Experiment #3: Fourier'S Law: The Effects of Varying Cross-Sectional Area

Uploaded by

Naeem AkramExperiment #3: Fourier'S Law: The Effects of Varying Cross-Sectional Area

Uploaded by

Naeem AkramMechanical Engineering Dep. Dr. Eng.

Kamel Guedri Heat Transfer: Lab Manual

EXPERIMENT #3

FOURIER'S LAW: THE EFFECTS OF VARYING CROSS-

SECTIONAL AREA

OBJECTIVE

The objective of this experiment is to understand how variable cross-sectional area

affects heat transfer by conduction.

INTRODUCTION

In some geometry, one-dimensional heat conduction occurs through a material with an

area that is not constant. In such cases, it is still necessary to be able to make accurate

predictions of heat transfer rates through the material. We will investigate the effect of

variable area on one-dimensional conduction in this experiment. Thermal conductivity of

the material will be known.

In Experiment #1 we have seen how to calculate the thermal conductivity of bar made of

the same material and uniform cross-section. Now, we would like to see how changes in

cross-sectional area affect heat transfer. In this experiment we will use the same brass test

bar, but instead of using the 25 mm diameter brass sample, we will use the brass sample

with a diameter of 13 mm.

THEORY

The equation that governs the heat flow is known as Fourier's Law, and in the axial

direction it is written as

(1)

where qx is the rate of heat conduction in the x-direction, k is the thermal conductivity of

the material, Ax is the cross-sectional area normal to the x-direction, and dT/dx is the

Experiment#3 Page 1/5

Mechanical Engineering Dep. Dr. Eng. Kamel Guedri Heat Transfer: Lab Manual

temperature gradient in the x-direction. The negative sign indicates that heat is

transferred in the direction of decreasing temperature.

For one dimensional heat flow, we can write the following:

(2)

where T1 is the temperature at the warmest point on the rod at the left end, TIL is the

interface temperature between the left end rod and the center rod, TIR is the interface

temperature between the center rod and the right end rod, T6 is the temperature at the

coolest point of the rod on the right, and the x's correspond to the appropriate distances.

The interface temperatures are sketched in Figure 1. Thermal conductivity k values

correspond to the appropriate materials. The first and third materials are brass. The center

section is stainless steel.

Figure 1: Determination of interface temperatures from the measured

temperature values.

Fourier’s Law (Eq. 1) states that the rate of heat transfer is proportional to the cross-

sectional area normal to the direction of heat flow. Since the outer surface is insulated,

Experiment#3 Page 2/5

Mechanical Engineering Dep. Dr. Eng. Kamel Guedri Heat Transfer: Lab Manual

the heat flow rate qx is the same for each section of the bar and since it is the same

material, the thermal conductivity k is assumed to be constant.

( ) ( ) ( ) (3)

where the subscripts h, s, and c denote the hot, sample, and cold segments of the bar,

respectively. In other words, the temperature gradient is inversely proportional to the

cross-sectional area. In this experiment, the hot and cold segments will have the same

cross-sectional area, which will differ from that of the sample inserted in between the two

segments.

Solving for the temperature gradient ratio in Eq. (3), we get

( )

(3)

( )

In this experiment you will compare the gradient ratio obtained from the plot of measured

temperatures vs. length (which is the experimental result) with the inverse ratio of the

two different areas (theoretical result).

APPARATUS

The apparatus for this experiment is the P.A. Hilton H940 Heat Conduction Unit,

described in Experiment #1. Figure 2 is a sketch of the apparatus used in this experiment.

It consists of three separable sections. The center section is removable. The left end

section contains a brass rod, and an electrical heater. The heat input to the heater can be

controlled and measured. The right end section is also made of brass, and contains a

hollowed out cavity with water tubes attached. Thus heat flows through from the heater

through the left end section, then through the center section, and finally through the right

end section to the water.

The entire apparatus is insulated so that one-dimensional heat conduction is well

approximated. The end sections contain instrumentation for measuring temperature. The

Experiment#3 Page 3/5

Mechanical Engineering Dep. Dr. Eng. Kamel Guedri Heat Transfer: Lab Manual

rods in the end sections have a diameter of 25 mm while the distance between adjacent

temperature measurements is 10 mm. The center section is 30 mm long.

Temperature versus length readings can be obtained with this apparatus. Several

experiments can be performed depending on what is used in the center section.

Figure 2: A schematic of the apparatus used to measure the effect of area on one

dimensional conduction.

PROCEDURE

1. Apply a very small amount (a drop) of thermal conducting paste to make a thin

layer on each side of the brass sample of 30 mm length and 13 mm diameter and

spread it uniformly.

2. Insert the sample into the test unit and allow cooling water to flow through the

test unit.

3. Connect the nine thermocouples in the appropriate order.

4. Adjust the power control knob to deliver 10 W to the test unit and allow the unit

to reach steady state (approximately 20 minutes).

5. Record the temperatures at each of the six thermocouples and the power input.

Experiment#3 Page 4/5

Mechanical Engineering Dep. Dr. Eng. Kamel Guedri Heat Transfer: Lab Manual

RESULTS

1. Plot the temperature profile along the length of the bar and determine the slopes

dT/dx of the best-fit lines for each distinct segment of the bar. Use these slopes to

compute the experimental value of the temperature gradient ratio and compare

that value to the theoretical value obtained from the cross-sectional areas.

2. Are the area and temperature gradient inversely proportional?

3. Discuss possible sources of error within the equipment or the assumptions made in

the theory.

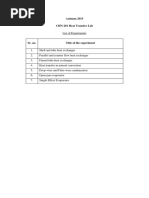

RAW DATA TABLES

Table 1: Raw Data for Experiment #3

q T1 T2 T3 T4 T5 T6

(W) (°C) (°C) (°C) (°C) (°C) (°C)

ASSIGNED READING:

Fundamentals of Heat and Mass Transfer; Incropera and DeWitt; pp. 3-6, pp. 58-67, App. A.

SAFETY GUIDELINES:

1. To avoid burns, do not touch any metal or plastic surfaces on the hot end of the

sample or test unit.

2. Avoid using a high cooling water flow to prevent disconnection of the hose from

the test unit.

3. Do not exceed 20 W power delivery under any circumstances, and do not allow

the temperature to go above 100 °C at any of the thermocouple locations.

4. Avoid using too much conducting paste as this may ‘fry’ the unit.

Experiment#3 Page 5/5

You might also like

- Heat Exchanger Model-Experiment Coursework100% (1)Heat Exchanger Model-Experiment Coursework27 pages

- Applications - Flash - Method Programa ComsolNo ratings yetApplications - Flash - Method Programa Comsol8 pages

- Shin-Nippon SLM-4000-5000 - Service Manual PDFNo ratings yetShin-Nippon SLM-4000-5000 - Service Manual PDF46 pages

- Dew Point - Thermo 2 Lab Report B1 (DEW POINT)No ratings yetDew Point - Thermo 2 Lab Report B1 (DEW POINT)5 pages

- Experiment #1: Fourier'S Law: Conduction Along A Simple Bar100% (2)Experiment #1: Fourier'S Law: Conduction Along A Simple Bar6 pages

- MAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeNo ratings yetMAK 302L Experiment 3 Extended Surface Heat Transfer 1. Purpose5 pages

- Experiment No. 4 Forced Convection Heat Transfer From A Flat Plate To Air 1No ratings yetExperiment No. 4 Forced Convection Heat Transfer From A Flat Plate To Air 13 pages

- Free/Force Convection H.T From Pinned&finnedNo ratings yetFree/Force Convection H.T From Pinned&finned14 pages

- Thermal Conductivity Apparatus: (Two Slab Guarded Hot Plate Method)No ratings yetThermal Conductivity Apparatus: (Two Slab Guarded Hot Plate Method)8 pages

- Combined Convection and Radiation Mechanical Engineering ThermoNo ratings yetCombined Convection and Radiation Mechanical Engineering Thermo15 pages

- Heat Exchangers: Heat Transfer, Lecture NotesNo ratings yetHeat Exchangers: Heat Transfer, Lecture Notes29 pages

- Expt. No. 3 Calibration of Temperature Measuring Device ExperimentNo ratings yetExpt. No. 3 Calibration of Temperature Measuring Device Experiment7 pages

- Measuring The Thermal Conductivity of CopperNo ratings yetMeasuring The Thermal Conductivity of Copper4 pages

- Experiment 11 - Thermal Conductivity of Insulating PowdersNo ratings yetExperiment 11 - Thermal Conductivity of Insulating Powders9 pages

- Me 409 Compressible Fluid Flow: Tutorial 3: Numerical Problems On One Dimensional Isentropic FlowNo ratings yetMe 409 Compressible Fluid Flow: Tutorial 3: Numerical Problems On One Dimensional Isentropic Flow8 pages

- Hydraulic Calculation For Bridge No.:-34 Mahesana-Taranga Gauge Conversion ProjectNo ratings yetHydraulic Calculation For Bridge No.:-34 Mahesana-Taranga Gauge Conversion Project3 pages

- Gas Solubility in Dilute Solutions: A Novel Molecular Thermodynamic PerspectiveNo ratings yetGas Solubility in Dilute Solutions: A Novel Molecular Thermodynamic Perspective17 pages

- Cambridge IGCSE: Additional Mathematics 0606/23No ratings yetCambridge IGCSE: Additional Mathematics 0606/2316 pages

- Problem Set No.1 Water and Wasterwater EngineeringNo ratings yetProblem Set No.1 Water and Wasterwater Engineering3 pages

- Likelihood Ratio Tests: Instructor: Songfeng ZhengNo ratings yetLikelihood Ratio Tests: Instructor: Songfeng Zheng9 pages

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingNo ratings yetSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - Blanking1 page

- Experiment #1: Fourier'S Law: Conduction Along A Simple BarExperiment #1: Fourier'S Law: Conduction Along A Simple Bar

- MAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeMAK 302L Experiment 3 Extended Surface Heat Transfer 1. Purpose

- Experiment No. 4 Forced Convection Heat Transfer From A Flat Plate To Air 1Experiment No. 4 Forced Convection Heat Transfer From A Flat Plate To Air 1

- Thermal Conductivity Apparatus: (Two Slab Guarded Hot Plate Method)Thermal Conductivity Apparatus: (Two Slab Guarded Hot Plate Method)

- Combined Convection and Radiation Mechanical Engineering ThermoCombined Convection and Radiation Mechanical Engineering Thermo

- Expt. No. 3 Calibration of Temperature Measuring Device ExperimentExpt. No. 3 Calibration of Temperature Measuring Device Experiment

- Experiment 11 - Thermal Conductivity of Insulating PowdersExperiment 11 - Thermal Conductivity of Insulating Powders

- Me 409 Compressible Fluid Flow: Tutorial 3: Numerical Problems On One Dimensional Isentropic FlowMe 409 Compressible Fluid Flow: Tutorial 3: Numerical Problems On One Dimensional Isentropic Flow

- Hydraulic Calculation For Bridge No.:-34 Mahesana-Taranga Gauge Conversion ProjectHydraulic Calculation For Bridge No.:-34 Mahesana-Taranga Gauge Conversion Project

- Gas Solubility in Dilute Solutions: A Novel Molecular Thermodynamic PerspectiveGas Solubility in Dilute Solutions: A Novel Molecular Thermodynamic Perspective

- Problem Set No.1 Water and Wasterwater EngineeringProblem Set No.1 Water and Wasterwater Engineering

- Likelihood Ratio Tests: Instructor: Songfeng ZhengLikelihood Ratio Tests: Instructor: Songfeng Zheng

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - Blanking