Fired Boilers: 2.1 Design Principles

Fired Boilers: 2.1 Design Principles

Uploaded by

Eric TingCopyright:

Available Formats

Fired Boilers: 2.1 Design Principles

Fired Boilers: 2.1 Design Principles

Uploaded by

Eric TingOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fired Boilers: 2.1 Design Principles

Fired Boilers: 2.1 Design Principles

Uploaded by

Eric TingCopyright:

Available Formats

OG.04.

20576 1 Confidential

2. FIRED BOILERS

2.1 DESIGN PRINCIPLES

2.1.1 Steam and Water System of the Fired Boiler

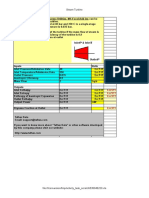

The “process flow diagram” of a fired steam boiler, Fig. 1 is divided into four main parts:

• the economiser,

• the steam drum,

• the evaporator,

• the superheater.

Typical conditions at

outlet evaporator 350 °C

3-10% Wt steam 23.5 Bar

97-90% Wt water

Temp °C

“ Steaming” 25.5 Bar 225 °C

ECO

185 °C A

140 °C Non steaming

27.5 Bar

Water Water-steam Steam Coil length

Economiser Evaporator Super heater

Steam Drum 50 t/h

Superheater

A 55 t/h water 1100 t/h water

1045 t/h steam

Economiser 1 t/h blow down

51 t/h Risers

Evaporator Downcomers

Fig. 1 “Process Flow Diagram” of a Natural Circulation Boiler 0009-0

The boiler is supplied with feed water by a boiler feed pump and it passes through the

economiser to the steam drum. The economiser is a tube bundle located in the coolest part of the

boiler’s flue gas side, just upstream of the flue gas stack. In the economiser, the feed water is

heated up to a temperature close to, or even equal to the saturation temperature of the boiler

water, Fig 1. Then the feed water enters the steam drum through a perforated distribution pipe

where it mixes with boiler water rising from the evaporator.

The mixed boiler water leaves the steam drum through the boiler downcomer pipes which feed

into the evaporator riser tubes via bottom headers or a bottom water drum. In the evaporator

tubes, heat is applied and the water partly vaporises on its return journey to the steam drum. The

flow of boiler water through the evaporator, in this case, is achieved by natural circulation.

In some boilers there may be two different evaporator sections equipped with riser tubes. Firstly

there is always a cooled radiant section where the heat from the burner flames is transferred by

radiation.

WUDG – Vol I. Energy and Power Systems – Boiler details

OG.04.20576 2 Confidential

Secondly, in some cases only, there is an evaporative convection bank, located as a vertical tube

bundle connecting the steam (top) and water (bottom) drums, Fig. 2.

Steam drum Saturated steam

to superheater

Blowdown

Boiler feed

Water

Section A-A Flue gas to stack

Boilerbank

A A Downcomers

Risers

Risers

Burners

Waterdrum

0022-0

Fig. 2 Horizontally Fired Bi-drum Boiler (Superheater Omitted)

From the top of the evaporator, the mixture of water and steam rises into the steam drum. Here,

the steam is separated from the water and dried by means of cyclones or baffle plates and

demisters. Some of the steam generated in the evaporator condenses in the steam drum in order

to heat the incoming feed water up to the saturation temperature of the boiler water.

The dried saturated steam leaves the steam drum through a pipe at the top and flows through the

superheater tube coils where it is heated up to its final process temperature. A constant steam

temperature at varying boiler loads is obtained by use of condensate spray desuperheating. To

reduce the metal temperature of the superheater outlet tubes, the superheater is often divided

into a primary and a secondary section with the desuperheater located in between, Fig. 3.

WUDG – Vol I. Energy and Power Systems – Boiler details

OG.04.20576 3 Confidential

Superheaters

Condensate injection

TC

Flue gas

Steam Drum

Blowdown

Economizer

Unheated

Section A -A A downcomer

Feed water

Furnace wall

Burners To Stack

Fig. 3 Horizontally Fired Single Drum Boiler 0005-0

2.1.2 Evaporator Sections

Fired boilers are available with different types of water circulation systems, for example natural

circulation, once-through, forced and assisted circulation. The natural circulation system,

however, is typical for the utility boilers used in Shell Group Refineries. Boilers with forced

circulation systems are discussed in Part II which deals with SIOP-type Waste Heat Boilers.

In natural circulation, the mixture of water and steam in the evaporator rises because it has a

lower density than the water supplied in the unheated or cooler downcomer tubes. In refinery

boilers, around 3% to 10% by mass of the circulated water is vaporised within the evaporator

tubes. In other words, the circulation ratio (CR), defined as the mass of water and steam

circulating to the mass of steam generated, is between 11 and 34. When the boiler load changes,

the steam generation rate changes and the CR adapts automatically to the prevailing conditions.

The objective of the boiler designer is to ensure that the evaporator tubes are effectively cooled

by nucleate boiling under all operating loads. This requires a well designed system for distribution

of water to each heated tube so that there is adequate cooling and there is no risk of overheating

of tubes due to film boiling, flow segregation, vapour locking, or flow starvation.

As mentioned above, there may be two different types of evaporator sections depending on the

type of boiler, these are the radiant section and the evaporative convection bank.

WUDG – Vol I. Energy and Power Systems – Boiler details

OG.04.20576 4 Confidential

Radiant Section

The walls of the radiant section are built from vertical riser tubes of 2 to 3 inches diameter. Boiler

water from the steam drum is supplied to the bottom of the riser tubes by the downcomer tubes

that are always cooler than the risers and in some boilers are unheated, Figs. 2, 3, 4.

4 x Corner Burners

Fireball

Fig. 4 Tangentially Fired Boiler 0609-0

In the radiant section, a number of (normally) horizontal firing burners are located in one of the

vertical walls, Fig. 2. In the corner- or tangentially-fired boiler, fuel burners are mounted in the four

corners of the radiant section, Fig. 4. In Group Refineries, boilers burn fuel oil and/or fuel gas and

part of the heat liberated within the radiant section is transferred by radiation to the riser tube

walls.

The non-vertical radiant section roof and floor tubes should have sufficient slope to allow proper

water circulation. Floor tubes are often protected from overheating by a layer of fire bricks.

Convective Evaporator

Figures 2 shows the general arrangements of a bi-drum boiler with horizontal burners. Here the

combustion gases have to turn near the radiant section rear wall opposite the burners and then

flow upwards and around an aerodynamic "nose" before reaching the convective evaporator

bank.

This tube bank is a bundle of convection tubes that are connected at the top to the steam drum

and at the bottom to the water drum. The tube bank consists of a number of steam raising riser

tubes located in front of a vertical partition baffle and a number of downcomer tubes located

behind this baffle. The boiler water enters the downcomer tubes at the top and flows by natural

WUDG – Vol I. Energy and Power Systems – Boiler details

OG.04.20576 5 Confidential

circulation through the water drum into the risers of both the boiler bank and the radiant section

walls.

A feature of the bi-drum design is that the downcomers are heated. This requires very careful

design in order to guarantee a positive downflow of non-vaporised water through the downcomers

at all boiler loads. There must be a clear-cut separation between the riser tubes with a high heat

load and the downcomer tubes with a lower heat load. Otherwise there would be a transition zone

with tubes that have no cooling flow. Such tubes would be overheated and would very soon fail.

The single-drum boiler, Figs. 3 and 4, uses unheated downcomers located outside of the flue gas

path. These consist of a small number of large diameter pipes which feed boiler water from the

steam drum to the bottom headers of the boiler wall tubes.

2.1.3 Steam Drum

Within the steam drum, the first stage of steam separation from the water takes place due to the

density difference between the two phases. Thereafter, the separation of entrained water droplets

from the steam is achieved by two basic methods:

• horizontal or vertical cyclones where centrifugal forces are used;

• baffles that direct the steam flow through a complete reversal of direction in the space above

the water level, thereby losing most of the entrained water.

In both cases a final separation stage is used consisting of a screen separator. This can be a

bank of closely-spaced corrugated plates that directs the steam through a tortuous path and

forces any remaining water droplets against the plates. Alternatively, the separator can be a

demister pad which collects the water droplets on its matrix of twisted wires. In both types of

separator, the water cannot be picked up again by the low velocity steam and it drains down into

the lower part of the drum.

2.1.4 Superheater

The job of the superheater is to take dry saturated steam from the steam drum and superheat it to

the required temperature. As a consequence, the superheater has the highest process and metal

temperatures in the boiler.

The superheater is located in the transition zone between the radiant section and the convection

bank, Fig. 2. It consists generally of a convection superheater (primary section) at the inlet of the

convection section and a radiant/convection superheater (secondary section) at the radiant

section exit.

The heat transfer film coefficient inside the superheater tubes is rather small, therefore the tube

metal temperature is rather high. There are several techniques used to minimise the maximum

wall temperature, for example by placing evaporative shield tubes in front of the secondary

superheater, Fig. 4 or by employing concurrent flow in the secondary superheater, Fig. 3.

WUDG – Vol I. Energy and Power Systems – Boiler details

OG.04.20576 6 Confidential

2.1.5 Economiser

The economiser is a convection tube bank located at the end of the flue gas path in the coolest

part of the boiler, Figs 3 and 4. To avoid the risk of acid corrosion from sulphur-bearing fuels, the

economiser water inlet temperature is nearly always controlled at or above 145°C.

In the bi-drum boiler, the economiser has a smaller duty than it does in a boiler with unheated

downcomers. In the latter case the economiser may be specially designed to produce a small

amount of steam (see "steaming eco" in Fig. 1).

2.1.6 Combustion Systems

For proper boiler design and operation, the following requirements must be met:

(a) The burners shall be designed and arranged such that:-

1. The radiant section walls are symmetrically loaded. This is to ensure an even distribution

of flue gases, circulating boiler water and steam generation;

2. At full boiler load (Maximum Continuous Rating) with one burner out of operation, flames

shall not impinge on the radiant section walls or on the superheater shield tubes;

3. Load variation from 30% to 110% of Maximum Continuous Rating (MCR) shall be

possible with all burners in operation and without changing fuel guns. This turndown can

only be realised with gas burners or with steam atomised oil burners.

(b) All critical parts of the radiant section shall be visible through an adequate number of

observation windows. This is to allow visual checking of combustion conditions both at the

burner throats and the flame extremities and also to verify that there is no flame

impingement on radiant section side wall tubes, rear wall tubes or superheater shield tubes.

(c) The burners shall be easily accessible and interchangeable.

(d) Boilers shall be forced draught, i.e. balanced draught boilers with both forced and induced

draught fans are not generally acceptable any more.

(e) The combustion air shall be supplied by a motor-driven forced draught fan complete with a

flow measuring venturi in the air intake stack. Automatic control of the air flow shall be by

variable inlet guide vanes or by electric variable speed motor drive.

WUDG – Vol I. Energy and Power Systems – Boiler details

You might also like

- Technical Query Sheet Format - Heat ExchangerNo ratings yetTechnical Query Sheet Format - Heat Exchanger5 pages

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002No ratings yetStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb0029 pages

- MODEL: PFTA 1500-4: Ratings & Performance DataNo ratings yetMODEL: PFTA 1500-4: Ratings & Performance Data4 pages

- Steel Duct Temp Estimation: Mineral Wool Thickness MMNo ratings yetSteel Duct Temp Estimation: Mineral Wool Thickness MM1 page

- Material Balance: Prepared By: Santunu Pathy (Chemical Engineering)No ratings yetMaterial Balance: Prepared By: Santunu Pathy (Chemical Engineering)27 pages

- 28-94-12 Gen Spec For Fabrication & Detailing of Pressure PartsNo ratings yet28-94-12 Gen Spec For Fabrication & Detailing of Pressure Parts17 pages

- Deaerator Fabrication BHPVL Tender SpecNo ratings yetDeaerator Fabrication BHPVL Tender Spec52 pages

- Feed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia PlantNo ratings yetFeed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia Plant10 pages

- Boilers, Boiler Fittings and Steam Offtakes: Academic Manual AC/18/03No ratings yetBoilers, Boiler Fittings and Steam Offtakes: Academic Manual AC/18/0368 pages

- Thermochemical Properties of Selected Substances at 298K and 1 AtmNo ratings yetThermochemical Properties of Selected Substances at 298K and 1 Atm1 page

- Atmospheric Air Ejector Liquid Ring Vacuum Pump Capacity Volumetric Flow Rate 707 Acfm Suction Pressure 15.6 Torr Mass Flow Rate 65.34 LBS/HRNo ratings yetAtmospheric Air Ejector Liquid Ring Vacuum Pump Capacity Volumetric Flow Rate 707 Acfm Suction Pressure 15.6 Torr Mass Flow Rate 65.34 LBS/HR1 page

- Desuperheater Boiler Feed Water RequirementNo ratings yetDesuperheater Boiler Feed Water Requirement2 pages

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsNo ratings yet414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si Units3 pages

- Design of Ejector Parameters and Geometr PDF100% (1)Design of Ejector Parameters and Geometr PDF6 pages

- LMOP Interactive Conversion Tool: Standard Cubic Feet Per Minute (SCFM)No ratings yetLMOP Interactive Conversion Tool: Standard Cubic Feet Per Minute (SCFM)6 pages

- Ok-Hydraulic Oil Flushing at Terminal AreaNo ratings yetOk-Hydraulic Oil Flushing at Terminal Area4 pages

- 3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 5No ratings yet3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 510 pages

- Ok-Venting & Charging of Nitrogen Accumulator at Terminal AreaNo ratings yetOk-Venting & Charging of Nitrogen Accumulator at Terminal Area3 pages

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andNo ratings yet4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun and3 pages

- 3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDFNo ratings yet3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDF3 pages

- Petronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow SchemesNo ratings yetPetronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow Schemes19 pages

- Petronastechnicalstandards: Pipe SupportsNo ratings yetPetronastechnicalstandards: Pipe Supports41 pages

- JHA Bolting & Unbolting & Servicing ActivitiesNo ratings yetJHA Bolting & Unbolting & Servicing Activities5 pages

- The Rusty Chronicle - Issue 10 December 2005No ratings yetThe Rusty Chronicle - Issue 10 December 200547 pages

- Hempadur Multi-Strength GF 3587910170 En-UsNo ratings yetHempadur Multi-Strength GF 3587910170 En-Us11 pages

- Science 8 8.3 Parts of A Simple CircuitNo ratings yetScience 8 8.3 Parts of A Simple Circuit16 pages

- Thermal Design Analysis of A Liquid Hydrogen VesselNo ratings yetThermal Design Analysis of A Liquid Hydrogen Vessel9 pages

- Pooshan Mahajan - Final Dissertation ReportNo ratings yetPooshan Mahajan - Final Dissertation Report42 pages

- Yu Et Al. - 2020 - Gradient Surgery For Multi-Task LearningNo ratings yetYu Et Al. - 2020 - Gradient Surgery For Multi-Task Learning27 pages

- Energies: Heating Performance Characteristics of High-Voltage PTC Heater For An Electric VehicleNo ratings yetEnergies: Heating Performance Characteristics of High-Voltage PTC Heater For An Electric Vehicle14 pages

- BEEE205L - ELECTRONIC-DEVICES-AND-CIRCUITS - TH - 1.0 - 67 - Electronic Devices and CircuitsNo ratings yetBEEE205L - ELECTRONIC-DEVICES-AND-CIRCUITS - TH - 1.0 - 67 - Electronic Devices and Circuits3 pages

- Karanijukar Hydroelectric Projectr - Iceland: The DamsNo ratings yetKaranijukar Hydroelectric Projectr - Iceland: The Dams4 pages

- 15-An Audit of The Orthodontic Treatment OutcomesNo ratings yet15-An Audit of The Orthodontic Treatment Outcomes6 pages

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002

- Steel Duct Temp Estimation: Mineral Wool Thickness MMSteel Duct Temp Estimation: Mineral Wool Thickness MM

- Material Balance: Prepared By: Santunu Pathy (Chemical Engineering)Material Balance: Prepared By: Santunu Pathy (Chemical Engineering)

- 28-94-12 Gen Spec For Fabrication & Detailing of Pressure Parts28-94-12 Gen Spec For Fabrication & Detailing of Pressure Parts

- Feed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia PlantFeed Gas Pre-Heater Efficiency Calculation and Enhancement of Ammonia Plant

- Boilers, Boiler Fittings and Steam Offtakes: Academic Manual AC/18/03Boilers, Boiler Fittings and Steam Offtakes: Academic Manual AC/18/03

- Thermochemical Properties of Selected Substances at 298K and 1 AtmThermochemical Properties of Selected Substances at 298K and 1 Atm

- Atmospheric Air Ejector Liquid Ring Vacuum Pump Capacity Volumetric Flow Rate 707 Acfm Suction Pressure 15.6 Torr Mass Flow Rate 65.34 LBS/HRAtmospheric Air Ejector Liquid Ring Vacuum Pump Capacity Volumetric Flow Rate 707 Acfm Suction Pressure 15.6 Torr Mass Flow Rate 65.34 LBS/HR

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si Units414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si Units

- LMOP Interactive Conversion Tool: Standard Cubic Feet Per Minute (SCFM)LMOP Interactive Conversion Tool: Standard Cubic Feet Per Minute (SCFM)

- 3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 53059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 5

- Ok-Venting & Charging of Nitrogen Accumulator at Terminal AreaOk-Venting & Charging of Nitrogen Accumulator at Terminal Area

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun and4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun and

- 3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDF3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDF

- Petronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow SchemesPetronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow Schemes

- Thermal Design Analysis of A Liquid Hydrogen VesselThermal Design Analysis of A Liquid Hydrogen Vessel

- Yu Et Al. - 2020 - Gradient Surgery For Multi-Task LearningYu Et Al. - 2020 - Gradient Surgery For Multi-Task Learning

- Energies: Heating Performance Characteristics of High-Voltage PTC Heater For An Electric VehicleEnergies: Heating Performance Characteristics of High-Voltage PTC Heater For An Electric Vehicle

- BEEE205L - ELECTRONIC-DEVICES-AND-CIRCUITS - TH - 1.0 - 67 - Electronic Devices and CircuitsBEEE205L - ELECTRONIC-DEVICES-AND-CIRCUITS - TH - 1.0 - 67 - Electronic Devices and Circuits

- Karanijukar Hydroelectric Projectr - Iceland: The DamsKaranijukar Hydroelectric Projectr - Iceland: The Dams