K Star

K Star

Uploaded by

v30003vCopyright:

Available Formats

K Star

K Star

Uploaded by

v30003vOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

K Star

K Star

Uploaded by

v30003vCopyright:

Available Formats

K-STAR

The K-STAR Carver is a two spindle table top mount, manual carving machine, that makes two copies of a pattern

per run. Each of the three K-STAR models can carve up to 10" in diameter (360°) or a 10" width in flat backed

(relief) carvings. The standard carving length is 24", with options to 48" or 60". All K-STAR's are powered by a

1/2 HP industrial electric motor, turning the spindles at 11,000 RPM through a belt and pulley system. This motor

provides the power and durability needed for tough carving applications. The electricity needed is a standard wall

outlet, as the motor runs on 115 volt, 60 HZ, 1 phase and draws only 6 amps. The twin spindles are counter

rotating to eliminate the side thrust forces generated by the cutters. This feature makes the K-STAR easy to use

and smooth through the cutting operation. These spindles are mounted on sealed high speed spindle bearings for

long life and zero maintenance.

Removable 24” long deck for relief carving

Cutter and styli kit consists of one size roughing bit, two

sizes of finishing bits and styli to match

Set of chuck and spindle wrenches

1/2 HP industrial motor, 115 volt, single phase, 60 Hz, 6

Amp

Dust Mask

WoodCarving Book

Options

48” or 60” Carving Lengths

The K-STAR carving machine is built for many years of hard use with a minimum of maintenance. The frame is

precisely built from heavy wall steel tubing and welded into one rigid unit. The carriage is built of several heavy

casted parts to insure durability, but the sliding weight balance system allows the user a light touch and easy to

operate feel. All the maintenance required is to clean the rails and carriage wheels regularly and grease pivot

bearings, worm and worm gears occasionally.

The pattern and work blanks are held in place by driving spur heads in the stationary front beam and a dead center

in the sliding rear beam. A worm and worm gear system attached to the front beam allows the pattern and work

blanks to turn in unison with a crank on the left side of the machine. This system allows the carver to get to

within .015 of an inch when the machine is properly leveled and bits are sharp.

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778

Email: info@terrco.com • Website: www.terrco.com

You might also like

- Atlas Lathe Operations ManualDocument5 pagesAtlas Lathe Operations Manualursind80% (5)

- MultiCam 6000-Series CNC PlasmaDocument10 pagesMultiCam 6000-Series CNC PlasmaDaniel AustinNo ratings yet

- Organic Farm Business Plan PDFDocument31 pagesOrganic Farm Business Plan PDFv30003v100% (1)

- Multi-Function CNC Lathe: FCL-18/25 SERIESDocument10 pagesMulti-Function CNC Lathe: FCL-18/25 SERIESBhargav SaiNo ratings yet

- Daniel Friederich - Varetaje InternoDocument1 pageDaniel Friederich - Varetaje Internov30003v100% (2)

- S01 Hydraulic Cylinders - TMKDocument8 pagesS01 Hydraulic Cylinders - TMKAnonymous iu95trpxNNo ratings yet

- E Translicer Cutter: Precision Slicing With Maximum VersatilityDocument2 pagesE Translicer Cutter: Precision Slicing With Maximum VersatilityLorenzo YapNo ratings yet

- MachinesDocument8 pagesMachinesrazanymNo ratings yet

- CM Knifed Stalks: Clarke Machine, IncDocument2 pagesCM Knifed Stalks: Clarke Machine, Incalecandro_90No ratings yet

- FalconDocument5 pagesFalconCristian MerlanoNo ratings yet

- Baxter 280M (08012017)Document2 pagesBaxter 280M (08012017)pc100xohmNo ratings yet

- Minimax Gen. - Rev01 - Jan18 - IngDocument136 pagesMinimax Gen. - Rev01 - Jan18 - IngWagner MenezesNo ratings yet

- GANESH VMC-2818: When Real Metal Removal Capability and Precision Machining Matters!!Document11 pagesGANESH VMC-2818: When Real Metal Removal Capability and Precision Machining Matters!!Arul SakthiNo ratings yet

- Coil To Coil Slitting LinesDocument2 pagesCoil To Coil Slitting LinesPurushottam KumarNo ratings yet

- Cantek - D405M 10 BrochureDocument2 pagesCantek - D405M 10 Brochurejacobortiz2245No ratings yet

- Tecnotest 5.2 Coring and Drilling PDFDocument8 pagesTecnotest 5.2 Coring and Drilling PDFRyan A.Y.No ratings yet

- Accurshear Brochure (Web 03 - 18) PDFDocument20 pagesAccurshear Brochure (Web 03 - 18) PDFFrancisco Javier Sandoval MoralesNo ratings yet

- CBI Annihilator ShredderDocument2 pagesCBI Annihilator ShredderHelmiNo ratings yet

- Wadkin AGSP SawbenchDocument6 pagesWadkin AGSP SawbenchmarkandersonsaNo ratings yet

- Durma IronworkerDocument9 pagesDurma IronworkerjasgxNo ratings yet

- 5d24d14660532aaa40364e62 - YOUJI YH21 60 OptDocument14 pages5d24d14660532aaa40364e62 - YOUJI YH21 60 Optadel allamNo ratings yet

- W-Series, Low Profile Hexagon Wrenches: Rigid Steel Design The Professional Low Profile SolutionDocument8 pagesW-Series, Low Profile Hexagon Wrenches: Rigid Steel Design The Professional Low Profile SolutionNHI_DKNo ratings yet

- Bridgeport XT630 5AX: Superior Machine Accuracy and RepeatabilityDocument8 pagesBridgeport XT630 5AX: Superior Machine Accuracy and RepeatabilityBow LinNo ratings yet

- Agma MachineDocument6 pagesAgma Machinemurali036No ratings yet

- Technical Specifications of Cutting and Spreading MachinesDocument49 pagesTechnical Specifications of Cutting and Spreading MachinesIndranil Saha50% (4)

- Oblique Type & Vertical CorrugationDocument4 pagesOblique Type & Vertical CorrugationAmmar AmmarNo ratings yet

- Uk Bro Eurotiller 240212Document4 pagesUk Bro Eurotiller 240212YuriyNo ratings yet

- ACE - Brochure Coil WindingDocument6 pagesACE - Brochure Coil WindingSikasep TeaNo ratings yet

- Acc-1224gx 2.5.24Document8 pagesAcc-1224gx 2.5.24Jerry LoeraNo ratings yet

- 2014 21 WoodturningDocument38 pages2014 21 WoodturningfrannetoNo ratings yet

- Metatech CatalougeDocument16 pagesMetatech CatalougeRohitShingadeNo ratings yet

- Hoffmann Picture Framing BrochureDocument6 pagesHoffmann Picture Framing BrochureomanpicNo ratings yet

- Compact, Portable, and Powerful Iron Roughneck For All Rig TypesDocument2 pagesCompact, Portable, and Powerful Iron Roughneck For All Rig Typesmohamed hamedNo ratings yet

- Fresadora FAMCO Model 100Document11 pagesFresadora FAMCO Model 100Carlos MedranoNo ratings yet

- SV Series CatalogoDocument8 pagesSV Series CatalogoEuler Vilca CarhuanchoNo ratings yet

- Jesse M BrochureDocument16 pagesJesse M Brochureavner127No ratings yet

- First MCV 1600 Katalogu 354Document13 pagesFirst MCV 1600 Katalogu 354鄭慶輝No ratings yet

- VX Series - English - 2019 09Document8 pagesVX Series - English - 2019 09Kiril AngelovNo ratings yet

- CUTTERMASTER Professional Catalog 2022 For WebDocument48 pagesCUTTERMASTER Professional Catalog 2022 For WebsalesNo ratings yet

- V-Turn 410 - 1000 DatasheetDocument3 pagesV-Turn 410 - 1000 Datasheetbhxdcj99qkNo ratings yet

- Sample Preparation: ConcreteDocument9 pagesSample Preparation: ConcreteJorge SanchezNo ratings yet

- FL Tool CatalogDocument82 pagesFL Tool CatalogJon Smart100% (2)

- Ik72t Pga Eng WebDocument2 pagesIk72t Pga Eng WebMazin MohammadNo ratings yet

- Multi CutDocument2 pagesMulti CutSEC MachinesNo ratings yet

- Axminster 05 - Engeneering Tools & Machinery - p141-p184Document44 pagesAxminster 05 - Engeneering Tools & Machinery - p141-p184Pierre799esNo ratings yet

- Quot. 070g Mos-23 Al Areen Projects Spacifications.Document22 pagesQuot. 070g Mos-23 Al Areen Projects Spacifications.Abuelgassim GarelnabiNo ratings yet

- Hydraulic Guillotine Shears: TypesDocument8 pagesHydraulic Guillotine Shears: TypesDominik RaczykNo ratings yet

- Darex E90 PlaquetteDocument2 pagesDarex E90 PlaquetteLaurent Enfield TricassesNo ratings yet

- Ybm 15 TDocument12 pagesYbm 15 Tdoanthanh_hpNo ratings yet

- 1632HS BrochureDocument2 pages1632HS BrochureMỸ VÕ HOÀNGNo ratings yet

- FSG 2A, 3A SeriesDocument16 pagesFSG 2A, 3A SeriessaehanksNo ratings yet

- JLH 36D10HL BrochureDocument2 pagesJLH 36D10HL BrochureOscar Dario Villada LopezNo ratings yet

- Nugent Engineering - Shear Grabs & BucketsDocument2 pagesNugent Engineering - Shear Grabs & BucketsseanfsmythNo ratings yet

- Sample Preparation: ConcreteDocument10 pagesSample Preparation: ConcreteKeith LaRueNo ratings yet

- Wheel MachiningDocument22 pagesWheel MachiningFuad IsmailNo ratings yet

- BB8100 Line Boring Machine E 2Document8 pagesBB8100 Line Boring Machine E 2azharzebNo ratings yet

- High Speed Precision Lathe TY-1845S: Main FeaturesDocument2 pagesHigh Speed Precision Lathe TY-1845S: Main FeaturesNand SavesNo ratings yet

- KO Lee A600 BrochureDocument6 pagesKO Lee A600 BrochureRobert W. Lamparter100% (1)

- Series: Ultra High Performance Vertical Machining CenterDocument20 pagesSeries: Ultra High Performance Vertical Machining Centerwataneta valveNo ratings yet

- Aeg Catalogue 2018 Emea WebDocument128 pagesAeg Catalogue 2018 Emea WebAli AlasadyNo ratings yet

- CNC MachineDocument12 pagesCNC MachineEr Faiyaz AhmedNo ratings yet

- Clausing Cylinder Grinders 2020-05-22Document20 pagesClausing Cylinder Grinders 2020-05-22Brayan PayanNo ratings yet

- Um GF Bracing DiscussionDocument215 pagesUm GF Bracing Discussionv30003vNo ratings yet

- 59 Valve Tweed 5wDocument40 pages59 Valve Tweed 5wv30003vNo ratings yet

- Ultra-Cheap Peizo Pickup For Acoustic Guitar Joebrown - Org.ukDocument3 pagesUltra-Cheap Peizo Pickup For Acoustic Guitar Joebrown - Org.ukv30003vNo ratings yet

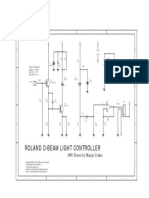

- D Beam ControllerDocument1 pageD Beam Controllerv30003vNo ratings yet

- Every New Daily Color CandleDocument4 pagesEvery New Daily Color Candlev30003vNo ratings yet

- AlforoDocument42 pagesAlforoKRISTIAN REY ALFORO (YanYan)No ratings yet

- Yamaha Energy Induction System.: Boots Bottles and ResonatorsDocument6 pagesYamaha Energy Induction System.: Boots Bottles and ResonatorsJoey GarciaNo ratings yet

- Npt56 Excitation SystemsDocument13 pagesNpt56 Excitation Systemsengmohsen.ramadanhotmail.comNo ratings yet

- Meyer-Pr Essner VolkswagenDocument15 pagesMeyer-Pr Essner Volkswagenharshal161987No ratings yet

- Automatic Transmission / Transaxle: Service DataDocument1 pageAutomatic Transmission / Transaxle: Service DataClodoaldo BiassioNo ratings yet

- Parts Guide Manual Di850Document173 pagesParts Guide Manual Di850Hugo Luis EscalanteNo ratings yet

- Sturmey Archer 8speedDocument2 pagesSturmey Archer 8speedLuvikas Maybe KscNo ratings yet

- Hagglund BV206D6 enDocument268 pagesHagglund BV206D6 enrodizianoNo ratings yet

- SEBF 8380 перечень инструкции по ремонту головокDocument8 pagesSEBF 8380 перечень инструкции по ремонту головокЕвгений АбрамовNo ratings yet

- Syllabus - Control of Electric DrivesDocument2 pagesSyllabus - Control of Electric DrivesTejas PanchalNo ratings yet

- 5-Axis CNC Machining Center With Moving Portal, Especially Designed For MillingDocument2 pages5-Axis CNC Machining Center With Moving Portal, Especially Designed For MillingElaine JohnsonNo ratings yet

- October/November 2013Document76 pagesOctober/November 2013Rodger Bland100% (3)

- Detroit Diesel Mbe 4000 Engine Epa04 Operators Manual DDC SVC Man 0056Document10 pagesDetroit Diesel Mbe 4000 Engine Epa04 Operators Manual DDC SVC Man 0056orpha100% (59)

- Polycab Pricelist Oct 2018Document5 pagesPolycab Pricelist Oct 2018Pranit RasailyNo ratings yet

- Bosch KE Jetronic OCRDocument27 pagesBosch KE Jetronic OCRbhanuka200983% (6)

- New KSB Spare Parts Service For Standard PumpsDocument2 pagesNew KSB Spare Parts Service For Standard PumpsayhamNo ratings yet

- Manual de Instalacin YORK YD Series MILLENIUMDocument36 pagesManual de Instalacin YORK YD Series MILLENIUMCésar NavaNo ratings yet

- Hot Startup Checklist1Document6 pagesHot Startup Checklist1Selva ManianNo ratings yet

- SC 360apr-Th-M 04 28-40Document13 pagesSC 360apr-Th-M 04 28-40Ivaylo IvanovNo ratings yet

- 3b. Winch Brochure 20170424 R1Document16 pages3b. Winch Brochure 20170424 R1Ardian20No ratings yet

- Summary Catalogue Ventilation SolutionsDocument50 pagesSummary Catalogue Ventilation SolutionsMalcom FredrickNo ratings yet

- Shop Manual: Wheel LoaderDocument174 pagesShop Manual: Wheel LoaderMinh Thuận QuangNo ratings yet

- Point Machine BSG 9Document59 pagesPoint Machine BSG 9Ade Indra Siboro100% (4)

- Unidad Hidráulica PF1019Document2 pagesUnidad Hidráulica PF1019Juan Carlos Lopez TorresNo ratings yet

- EG Graf High IdleDocument7 pagesEG Graf High IdleM WahyudiNo ratings yet

- Hangcha 2.0 - 2.5T RDocument298 pagesHangcha 2.0 - 2.5T RAdriana TamashiroNo ratings yet

- Engine Control System: SectionDocument501 pagesEngine Control System: SectionNilson MaldonadoNo ratings yet

- Thermal Analysis of I.CDocument19 pagesThermal Analysis of I.CSri KanthNo ratings yet

- Construction Industry Council: Development BureauDocument25 pagesConstruction Industry Council: Development BureauAlex Sandro Borges Pereira100% (1)