MP4012

MP4012

Uploaded by

Ba RownaCopyright:

Available Formats

MP4012

MP4012

Uploaded by

Ba RownaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MP4012

MP4012

Uploaded by

Ba RownaCopyright:

Available Formats

MP4012

High-Brightness, High-Current Accuracy

WLED Controller

The Future of Analog IC Technology

DESCRIPTION FEATURES

The MP4012 is a current mode controller • Constant-current WLED Controller

designed for driving the high brightness Light • 8V~55V Input Voltage

Emitting Diodes (LEDs) from extremely wide • Constant Frequency Mode Or Constant Off

input voltage 8V~55V. It can be used in Boost, Time Mode

Buck, Buck-boost and SEPIC topologies. • Programmable Switching Frequency or Off-

The MP4012 drives external MOSFET with Time

fixed frequency/constant off-time architecture to • Leading Edge Blanking for Current Sense

regulate the LED current, which is measured • High Frequency PWM Dimming and Analog

through an external current sense resistor. Its Dimming

feedback voltage can be adjusted by the • Output-to-Input Disconnect in Shutdown

external DC bias voltage. Mode

• Synchronization Function

The MP4012 can work in constant frequency

operation mode or constant off time mode. It • Programmable Over Voltage Protection

features programmable slop compensation that • Open Load Hiccup Mode Protection

can optimize the control loop regulation and • Short Load Hiccup Mode Protection

avoid sub harmonic oscillation. • Programmable Current Limit

• UVLO, Thermal Shutdown

The MP4012 implements high frequency PWM • Soft Start

Dimming with external disconnect MOSFET. It

• Available in 16-pin SOIC package

achieves analog dimming by adjusting the

feedback voltage. APPLICATIONS

The MP4012 has synchronizing function, which • LCD Backlighting Applications

makes multiple ICs synchronized to each other • DC/DC LED Controller Applications

by connecting SYNC pins together. • General Illumination

The MP4012 includes under-voltage lockout, • Industrial Lighting

over voltage protection, open and short hiccup • Automotive/ Decorative LED Lighting

mode protection, overload protection and All MPS parts are lead-free and adhere to the RoHS directive. For MPS green

status, please visit MPS website under Quality Assurance. “MPS” and “The

thermal protection to prevent damage in the Future of Analog IC Technology” are Registered Trademarks of Monolithic

case of fault condition. Power Systems, Inc.

The MP4012 is available in a 16-pin SOIC

package.

MP4012 Rev. 1.12 www.MonolithicPower.com 1

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

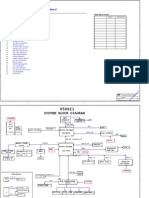

TYPICAL APPLICATION

L1 D1

VIN

C IN

R OVP1

M1 COUT

1 3 R OVP2

VIN GATE

CDD R SC

2 5

VDD CS

R CS

13 4

PWM DIM PWM GND

8 12

SYNC SYNC OVP

CCOMP

14

COMP FAULT

11 M2

CREF

10 16

REF FB

15 6

RFB

ISET SL

R SET2 R SET1 RSL

9 7

CL RT

R CL1

R CL2 RT

MP4012 Rev. 1.12 www.MonolithicPower.com 2

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

ORDERING INFORMATION

Part Number* Package Top Marking Free Air Temperature (TA)

MP4012DS SOIC16 MP4012 -40°C to +85°C

*For Tape & Reel, add suffix –Z (e.g. MP4012DS–Z);

For RoHS, compliant packaging, add suffix –LF (e.g. MP4012DS–LF–Z).

PACKAGE REFERENCE

TOP VIEW

VIN 1 16 FB

VDD 2 15 ISET

GATE 3 14 COMP

GND 4 13 PWM

CS 5 12 OVP

SL 6 11 FAULT

RT 7 10 REF

SYNC 8 9 CL

(4)

Thermal Resistance θJA θJC

ABSOLUTE MAXIMUM RATINGS (1)

VIN................................................ -0.5V to 60V SOIC16................................... 80 ...... 30... °C/W

VDD................................................-0.5V to 13.5V Notes:

VGATE, VFAULT, VPWM, VRT ..........-0.5V to VDD+0.3V 1) Exceeding these ratings may damage the device.

All Other Pins ...............................-0.3V to 6.5V 2) The maximum allowable power dissipation is a function of the

maximum junction temperature TJ (MAX), the junction-to-

Junction Temperature ...............................150°C ambient thermal resistance θJA, and the ambient temperature

Lead Temperature ....................................260°C TA. The maximum allowable continuous power dissipation at

(2) any ambient temperature is calculated by PD (MAX) = (TJ

Continuous Power Dissipation (TA = +25°C) (MAX)-TA)/θJA. Exceeding the maximum allowable power

dissipation will cause excessive die temperature, and the

............................................................ 1.6 W regulator will go into thermal shutdown. Internal thermal

(3) shutdown circuitry protects the device from permanent

Recommended Operating Conditions damage.

IN Supply Voltage VIN .........................8V to 55V 3) The device is not guaranteed to function outside of its

operating conditions.

Operating Junction Temp. (TJ).-40°C to +125°C 4) Measured on JESD51-7, 4-layer PCB.

MP4012 Rev. 1.12 www.MonolithicPower.com 3

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

ELECTRICAL CHARACTERISTICS

VIN =24V, TA = +25°C, unless otherwise noted.

Parameters Symbol Condition Min Typ Max Units

Operating Input Voltage VIN 8 55 V

VDD Voltage VVDD VIN ≥ 8V 7.25 7.75 8.15 V

Supply Current (Shutdown) ISD VPWM = 0V 0.8 1.0 mA

VDD Under Voltage Lockout UVLO VDD Rising 6.40 6.70 7.20 V

Under Voltage Lockout Hysteresis 500 mV

VDD(external) Connect external DC voltage 12 V

Internal Regulator

Reference Voltage VREF 1.218 1.243 1.268 V

0.1μF bypassed capacitor,

Reference Line Regulation VREFLINE 0 20 mV

IREF=0 VDD=7.25-12V

0.1μF bypassed capacitor,

Reference Load Regulation VREFLOAD 0 13 mV

IREF=0-500uA

PWM Dimming

PWM Low Threshold VPWMI-LO VPMWI Falling 0.8 V

PWM High Threshold VPWMI-HI VPMWI Rising 1.5 V

PWM Pull-down Resistance RPWM 50 100 150 kΩ

Gate

GATE Short Circuit Current ISOURCE VGATE=0V, VDD=7.75V 0.2 0.4 A

GATE Sink Current ISINK VGATE=7.75V, VDD=7.75V 0.4 0.7 A

GATE Output Rise Time TRISE CGATE=1nF, VDD=7.75V 50 85 ns

GATE Output Fall Time TFALL CGATE=1nF, VDD=7.75V 25 45 ns

Current Sense

Leading Edge Blanking TBLANK 100 250 ns

Delay to Output of COMP Comparator TDELAY1 200 ns

Delay to Output of CLIMIT Comparator TDELAY2 200 ns

Comparator Offset Voltage VOFFSET -25 25 mV

Oscillator

Oscillator Frequency fOSC1 RT=96kΩ 510 580 650 kHz

Oscillator Frequency fOSC2 RT=500kΩ 100 115 130 kHz

Maximum Duty Cycle DMAX 90 92 95 %

SYNC Input High VSYNCH 1.5 V

SYNC Input Low VSYNCL 0.8 V

SYNC Output Current ISYNC 16 μA

Slope Compensation

Current Source Out of SL Pin ISLOPE 0 95 μA

Internal Current Mirror Ratio GSLOPE ISLOPE=50μA, RSL=1kΩ 1.8 2.0 2.2

Over Voltage Protection

OVP Threshold VOVP-TH 4.60 4.95 5.30 V

OVP Threshold Hysteresis 500 mV

MP4012 Rev. 1.12 www.MonolithicPower.com 4

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

ELECTRICAL CHARACTERISTICS (continued)

VIN =24V, TA = +25°C, unless otherwise noted.

Parameters Symbol Condition Min Typ Max Units

Output Short Circuit Protection

Gain for Short Circuit Comparator GSC 1.8 2.0 2.2

Propagation time for short circuit ISET=200mV, FB=450mV,

TOFF 250 ns

detection FAULT goes form high to low

Fault Output Rise Time TRISE 330pF capacitor at FAULT pin 300 ns

Fault Output Fall Time TFALL 330pF capacitor at FAULT pin 200 ns

Short Circuit Detecting Blanking Time TSC_BT 500 950 ns

Current Source/Sink at COMP Pin for

IHICCUP 5.0 μA

Hiccup Mode Protection

Thermal Shutdown (5) 150 °C

Notes:

5) Guaranteed by design

MP4012 Rev. 1.12 www.MonolithicPower.com 5

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

TYPICAL PERFORMANCE CHARACTERISTICS

Performance waveforms are tested on the evaluation board of Typical Application Circuit

(Figure 5).

VIN = 64V, 12VIN=12V, ILED = 120mA, VLED=200V, 66WLEDs in series, TA = 25°C, Boost

Application, unless otherwise noted.

PWM Dimming Curve Efficiency vs. VIN

140 97.00

120 96.00

100 95.00

80 94.00

60 93.00

40 92.00

20 91.00

0 90.00

0 0.2 0.4 0.6 0.8 1 50 60 70 80 90

PWM DUTY VIN (V)

Steady State Soft Start PWM Dimming

VDS VDS VDS

100V/div. 100V/div. 100V/div.

VCOMP VCOMP VPWM

5V/div. 5V/div. 5V/div.

VOUT VOUT

100V/div. 100V/div. VOUT

100V/div.

IL ILED ILED

500mA/div. 100mA/div. 100mA/div.

OVP Recovery Short Load Recovery

VDS VDS

100V/div. 100V/div.

VCOMP VCOMP

5V/div. 5V/div.

VOUT VOUT

100V/div. 100V/div.

IL ILED

500mA/div. 100mA/div.

MP4012 Rev. 1.12 www.MonolithicPower.com 6

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

PIN FUNCTIONS

Pin # Name Pin Function

1 VIN Input Supply Pin. It is the input of internal linear regulator. Must be locally bypassed.

The Internal Linear Regulator Output Pin. VDD provides power supply for the external

2 VDD MOSFET gate driver and the internal control circuitry. Bypass VDD to GND with a 0.47μF

or larger ceramic capacitor.

3 GATE External MOSFET Gate Driver Pin.

4 GND Ground.

Switch Current Sense Input Pin. It is used to sense the current of the external power FET.

5 CS

It has a built-in 100ns (min) blanking time.

Slope Compensation Pin for current sense. Connecting a resistor between SL and GND

6 SL programs the slope compensation. In case of constant off-time mode of operation, slope

compensation is unnecessary and let this pin open.

Switching frequency/off-time set Pin. A resistor connected between this pin and

7 RT

GND/GATE sets the frequency/off-time.

Synchronization Pin. Connecting the multiple MP4012 SYNC pins together to achieve the

8 SYNC

synchronous working mode.

Current Limit Set Pin. This pin sets the external MOSFET current limit. The current limit

9 CL

can be set by using a resistor divider from the REF pin to GND.

Reference Output Pin. A 0.1μF or larger ceramic capacitor should be connected to bypass

10 REF

this pin to GND.

Fault Indication Output Pin. This pin is pulled down to GND in case of short circuit

11 FAULT condition or over voltage condition. It is also used to drive the external MOSFET to

disconnect the load from Vin for boost converter.

Over Voltage Protection Input Pin. Connect a resistor divider from output to this pin to

12 OVP program the OVP threshold. When the voltage of this pin reaches 4.95V, the MP4012

triggers over voltage protection.

PWM Dimming Input Pin. Apply a PWM signal on this pin for brightness control. The

13 PWM GATE is disabled when PWM signal is low. The GATE is enabled when PWM signal is

high.

Converter Compensation Pin. This pin is used to compensate the regulation control loop.

Connect a capacitor or a series RC network from COMP to GND. COMP pin is also used

14 COMP for hiccup timer. At IC start up, short protection or over voltage protection, the 5uA current

source charges COMP pint until 5V, and then the 5μA current source discharges COMP

voltage. IC is active when COMP voltage reduces to 1V.

LED Current Set Pin. Connect a resistor divider from REF pin to set the LED current

15 ISET reference. The analog dimming function can be achieved through adjusting the voltage on

ISET pin.

Feedback Input Pin. Connect a current sense resistor from FB to GND. The MP4012

16 FB regulates the voltage across the current sense resistor. The regulation voltage is set by

ISET pin.

MP4012 Rev. 1.12 www.MonolithicPower.com 7

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

OPERATION

The MP4012 drives external MOSFET with GATE pin sets the off time for CT mode. For

current mode architecture to regulate the LED constant switching frequency mode, MP4012

current, which is measured through an external includes a slope compensation section to ensure

current sense resistor. Figure 1 shows the the converter stability when duty cycle is greater

functional block diagram. than 0.5.

MP4012 employs a special circuit for regulating For synchronization, the SYNC pins of multiple

the internal power supply, which covers a wide MP4012 can be connected together, and may

input voltage from 8V to 55V. The 7.75V linear also be connected to the open drain output of a

regulator provides all the power for internal master clock. When connected in this manner,

circuits and external MOSFET gate drive energy. the oscillators will lock to the device with the

MP4012 has a 2% accurate 1.25V reference, highest operating frequency.

which is used as the reference for LED current.

MP4012 has two high-speed current comparators.

The reference is also used to set the current limit

One is used during normal operation, which

and over voltage threshold.

contains an internal 100ns blanking time to

MP4012 can be programmed as constant prevent the current spike from mis-triggering the

switching frequency (CF) or constant off time (CT) comparator. The other is used to limit the

operation. Connecting a resistor between RT pin maximum switch current, which is programmable

and GND sets the switching frequency for CF by connecting a resistor divider from REF pin.

mode. Connecting a resistor between RT pin and

REF BandGap Linear Regulator VIN

Thermal

POR POR

VDD POR

POR GATE

CL Reset -

+

FAULT

R Q

Slope

+ GND

CS Compensation LEB

QN R Hiccup Done

-

S

SL EN

- 5V

Q S +

OVP

FB PWM blank +

-

-

Hiccup Done SYNC

ISET +

Oscillator RT

2

POR

Hiccup Done

PWM

COMP Reset Hold

EN

Hiccup Hiccup Control 100k

POR

Figure 1—Functional Block Diagram

MP4012 Rev. 1.12 www.MonolithicPower.com 8

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

Start up

The start up process is shown in Figure 2. discharged to 1V. The high level Fault turns on

During start up, the COMP is charged to 5V first, the external disconnected MOSFET. The output

then it is discharged by an internal current source, current is regulated by the converter.

MP4012 is active until the COMP voltage is

VIN

VCC

5V

COMP

1V

Fault t hiccup

Iout

Figure 2—Start up Process

Analog Dimming can be hold by external capacitor. And the

Analog dimming can be accomplished by varying disconnecting MOSFET can prevent the output

the voltage at the ISET pin. This can be done voltage from being discharged, which helps to

either by using resistor divider from the REF pin achieve the high frequency PWM dimming with

or by applying an external DC voltage at the better linear dimming performance.

ISET pin.

Protection

PWM Dimming MP4012 includes short circuit protection and over

PWM dimming can be achieved by applying a voltage protection, If the fault conditions are

square wave signal on PWM pin. The PWM detected (either short circuit or open circuit), the

signal controls the internal error amplifier (EA), COMP pin is disconnected from the internal EA

FAULT output and GATE output. When the PWM and the Gate and Fault pins are pulled down to

signal is high, the GATE and FAULT pins are disable the LED controller, once the fault is

enabled, and the output of the EA is connected to remove, the COMP pin is charged by an internal

the external compensation network. So the LED current source until it reaches 5V, then the

current is regulated accurately. When the PWM COMP is discharged by an internal current

signal goes low, the GATE signal is disable. And source. When it reaches 1V, the current source is

the FAULT pin is pulled down to GND to turn off disconnected from COMP pin and the internal EA

the disconnecting MOSFET. Meanwhile the is connected to it, the Fault pin starts to go high

output of the EA is disconnected from the and the Gate pin is allowed to switch.

compensation network. Thus, the COMP voltage

MP4012 Rev. 1.12 www.MonolithicPower.com 9

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

The short circuit threshold current is internally set Short Load

to 200% of the steady state current. When the

output current becomes higher than the short

Short Load

circuit threshold after some delay, the short Output

Current

Recover Normal Current

circuit protection circuit is activated. See Figure

3. This allows the LED drive system auto-restart

in an accident short condition without having to 5V

reset the IC. COMP

1V

The open load protection is achieved through

detecting the OVP pin voltage. When open load

fault occurs, the output voltage rises as the Fault

Hiccup Time

output capacitor is still charged. The over voltage

protection turns off the MP4012 and takes

FAULT to GND when the OVP pin exceeds

4.95V. The converter turns on when the output Figure 3 — Hiccup Mode Short Load

voltage falls below the falling OVP threshold after Protection

a hiccup mode delay timer. MP4012 will repeat Open Load

Recover

the process until the open load fault is removed.

Open Load

OVP-H

Output OVP-L

When recovering from the open load condition, Voltage

Vout-normal

the output current might have some spike which

caused by the high output voltage, and trigger

the short load protection. But it can enter normal

5V

work mode when output voltage is close to the

COMP

1V

normal value. See Figure 4.

Output thiccup1 thiccup2 Normal Current

Current

Fault

t delay

Figure 4 — Open Load Protections

MP4012 Rev. 1.12 www.MonolithicPower.com 10

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

APPLICATION INFORMATION

Switching Frequency Set RCS is the current sense resistor which senses

An external resistor RT on RT pin can be used to the switch current. It is recommended that the

set the switching frequency through the following current sense resistor RCS can be chosen to

equation: provide 200mV current sense signal (also need

55.6 × 109 to take the power consumption into

fS = consideration).

RT

LED Current Set The RSL is the slope resistor on SL pin, its value

Choose an external current sense resistor (RFB) is limited by the maximum source current of SL

to set the LED current. pin. The minimum value of RSL is 25kΩ. 25kΩ –

VISET 50kΩ of slope resistor value is recommended.

RFB =

ILED

Current Limit

Here, VISET is LED current reference on ISET pin,

Current limit value can be set by a resistor divider

which is set by a resistor divider from REF pin to

from REF pin to GND. The voltage of CL can be

GND. It is recommended to add a 0.1uF ceramic

set as:

capacitor on ISET pin to avoid noise injection.

Over Voltage Protection Set 4.5 × RSC

VCL ≥ 1.2 × IPK × RCS +

Choose a voltage divider (ROVP1, ROVP2 in typical RSL

application) from the output to set the over

Here, IPK is peak current of inductor.

voltage protection threshold:

The VCL value should NOT be greater than

ROVP1 + ROVP2

VOVP = 4.95V × 450mV, NO capacitor should be connected

ROVP2 between CL pin and GND.

Slope Compensation Hiccup Timer

MP4012 employs peak current mode control If the fault conditions are detected (either short

which need slope compensation to avoid sub- circuit or open circuit), the COMP pin is

harmonic oscillation when duty cycle exceeds disconnected from the internal EA and the Gate

50%. To ensure current loop stability, choosing a and Fault pins are pulled down to disable the

slope compensation which is at least half of the LED controller. Once the fault condition is

down slope of inductor current. cleared, the COMP pin is charged by an internal

5μA current source until it reaches 5V, then the

The slope compensation is set by two external

COMP is discharged by an internal 5μA current

resistors RSL and RSC. The slope compensation

source. When it reaches 1V, the current source is

resistor can be calculated as:

disconnected from COMP pin and the internal EA

RSC = RSL × RCS × SDOWN × TS × 105 is reconnected to it, the Fault pin starts to go high

and the Gate pin is allowed to switch. The hiccup

SDOWN (A/μs) is the down slope of the inductor timer can be programmed by R -C network (RZ,

current. CZ in series and parallel with CC) on COMP pin.

VL

SDOWN = The delay time of Startup (Figure 2) can be

L

approximately calculated as:

Where VL is the voltage across the inductor, and

L is the inductor value. 9V

thiccup ≈ (CC + CZ)

TS is the switching period, which is set by the 5μA

frequency set resistor RT.

In most case the voltage drop on RZ can be

neglected.

MP4012 Rev. 1.12 www.MonolithicPower.com 11

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

The hiccup time of Over Current Protection (Figure

3) can be approximately calculated as:

9V-VCOMP

thiccup ≈ (CC + CZ)

5μA

Here, VCOMP is the voltage of COMP when fault

condition is detected.

The hiccup time of Over Voltage Protection (Figure

4) can be approximately calculated as:

tdelay ≈ 0.1× (ROVP1 + ROVP2) × CO

9V-VCOMP

thiccup1 ≈ (CC + CZ)

5μA

8V

thiccup2 ≈ (CC + CZ)

5μA

MP4012 Rev. 1.12 www.MonolithicPower.com 12

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

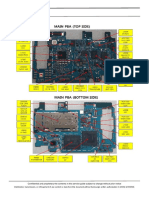

TYPICAL APPLIACTION CIRCUIT

LED+ LED-

L1 D2

US1G C13 C14 C15

R3 R21

C1 C2 M1 NC NC 953k

NC

C11

U1 C8 100nF M2

MP4012/SO16 R19

CN1 1 16 220pF

VIN FB

C3 R14 1k

8 R18

D1 C7 R22 R23 R24

7 VIN 2 15 4.3k 3.32 NC NC

NC VDD ISET REF NC

6 12VIN R13 9.09k R17

R10 R12 C10 NC

5 3 14

GATE COMP

C5 C12

4 NC 20 3k 33nF

3

R1 4 13 220pF

R6 GND PWM

PWM

2 1k

A-DIM

R4

1 C4 5 12

R2 R5 CS OVP

SYNC 20.5k 1nF 1.58k

R16 R20

C6 NC 6

SL FAULT

11 Fault 21.5k

2k

REF

R9 30k REF C9

7 10

RT REF

R8

560k R11

8 9 21k

SYNC CL R15

R7 NC 10k

Figure 5—MP4012 Boost Application

MP4012 Rev. 1.12 www.MonolithicPower.com 13

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

VIN L1 D1 LED 1+

CIN ROVP1

M1 C OUT

DC VDD 12V 1 3 R OVP2

VIN GATE

Supply 2

VDD CS

5

RSC

CDD

4

RCS

13 PWM

PWM DIM GND

8 12

SYNC SYNC OVP

CCOMP LED 1-

14

COMP FAULT

11 M2

CREF

10 16

REF FB

15 6 RFB

ISET SL

RSET2 RSET1 RSL

9 7

CL RT

RCL1

RCL2 RT

LED 2+

VIN

VDD 12V

PWM DIM

Block 2

SYNC

LED 2-

LED n+

VIN

VDD 12V

PWM DIM

Block n

SYNC

LED n-

Figure 6—Typical Application Circuit for TV LED Backlighting

MP4012 Rev. 1.12 www.MonolithicPower.com 14

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

VIN

L1 L2

D1

CIN

C1 ROVP1

COUT

1 3

M1 R OVP2

VIN GATE

RSC

2 5

VDD CS

CDD

4

RCS

13 PWM

PWM DIM GND

8 12

SYNC SYNC OVP

CCOMP M2

14 11

COMP FAULT

CREF

10 16

REF FB

15 6 RFB

ISET SL

RSET2 RSET1 RSL

9 7

CL RT

RCL1

RCL2 RT

Figure 7—MP4012 Sepic Application Circuit

MP4012 Rev. 1.12 www.MonolithicPower.com 15

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

Rsense

RG2

MP8110DS RG1

6 RG2 RG1 3

8

OUT2 VCC 7

COUT2 2 C VCC

NC SHDN 1

5

FB OUT1 GND 4

L1 D1

VIN

C IN

R OVP1

M1 COUT

MP4012DS

1 3 R OVP2

VIN GATE

CDD R SC

2 5

VDD CS

R CS

13 4

PWM DIM PWM GND

8 12

SYNC SYNC OVP

CCOMP

14 11

COMP FAULT

FB

CREF

10 16

REF FB

R FB

15 6

ISET SL

R SET2 R SET1 R SL

9 7

CL RT

R CL1

R CL2 RT

Figure8—MP4012 Buck-Boost Application Circuit

MP4012 Rev. 1.12 www.MonolithicPower.com 16

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

MP4012 ─ HIGH-VOLTAGE, HIGH-CURRENT ACCURACY WLED CONTROLLER

PACKAGE INFORMATION

SOIC16

0.386( 9.80)

0.394(10.00) 0.024(0.61) 0.050(1.27)

16 9

0.063

(1.60)

0.150 0.228

(3.80) (5.80) 0.213

PIN 1 ID 0.157 0.244 (5.40)

(4.00) (6.20)

1 8

TOP VIEW RECOMMENDED LAND PATTERN

0.053(1.35)

0.069(1.75)

SEATING PLANE 0.0075(0.19)

0.0098(0.25)

0.013(0.33) 0.050(1.27) 0.004(0.10)

0.020(0.51) BSC 0.010(0.25) SEE DETAIL "A"

FRONT VIEW SIDE VIEW

NOTE:

0.010(0.25)

x 45o

0.020(0.50) 1) CONTROL DIMENSION IS IN INCHES. DIMENSION IN

BRACKET IS IN MILLIMETERS.

GAUGE PLANE 2) PACKAGE LENGTH DOES NOT INCLUDE MOLD FLASH,

0.010(0.25) BSC PROTRUSIONS OR GATE BURRS.

3) PACKAGE WIDTH DOES NOT INCLUDE INTERLEAD FLASH

OR PROTRUSIONS.

4) LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING)

0.016(0.41) SHALL BE 0.004" INCHES MAX.

0o-8o 0.050(1.27) 5) DRAWING CONFORMS TO JEDEC MS-012, VARIATION AC.

6) DRAWING IS NOT TO SCALE.

DETAIL "A"

NOTICE: The information in this document is subject to change without notice. Please contact MPS for current specifications.

Users should warrant and guarantee that third party Intellectual Property rights are not infringed upon when integrating MPS

products into any application. MPS will not assume any legal responsibility for any said applications.

MP4012 Rev. 1.12 www.MonolithicPower.com 17

10/12/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

You might also like

- NM - B681 M/B Schematics Document: Amd R17M-P1-50/R18M-M2-60 Amd Fp5 Raven Ridge Soc With DdrivDocument53 pagesNM - B681 M/B Schematics Document: Amd R17M-P1-50/R18M-M2-60 Amd Fp5 Raven Ridge Soc With DdrivMike Otte0% (1)

- HP ActualTests HP2-H08 v2011-06-14 by NowerdaysDocument39 pagesHP ActualTests HP2-H08 v2011-06-14 by NowerdaysLai Jack0% (2)

- Sony KD-43X705F Chassis GN4UNDocument85 pagesSony KD-43X705F Chassis GN4UNJose Salazar CalderonNo ratings yet

- 6050a2386601 MB A02Document69 pages6050a2386601 MB A02tushar100% (1)

- Notebook Cce w52 Ecs U50si1 - 37gu50100-C1 IDocument32 pagesNotebook Cce w52 Ecs U50si1 - 37gu50100-C1 IRicardo GonçalvesNo ratings yet

- TC 32a400bDocument16 pagesTC 32a400bAlexandredeAguiar0% (1)

- Yamaha RX-V679 - HTR-6068 - RX-A750 PDFDocument181 pagesYamaha RX-V679 - HTR-6068 - RX-A750 PDFboroda241083% (6)

- Oscilador Booster Led Sony BD9397EFVDocument30 pagesOscilador Booster Led Sony BD9397EFVAntonio Chavez100% (1)

- SM G531H Tshoo 7Document34 pagesSM G531H Tshoo 7Carbajal Elí100% (1)

- Xbox One Controller Object Manual - CDocument13 pagesXbox One Controller Object Manual - Capi-537722323No ratings yet

- SM-J600F Common EPLIS 11Document45 pagesSM-J600F Common EPLIS 11Cosme Ronceros Mayon100% (1)

- HCD DX9Document70 pagesHCD DX9PALAGUERRA LENIS EVERNo ratings yet

- Stepper Motor Driver SpecificationDocument5 pagesStepper Motor Driver SpecificationMimo AbduNo ratings yet

- Samsung M105GDocument61 pagesSamsung M105GMerku MichoNo ratings yet

- Umc202hd Behringer Audio Interface Service ManualDocument16 pagesUmc202hd Behringer Audio Interface Service Manualmatheus.designer.graficoNo ratings yet

- Un32c5000 - 40C5000 - 46C5000 MainDocument16 pagesUn32c5000 - 40C5000 - 46C5000 Mainmj15015100% (1)

- Taramps® T500D X1 - R3 - 1 OhmsDocument3 pagesTaramps® T500D X1 - R3 - 1 OhmsFRANK NIELE DE OLIVEIRANo ratings yet

- XT2052 SilinktekDocument8 pagesXT2052 SilinktekRafael BrunoNo ratings yet

- Electrical Service Manual Original Manual Issue Date: 4/2010Document51 pagesElectrical Service Manual Original Manual Issue Date: 4/2010Marcyo LimaNo ratings yet

- Toshiba Satellite M300 M305 Quanta TE1 Laptop SchematicsDocument40 pagesToshiba Satellite M300 M305 Quanta TE1 Laptop SchematicsErick RodriguezNo ratings yet

- 2N5320 e 2N5322 DatasheetDocument3 pages2N5320 e 2N5322 DatasheetJosé ProençaNo ratings yet

- Micro Ondas NN-ST252W Original InglesDocument40 pagesMicro Ondas NN-ST252W Original InglesFernando FonsecaNo ratings yet

- H buster+HBTV 32L07HDDocument12 pagesH buster+HBTV 32L07HDronaldoNo ratings yet

- Power Sinus Black Novo Pciv011940Document1 pagePower Sinus Black Novo Pciv011940Elenilson Fernandes100% (1)

- Toshiba - STI 1422 - ECS R42IIX - 37GR42000-C0 PDFDocument39 pagesToshiba - STI 1422 - ECS R42IIX - 37GR42000-C0 PDFAnildo Eldivar De Oliveira Sarmento100% (1)

- Electro HelpDocument6 pagesElectro Helpjacks uaeNo ratings yet

- Samsung LN55C630K1FXZA Fast Track Guide (SM)Document4 pagesSamsung LN55C630K1FXZA Fast Track Guide (SM)Carlos OdilonNo ratings yet

- DX 1227Document11 pagesDX 1227Marcos Daniel Muñoz ToledoNo ratings yet

- Tabela Substituicao Ci SharpDocument3 pagesTabela Substituicao Ci Sharppepitito22100% (2)

- Samsung T27B750Document62 pagesSamsung T27B750boroda2410No ratings yet

- Manual de Serviço Técnico - Esquema Elétrico - Samsung Galaxy A7 - SM-A750CDocument41 pagesManual de Serviço Técnico - Esquema Elétrico - Samsung Galaxy A7 - SM-A750CRivaldoNo ratings yet

- Sony Chasis EX2M Training y TroubleshootingDocument45 pagesSony Chasis EX2M Training y TroubleshootingMario Sche100% (1)

- Sony KLV-40S200ADocument120 pagesSony KLV-40S200AClaudio BarrosNo ratings yet

- An7591 CircuitDocument1 pageAn7591 Circuitgheo23No ratings yet

- PcWare IPMH61G1 (DIAGRAMAS - COM.BR)Document30 pagesPcWare IPMH61G1 (DIAGRAMAS - COM.BR)silas estevam0% (1)

- Level 3 Repair: 8-1. Components LayoutDocument40 pagesLevel 3 Repair: 8-1. Components LayoutJerry Isaac Guerra HilarioNo ratings yet

- BN44-00249C Pwi1902ss (A) (U101 FSFM260, U1 Oz9938 - B1, U2 Fan431a)Document3 pagesBN44-00249C Pwi1902ss (A) (U101 FSFM260, U1 Oz9938 - B1, U2 Fan431a)Leandro PalmeiraNo ratings yet

- Mini Hi-Fi System: Service ManualDocument85 pagesMini Hi-Fi System: Service Manualthe profeNo ratings yet

- Lenovo D153aDocument51 pagesLenovo D153amarco100% (1)

- SM-J600F Common Tshoo 7 PDFDocument30 pagesSM-J600F Common Tshoo 7 PDFJhon OrtizNo ratings yet

- Diagnose Failure in T-CON BoardDocument7 pagesDiagnose Failure in T-CON Boardafonso juniorNo ratings yet

- CHINA HBTV-3201HD Chassis MSTAR 6U89 PDFDocument36 pagesCHINA HBTV-3201HD Chassis MSTAR 6U89 PDFIvanilto Martins da CruzNo ratings yet

- SM-G530BT Service Manual PDFDocument54 pagesSM-G530BT Service Manual PDFNelson Marcio0% (1)

- LG-Component Level Repair Y-Z Board IPMDocument3 pagesLG-Component Level Repair Y-Z Board IPMcaseysamNo ratings yet

- Aoz1212ai PDFDocument18 pagesAoz1212ai PDF060279No ratings yet

- LG 50pa4500-Sf - Ch. Pb21a PDFDocument48 pagesLG 50pa4500-Sf - Ch. Pb21a PDFJuliano ZanchiNo ratings yet

- BOE HV280WX2-270 Product Specification Rev. O 20141111Document24 pagesBOE HV280WX2-270 Product Specification Rev. O 20141111abir ahmedNo ratings yet

- Mobile Phone: Service ManualDocument129 pagesMobile Phone: Service Manualnatanael100% (1)

- TNPA5364 Power SupplyDocument1 pageTNPA5364 Power SupplyNicolas Gandolfo100% (1)

- Hex WorkshopDocument1 pageHex Workshopdiego742000100% (1)

- Esquema Elétrico Samsung SM-G531H Galaxy Gran Prime DuosDocument79 pagesEsquema Elétrico Samsung SM-G531H Galaxy Gran Prime DuosAlcides Prince100% (2)

- TV Plasma 50 LG 50pa4500 ManualDocument2 pagesTV Plasma 50 LG 50pa4500 ManualfrankNo ratings yet

- HP Pro 3330Document3 pagesHP Pro 3330عبد الجبار توفيق اللهNo ratings yet

- Sony Klv-22ex300 Klv-26ex300 Klv-32ex300 Klv-32ex400 Klv-40ex400 Klv-46ex400 B L RDocument67 pagesSony Klv-22ex300 Klv-26ex300 Klv-32ex300 Klv-32ex400 Klv-40ex400 Klv-46ex400 B L RDinuka MalinthaNo ratings yet

- NAE Commissioning GuideDocument101 pagesNAE Commissioning GuideDiego SantosNo ratings yet

- Schematic - Full Protocol Power Bank IP5358 - 2021!02!22Document1 pageSchematic - Full Protocol Power Bank IP5358 - 2021!02!22risirarocksNo ratings yet

- MP3391Document18 pagesMP3391Raul AlfaroNo ratings yet

- MP3391 r1.12Document18 pagesMP3391 r1.12Elsa Nababan EchaNo ratings yet

- MP3394 r1.07 PDFDocument17 pagesMP3394 r1.07 PDFAnonymous biMSzTyszNo ratings yet

- High Efficiency 3A, 16V, 500Khz Synchronous Step Down ConverterDocument15 pagesHigh Efficiency 3A, 16V, 500Khz Synchronous Step Down ConverterkadirovNo ratings yet

- Nu-Pulse, Half-Bridge and Push-Pull CCFL Inverter ControllerDocument12 pagesNu-Pulse, Half-Bridge and Push-Pull CCFL Inverter ControllerRicardo PiovanoNo ratings yet

- Paper1 PDFDocument18 pagesPaper1 PDFBa RownaNo ratings yet

- Paper1 PDFDocument18 pagesPaper1 PDFBa RownaNo ratings yet

- Paper1 PDFDocument18 pagesPaper1 PDFBa RownaNo ratings yet

- The Relationship Between Gender and Reading Comprehension at College LevelDocument18 pagesThe Relationship Between Gender and Reading Comprehension at College LevelBa RownaNo ratings yet

- Methodology: Profile of The Grade 7-Gold Learners of Dinapa National High SchoolDocument4 pagesMethodology: Profile of The Grade 7-Gold Learners of Dinapa National High SchoolRonaAñonuevoMelgarNo ratings yet

- 3rd QUARTER 7Document4 pages3rd QUARTER 7Ba RownaNo ratings yet

- 3 Quarterly Exam I. Reading and Literature A. Read The Following Poem and Answer The Questions That Follow. Chronicle of KingsDocument3 pages3 Quarterly Exam I. Reading and Literature A. Read The Following Poem and Answer The Questions That Follow. Chronicle of KingsBa RownaNo ratings yet

- Service Manual: Model Cd-Es770Document7 pagesService Manual: Model Cd-Es770Hernan Ortiz EnamoradoNo ratings yet

- 1606-XLE240E: POWER SUPPLY ESS 1PH 100-240VAC TO 24-28VDC 240W 10A Catalogue NoDocument2 pages1606-XLE240E: POWER SUPPLY ESS 1PH 100-240VAC TO 24-28VDC 240W 10A Catalogue NoA. Muhsin PamungkasNo ratings yet

- 555Document16 pages555vivekNo ratings yet

- Unit - Ii Single Phase and Three Phase Controlled RectifiersDocument36 pagesUnit - Ii Single Phase and Three Phase Controlled RectifiersSukhpal Singh100% (2)

- Electronic Voting MachineDocument70 pagesElectronic Voting MachineSalman Naveed67% (3)

- Basic RadioTheoryDocument146 pagesBasic RadioTheoryyrwn72t48hNo ratings yet

- Datasheet Katrhein 80010767-2019-r1.0Document9 pagesDatasheet Katrhein 80010767-2019-r1.0Amor MovimentoNo ratings yet

- Dell Client Peripherals Tel: 63346455 / 63341373 Fax: 63341615 / SMS/Whatsapp - 8777 6955 / Wechat ID - BizgramSG Bizgram Asia Pte Ltd (ROC :200903547Z) Shop & Collection : 1 Rochor Canal Road, # 05-49 / 50 Simlim Square, Singapore 188504.Document2 pagesDell Client Peripherals Tel: 63346455 / 63341373 Fax: 63341615 / SMS/Whatsapp - 8777 6955 / Wechat ID - BizgramSG Bizgram Asia Pte Ltd (ROC :200903547Z) Shop & Collection : 1 Rochor Canal Road, # 05-49 / 50 Simlim Square, Singapore 188504.Bizgram AsiaNo ratings yet

- 2.10 Phase Locked LoopDocument20 pages2.10 Phase Locked LoopRamya KarriNo ratings yet

- Interleaved Power Factor Correction (IPFC)Document21 pagesInterleaved Power Factor Correction (IPFC)Asad IqbalNo ratings yet

- Harmonic DS NetProcessor 9030-40Document3 pagesHarmonic DS NetProcessor 9030-40Samiul Islam KhanNo ratings yet

- Reset Equipo Sony HCD-GRX80Document1 pageReset Equipo Sony HCD-GRX80Javier Arias LuceroNo ratings yet

- Luvox f100Document30 pagesLuvox f100patrick-leefnuNo ratings yet

- Introduction To Power ElectronicsDocument29 pagesIntroduction To Power ElectronicsSiddarameshwara HNNo ratings yet

- PG - LLC Tentative List II-SemDocument27 pagesPG - LLC Tentative List II-Semprithviraj thoratNo ratings yet

- AES 145 - Improving Audio Performance of Microphones Using A Novel Approach Rev23Document8 pagesAES 145 - Improving Audio Performance of Microphones Using A Novel Approach Rev23Scribber BibberNo ratings yet

- AudioPrecision AN5 DigitalAudioMeasurementDocument203 pagesAudioPrecision AN5 DigitalAudioMeasurementAntonioCésarUtreraNo ratings yet

- MJE2955T (PNP) MJE3055T (NPN) Complementary Silicon Plastic Power TransistorsDocument4 pagesMJE2955T (PNP) MJE3055T (NPN) Complementary Silicon Plastic Power TransistorsRoyston fernandesNo ratings yet

- Lecture Notes From Peter Mclean, UTSDocument599 pagesLecture Notes From Peter Mclean, UTSMin Khine KyawNo ratings yet

- 7701 02 PDFDocument2 pages7701 02 PDFЕгор ПоляковNo ratings yet

- Communication Lab ReportDocument23 pagesCommunication Lab ReportBezawada VisaliNo ratings yet

- BU941 ChispaDocument9 pagesBU941 ChispaJoseph SantanaNo ratings yet

- UB1622FX ManualDocument16 pagesUB1622FX ManualMrTwist100% (1)

- H43 Hsd043i9w1Document22 pagesH43 Hsd043i9w1mvr89No ratings yet

- Automatic Start: DescriptionDocument2 pagesAutomatic Start: DescriptionMasnawiNo ratings yet

- OF FOR Room: Principles Designing A N Algorithm Acoustic Multichannel SimulationDocument6 pagesOF FOR Room: Principles Designing A N Algorithm Acoustic Multichannel SimulationJohn Chester GayetaNo ratings yet

- Ta Kmsw500Document24 pagesTa Kmsw500Orangzeb Khan0% (1)