Inspection

Uploaded by

Darius DsouzaCopyright:

Available Formats

Site Safety Inspection

Site Safety Inspection

Uploaded by

Darius DsouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Site Safety Inspection

Site Safety Inspection

Uploaded by

Darius DsouzaCopyright:

Available Formats

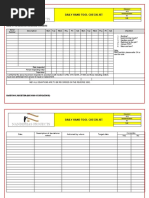

Example by Coldrop

YOUR Company LOGO here

Internal Health + Safety Inspection

CONSTRUCTION

SITE: Date:

Reference number: Site Manager:

Inspected by: Health & Safety Advisor Next Inspection due:

Note:

This check sheet is intended to assist inspections of construction sites. A list such as this cannot be comprehensive and initiative should be used when

inspecting a site. Many of the questions can only be answered by talking to site staff and workforce. Amend this form to suit your own personel use.

No. Activity Comments, opportunities for improvement

Assessed

1. General Y/N?

a) Are the CDM Site files available on site?

Is the CDM board displayed?

b) Are the method statements available for all contractors

and their activities and is there evidence that the

workforce have been briefed and understand them?

c) Is it clear to visitors where they are supposed to report?

Are visitors booked in?

Is there a record of CSCS card?

Is there an induction for visitors?

d) Is appropriate PPE being worn by all site personel?

Eye protection, hearing protection, HI-VIZ, hard hats,

boots, gloves etc

e) Are the F10 notification, Employers liability insurance,

H+S policy statement, HSE law poster, COSHH poster

clearly displayed?

f) Is there evidence of the competence of the workforce?

Copies of employees training certification on file?

g) Are fire extinguishers & First Aid facilities available?

Qualified First Aid personel on site? How many?

Is the hospital route displayed and emergency contact

numbers available?

h) Are there systems on site for monitoring weather

conditions and changes which could pose a threat?

2. General public

a) Is the site enclosed, or is there other protection for the

public?

b) Are there any areas where trespassers might gain access

to site? How will you stop access?

c) Are there any trips or similar hazards in public areas?

d) Is there adequate signage for the public?

Warnings of danger, keep out, contact numbers for out

of hours Emergency response?

3. Slips and trips

a) Are there clear designated pedestrian walkways?

Areas for material storage?

b) Is the site accessible, kept tidy with no materials or

debris causing trip/slip hazards?

4. Site traffic

a) Is there a traffic management plan in place, updated as

site progresses?

Has all personel seen it?

b) Does the plan identify separate pedestrian & vehicle

routes where possible?

c) Are obstacles such as excavations and scaffolds clearly

marked or protected?

d) Does any plant need a banksman and if so, is there one

present?

e) Are there any potentially dangerous slopes where

machinery might slide or overturn?

f) Are operators of dumpers wearing lap-belts?

Are flashing beacons working on all plant?

Is there a speed limit on site? Is it obeyed?

5. Falls from height

a) Has a safe system of work been put in place to ensure

fall protection or prevention?

b) Are all open edges and holes appropriately protected to

guard against falls of people and materials?

c) Have all scaffolds been erected appropriately to meet

the needs for which they are constructed?

Are recorded inspections/handover tickets available?

d) Are all working platforms fully & properly boarded

out? Boards in good condition?

e) Are guardrails, toe boards and brick guards been fitted?

Example by Coldrop

f) Stored materials are evenly distributed on the scaffold

platforms and not excessive or above guardrails?

g) Are ladders used only as means of access, except for

short duration work?

h) Are ladders secured before use to prevent slipping?

6. Lifting equipment

a) Is any lifting equipment suitable for this purpose?

Are weekly checks undertaken?

b) Is the load secure?

c) Is the lifting equipment working on solid even ground.

d) Is there a certification of thorough examination for the

crane and the lifting accessories?

e) Is there a suitable Lift Plan and an appointed person?

Operators license on file?

7. Services

a) Are appropriate precautions in place to safe guard

against striking underground services during the work?

b) Has identification of buried services or services

exposed during the works been carried out & recorded

c) Have all overhead lines been identified and steps taken

to remove divert or mark lines to prevent contact?

d) Is there a permit to dig system in place?

e) Are goal posts and signage being used to warn of

overhead services?

8. Confined spaces

a) Are there any designated confined spaces?

b) If so is there a thorough risk assessment and method

statement and are the requirements being adhered to?

c) Are there any other locations which might be a confined

space but which have not been designated?

9. Manual handling

a) Have positive steps been taken to identify materials

likely to be supplied in bulk, in unacceptably large size

units? (blocks, dry goods, cement)

b) Are workers manually lifting any large items of

equipment or material? What is the largest?

c) Is COSHH information available for materials being

used on site?

10. Welfare

a) Are all welfare facilities reasonably accessible to all

workers on site?

b) Is there accommodation available for sitting, heating

water & preparing food?

c) Are there adequate numbers of toilets, & wash basins

with warm water, cleaners & towels and are they being

well maintained?

d) If cooking personel on site, does she/he hold a current

food hygiene certificate?

Additional comments

You might also like

- SHE App 7 - Fire Equipment Inspector CR 29 (H)Document2 pagesSHE App 7 - Fire Equipment Inspector CR 29 (H)Munaku Tafadzwa100% (1)

- Revised Site Audit TemplateDocument4 pagesRevised Site Audit TemplateLucian100% (2)

- Construction Phase Plan ExampleDocument3 pagesConstruction Phase Plan ExampleYasmine100% (1)

- DSTI (Daily Safety Task Instruction) TemDocument4 pagesDSTI (Daily Safety Task Instruction) TemMahmoud GaberNo ratings yet

- Workplace Inspection Checklist For Construction Works - KenyaDocument20 pagesWorkplace Inspection Checklist For Construction Works - KenyaWinstone Audi100% (1)

- Lifting PlanDocument31 pagesLifting PlanDarius DsouzaNo ratings yet

- Construction Site Health and Safety InspectionDocument47 pagesConstruction Site Health and Safety InspectionSayed AbbasNo ratings yet

- Construction Site Safety Inspection Checklist FormDocument6 pagesConstruction Site Safety Inspection Checklist FormDarryl Verano100% (1)

- Evacuation Plan - UAE Civil Defence GuidelineDocument1 pageEvacuation Plan - UAE Civil Defence GuidelineNaeem IqbalNo ratings yet

- Construction Safety Checklist: Find and Record Common Construction HazardsDocument3 pagesConstruction Safety Checklist: Find and Record Common Construction HazardsKhyle Laurenz Duro100% (1)

- Omni Channel - Capsule Rooms PDFDocument56 pagesOmni Channel - Capsule Rooms PDFHarsh0% (1)

- Ms It BrochureDocument6 pagesMs It BrochureAbdul Salam NMNo ratings yet

- Method Statement For Underground ELV Cable Laying WorkDocument2 pagesMethod Statement For Underground ELV Cable Laying WorkYe Yint67% (6)

- Annex 2.1 - Safe Work Practices (Rev 3)Document25 pagesAnnex 2.1 - Safe Work Practices (Rev 3)Kyaw Zin WinNo ratings yet

- Safe Work Method Statement (SWMS) : DemolitionDocument11 pagesSafe Work Method Statement (SWMS) : DemolitionSafety HaveLockNo ratings yet

- Safety PORR SAR - Week 49-2013Document11 pagesSafety PORR SAR - Week 49-2013Darjan VeličkovNo ratings yet

- Temporary Works RegisterDocument2 pagesTemporary Works Registerrachel banfieldNo ratings yet

- Proper and Safe Use of Scissor LiftDocument3 pagesProper and Safe Use of Scissor LiftFajrin M. NatsirNo ratings yet

- 8-Pipe Fitting Risk Assessment ReportDocument8 pages8-Pipe Fitting Risk Assessment ReportSyed Ali HassanNo ratings yet

- Plumbing Sewerage - Drainage Swms 10Document26 pagesPlumbing Sewerage - Drainage Swms 10Shahrin KamaruzamanNo ratings yet

- Checklist For ScaffoldingDocument3 pagesChecklist For ScaffoldingrickymmaNo ratings yet

- JSA-Piling or Concreting For Foundations & BuildingDocument2 pagesJSA-Piling or Concreting For Foundations & BuildingSanjeet SinghNo ratings yet

- Jsa Manual ExcavationDocument1 pageJsa Manual ExcavationIan MardiansyahNo ratings yet

- Quarterly Safety Inspection ChecklistDocument2 pagesQuarterly Safety Inspection ChecklistAJ Compilation100% (1)

- Weekly Site Safety Inspection ChecklistDocument27 pagesWeekly Site Safety Inspection ChecklistzakariaNo ratings yet

- Welding Method Statement (SWMS) PDFDocument6 pagesWelding Method Statement (SWMS) PDFallanidunNo ratings yet

- Toolbox Talk 11: Critical Risks - Traffic ManagementDocument2 pagesToolbox Talk 11: Critical Risks - Traffic ManagementPravin Gowardun100% (1)

- Risk Assessment GardenDocument2 pagesRisk Assessment GardenMatthew BaguleyNo ratings yet

- Excavation PermitDocument2 pagesExcavation PermitRajesh Kumar SinghNo ratings yet

- WMS Infineon Project Tower ( Lifting Activities)Document14 pagesWMS Infineon Project Tower ( Lifting Activities)tanaNo ratings yet

- 26 Barricades&TapeDocument3 pages26 Barricades&TapeMohammed MinhajNo ratings yet

- Manual Excavation Drain PDFDocument3 pagesManual Excavation Drain PDFSafiuddin Afdal Laudin100% (1)

- Example Site Observational Checklist PDFDocument4 pagesExample Site Observational Checklist PDFjegosssNo ratings yet

- Construction Job Safety Analysis - Safety Science Y2010Document10 pagesConstruction Job Safety Analysis - Safety Science Y2010Yongsak Yungyuen100% (2)

- Checklist For Scaffolding: Construction of Srr2-Construction Management ServicesDocument3 pagesChecklist For Scaffolding: Construction of Srr2-Construction Management ServicesChayank TiwariNo ratings yet

- Fall Protection Plan (Feb 2023)Document3 pagesFall Protection Plan (Feb 2023)Keong Chee TongNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Permit To Work at HeightsDocument2 pagesPermit To Work at HeightsRj Hush Esguerra100% (1)

- Checklist For VDF FloaterDocument2 pagesChecklist For VDF FloaterGyanendra SrivastavaNo ratings yet

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- Critical Risk: Housekeeping: What Is The Risk?Document5 pagesCritical Risk: Housekeeping: What Is The Risk?Zegera MgendiNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- 2 - Site Safety ReportDocument15 pages2 - Site Safety ReportFareez Sedaka100% (2)

- Safe Work Procedure TemplateDocument2 pagesSafe Work Procedure TemplateAmirulAkmalNo ratings yet

- Safe Work Method Statement WorksheetDocument7 pagesSafe Work Method Statement WorksheetianllagasNo ratings yet

- Health and Safety FileDocument3 pagesHealth and Safety Fileaaktgt MepNo ratings yet

- HSE-CDS-003 Safe Operating SpecificationDocument16 pagesHSE-CDS-003 Safe Operating SpecificationRoza AzaleaNo ratings yet

- Falling Hazards in The Workplace - Protection & OSHA Standards PDFDocument4 pagesFalling Hazards in The Workplace - Protection & OSHA Standards PDFMuhammad MalikNo ratings yet

- Safety FileDocument36 pagesSafety FileAnonymous SVH04bUaNo ratings yet

- 8-22 Roller Shutter Door OHS TemplateDocument11 pages8-22 Roller Shutter Door OHS Templatemsc920138No ratings yet

- Nandiphas Projects: Daily Hand Tool ChecklistDocument2 pagesNandiphas Projects: Daily Hand Tool ChecklistTshireletso MphaneNo ratings yet

- Site Induction PresentationDocument16 pagesSite Induction PresentationMewan Naveenda Perera100% (3)

- SDS - Fenomastic Emulsion Matt - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Emulsion Matt - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Job Safety Analysis Installation (JSA)Document4 pagesJob Safety Analysis Installation (JSA)Aser Batoy Jr.No ratings yet

- Safe Job Procedure For Erecting Tube and Clamp and All Around Scaffolding June 2014Document7 pagesSafe Job Procedure For Erecting Tube and Clamp and All Around Scaffolding June 2014Abel DemNo ratings yet

- Construction Project Safety Management Best Practices Handbook PDFDocument332 pagesConstruction Project Safety Management Best Practices Handbook PDFVENKATESWARA RAO VOONANo ratings yet

- JSA General-Hot-Height-Confined SpaceDocument26 pagesJSA General-Hot-Height-Confined SpaceGMA100% (1)

- Explosives in Demolition - Exclusive ZoneDocument2 pagesExplosives in Demolition - Exclusive ZoneVignesh KmNo ratings yet

- SWP-20 Usage of Ladder DaimanDocument1 pageSWP-20 Usage of Ladder DaimanHassan AbdullahNo ratings yet

- Core Drilling Sample JHADocument1 pageCore Drilling Sample JHAluis VelozNo ratings yet

- CS ChecklistDocument2 pagesCS ChecklistYQ GanNo ratings yet

- Safety Flash- Water Tank Damage IncidentDocument1 pageSafety Flash- Water Tank Damage IncidentDarius DsouzaNo ratings yet

- 14-Telescopic Forklift Check List Hindi English - Page - 1Document1 page14-Telescopic Forklift Check List Hindi English - Page - 1Darius DsouzaNo ratings yet

- Combustible DustDocument12 pagesCombustible DustDarius DsouzaNo ratings yet

- Confined Space Atmospheric TestDocument1 pageConfined Space Atmospheric TestDarius DsouzaNo ratings yet

- TRA # 102 For Installation of Piping and Pipe SupportsDocument5 pagesTRA # 102 For Installation of Piping and Pipe SupportsDarius DsouzaNo ratings yet

- Heat Stress Program - J38Document24 pagesHeat Stress Program - J38Darius DsouzaNo ratings yet

- P111-RSME-TRA-007 - TRA For Cold Tie in PDFDocument4 pagesP111-RSME-TRA-007 - TRA For Cold Tie in PDFDarius DsouzaNo ratings yet

- Valve Station DrawingDocument1 pageValve Station DrawingDarius DsouzaNo ratings yet

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- HSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDocument1 pageHSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDarius DsouzaNo ratings yet

- Construction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Document1 pageConstruction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Darius DsouzaNo ratings yet

- HIP-Wastewater Revision 03Document14 pagesHIP-Wastewater Revision 03Darius DsouzaNo ratings yet

- HSE ALERT (XX-2012) - Title (Brief Description)Document1 pageHSE ALERT (XX-2012) - Title (Brief Description)Darius DsouzaNo ratings yet

- Trade-Related Intellectual Property Rights (Trips) by Amit RathiDocument19 pagesTrade-Related Intellectual Property Rights (Trips) by Amit RathibafnaharshitNo ratings yet

- An EFL Flipped Classroom Teaching Model: Effects On English Language Higher-Order Thinking Skills, Student Engagement and SatisfactionDocument15 pagesAn EFL Flipped Classroom Teaching Model: Effects On English Language Higher-Order Thinking Skills, Student Engagement and SatisfactionYa LiNo ratings yet

- Business Proposal LetterDocument12 pagesBusiness Proposal LetterJakeRyanHermosoNo ratings yet

- Facebok Ads Scaling LessonDocument3 pagesFacebok Ads Scaling LessonThe Vendor's KeyNo ratings yet

- Module 2 For Gen Ed 9 Rizal (WEEK 2) 4A'S FORMATDocument9 pagesModule 2 For Gen Ed 9 Rizal (WEEK 2) 4A'S FORMAT2BGrp3Plaza, Anna MaeNo ratings yet

- 21st Century Learning ESLDocument9 pages21st Century Learning ESLJoyce Voon Ern CzeNo ratings yet

- Socrates Research PaperDocument7 pagesSocrates Research Paperapi-462123330No ratings yet

- VentiDocument9 pagesVentisri astiniNo ratings yet

- Module 3Document26 pagesModule 3Laong laanNo ratings yet

- Tagore International School: Vasant Vihar, New Delhi Practice Paper - 1 Social Science Class - XDocument2 pagesTagore International School: Vasant Vihar, New Delhi Practice Paper - 1 Social Science Class - XDivyansh Singh0% (1)

- Bio ExamDocument24 pagesBio ExamMiss RambaranNo ratings yet

- Oudolf Garden Detroit BrochureDocument6 pagesOudolf Garden Detroit BrochureClickon Detroit67% (3)

- Iso 9001 Implementation WorkplanDocument9 pagesIso 9001 Implementation WorkplanSANo ratings yet

- Managing Projects: Managing Engineering and Technology Fourth Morse and BabcockDocument36 pagesManaging Projects: Managing Engineering and Technology Fourth Morse and Babcockmarwan100% (1)

- PART A: Guidelines On Promoting A Cost Conscious Culture What Is Cost Conscious Culture (CCC) ?Document6 pagesPART A: Guidelines On Promoting A Cost Conscious Culture What Is Cost Conscious Culture (CCC) ?maliqNo ratings yet

- Dhaka University of Engineering & Technology, Gazipur: Application FORM For TRANSCRIPTDocument1 pageDhaka University of Engineering & Technology, Gazipur: Application FORM For TRANSCRIPTMohammad Parvej100% (1)

- Summer Internship - KirtiDocument56 pagesSummer Internship - KirtiYOGI BAGRINo ratings yet

- Blowing The Lid On World History and The Hidden PowersDocument129 pagesBlowing The Lid On World History and The Hidden PowersSeoirse DionysosNo ratings yet

- Educ 102 MidtermDocument43 pagesEduc 102 MidtermellaineNo ratings yet

- Authentic Leadership (2) .EditedDocument18 pagesAuthentic Leadership (2) .EditedsirjamssyNo ratings yet

- VoLTE (eRAN12.1 08) PDFDocument461 pagesVoLTE (eRAN12.1 08) PDFJosueMancoBarrenecheaNo ratings yet

- DPS-3-C and DPS-67-CDocument3 pagesDPS-3-C and DPS-67-CrjmilaneseNo ratings yet

- CA Content Standard(s) /common Core Standard(s) :: Big Ideas/Unit GoalsDocument3 pagesCA Content Standard(s) /common Core Standard(s) :: Big Ideas/Unit Goalsapi-453655004No ratings yet

- Trends Module What Is TrendDocument2 pagesTrends Module What Is TrendLsrc Lala RamosNo ratings yet

- AirPort Hotel TeaserDocument5 pagesAirPort Hotel Teaserwildy FMNo ratings yet

- 2nd Grade Class SyllabusDocument2 pages2nd Grade Class Syllabusapi-530264354No ratings yet

- Role of The Engineer in Poverty AlleviationDocument7 pagesRole of The Engineer in Poverty AlleviationEmmanuel Mends FynnNo ratings yet