QAP Format PDF

QAP Format PDF

Uploaded by

Sree VBroCopyright:

Available Formats

QAP Format PDF

QAP Format PDF

Uploaded by

Sree VBroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

QAP Format PDF

QAP Format PDF

Uploaded by

Sree VBroCopyright:

Available Formats

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.

2010

Document Title: Guidelines for preparing QAP during registration

RESEARCH DESIGNS & STANDARDS ORGANIZATION

Manaknagar, Lucknow – 226011

QM-RF-7.1-3

Guidelines for preparing QAP during registration

1.0 Amendment History:

S. No. Amendment Date Version Reasons for Amendment

1 28.09.2010 1.0 Updation to ISO 9001:2008

2 20.10.2010 1.1 Annexure (format) pages renumbered

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 1 of 2

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.2010

Document Title: Guidelines for preparing QAP during registration

2.0 Purpose:

These are guidelines for preparing the QAP for product.

3.0 Scope of Application:

Applicable for all vendors registered with QA Mechanical Directorate.

4.0 Details:

Guidelines for preparing QAP during registration is attached as Annexure.

5.0 Referenced Documents:

None

6.0 Referenced Documents of External Origin:

None

7.0 Associated Records:

None

8.0 Responsibility and Authority:

Activity Responsible Approver Supporting Consulted Informed

Creation, Director/I&L/ ED/QA(Mech) Staff of All Zonal office of

maintenance LKO QA(Mech) Dte. QA(Mech) Dte.

of this

document

Requirement Director/I&L/ ED/QA(Mech) Respective MR/ISO All Zonal office of

of deviation LKO AIE/I&L Cell QA(Mech) Dte.

from this

form

template.

9.0 Abbreviations:

QA Quality Assurance

ED/QA (Mech) Executive Director/ Quality Assurance (Mechanical)

RDSO Research Designs & Standards Organisation

M&C Metallurgical & Chemical

ARO Assistant Research Officer

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 2 of 2

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.2010

Document Title: Guidelines for preparing QAP during registration

Annexure

GUIDELINES FOR PREPARING QAP DURING

REGISTRATION

The QAP to be submitted by the vendor in triplicate (along with the application form for registration) shall

cover the following aspects –

SECTION A

ORGANISATION CHART

Organisational Chart, clearly indicating the Quality Control Set-up, role and responsibilities of key

personal.

SECTION B

QUALIFICATION / EXPERIENCE OF QC PERSONNEL

Part I: Details of qualification/experience of the quality control personnel specified in the

STR/Specification of RDSO of the items applied for approval/renewal

Requirement as per STR/Spec. Details of personnel employed

STR/Spec Experience Brief

Qualification

SN Para No Specified in Technical scope of

Specified in Name Dsgn. Experience

STR/ Spec. / Qualification responsi

Para Spec. / STR

Spec STR bilities

Part II: Qualification of other key personnel and the officials deployed in Quality Control Cell:

Technical Brief scope of

SN Name Designation Experience

Qualification responsibilities

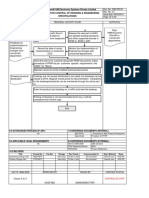

SECTION C

PROCESS FLOW CHART/DESCRIPTION OF

MANUFACTURING PROCESS

Part I: Process Flow Chart indicating process of manufacture for an individual product, with quality control

points.

Note:

i Process flow chart shall indicate all the operation involving manufacturing & testing of

product from raw material to finish product, including RDSO/RITES/Consignee

inspection/dispatch.

ii There should be separate flow chart for each item.

Part II: Brief description of different manufacturing process mentioned in flow chart :

a) Details of the manufacturing & testing process specially mentioned in the specification.

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 1 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.2010

Document Title: Guidelines for preparing QAP during registration

Requirement of manufacturing/testing Details of the process being

SN Para no of spec.

process as per spec installed/ follows

.

..

b) Brief details of the other manufacturing process.

SN Name of the manufacturing process Brief description

.

..

Part III: Brief description of ancillaries & additional units (if any):

i Whether all the facilities are available at a single location (or) multiple location –

ii In case of multiple location give details in following formats :

Whether unit is Whether unit

Mfg. processes

SN units Address covered under is ISO

details

factory license certified

SECTION D

Details of Sub-assemblies / components manufactured in-

house and outsourced.

Part I: Details of in-house manufactured (Components/sub-assemblies)

SN Item Name Drawing No

.

..

Part II: Details of components/Sub-assemblies purchased from RDSO approved primary / sublet

vendors

Item Name Is it a Primary Is it a Sublet

SN Drawing No Name of the source

Item of RDSO Item of RDSO

.

..

Part III : Details of items outsourced from other than RDSO approved items

Frequency of

review of the

SN Item Name Drawing No Name of the source

performance of

sublet source

.

..

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 2 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.2010

Document Title: Guidelines for preparing QAP during registration

SECTION E

INCOMING RAW MATERIAL & INPROCESS/FINAL

INSPECTION

Stage inspection detailing inspection procedure, inspection parameters, method of testing/test procedure

including sample sizes for destructive and non- destructive testing etc.

Part I : Incoming raw materials/parts/sub-assemblies

Acceptance Rejection &

Mode of Disposal

Sample Size limits/

Incoming Parameters inspection

& its Traceability

SN Product/ for /

Frequency of Reprocessed register no

assembly inspection equipmen Criteria

inspection / Scrapped

t used /specified

Value

.

..

Part II: In process inspection (of the product)

Acceptance

Sample Mode of Correcti

limits/ Traceab

Name of Size & its Parameter inspection Rejection ve &

ility

SN the Frequency s for / / Disposal preventi

register

process of inspection equipmen Criteria ve

no

inspection t used /specified action

Value

.

..

Part III: Final internal inspection of the product by the firm

Acceptance Rejection

Mode of disposal /

Sample Size limits/

Name of Parameters inspection

& its Traceability

SN the test/ for /

Frequency of Reprocessed register no

process inspection equipmen Criteria

inspection / Scrapped

t used /specified

Value

.

..

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 3 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.2010

Document Title: Guidelines for preparing QAP during registration

SECTION F

CALIBRATION OF TESTING MEASURING EQUIPMENT

Part I : Inhouse Testing facilities available for calibration with the firm

Traceability to

Frequency of

SN Name of Master Make Range national

calibration

standard

Part II : Personnel trained for inhouse calibration

SN Name Qualification Experience

Part III : Calibration plan for the items identified for specified calibration in STR/Specification

Ref. para of

Frequency Name of

Measuring STR/Spec. Range/ Inhouse/

SN Specified in agency if

Equipment STR/Spec./Para Accuracy Outsourced

STR/Spec outsourced

no.

.

..

Part IV : Calibration plan for other measuring equipment

Measuring Inhouse/

SN Range/ Accuracy Frequency Name of calibration agency

Equipment Outsourced

.

..

SECTION G

SYSTEM OF MAINTAINING THE DATE OF CUSTOMER

COMPLAINTS/WARRANTY FAILURES

Warranty failures/In-service failures reported from customers

Classification of failure

Brief details of complaint

Complaint received from

Failure analysis & cause

Date of joint inspection

deputed for collecting

Date of compliance in

Whether any person

C & P action taken

case of warranty

for joint inspection /

Date of report of

service failure/ Call

Warranty failure/ In

rejection / General

field sample

Consignee end

complaint

of failure

Letter no

complaints

SN

.

..

* The firm shall maintain a complaint register in the above format and the summary required to be

given during renewal

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 4 of 5

ISO9001:2008 Document No: QM-RF-7.1-3 Version No: 1.1 Date Effective: 21.10.2010

Document Title: Guidelines for preparing QAP during registration

SECTION - H

ANY ADDITIONAL INFORMATION FIRM WISH TO SUBMIT

The firm can furnish any other information which they wish to submit on items other than furnished in

annexure A to F.

Note :

1. QAP covering all the information as asked above under section ‘A’ to ‘F’ must be given in the form

of single document indicating name of the firm and page no. ‘x’ of ‘y’ on each page. Each page

should be signed by Quality Control in-charge. The approved QAP must be a controlled document

and a quality record of ISO Quality Control System of the vendor. A certificate to this effect shall

be provided along with the QAP by the vendor.

2. In case of the QAP for sublet items, it is to be provisionally approved by the sponsor and final

approval shall be given by the nominated officer for capability assessment.

3. One copy of the QAP, after final approval will be given back to the vendor for implementation

___________

AIE/QA(Mech) Director/ QA(Mech) Printed: 2010/09/30

Prepared By: Issued By: Page 5 of 5

You might also like

- Audit Plan - ISO 9001 - ISO 14001 - 2015Document8 pagesAudit Plan - ISO 9001 - ISO 14001 - 2015Corrosion Factory100% (2)

- Airline Domain KnowledgeDocument1 pageAirline Domain KnowledgeNadeem Ansari33% (3)

- SQCS Supplier Quality Confirmation Stage HVPT (High Volume Production TrialDocument33 pagesSQCS Supplier Quality Confirmation Stage HVPT (High Volume Production TrialClaudia PEÑANo ratings yet

- L1-CHE-PRO-001 - Standard Waiver ProcedureDocument16 pagesL1-CHE-PRO-001 - Standard Waiver ProcedureCK TangNo ratings yet

- QAP FormatDocument7 pagesQAP FormatRajesh Kumar JhaNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- Infineon BTS50025 1TEA DS V01 - 00 EN DataSheet v01 - 00 EN PDFDocument44 pagesInfineon BTS50025 1TEA DS V01 - 00 EN DataSheet v01 - 00 EN PDFAgustinNo ratings yet

- QM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During RegistrationDocument8 pagesQM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During Registrationsanjayde100% (1)

- Research Designs & Standards Organization: 1.0 Amendment HistoryDocument8 pagesResearch Designs & Standards Organization: 1.0 Amendment Historynvnrajesh123No ratings yet

- QM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorsDocument5 pagesQM-F-7.1-15 Ver.2.0 - Annual Quality Audit of VendorssanjaydeNo ratings yet

- QO-F-7.1-9 Ver. 1.0 Quality Audit Report ADocument27 pagesQO-F-7.1-9 Ver. 1.0 Quality Audit Report Apuri16No ratings yet

- Annexure M QAP (1)Document7 pagesAnnexure M QAP (1)Nirmal WiresNo ratings yet

- QSP 01 - Document Control ProcedureDocument7 pagesQSP 01 - Document Control ProcedureVivek VNo ratings yet

- Functional Specification FOR Level GaugeDocument11 pagesFunctional Specification FOR Level Gaugesumit kumarNo ratings yet

- Installation Qualification: Astam Health Care Pvt. LTD., Theda (H.P.)Document12 pagesInstallation Qualification: Astam Health Care Pvt. LTD., Theda (H.P.)Ranveer SinghNo ratings yet

- QSP 02 - Record Control ProcedureDocument5 pagesQSP 02 - Record Control ProcedureVivek V100% (1)

- Lesson Plan Information Sheet: Facilities, Equipment Inspections, and Training Evaluation Version Date: 07/30/2012Document44 pagesLesson Plan Information Sheet: Facilities, Equipment Inspections, and Training Evaluation Version Date: 07/30/2012AnandaMandalNo ratings yet

- Batch ReleaseDocument12 pagesBatch Releasemarkandey gupta67% (3)

- Toaz - Info 30 Inspection Amp Test Plan PRDocument10 pagesToaz - Info 30 Inspection Amp Test Plan PRtupuhinajiNo ratings yet

- SOP For SOPDocument3 pagesSOP For SOPtridentindiacompanyNo ratings yet

- 2 0 Project Quality Control PlanDocument24 pages2 0 Project Quality Control Planjohn doeNo ratings yet

- QO-D-7.1-4 Ver-2.0 - Change of Controlling Authority For SpecificationDocument2 pagesQO-D-7.1-4 Ver-2.0 - Change of Controlling Authority For SpecificationSaugata HalderNo ratings yet

- QO-D-7.1-7 Ver-3.0 Relaxation of Vendor Registration RequirementsDocument3 pagesQO-D-7.1-7 Ver-3.0 Relaxation of Vendor Registration RequirementssanjaydeNo ratings yet

- Prepared byDocument11 pagesPrepared byaboemadaldeenNo ratings yet

- Fish PlatesDocument14 pagesFish Platesanildondapati1No ratings yet

- 714 92 Certification Scheme For Basic Scaffolding Supervisor Rev 02 PDFDocument7 pages714 92 Certification Scheme For Basic Scaffolding Supervisor Rev 02 PDFvella thuraiNo ratings yet

- Design Qualification Protocol Cum Report For Lifting Positioning DeviceDocument12 pagesDesign Qualification Protocol Cum Report For Lifting Positioning Devicesantosh yadavNo ratings yet

- SAIC-A-2001 Rev 6 Review Procedure - Pressure Testing (All Applications)Document23 pagesSAIC-A-2001 Rev 6 Review Procedure - Pressure Testing (All Applications)pookkoya thangalNo ratings yet

- SI-WI-8.1-3 Ver 2.1 Work Instruction For Vendor ApprovalDocument14 pagesSI-WI-8.1-3 Ver 2.1 Work Instruction For Vendor ApprovalVKGNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- Generic RTM Template First Edition (Rev.1) - 17 Oct 2022Document94 pagesGeneric RTM Template First Edition (Rev.1) - 17 Oct 2022Argha BanerjeeNo ratings yet

- Metal LinersDocument13 pagesMetal Linersanildondapati1No ratings yet

- 2) Change ControlDocument4 pages2) Change ControlSagar DaundNo ratings yet

- Prepared byDocument11 pagesPrepared byaboemadaldeenNo ratings yet

- IxSQ Program DocumentDocument9 pagesIxSQ Program Documentdapp.70No ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- PQ Sifter2Document10 pagesPQ Sifter2Ranveer SinghNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- STR-ISEJ - Final - 19 - 09 - 2022Document10 pagesSTR-ISEJ - Final - 19 - 09 - 2022Preeti goswamiNo ratings yet

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- DFM-Kudgi BMDRMDocument20 pagesDFM-Kudgi BMDRMSathish MskNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta67% (3)

- QO-D-7.1-1 Ver-6.0 - Creation of Equipment, Item SpecificationDocument4 pagesQO-D-7.1-1 Ver-6.0 - Creation of Equipment, Item SpecificationSaugata HalderNo ratings yet

- QO-D-7.1-1 Ver-7.0 - Creation of New Specification For ItemsDocument3 pagesQO-D-7.1-1 Ver-7.0 - Creation of New Specification For ItemsSaugata HalderNo ratings yet

- PRC-0008 CurrentDocument50 pagesPRC-0008 CurrentbeyNo ratings yet

- A00F204e Audit Report - Stage 1Document5 pagesA00F204e Audit Report - Stage 1Md sameerNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- DocumetsDocument11 pagesDocumetsaboemadaldeenNo ratings yet

- Img 0004Document3 pagesImg 0004Shruti BhatiaNo ratings yet

- DRP001-OUF-PRO-Q-000-503 B1 NCR ProcedureDocument13 pagesDRP001-OUF-PRO-Q-000-503 B1 NCR ProcedureDaniel Martinez50% (2)

- SOP-03 Management Review MeetingsDocument3 pagesSOP-03 Management Review Meetingstrivesh100% (1)

- Site Audit Report - VeoliaDocument2 pagesSite Audit Report - VeoliaBALAKRISHANANNo ratings yet

- DocumetsDocument11 pagesDocumetsaboemadaldeenNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- Admin IQA Question:ChecklistDocument2 pagesAdmin IQA Question:Checklistvanessa bianca ortizNo ratings yet

- VAL-SV - E-0170-P TD WSM 450 Wave Solder Machine Rev 1 Gabriel 2 Dec 2016 (1) - Edy4decDocument19 pagesVAL-SV - E-0170-P TD WSM 450 Wave Solder Machine Rev 1 Gabriel 2 Dec 2016 (1) - Edy4decarumNo ratings yet

- FMLF-TNI-007B Rev.01 Audit Plan - SA1 - KAI Commuter Line Rev.01Document9 pagesFMLF-TNI-007B Rev.01 Audit Plan - SA1 - KAI Commuter Line Rev.01danieshusodoNo ratings yet

- FS 3210 - FS-Gas Flow ComputerDocument6 pagesFS 3210 - FS-Gas Flow ComputerBinu ManiNo ratings yet

- DocumetsDocument11 pagesDocumetsaboemadaldeenNo ratings yet

- Codification of Statements on Standards for Attestation Engagements, January 2018From EverandCodification of Statements on Standards for Attestation Engagements, January 2018No ratings yet

- ADRA Relay 103 ConfigDocument2 pagesADRA Relay 103 ConfigSree VBroNo ratings yet

- Bitlocker PDFDocument1 pageBitlocker PDFSree VBroNo ratings yet

- FDR AnalogDocument13 pagesFDR AnalogSree VBroNo ratings yet

- ProjectorDocument2 pagesProjectorSree VBroNo ratings yet

- Foreign Exchange Markets: Market StructureDocument9 pagesForeign Exchange Markets: Market StructureIbnu Mas'udNo ratings yet

- Tutorial Answers 6Document14 pagesTutorial Answers 6Thương Lê Như HoàiNo ratings yet

- Student Transfer PolicyDocument4 pagesStudent Transfer PolicyLasha ChakhvadzeNo ratings yet

- Best Implementation Practices With XML Publisher! Dibyajyoti Koch - A Blog On Oracle ApplicationDocument106 pagesBest Implementation Practices With XML Publisher! Dibyajyoti Koch - A Blog On Oracle ApplicationappsloaderNo ratings yet

- Department of Commerce: Faculty of Commerce A.M.U., Aligarh Syllabus For PH.D Admissions Test 2019-20Document2 pagesDepartment of Commerce: Faculty of Commerce A.M.U., Aligarh Syllabus For PH.D Admissions Test 2019-20Rameez AshrafNo ratings yet

- Define ServicesDocument15 pagesDefine ServicesShikha GuptaNo ratings yet

- 95010-MS Water ShutoffDocument12 pages95010-MS Water Shutoffhade wantoNo ratings yet

- Chp-4 Capital Project FundDocument8 pagesChp-4 Capital Project FundkasimNo ratings yet

- BSRIA - Blue Book (2009 Data Sets)Document109 pagesBSRIA - Blue Book (2009 Data Sets)Rui100% (1)

- Colleges of NUSTDocument70 pagesColleges of NUSTKamran786No ratings yet

- Full Leadership Development: Building The Vital Forces in OrganizationsDocument15 pagesFull Leadership Development: Building The Vital Forces in Organizationsmanishaamba7547No ratings yet

- IgrDocument79 pagesIgrIram Khan0% (1)

- Example CalculationsDocument4 pagesExample CalculationsElla BowlingNo ratings yet

- GMW 14670 - May 2007 - Organic Coat For Finish WheelsDocument4 pagesGMW 14670 - May 2007 - Organic Coat For Finish WheelsatulmkaushalNo ratings yet

- PdfjoinerDocument48 pagesPdfjoinerAnisha SapraNo ratings yet

- VTA28-G5: Fuel OptimizedDocument3 pagesVTA28-G5: Fuel OptimizedIslam Hemdan100% (1)

- Sinterformteile MIM EnglDocument12 pagesSinterformteile MIM EnglMatija BušićNo ratings yet

- StrengthsDocument2 pagesStrengthsAmol HingeNo ratings yet

- Citations For Images & QuotesDocument17 pagesCitations For Images & Quotesejidsf55No ratings yet

- Stratma-1-Case-Paper-Dimaano, Rian JayDocument6 pagesStratma-1-Case-Paper-Dimaano, Rian JayRJ DimaanoNo ratings yet

- Abend CodesDocument7 pagesAbend CodesLeon BonillaNo ratings yet

- 9999 9999 263 en-GBDocument292 pages9999 9999 263 en-GBSalih PehlivanNo ratings yet

- Certificate Good Standing 90601 202401046595918d23dd3Document1 pageCertificate Good Standing 90601 202401046595918d23dd3ma.loidarollorataNo ratings yet

- Sale Contract:: Cong Ty TNHH Mot Thanh Vien Thuong Mai Gia LocDocument2 pagesSale Contract:: Cong Ty TNHH Mot Thanh Vien Thuong Mai Gia LocNiron CompanyNo ratings yet

- Rotex ECV Actuator CatalogDocument12 pagesRotex ECV Actuator CatalogRahimNo ratings yet

- R2 Rotary CombineDocument3 pagesR2 Rotary Combinealaynnastaabx786No ratings yet

- Valtex InsuranceDocument24 pagesValtex InsuranceMike PhiriNo ratings yet

- Advantages of RmsDocument11 pagesAdvantages of RmsRafiullah AmanzaiNo ratings yet