Powerhead: Section 4A - Cylinder Head

Powerhead: Section 4A - Cylinder Head

Uploaded by

pedroCopyright:

Available Formats

Powerhead: Section 4A - Cylinder Head

Powerhead: Section 4A - Cylinder Head

Uploaded by

pedroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Powerhead: Section 4A - Cylinder Head

Powerhead: Section 4A - Cylinder Head

Uploaded by

pedroCopyright:

Available Formats

CYLINDER HEAD

POWERHEAD

Section 4A - Cylinder Head

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . 4A-1 Valve Removal . . . . . . . . . . . . . . . . . . . . . . . 4A-26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2 Rocker Shaft and Rocker Arm . . . . . . . . . . 4A-27

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-5 Cleaning/Inspection/Repair . . . . . . . . . . . . . . . 4A-28

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-6 Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-28

Camshaft/Oil Pump . . . . . . . . . . . . . . . . . . . . . . 4A-8 Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 4A-30

Intake/Exhaust Valves . . . . . . . . . . . . . . . . . . . 4A-10 Valve Guide inspection . . . . . . . . . . . . . . . . 4A-30

Torque Sequence . . . . . . . . . . . . . . . . . . . . . . . 4A-12 Valve Guide Replacement . . . . . . . . . . . . . 4A-31

Valve Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4A-13

4A-13

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Springs . . . . . . . . . . . . . . . . . . . . . . . .

4A-32

4A-33

4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-15 Valve Seat Reconditioning . . . . . . . . . . . . . 4A-35 A

Valve Clearance Adjustment . . . . . . . . . . . . . . 4A-18 Valve Refacing Steps . . . . . . . . . . . . . . . . . 4A-36

Checking Valve Clearance . . . . . . . . . . . . . 4A-18 Cylinder Head Reassembly . . . . . . . . . . . . . . . 4A-37

Adjusting Valves . . . . . . . . . . . . . . . . . . . . . 4A-19 Valve Installation . . . . . . . . . . . . . . . . . . . . . 4A-37

Timing Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-20 Camshaft Oil Seal Installation . . . . . . . . . . 4A-38

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-20 Camshaft Installation . . . . . . . . . . . . . . . . . 4A-39

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-21 Oil Pump Installation . . . . . . . . . . . . . . . . . . 4A-40

Cylinder Head Removal . . . . . . . . . . . . . . . . . . 4A-22 Rocker Arm Shaft Assembly . . . . . . . . . . . 4A-40

Cylinder Head Disassembly . . . . . . . . . . . . . . 4A-24 Rocker Arm Shaft Installation . . . . . . . . . . 4A-41

Rocker Arm Assembly Removal . . . . . . . . 4A-24 Cylinder Head Gasket . . . . . . . . . . . . . . . . . 4A-42

Oil Pump Removal . . . . . . . . . . . . . . . . . . . 4A-24 Cylinder Head Installation . . . . . . . . . . . . . . . . 4A-43

Camshaft Removal . . . . . . . . . . . . . . . . . . . 4A-25

90-857046R1 NOVEMBER 2001 Page 4A-1

CYLINDER HEAD

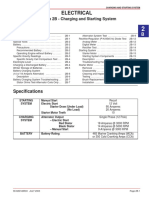

Specifications

Camshaft Dimensions

Intake “A” 1.214 - 1.222 in. (30.83 - 31.03 mm)

Exhaust “A” 1.214 - 1.222 in. (30.83 - 31.03 mm)

A

Intake “B” 1.020 - 1.028 in. (25.90 - 26.10 mm)

Exhaust “B” 1.020 - 1.028 in. (25.90 - 26.10 mm)

Run-out Limit B 0.0039 in. (0.1 mm)

Camshaft Bearing Diameter “b” 1.4541 - 1.4549 in.

(36.935 - 36.955 mm)

CAMSHAFT

b

b b

Free Length “a” 1.491-1.569 in. (37.85-39.85 mm)

Tilt Limit “b” Less than 0.060 in. (1.7 mm)

bb

aa

VALVE SPRING

Compressed Pressure (Installed)

Intake 19.8 - 22.0 lbs. (9.0 - 10.0 kg)

Exhaust 19.8 - 22.0 lbs. (9.0 - 10.0 kg)

Tilt Limit (Intake & Exhaust) 0.043 in. (1.1 mm)

Dir. of Winding (Intake & Exhaust) Left Hand

Page 4A-2 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Warp Limit 0.004 in. (0.1 mm)

* Lines indicate

straight edge 56899

measurement

CYLINDER HEAD

Camshaft Bore Inside Diameter “a” 1.4567 - 1.4577 in.

(37.000 - 37.025 mm)

a

a

a

56900

Valve/Valve Seat/Valve Guides:

Valve Clearance (cold)

Intake 0.006 - 0.010 in. (0.15 - 0.25 mm)

Exhaust 0.010 - 0.014 in. (0.25 - 0.35 mm)

Valve Dimensions:

“A” Head Diameter

Intake 1.256 - 1.264 in. (31.9 - 32.1 mm)

Exhaust 1.020 - 1.028 in. (25.9 - 26.1 mm)

“B” Face Width

Intake 0.079 - 0.124 in. (2.00 - 3.14 mm)

Exhaust 0.079 - 0.124 in. (2.00 - 3.14 mm)

“C” Seat Width

Intake 0.035 - 0.043 in. (0.9 - 1.1 mm)

Exhaust 0.035 - 0.043 in. (0.9 - 1.1 mm)

“D” Margin Thickness

VALVES Intake 0.020 - 0.035 in. (0.5 - 0.9 mm)

Exhaust 0.020 - 0.035 in. (0.5 - 0.9 mm)

Stem Outside Diameter

Intake 0.2156 - 0.2161 in. (5.475 - 5.490 mm)

Exhaust 0.2150 - 0.2156 in. (5.460 - 5.475 mm)

Guide Inside Diameter

Intake 0.2165 - 0.2170 in. (5.500 - 5.512 mm)

Exhaust 0.2165 - 0.2170 in. (5.500 - 5.512 mm)

Stem To Guide Clearance

Intake 0.0004 - 0.0015 in. (0.010 - 0.037 mm)

Exhaust 0.0010 - 0.0020 in. (0.025 - 0.052 mm)

Stem Run-out Limit (max.) 0.0006 in. (0.016 mm)

90-857046R1 NOVEMBER 2001 Page 4A-3

CYLINDER HEAD

Valve Dimensions

“C”

“B”

“D”

“A”

Head Diameter Face Width Seat Width Margin Thickness

ROCKER SHAFT Outside Diameter 0.6288 - 0.6296 in.

(15.971 - 15.991 mm)

ROCKER ARM Inside Diameter of Bore 0.6299 - 0.6306 in.

(16.000 - 16.018 mm)

Page 4A-4 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Special Tools

1. Flywheel Holder P/N 91-83163M

2. Valve Guide Remover P/N 91-809495A1

3. Valve Guide Installer Bushing P/N 91-809496A1

4. Valve Guide Reamer P/N 91-809497A1

5. Valve Spring Compressor P/N 91-809494A1

6. Valve Seat Cutter Kit (Obtain Locally).

90-857046R1 NOVEMBER 2001 Page 4A-5

CYLINDER HEAD

CYLINDER HEAD

110

110

110

110 4-Stroke Outboard Oil

Page 4A-6 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

CYLINDER HEAD

TORQUE

REF.

REF

NO. QTY. DESCRIPTION lb. in. lb. ft. N·m

1 CYLINDER HEAD (ELECTRIC)

–

1 CYLINDER HEAD (MANUAL)

1 1 CYLINDER HEAD

2 6 GUIDE

3 3 SCREW M6 X 8 57 6.0

4 3 GASKET

5 1 OIL SEAL

6 5 PIPE PLUG

7 1 O RING

8 1 COVER

9 1 BREATHER PIPE

10 1 DECAL-Servicing Referral

11 1 DECAL-Engine Oil/Valve Clearance

12 8 SCREW (M9 x 1.5 x 95) 35.0 47

13 4 SCREW (M6 x 25) 106 12

14 1 GASKET

15 7 SCREW (M6 x 20) 70 8

16 1 BAFFLE PLATE

17 4 SCREW (M4 x 10)

18 1 ELBOW

19 1 BRACKET (HANDLE)

20 2 SCREW (M6 x 13) (HANDLE)

21 1 PLUG

22 1 O RING

1 DECAL - HP ID (30)

23

1 DECAL - HP ID (40)

24 2 DOWEL PIN

90-857046R1 NOVEMBER 2001 Page 4A-7

CYLINDER HEAD

CAMSHAFT/OIL PUMP

1

3

4

7

110

6

8

110

10

9

12 11

13

51

110 4-Stroke Outboard Oil

51 Loctite 222

Page 4A-8 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

CAMSHAFT/OIL PUMP

TORQUE

REF.

REF

NO. QTY. DESCRIPTION lb. in. lb. ft. N·m

1 1 SCREW (M8 x 40 x 1.25) 28 38

2 1 WASHER

3 1 BELT

4 1 GEAR-Driven

5 1 DOWEL PIN

6 1 CAMSHAFT (MANUAL)

7 1 CAMSHAFT (ELECTRIC)

8 1 PIN

9 1 OIL PUMP ASSEMBLY

10 1 O RING

11 1 O RING

12 1 O RING

13 4 SCREW (M6 x 35) 70 8

90-857046R1 NOVEMBER 2001 Page 4A-9

CYLINDER HEAD

INTAKE/EXHAUST VALVES

110

110

110

110

110 4-Stroke Outboard Oil

Page 4A-10 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

INTAKE/EXHAUST VALVES

TORQUE

REF.

REF

NO. QTY. DESCRIPTION lb. in. lb. ft. N·m

1 3 EXHAUST VALVE

2 3 INTAKE VALVE

3 6 SEAL–Valve Stem

4 6 VALVE SPRING–Outer

5 6 RETAINER–Valve Spring

6 12 KEY

7 6 ROCKER ARM

8 6 SCREW

9 6 NUT 120 10 13.5

10 1 ROCKER SHAFT

11 2 PLUG

12 1 BRACKET

13 1 SPRING

14 1 BRACKET

15 1 SPRING

16 1 SEAL

17 1 PIN - CAM THRUST

18 4 SCREW (M8 x 23) 160 13.3 18

19 2 SPRING - Overload (If Equipped) 160 13.3 18

90-857046R1 NOVEMBER 2001 Page 4A-11

CYLINDER HEAD

Torque Sequence

7 6

8

4

4

2

3

3 4

1

1 2

1

2

5

3

6

5

Page 4A-12 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Valve Cover

NOTE: Valves should be adjusted when engine is cold.

WARNING

Engine could possibly start when turning flywheel during adjustment. To prevent

this type of accidental engine starting and possible serious injury, always remove

spark plug leads from spark plugs.

Removal

1. Disconnect spark plug leads and remove spark plugs.

2. Remove flywheel cover/manual starter components (if equipped).

3. Remove lower cowl (if desired) for easier access to lower screws.

NOTE: Refer to section 8 for removal of manual starter.

a - Screw (4) M6 x 25

b - Flywheel Cover

90-857046R1 NOVEMBER 2001 Page 4A-13

CYLINDER HEAD

4. Disconnect the crankcase breather hose, vent hose, and fuel pump in/out hoses.

5. Disconnect fuel cooler in/out hoses (If equipped).

IMPORTANT: The hose fittings on the fuel pump can break if you try twisting or pull-

ing off the hoses. Remove fuel pump hoses by slowly prying them off using a small

screwdriver.

6. Remove coils from valve cover. Refer to section 2A - Ignition Coil Removal.

7. Remove valve cover.

h d

59250

g

f

a - Screw (7) M6 x 20

b - Valve Cover

c - Crankcase Breather Hose

d - Crankcase Vent Hose

e - Fuel Pump Output Hose

f - Fuel Pump Input Hose

g - Fuel Cooler OUT Hose

h - Fuel Cooler IN Hose

Page 4A-14 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Installation

1. Install valve cover seal into groove.

2. If removed, reinstall baffle plate. Tighten screws securely.

a - Baffle Plate

b - Screw (4) M4 x 10

c - Cover Seal

90-857046R1 NOVEMBER 2001 Page 4A-15

CYLINDER HEAD

3. Reinstall the valve cover. Tighten screws to the specified torque.

4. Install coils. Refer to section 2A - Ignition Coil Installation.

5. Install fuel pump. Refer to section 3C - Fuel Pump Installation.

6. Connect fuel pump in/out hoses, fuel cooler in/out hoses, crankcase breather and vent

hose. Secure all with sta-straps.

7. Reinstall spark plugs and spark plug leads.

h d

59250

g

f

a - Screw (7) M6 x 20

b - Valve Cover

c - Crankcase Breather Hose

d - Crankcase Vent Hose

e - Fuel Pump Output Hose

f - Fuel Pump Input Hose

g - Fuel Cooler OUT Hose

h - Fuel Cooler IN Hose

Valve Cover Screw Torque

70 lb-in. (8 Nm)

Coil Mounting Screw

75 lb-in. (8.5 Nm)

Page 4A-16 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

8. Install flywheel cover/manual starter components (if equipped). Tighten screws to speci-

fied torque.

NOTE: Refer to section 8 for installation of manual starter.

a - Flywheel Cover

b - Screw (4) M6 x 25

Flywheel Cover Screw Torque

75 lb. in. (8.5 N·m)

90-857046R1 NOVEMBER 2001 Page 4A-17

CYLINDER HEAD

Valve Clearance Adjustment

NOTE: Valve should be adjusted when the engine is cold.

WARNING

Engine could possibly start when turning flywheel during adjustment. To prevent

this type of accidental engine starting and possible serious injury, always remove

spark plug leads from spark plugs.

Checking Valve Clearance

1. Remove valve cover as outlined in “Valve Cover Removal”.

2. Measure valve clearance with a feeler gauge. Adjust if out of specification.

NOTE: When loosening lock nuts, hold the adjusting screw with a screw driver to prevent

it from moving.

Valve Clearance (Cold)

Intake 0.006 - 0.010 in. (0.15 - 0.25 mm)

Exhaust 0.010 - 0.014 in. (0.25 - 0.35 mm)

d c

a - Lock nut

b - Adjusting Screw

c - Intake Valve Clearance

d - Exhaust Valve Clearance

Page 4A-18 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Adjusting Valves

1. Perform the following adjustment steps:

a. Turn the driven gear and align the “1 / ∆” mark on the driven gear with the “∆” mark

on the cylinder block.

b. Adjust the intake and exhaust valve clearance for cylinder #1.

c. Turn the driven gear 120° clockwise and align the “∆” mark on the driven gear with

the “∆” on the cylinder block.

d. Adjust the intake and exhaust valve clearance for cylinder #2

e. Turn the driven gear 120° clockwise and align the “∆” mark on the driven gear with

the “∆” on the cylinder block.

f. Adjust the intake and exhaust valve clearance for cylinder #3

d c

b

1

57191

a

a - Cylinder Block “∆” Mark

b - Driven Gear “1 or ∆” Mark (Cylinder #1)

c - Driven Gear “∆” Mark at 120° (Cylinder #2)

d - Driven Gear “∆” Mark at 240° (Cylinder #3)

2. Tighten the lock nuts.

NOTE: When tightening lock nuts, hold the adjusting screw with a screw driver to prevent

it from moving.

Valve Adjusting Lock Nut Torque

120 lb. in. (13.5 N·m)

90-857046R1 NOVEMBER 2001 Page 4A-19

CYLINDER HEAD

Timing Belt

Removal

1. Remove flywheel and stator. Refer to section 2B Charging and Starting System.

2. Remove timing belt from driven gear and drive gear.

a - Timing Belt

Page 4A-20 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Installation

Timing Belt Installation Notes:

• Protect the timing belt from water and oil.

• Use care not to scratch the belt.

• Do not use any metal device to help stretch the belt onto the driven gear.

1. Align marks on drive and driven gear with marks on cylinder block as shown.

2. Install timing belt onto drive gear as shown. Numbers/letters on belt should be readable

once belt is installed.

3. Install stator and flywheel. Refer to section 2A - Ignition.

a d

1

b

c c e

a - Drive Gear Mark

b - Driven Gear Mark

c - Cylinder Block Marks

d - Timing Belt Installed Correctly

e - Timing Belt Installed Incorrectly

90-857046R1 NOVEMBER 2001 Page 4A-21

CYLINDER HEAD

Cylinder Head Removal

WARNING

Engine could possibly start when turning flywheel during adjustment. To prevent

this type of accidental engine starting and possible serious injury, always remove

spark plug leads from spark plugs.

1. Remove valve cover. Refer to Valve Cover Removal.

2. Remove timing belt from driven gear.

a - Timing Belt

b - Driven Gear

3. Remove the throttle and shift levers from side of cylinder head.

4. Remove the cylinder head and intake manifold assembly mounting screws.

a - Center Screw (8) M9 x 95

b - Flange Screw (4) M6 x 25

c - Intake Manifold Screw (6)

Page 4A-22 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

5. Separate cylinder head from cylinder block.

NOTE: Cylinder head gasket is not reusable.

a - Gasket (Discard)

b - Dowel Pins (2) (Retain)

90-857046R1 NOVEMBER 2001 Page 4A-23

CYLINDER HEAD

Cylinder Head Disassembly

Rocker Arm Assembly Removal

1. Remove screws securing rocker arm shaft to cylinder head. Remove rocker arm assem-

bly and retainers.

b

a

a - Screws (4) M8 x 30

b - Rocker Arm Assembly

Oil Pump Removal

1. Refer to section 4C - Oil Pump Removal.

Page 4A-24 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Camshaft Removal

1. Hold driven gear using tool (91-83163M) and loosen screw. Remove screw, washer,

driven gear and dowel pin.

NOTE: The camshaft can be removed from the top without removing the cylinder head from

the engine.

b

a

91-83163M

a - Holder 91-83163M

b - Driven Gear

c - Screw M8 x 40

d - Washer

e - Dowel Pin

2. Remove camshaft retaining pin and seal.

3. Remove oil seal and camshaft.

a - Oil Seal

b - Camshaft

c - Camshaft Retaining Pin with Seal

90-857046R1 NOVEMBER 2001 Page 4A-25

CYLINDER HEAD

Valve Removal

VALVE COMPONENTS

e

d

c

b

a

a - Valve

b - Valve Seal

c - Valve Spring

d - Spring Retainer

e - Valve Keepers

REMOVING VALVES

NOTE: Anytime a valve is removed, replace the valve seal.

1. Compress valve springs using tool (91-809494A1). Remove valve keepers and valves.

91-809494A1

58256

a - Valve Spring Compressor (P/N 91-809494A1)

b - Valve Keepers

Page 4A-26 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Rocker Shaft and Rocker Arm

1. Measure rocker shaft diameter. Replace shaft if out of specification.

Rocker Shaft Diameter

0.6288 - 0.6296 in. (15.971 -15.991 mm)

2. Measure rocker arm inside diameter. Replace rocker arms if out of specification.

55804

Rocker Arm Inside Diameter

0.6299 - 0.6306 in. (16.000 -16.018 mm)

90-857046R1 NOVEMBER 2001 Page 4A-27

CYLINDER HEAD

Cleaning/Inspection/Repair

Camshaft

Manual start models are equipped with a cam shaft featuring a compression release

mechanism. The compression relief mechanism releases a percentage of the cylinder

compression during engine cranking, which lowers the starter rope pull force.

At cranking speeds (RPM) the cam shaft decompression levers rest against the side of the

exhaust cam lobes, protruding out from the heal of the lobe. This protrusion contacts the

exhaust valve rocker arms during the compression stroke, slightly opening the exhaust

valve.

With the increase of centrifugal force at engine running speeds, the decompression levers

swing out of contact with the exhaust valve rocker arms, allowing the exhaust valves to operate

normally (fully closed) during the compression stroke.

a - Exhaust Valve Rocker Arm

b - Decompression Lever

1. Inspect the camshaft for pitting, heat discoloration, or scratches, and for the following

measurements. Replace camshaft if worn or not within specification.

2. Inspect the compression relief cam lever (if equipped) for free movement. Replace cam-

shaft if necessary.

a - Compression Relief Cam

Page 4A-28 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

3. Measure the cam lobe length (a) and width (b).

a

b

Cam Lobe Specifications

a Intake 1.214 - 1.222 in.

(30.83 - 31.03 mm)

Exhaust 1.214 - 1.222 in.

(30.83 - 31.03 mm)

b Intake 1.020 - 1.028 in.

(25.90 -26.10 mm)

Exhaust 1.020 - 1.028 in.

(25.90 -26.10 mm)

4. Measure the camshaft bore diameters (a) and camshaft bearing diameters (b).

b b

b a

Camshaft Bore Inside Diameter “a”

1.4567 - 1.4577 in. (37.000 - 37.025 mm)

Camshaft Bearing Inside Diameter “b”

1.4541 - 1.4549 in. (36.935 - 36.955 mm)

90-857046R1 NOVEMBER 2001 Page 4A-29

CYLINDER HEAD

Cylinder Head

1. Inspect the cylinder head for the following conditions:

• Mineral deposits/corrosion in water passage ways.

• Carbon deposits in combustion chamber (use round scraper to clean away depos-

its). Be careful not to scratch or remove material.

2. Using a straight edge and a thickness gauge inspect cylinder head for warpage. Re-

place cylinder head if out of specification. Measure in locations illustrated.

56899

Cylinder Head Warpage Limit

0.004 in. (0.1 mm)

Valve Guide inspection

1. Measure the valve guide bore (a). If valve guide wear is out of specification, replace the

valve guide.

58257

Valve Guide Inside Diameter

Intake Valve 0.2165 - 0.2170 in.

Exhaust Valve (5.500

(5 500 - 5

5.512

512 mm))

Page 4A-30 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Valve Guide Replacement

1. Heat the cylinder head in an oven to 390° F (200° C). This will help to ease guide removal

and installation and to maintain correct interference fit.

2. Remove the valve guide using a valve guide remover.

a - Valve Guide Remover (91-809495A1)

3. Install the new valve guide and circlip using a valve guide installer bushing along with

the valve guide remover.

a - Valve Guide Remover (91-809495A1)

b - Valve Guide Installer Bushing (91-809496A1)

4. After installing the valve guide, ream the valve guide using a valve guide reamer to ob-

tain proper stem-to-guide clearance.

a - Valve Guide Reamer (91-809497A1)

90-857046R1 NOVEMBER 2001 Page 4A-31

CYLINDER HEAD

Valves

1. Clean the carbon deposits from the valve. Discard any cracked, warped, or burned

valves.

2. Measure the valve stem diameter to check for wear. Replace valves if not within specifi-

cation.

Valve Stem Diameter

Intake Valve 0.2156 - 0.2161 in.

(5.475 - 5.490 mm)

Exhaust Valve 0.2150 - 0.2156 in.

(5.460 - 5.475 mm)

3. Check the valve face for pitting. Valves faces that are pitted must be refaced.

NOTE: Several different types of equipment are available for refacing valves. Follow the

equipment manufacturer’s instructions.

NOTE: After refacing the valve seat or replacing the valve and valve guide, the valve seat

and valve face should be lapped.

4. Check the margin thickness (a) of the valves after the valves have been ground. Any

valve with a margin thickness of less than the specification, should be replaced.

45 °

Margin Thickness “a”

Intake Valve 0.020 - 0.035 in.

(0.5 - 0.9 mm)

Exhaust Valve 0.020 - 0.035 in.

(0.5 - 0.9 mm)

Page 4A-32 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

5. Measure valve stem runout, replace if out of specification.

Valve Stem Runout Limit (Max.)

Intake Valve 0.0006 in. (0.016 mm)

Exhaust Valve

Valve Springs

1. Check each spring under load on a spring tester. Replace any weak springs.

2. Check free length limit of each spring. Replace valve springs if not in specification.

Valve Spring Free Length

1.491 - 1.569 in. (37.85 – 39.85 mm)

90-857046R1 NOVEMBER 2001 Page 4A-33

CYLINDER HEAD

3. Check each spring on a flat surface using a square. Rotate spring and check space be-

tween the top coil and square. Replace valve springs if not in specification.

Valve Spring Tilt Specification “a”

Less than 0.06 in. (1.7 mm)

Page 4A-34 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Valve Seat Reconditioning

Clean the carbon deposits from the combustion chambers and valve seats and check for

pitting.

Several different types of equipment are available for reseating valve seats. Follow the

equipment manufacturer’s instructions.

Measure valve seat width (a). Resurface the valve seat if not in specification.

Reface valve seat, use a 60°, 45°, 15° valve seat cutter.

NOTE: When twisting cutter, keep an even downward pressure to prevent chatter marks.

Valve Seat Width Specification “a”

Intake Valve 0.035 - 0.043 in.

Exhaust Valve (0.9 - 1.1 mm)

NOTE: If resurfacing the valve seats is required, resurface the valve seats to the specified

angles shown in chart following.

b

a

Valve Seat Angle Specifications

a 15°

b 45°

c 60°

90-857046R1 NOVEMBER 2001 Page 4A-35

CYLINDER HEAD

Valve Refacing Steps

Condition: The valve seat is centered on valve face but it is too wide.

Valve Seat Cutter Set Desired Results

Use 15° Cutter To reduce valve seat

Lightly

Li htl 60° Cutter width

idth

Condition: The valve seat is in the middle of the valve face but it is too narrow.

Valve Seat Cutter Set Desired Results

Use 45° Cutter To achieve a uniform valve

seatt width

idth

Condition: Valve seat is too narrow and it is near valve margin.

Valve Seat Cutter Set Desired Results

Use 15° Cutter, First To center the seat and to

45° Cutter achieve

hi itits Width

Page 4A-36 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Condition: Valve seat is too narrow and is located near the bottom edge of the valve face.

Valve Seat Cutter Set Desired Results

Use 60° Cutter, First To center the seat and to in-

45° Cutter crease itits Width

Cylinder Head Reassembly

Valve Installation

INTAKE AND EXHAUST VALVE COMPONENTS

e

d

c

b

a

a - Valve

b - Valve Seal

c - Valve Spring

d - Spring Retainer

e - Valve Keepers

90-857046R1 NOVEMBER 2001 Page 4A-37

CYLINDER HEAD

INSTALLING VALVES

NOTE: Always use new valve seals.

1. Apply engine oil to the valves and valve seats.

2. Compress the valve spring and retainer and install the valve keepers around the valve

stem. You may have to tap lightly on the end of the valve to seat the keepers.

NOTE: Valve springs are symmetrical and may be installed in either direction.

91-809494A1

a - Valve Spring Compressor Tool (91-809494A1)

b - Valve Keepers

Camshaft Oil Seal Installation

1. If removed, install new oil seal. Position seal so part number side is facing outward.

Press seal in until it makes contact with the inside flat surface.

58261

a - Upper Camshaft Oil Seal

Page 4A-38 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Camshaft Installation

1. Apply engine oil to the main journals (4 places) on the camshaft.

2. Slide camshaft into cylinder head (threaded end towards driven gear).

NOTE: Camshaft retaining pin groove must align with retaining pin hole in cylinder head.

3. Install camshaft retaining pin. Install seal over pin.

4. Place driven gear on camshaft so alignment pin is in hole. Hold gear with tool

(91-83163M) and fasten with washer and screw. Tighten screw to the specified torque.

5. Remove any oil from the camshaft lobes and apply Moly Grease to the lift portion of the

lobes. Obtain Moly Grease from a local source.

NOTE: Rotate camshaft after assembly to ensure it rotates smoothly.

f e

d c

a

b

58477

58287

91-83163M

58278

a - Camshaft d - Driven Gear

b - Camshaft Retaining Pin w/Seal e - Washer

c - Alignment Pin f - Screw M10 x 40

Driven Gear Screw Torque

28 lb-ft (38 Nm)

90-857046R1 NOVEMBER 2001 Page 4A-39

CYLINDER HEAD

Oil Pump Installation

1. Refer to section 4C - Oil Pump Installation.

Rocker Arm Shaft Assembly

1. Apply engine oil to the rocker shaft and arms.

2. Locate the end of the rocker shaft that gets installed towards driven gear (oil holes will

line-up with the mating oil holes in the cylinder head).

3. Slide the rocker arms onto rocker shaft as shown.

c

a

b

c

110

110 4-Stroke Outboard Oil 53739

c

a - Rocker Shaft

b - Rocker Arm (6)

c - Oil Holes (4)

Page 4A-40 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Rocker Arm Shaft Installation

1. Install the rocker arm shaft assembly as shown.

2. Install rocker arm retainers on rocker shaft as shown. Tighten screws to the specified

torque.

NOTE: Leave all adjustment screws loose at this time.

110

c

b

58987

110 4-Stroke Outboard Oil

a - Mounting Screw (4)-M8 x 30

b - Rocker Arm Bracket (1)

c - Rocker Arm Spring - Overload (2) Arrow Must Point Toward Driven Gear

d - Rocker Arm Spring (1)

e - Rocker Arm Bracket (1)

f - Rocker Arm Spring (1) Arrow Must Point Toward Driven Gear

Rocker Arm Shaft Mounting Screw Torque

160 lb. in. (18 N·m)

90-857046R1 NOVEMBER 2001 Page 4A-41

CYLINDER HEAD

Cylinder Head Gasket

1. Install new cylinder head gasket and dowel pins.

a - Gasket (New)

b - Dowel Pin (2)

Page 4A-42 90-857046R1 NOVEMBER 2001

CYLINDER HEAD

Cylinder Head Installation

1. Apply engine oil to the threads of each screw and seat surface.

2. Fasten cylinder head with screws shown. Do not tighten.

110

b

a

110 4-Stroke Outboard Oil

a - Screw (8) M9 x 95

b - Flange Screw (4) M6 x 25

90-857046R1 NOVEMBER 2001 Page 4A-43

CYLINDER HEAD

3. Torque center screws (first) in sequence and in two steps.

4. Torque the cylinder head and carburetor intake manifold screws in sequence and in two

steps.

5. Refer to “Timing Belt Installation” preceding, and install timing belt.

6. Refer to “Valve Clearance Adjustment” preceding, to perform valve clearance adjust-

ments.

7. Refer to “Valve Cover Installation” preceding, and install valve cover.

7 6

8

4 4

3

b

4

2

1

3

2

2

1 5

1 c

3 6

5

a

a - Center Screw (8) M9 x 95

b - Flange Screw (4) M6 x 25

c - Intake Manifold Screw (6) M6 x 25

Intake Manifold Screw Torque

70 lb. in. (8 N·m)

Cylinder Head Screw Torque

Center Screw (Qty. 8)

1st: 17 lb-ft (23 Nm)

2nd: 35 lb-ft (47 Nm)

Cyl. Head Flange Screw (Qty. 4)

1st: 53 lb-in. (6 Nm)

2nd: 106 lb-in. (12 Nm)

Page 4A-44 90-857046R1 NOVEMBER 2001

You might also like

- 16839634-Ih International 684 784 884 Tractors Shop Service Repair Manual - DownloadDocument64 pages16839634-Ih International 684 784 884 Tractors Shop Service Repair Manual - Downloadtom82% (38)

- Ih b275-b414 354-364-384 424-444 2424-2444 ManualDocument81 pagesIh b275-b414 354-364-384 424-444 2424-2444 Manualvoetsek00791% (11)

- ALPHA ONE Gen.2Document43 pagesALPHA ONE Gen.2Andrea Nakicenovic100% (2)

- A-212 Pressure Vessel Steel - A Case Against Continued UseDocument11 pagesA-212 Pressure Vessel Steel - A Case Against Continued Usealexthecrusader7206100% (4)

- Probation Period Assessment FormDocument2 pagesProbation Period Assessment Formpreeti100% (7)

- 454-502 MercruiserDocument71 pages454-502 Mercruiserjaumegus80% (5)

- ZF Marine Transmission Repair ManualDocument112 pagesZF Marine Transmission Repair ManualDavid Chalker85% (13)

- 1 ADocument10 pages1 ApedroNo ratings yet

- Alpha One Generation Ii Stern Drive: IndexDocument37 pagesAlpha One Generation Ii Stern Drive: IndexNicholas Ribic100% (1)

- Linked PDFDocument104 pagesLinked PDFroparts cluj0% (2)

- Fisher Type 667 Diaphragm ActuatorDocument32 pagesFisher Type 667 Diaphragm Actuatorimran khan100% (1)

- 4a MercuryDocument58 pages4a MercuryDr. Centelha Mecânica NaúticaNo ratings yet

- Section 4A - Powerhead: Special ToolsDocument26 pagesSection 4A - Powerhead: Special ToolsRandall PettersonNo ratings yet

- Sterndrive Unit: Gear Housings Mr/Alpha One/Alpha One SsDocument56 pagesSterndrive Unit: Gear Housings Mr/Alpha One/Alpha One SsdarrylloachNo ratings yet

- Section 4 - PowerheadDocument53 pagesSection 4 - PowerheadpedroNo ratings yet

- Section 4 - PowerheadDocument54 pagesSection 4 - PowerheadpedroNo ratings yet

- 5 BDocument60 pages5 BpedroNo ratings yet

- Power Steering Gear: Section 6CDocument36 pagesPower Steering Gear: Section 6CJarry PotterNo ratings yet

- Service Manual Musso Engine (OM 600)Document187 pagesService Manual Musso Engine (OM 600)Dennis Cezar Mendes100% (1)

- Electrical Systems: Starting SystemDocument33 pagesElectrical Systems: Starting SystemagmwwNo ratings yet

- Engine Mechanical : Group 11ADocument38 pagesEngine Mechanical : Group 11AJim LiebNo ratings yet

- Clutch: Section 5CDocument24 pagesClutch: Section 5CJarry PotterNo ratings yet

- Sterndrive Unit: Section 3A - Drive Shaft HousingDocument50 pagesSterndrive Unit: Section 3A - Drive Shaft HousingАлександр ГершукNo ratings yet

- Tintin Et Les GrololoDocument16 pagesTintin Et Les GrololoYamahauki SusukiNo ratings yet

- Reparaturanleitung U Ersatzteilliste ZF63A Bis ZF85ADocument112 pagesReparaturanleitung U Ersatzteilliste ZF63A Bis ZF85APaul De Caluwe0% (2)

- En 4J2 1C2Document75 pagesEn 4J2 1C2Trafu LarNo ratings yet

- Merc Service Manual 6 4bDocument40 pagesMerc Service Manual 6 4bHayduke them100% (5)

- Service Manualspolaris200620 20200720Polaris20Outlaw2050020Service20Manual PDFDocument85 pagesService Manualspolaris200620 20200720Polaris20Outlaw2050020Service20Manual PDFzacharylacasse171No ratings yet

- Section 2C: General SpecificationsDocument36 pagesSection 2C: General SpecificationsJarry PotterNo ratings yet

- Bobcat 450-453Document133 pagesBobcat 450-453ostiano garcia100% (1)

- 4T40-E Automatic Transaxle: Section 5ADocument301 pages4T40-E Automatic Transaxle: Section 5AJarry PotterNo ratings yet

- 1B. SOHC Engine MechanicalDocument95 pages1B. SOHC Engine Mechanicaladelelsayed640No ratings yet

- 6a MercuryDocument50 pages6a MercuryDr. Centelha Mecânica NaúticaNo ratings yet

- Mercury Service ManualDocument51 pagesMercury Service ManualsamNo ratings yet

- Alpha Transom Assembly & ServiceDocument73 pagesAlpha Transom Assembly & ServiceDave Lamers100% (1)

- zf4hp24a (1)_bc0d61d7-0da7-488a-ac28-309020a337aaDocument4 pageszf4hp24a (1)_bc0d61d7-0da7-488a-ac28-309020a337aaleshchenko.maxym5No ratings yet

- Mitsubishi Lancer Evolution Viii 2003 2006 Engine MechanicalDocument6 pagesMitsubishi Lancer Evolution Viii 2003 2006 Engine Mechanicalbarbara100% (62)

- Section 4 - Driveline-AxleDocument171 pagesSection 4 - Driveline-AxleMTK2016No ratings yet

- Reparaturanleitung U Ersatzteilliste ZF25 Bis ZF45-1Document85 pagesReparaturanleitung U Ersatzteilliste ZF25 Bis ZF45-1Claudio CastioniNo ratings yet

- Alpha One Generation II Stern DriveDocument37 pagesAlpha One Generation II Stern DriveAndrea Ignacia Ibieta100% (2)

- Diesel Engine Bolt Torques (Metric & English) : 645 and 710 EnginesDocument2 pagesDiesel Engine Bolt Torques (Metric & English) : 645 and 710 EnginesRafael Dutil Luciana100% (1)

- Manual Transaxle: Precaution Components RepairDocument40 pagesManual Transaxle: Precaution Components RepairJames HavocNo ratings yet

- 19-20 Central Gear 1Document80 pages19-20 Central Gear 1Mamat salto100% (1)

- Pages From 2005 - Crossfire - SRT6 - Service - ManualDocument85 pagesPages From 2005 - Crossfire - SRT6 - Service - ManualJoeNo ratings yet

- MercjetDocument30 pagesMercjetBaxter LoachNo ratings yet

- pdf138 Zf4hp18flaDocument4 pagespdf138 Zf4hp18flaGustavo PiresNo ratings yet

- Braking System: GeneralDocument14 pagesBraking System: GeneralYann DaynatNo ratings yet

- 4 Litros y 242 - 258 PDFDocument62 pages4 Litros y 242 - 258 PDFCarlos Andres Guzman SalamancaNo ratings yet

- Gold Cup Series 6C, 7A & 8A: Denison HydraulicsDocument47 pagesGold Cup Series 6C, 7A & 8A: Denison Hydraulicslonsdale.88No ratings yet

- Luv Petrol PDFDocument442 pagesLuv Petrol PDFjaimeNo ratings yet

- WDBR50 en 00Document684 pagesWDBR50 en 00hubdiagNo ratings yet

- 407 MM CH64 PDFDocument66 pages407 MM CH64 PDFAnanta KumarNo ratings yet

- Front Axle Front Suspension: ColeDocument53 pagesFront Axle Front Suspension: ColeHarvian S. - ESSENTIA TINo ratings yet

- BERG: Chain and Belt DrivesDocument238 pagesBERG: Chain and Belt DriveszhangmpNo ratings yet

- 1K 2K Technician's GuideDocument68 pages1K 2K Technician's GuideJohn Michael100% (2)

- The Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017From EverandThe Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017No ratings yet

- The Complete Anchoring Handbook: Stay Put on Any Bottom in Any WeatherFrom EverandThe Complete Anchoring Handbook: Stay Put on Any Bottom in Any WeatherRating: 3 out of 5 stars3/5 (1)

- English-French and French-English dictionary of the motor car, cycle, and boatFrom EverandEnglish-French and French-English dictionary of the motor car, cycle, and boatNo ratings yet

- Bluewater Cruisers: A By-The-Numbers Compilation of Seaworthy, Offshore-Capable Fiberglass Monohull Production Sailboats by North American Designers: A Guide to Seaworthy, Offshore-Capable Monohull SailboatsFrom EverandBluewater Cruisers: A By-The-Numbers Compilation of Seaworthy, Offshore-Capable Fiberglass Monohull Production Sailboats by North American Designers: A Guide to Seaworthy, Offshore-Capable Monohull SailboatsRating: 5 out of 5 stars5/5 (2)

- Midsection: Section 5 - Clamp and Swivel BracketDocument8 pagesMidsection: Section 5 - Clamp and Swivel BracketpedroNo ratings yet

- Midsection: Section 5 - Clamp and Swivel BracketDocument8 pagesMidsection: Section 5 - Clamp and Swivel BracketpedroNo ratings yet

- Fuel System: Section 3B - CarburetorDocument31 pagesFuel System: Section 3B - CarburetorpedroNo ratings yet

- Attachments/Control Linkage: Section 7A - Throttle/Shift LinkageDocument10 pagesAttachments/Control Linkage: Section 7A - Throttle/Shift LinkagepedroNo ratings yet

- Controls: Section 7A - Throttle/Shift LinkageDocument16 pagesControls: Section 7A - Throttle/Shift LinkagepedroNo ratings yet

- Electrical: Section 2A - IgnitionDocument34 pagesElectrical: Section 2A - IgnitionpedroNo ratings yet

- Electrical: Section 2B - Charging & Starting SystemDocument25 pagesElectrical: Section 2B - Charging & Starting SystempedroNo ratings yet

- 5 BDocument60 pages5 BpedroNo ratings yet

- Electrical: Section 2B - Charging and Starting SystemDocument28 pagesElectrical: Section 2B - Charging and Starting SystempedroNo ratings yet

- Controls: Section 7B - Tiller HandleDocument11 pagesControls: Section 7B - Tiller HandlepedroNo ratings yet

- Mid-Section: Section 5A - Clamp/Swivel Brackets & Drive Shaft HousingDocument13 pagesMid-Section: Section 5A - Clamp/Swivel Brackets & Drive Shaft HousingpedroNo ratings yet

- 3 ADocument29 pages3 ApedroNo ratings yet

- Fuel System: Section 3A - Fuel PumpDocument19 pagesFuel System: Section 3A - Fuel PumppedroNo ratings yet

- 1 ADocument8 pages1 ApedroNo ratings yet

- Fuel System: Section 3B - EmissionsDocument8 pagesFuel System: Section 3B - EmissionspedroNo ratings yet

- CatalogoDocument10 pagesCatalogopedroNo ratings yet

- 1 en Act Part1 v8 0Document24 pages1 en Act Part1 v8 0Tara ReashaNo ratings yet

- Increase of Efficiency in Wireless Train Control Systems (Etcs Level 2) by The Use of Actual Packet-Oriented Transmission ConceptsDocument10 pagesIncrease of Efficiency in Wireless Train Control Systems (Etcs Level 2) by The Use of Actual Packet-Oriented Transmission ConceptsAnonymous HiQx2gFNo ratings yet

- Woodward Governor'S Troubleshooting and Rectification: A Case On Jamuna Fertilizer Company PerspectiveDocument0 pagesWoodward Governor'S Troubleshooting and Rectification: A Case On Jamuna Fertilizer Company PerspectiveSofiane HalimiNo ratings yet

- Chap 4 Molecular Velocity DistributionDocument22 pagesChap 4 Molecular Velocity Distribution李侑霖 LEE YULIN P46094163No ratings yet

- Chem 116 FinalsDocument2 pagesChem 116 FinalsAnna Belle AnonuevoNo ratings yet

- No Evidence For Contraindications To The Use of Propofol in Adults Allergic To Egg, Soy or PeanutDocument6 pagesNo Evidence For Contraindications To The Use of Propofol in Adults Allergic To Egg, Soy or PeanutMichelleValeriaFredyNo ratings yet

- Block JailbreakDocument2 pagesBlock JailbreakStephen EbodaNo ratings yet

- Total Hip Replacement Rehab ProtocolDocument11 pagesTotal Hip Replacement Rehab ProtocolnurulishtimalNo ratings yet

- SCALE DRAWING FORM 3 - Print - QuizizzDocument6 pagesSCALE DRAWING FORM 3 - Print - QuizizzMATHANA SOORIA A/P ADEYAH MoeNo ratings yet

- Software Testing (Introduction) : Alessandro Marchetto Fondazione Bruno Kessler - IRSTDocument26 pagesSoftware Testing (Introduction) : Alessandro Marchetto Fondazione Bruno Kessler - IRSTAnkur SinghNo ratings yet

- ResumeAdolphusBethune PDFDocument8 pagesResumeAdolphusBethune PDFJenniferNo ratings yet

- FRX Basics: Essential For SuccessDocument17 pagesFRX Basics: Essential For SuccessDamola SolankeNo ratings yet

- Script - Food BankDocument1 pageScript - Food BankRoxanneMeatsNo ratings yet

- Rongpur Foundary Limited: ContentsDocument18 pagesRongpur Foundary Limited: ContentsRazzak RazzNo ratings yet

- ProductsDocument6 pagesProductsaledangieNo ratings yet

- 166 194 1 PBDocument5 pages166 194 1 PBnovitalumintusariNo ratings yet

- 2007 5 Series (Except M5) EngDocument49 pages2007 5 Series (Except M5) EngNiki AndersonNo ratings yet

- Occlusal Onlay As Mordern RX PDFDocument13 pagesOcclusal Onlay As Mordern RX PDFSMART SMAR100% (1)

- Modelling and Simulation of A Map Aided Inertial Navigation Algorithm For Land VehiclesDocument12 pagesModelling and Simulation of A Map Aided Inertial Navigation Algorithm For Land VehiclesVũ Huy MừngNo ratings yet

- Self Taught Mastery The Ultimate Guide To Learning AnythingDocument89 pagesSelf Taught Mastery The Ultimate Guide To Learning AnythingGustavo SantosNo ratings yet

- Wa0023 PDFDocument32 pagesWa0023 PDFManisha GoonNo ratings yet

- Dissolution MethodsDocument114 pagesDissolution MethodsBusdev Catur DakwahNo ratings yet

- Bachelor of Medical Lab. Technology-BmltDocument33 pagesBachelor of Medical Lab. Technology-BmltSantosh KanelNo ratings yet

- BCP - CovidDocument26 pagesBCP - CovidSenthil KumarNo ratings yet

- Free PDF To Word Converter From Smartsoft PortableDocument2 pagesFree PDF To Word Converter From Smartsoft PortableBrandon0% (1)

- Company Profile ElwanyDocument6 pagesCompany Profile ElwanyRena YulianaNo ratings yet

- Transaction Confirmation Report Ro Ro 4e4d36Document1 pageTransaction Confirmation Report Ro Ro 4e4d36hndvkmdbwkNo ratings yet

- Are Edtech Valuations in A Bubble?: June 2021Document23 pagesAre Edtech Valuations in A Bubble?: June 2021S1626No ratings yet