WPQR - Form As Per EN PDF

WPQR - Form As Per EN PDF

Uploaded by

AnilCopyright:

Available Formats

WPQR - Form As Per EN PDF

WPQR - Form As Per EN PDF

Uploaded by

AnilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

WPQR - Form As Per EN PDF

WPQR - Form As Per EN PDF

Uploaded by

AnilCopyright:

Available Formats

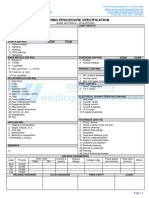

WELDING PROCEDURE QUALIFICATION RECORD (WPQR)

acc. to EN ISO 15614-1:2004

WPQR No: Examiner or examining body:

WPS No: Reference No:

Manufacturer: Code/Testing Standard:

Address: Date of welding:

Range of qualification

Type of joint and weld: Parent material group(s):

Weld metal thickness: Parent material thickness:

Throat thickness [mm]: Outside pipe diameter [mm]:

Mode of metal transfer: Welding positions:

Welding Size of Current Voltage Type of Wire feed Travel Heat Metal

Pass

process filler metal I U current speed speed v input h Transfer

[mm] [A] [V] +/-/~ [m/min] [mm/min] [kJ/mm] [kg/h]

Torch angle: Designation (Ref. No):

Filler metal class.: Trade name :

Filler metal type: Preheat temp. (oC):

Pulse/Plasma details: Tungsten electrode:

Freq., dwell time: Details of Backing:

Oscilation amplitude: Stand off distance [mm]:

Interpass temp. (oC): Time, temp. & method

Heat treatment: Heating/cooling rate:

Shielding gas: Ref standard:

Flow rate [l/min]: Group designation:

Other Information:

Date and signature:

(your name)

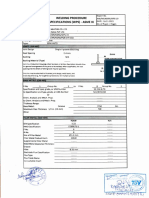

RECORD OF WELD TEST

WPQR No: CEV max:

WPS No: Welding positions:

Manufacturer: Joint preparation:

Welding process: Preparation and cleaning:

Material ref standard:

Base materials

Product form Specification Grp-no Size [mm] Sch. Thick. [mm] Dia. [mm]

Welded to:

Joint image Welding sequences & joint design

Welding parameters:

Welding Size of Current Type of Wire feed Travel Heat Metal

Voltage U

Pass process filler metal I current speed speed v input h Transfer

[mm] [A] [V] +/-/~ [m/min] [mm/min] [kJ/mm] [kg/h]

Torch angle: Designation (Ref. No):

Filler metal class.: Trade name :

Filler metal type: Preheat temp. (oC):

Pulse/Plasma details: Tungsten electrode:

Freq., dwell time: Details of Backing:

Oscilation amplitude: Stand off distance [mm]:

Interpass temp. (oC): Time, temp. & method

Heat treatment: Heating/cooling rate:

Shielding gas: Ref standard:

Flow rate [l/min]: Group designation:

Other Information:

Date and signature:

(your name)

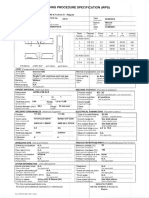

TEST RESULTS

WPQR No: Examiner or examining body:

WPS No: Reference No:

Manufacturer: Date of test:

Non destructive testing

Test method Requirements Results / Attachments / Sheet

Visual testing:

Penetrant testing:

Magnetic particle testing:

Radiographic testing:

Ultrasonic testing:

Macro-microscopic testing

Destructive testing

Tensile test

Reh/Rp1,0

Dimensions Temp. /Rp0,2

Rm Lo A Z Fracture

Specimen No

Position

[mm] [°C] [kN/mm²] [kN/mm²] [mm] [%] [%]

Appearance of fracture / remarks

Bend test (EN ISO 5173)

Type / Bend angle Elongation Former diameter

Results

Specimen No [°] [%] [mm]

Remarks

Impact test (EN ISO 9016)

Notch location / Type Size Temp. Values Average Remarks

Direction [°C] 1 2 3

Appearance of fracture

Hardness test (EN 9015-1&2) Macro-microscopic testing (EN ISO 17639

Type Load Measurements Location of measurements (sketch)

Date and signature:

(your name)

You might also like

- MIG Welding PWPSDocument1 pageMIG Welding PWPSelectronicmail2ughf6525No ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (3)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman50% (2)

- PWPS - ISO EN 15614-1 - DNV-GLDocument1 pagePWPS - ISO EN 15614-1 - DNV-GLvinoth100% (1)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin Cruz100% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections Community100% (1)

- Steps To Be Prepared A PWPS and PQRDocument9 pagesSteps To Be Prepared A PWPS and PQRAdit Nugraha100% (3)

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPQR PipeDocument3 pagesWPQR PipeThanasis KyrgiazoglouNo ratings yet

- MTC JSPLDocument2 pagesMTC JSPLAnil0% (1)

- En 10204 - 3.1 & 3.2Document1 pageEn 10204 - 3.1 & 3.2Anil100% (1)

- Cec 204 PracticalDocument35 pagesCec 204 PracticalPratibha Singh50% (2)

- Manufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoDocument2 pagesManufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoAMIT SHAHNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2Document2 pagesWelding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2phong NguyenduyNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints Qualifiedmurshid badshahNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauni100% (1)

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- WPS & PQR - 2021Document82 pagesWPS & PQR - 2021Subramanian R100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad Daniel100% (1)

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- WPQR SMAW EN-2 - 30mm (Under Modification)Document2 pagesWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil Sorcaru0% (1)

- Visual Inspection Report-BaiturDocument5 pagesVisual Inspection Report-BaiturBlusukan negeri100% (1)

- Contact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Document4 pagesContact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Maulik PatelNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WQT - 1 PDFDocument2 pagesWQT - 1 PDFLuttpi100% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro Sandeep100% (1)

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- WPS - 020Document15 pagesWPS - 020MAT-LION100% (2)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Radiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRDocument2 pagesRadiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRBalkishan Dyavanapelly100% (1)

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- En Iso 9606 1 ADocument2 pagesEn Iso 9606 1 AvitharvanNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Welding Coordination-Tasks & ResponsibilitiesDocument14 pagesWelding Coordination-Tasks & Responsibilitieskumaraswamy.kNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Consumable by AWS D5.1Document8 pagesConsumable by AWS D5.1Fuaz Sukarya Abu Fatih100% (1)

- Selection of Welding ConsumablesDocument13 pagesSelection of Welding ConsumablesbassemaeNo ratings yet

- Welcome To Preheat Calculation Program: C.brak@it - Fnt.hvu - NLDocument16 pagesWelcome To Preheat Calculation Program: C.brak@it - Fnt.hvu - NLKelvin Labarez100% (1)

- 488822949-WPQR-01-40mm-docxDocument10 pages488822949-WPQR-01-40mm-docxLeenNo ratings yet

- WPQRDocument3 pagesWPQRDimitris NikouNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- Quality Control Form: Pocedure Qualification Record Wps No: Date: PQR No: PreheatDocument3 pagesQuality Control Form: Pocedure Qualification Record Wps No: Date: PQR No: PreheatAlesol EquipmentNo ratings yet

- What We Will CoverDocument4 pagesWhat We Will CoverAnilNo ratings yet

- WPS ISO 15609 Template PDFDocument1 pageWPS ISO 15609 Template PDFAnil100% (1)

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document12 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Anil100% (1)

- WPS ISO 15609 Template PDFDocument1 pageWPS ISO 15609 Template PDFAnil100% (1)

- WPS As Per ISO 15609 Ref.Document3 pagesWPS As Per ISO 15609 Ref.AnilNo ratings yet

- List of En/Iso Standards: SR No Standard Description EditionDocument4 pagesList of En/Iso Standards: SR No Standard Description EditionAnilNo ratings yet

- Echo Water Pump Manual WP1000esT1T1E03 - 030813Document32 pagesEcho Water Pump Manual WP1000esT1T1E03 - 030813digitaltextNo ratings yet

- nUCLEAR ENG BASICSDocument77 pagesnUCLEAR ENG BASICSAsad SaeedNo ratings yet

- BYK L-AG1.2.2 Solvent-Borne Solvent-Free IndustrialCoatings enDocument3 pagesBYK L-AG1.2.2 Solvent-Borne Solvent-Free IndustrialCoatings enKinhNguyenNo ratings yet

- Magnesium JoiningDocument4 pagesMagnesium Joiningst_anbu9650No ratings yet

- PR 2 Group 5Document12 pagesPR 2 Group 5REYMUNDO ROSALESNo ratings yet

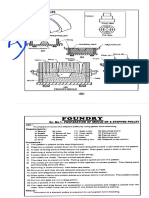

- Foundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyDocument4 pagesFoundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyAtshayaNo ratings yet

- Barangitao Einsteim Generalchemistry (Q2module9)Document7 pagesBarangitao Einsteim Generalchemistry (Q2module9)Hannah GwynethNo ratings yet

- What Are Magic RocksDocument2 pagesWhat Are Magic Rocksdatta sdNo ratings yet

- Z 15 LC Distacc - Cera Liq: Safety Data SheetDocument14 pagesZ 15 LC Distacc - Cera Liq: Safety Data Sheettitus gurningNo ratings yet

- Arenes Reactions ch12 2022 UpdatedDocument164 pagesArenes Reactions ch12 2022 UpdatedNizarNo ratings yet

- Chapter 4Document42 pagesChapter 4Patchole Alwan Tiarasi100% (1)

- EmulgatorenDocument1 pageEmulgatorenvalkira1No ratings yet

- Asme Sec Ix PT QW Article IVDocument139 pagesAsme Sec Ix PT QW Article IVjorgeNo ratings yet

- Lead NitrateDocument3 pagesLead NitrateSujinNo ratings yet

- AFA-Horti-Crop Production 7&8 LMDocument46 pagesAFA-Horti-Crop Production 7&8 LMCherryl Rivera Miro79% (28)

- Certificate Save Earth - ShruyuktaDocument10 pagesCertificate Save Earth - ShruyuktaNitesh KotianNo ratings yet

- 1195 Specification For Bitumen Mastic For FlooringDocument14 pages1195 Specification For Bitumen Mastic For FlooringRakesh RanjanNo ratings yet

- K.pratyusha Assst - Prof, NECDocument9 pagesK.pratyusha Assst - Prof, NECSaddaqatNo ratings yet

- RT L2 General Examination PaperDocument4 pagesRT L2 General Examination PaperdaddadNo ratings yet

- 10th Sci Eng April MayDocument34 pages10th Sci Eng April MaygursewaksinghmaahuNo ratings yet

- Bomba de Levante Electrica QST30Document12 pagesBomba de Levante Electrica QST30MrDon Rulox100% (3)

- Question Bank Chapter-1: Principles of Food ScienceDocument21 pagesQuestion Bank Chapter-1: Principles of Food ScienceHafsa JahanNo ratings yet

- RASCHIG-Ring DataDocument23 pagesRASCHIG-Ring Datalhphong021191No ratings yet

- UEMX3613 Lab 1Document4 pagesUEMX3613 Lab 1Wong Li XuanNo ratings yet

- 150Z Spec & AccessoriesDocument3 pages150Z Spec & Accessoriesshady yehiaNo ratings yet

- Piping Codes ListingDocument42 pagesPiping Codes ListingSamuel AnemeNo ratings yet

- Eme Notes1Document83 pagesEme Notes1Anonymous ZVRfhVaER75% (4)

- Sand Trap LouversDocument7 pagesSand Trap LouversAslam SageerNo ratings yet

- CBLM HogDocument79 pagesCBLM Hogream ruivivar100% (9)