0 ratings0% found this document useful (0 votes)

116 viewsAskaynak - As B-248

Askaynak - As B-248

Uploaded by

Faraj KhalikovAS B-248 is a basic coated electrode used for welding rigidly restrained mass structures where high welding stresses are unavoidable. It has high resistance to cracking and produces smooth, easy to remove weld beads with excellent quality. It is suitable for vertical upwards welding at high speeds and has 125% metal recovery. The electrode can join steel parts to steel casts and is suitable for root passes and difficult welding positions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Askaynak - As B-248

Askaynak - As B-248

Uploaded by

Faraj Khalikov0 ratings0% found this document useful (0 votes)

116 views1 pageAS B-248 is a basic coated electrode used for welding rigidly restrained mass structures where high welding stresses are unavoidable. It has high resistance to cracking and produces smooth, easy to remove weld beads with excellent quality. It is suitable for vertical upwards welding at high speeds and has 125% metal recovery. The electrode can join steel parts to steel casts and is suitable for root passes and difficult welding positions.

Original Title

ASKAYNAK - AS B-248

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

AS B-248 is a basic coated electrode used for welding rigidly restrained mass structures where high welding stresses are unavoidable. It has high resistance to cracking and produces smooth, easy to remove weld beads with excellent quality. It is suitable for vertical upwards welding at high speeds and has 125% metal recovery. The electrode can join steel parts to steel casts and is suitable for root passes and difficult welding positions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

116 views1 pageAskaynak - As B-248

Askaynak - As B-248

Uploaded by

Faraj KhalikovAS B-248 is a basic coated electrode used for welding rigidly restrained mass structures where high welding stresses are unavoidable. It has high resistance to cracking and produces smooth, easy to remove weld beads with excellent quality. It is suitable for vertical upwards welding at high speeds and has 125% metal recovery. The electrode can join steel parts to steel casts and is suitable for root passes and difficult welding positions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

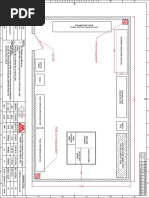

AS B - 248

AS B-248 is a basic coated electrode. It is used particularly to weld rigidly restrained mass structures

where high welding stresses are unavoidable. Weld metal has a high resistance to cracking. The slag is

easy to remove and it gives excellent quality, smooth weld beads. It is also suitable for welding in

vertical upwards position at a high welding speed. It has 125 % metal recovery.

Classification and Typical Weld Metal Composition (%)

EN ISO 2560-A : E 42 3 B 42 H10

AWS A5.1 : E 7018

2

C Si Mn Approvals

0.07 0.5 0.9

ABS : 3H10, 3Y

BV : 3Y HH

Mechanical Properties of the Weld Metal, Typical DNV : 3 YH10

GL : 3YH10

Yield Strength [ N/mm² ] : 460

LRS : 3m 3Ym H10

Tensile Strength [ N/mm² ] : 530

RINA : 3YH10

Elongation (L=5d) [ % ] : 28

RMRS : 3Y40HH

Impact (ISO-V) [ Joule ] : 110 @ - 30°C

80 @ - 40°C CE , DB , GOST , NAKS

SEPRO , TÜV

Applications Redrying Temp :

250-400°C / 2-3 hrs

AS B-248 is suitable for steel constructions and machines operating under dynamic forces. Ship

building, boiler and pressure vessel manufacturing and pipe connections are among its application

areas. It is recommended for the welding of high carbon, high strength low alloyed steels having high

(P) and (S) content; high strength ship's plate of A-, D- and E- quality and vessel plates of 17 Mn 4 and

19 Mn 5 type. AS B-248 can join steel parts to steel casts and can be used in welding of thick parts. It is

suitable for the root pass and welding in difficult positions. It gives excellent weld beads with high

impact strength values at subzero temperatures. It is also very suitable for welding of GALVANIZED

plates.

General Structural Steels : St 34, St 37, St 42, St 44, St 52, C 55, Ck 55

Fine Grained Steels : St E 255 - St E 420 ; WSt E 255 - WSt E 420

: TSt E 255 - TSt E 420

Pipe Materials : St E 240-7, St E 290-7, St E 360-7 ; 5LX42 - 5LX60

Boiler and Pressure Vessel Steels : HI, HII, HIII, 17 Mn 4, 19 Mn 6

Elevated Temperature Steels : St 35.8, St 45.8

Ship Plates : A-, D-, E-, AH-, DH-, EH

Cast Steels : GS-38, GS-45, GS-52, GS-60, GS-62

Current Type : [ DC (+) ] Welding Positions

Diameter Length Current Weight (100 pcs)

[ mm ] [ mm ] [A] [g]

2.00 300 50 - 80 1400

2.50 350 80 - 110 2420

3.25 350 110 - 145 3800

4.00 450 130 - 190 7230

5.00 450 190 - 245 10700

27

You might also like

- FhryhfhfhDocument3 pagesFhryhfhfhAffan AhmadNo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Cu CR 1 ZRDocument38 pagesCu CR 1 ZRDaško MedenjaškoNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- AWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Document2 pagesAWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Andre Brama AlvariNo ratings yet

- Datasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1Document3 pagesDatasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1bhuvandesignNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- CHW 50C6Document1 pageCHW 50C6scribdsonbaNo ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Standards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostDocument3 pagesStandards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostKhaled GamalNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'abdulazeez88No ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocument1 pageCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- Laser B 47: Chemical Composition of Weld Metal % (Typical) StandardsDocument1 pageLaser B 47: Chemical Composition of Weld Metal % (Typical) StandardsMartina KokanovicNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- Magmaweld - E7018 Data SheetDocument3 pagesMagmaweld - E7018 Data Sheetnenozx.zedan0% (1)

- European Steel and Alloy Grades: 10crmo9-10 (1.7380)Document3 pagesEuropean Steel and Alloy Grades: 10crmo9-10 (1.7380)farshid KarpasandNo ratings yet

- 21CrMoV5 11Document1 page21CrMoV5 11anubhavlNo ratings yet

- Böhler HL 51 T-MC: Seamless Cored WireDocument2 pagesBöhler HL 51 T-MC: Seamless Cored WireFer VFNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- Supercito E: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito E: MMA Electrodes C-MN and Low-Alloy Steelsantonio111aNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- Smaw Type: Lime-Basic E7018Document1 pageSmaw Type: Lime-Basic E7018Gummadi YugandharNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- Vautid100 EnglDocument1 pageVautid100 EnglRamona CrangasNo ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- ETC PH25S DRYDocument1 pageETC PH25S DRYstefavaNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-3 EN 10087Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-3 EN 10087farshid KarpasandNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- WPS 50-34Document2 pagesWPS 50-34rafaljt100% (1)

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 52crmov4: Steel GradeDocument2 pages52crmov4: Steel GradeHEMANTNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- Flux Cored Wires PDFDocument71 pagesFlux Cored Wires PDFCristian Camilo QuirogaNo ratings yet

- 20160401103255-1149 1151 C22e C22RDocument2 pages20160401103255-1149 1151 C22e C22RShabanali Omrani100% (1)

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- Catalog ElectrDocument140 pagesCatalog ElectrMocanu Stefan ArtemonNo ratings yet

- Seamless Fiux Fored Wire - Megafil250Document1 pageSeamless Fiux Fored Wire - Megafil250SungJun ParkNo ratings yet

- Smaw Type: Lime-Basic E7018-1Document1 pageSmaw Type: Lime-Basic E7018-1Gummadi YugandharNo ratings yet

- Revofil R308Lt: Stainless Filler MetalDocument1 pageRevofil R308Lt: Stainless Filler MetalAris WicaksonoNo ratings yet

- C60 - 1.0601 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocument2 pagesC60 - 1.0601 - SteelNumber - Chemical Composition, Equivalent, PropertiespopoNo ratings yet

- Bahra BusbarDocument4 pagesBahra BusbarSalmanNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- 7 - Gear Units - R..7 F..7 K..7 K..9 S..7 Spiroplan W S20070144 PDFDocument164 pages7 - Gear Units - R..7 F..7 K..7 K..9 S..7 Spiroplan W S20070144 PDFFaraj KhalikovNo ratings yet

- Swivel Flange CalculationsDocument45 pagesSwivel Flange CalculationsFaraj KhalikovNo ratings yet

- Stem Forged Steel ACME Screw Single Part Bonnet Bo Cast IronDocument18 pagesStem Forged Steel ACME Screw Single Part Bonnet Bo Cast IronFaraj KhalikovNo ratings yet

- ProblemsDocument1 pageProblemsFaraj KhalikovNo ratings yet

- API Gate Valve CalculationsDocument140 pagesAPI Gate Valve CalculationsFaraj KhalikovNo ratings yet

- Welding Stal 20 PDFDocument20 pagesWelding Stal 20 PDFFaraj KhalikovNo ratings yet

- Iso 6506-4 PDFDocument17 pagesIso 6506-4 PDFFaraj Khalikov100% (1)

- Solidworks 2001 Teachers Complete LessonsDocument267 pagesSolidworks 2001 Teachers Complete LessonsFaraj KhalikovNo ratings yet

- Low Noise General Purpose Audio Amplifiers: BC107 BC108Document7 pagesLow Noise General Purpose Audio Amplifiers: BC107 BC108Donato FormicolaNo ratings yet

- Avishkar New GuidelinesDocument47 pagesAvishkar New GuidelinesAkshay ShindeNo ratings yet

- Lashing ProcedureDocument97 pagesLashing Proceduregessy196867% (3)

- Main Differences Between BSPP or Gas, BSPT and NPT Threads - RedfluidDocument9 pagesMain Differences Between BSPP or Gas, BSPT and NPT Threads - Redfluidarnie786No ratings yet

- Hydraulic Room Drawing PDF 3 ColourDocument1 pageHydraulic Room Drawing PDF 3 ColourKarthii AjuNo ratings yet

- Orthman CultivatorDocument3 pagesOrthman CultivatorSandeep KumarNo ratings yet

- Hitachi Device Manager Software DatasheetDocument2 pagesHitachi Device Manager Software DatasheetSáriné Rasztik AngélaNo ratings yet

- Pptpresentationoncomputerfundamemntal 170831052423Document111 pagesPptpresentationoncomputerfundamemntal 170831052423yaswanthNo ratings yet

- Host Interface Manual: BS-200/BS-220/BS-120/BS-130Document41 pagesHost Interface Manual: BS-200/BS-220/BS-120/BS-130Daniel CortesNo ratings yet

- Modulo Monocristalino 144 Células 535W - Bel EnergyDocument2 pagesModulo Monocristalino 144 Células 535W - Bel EnergyRoswel Piovezani FerreiraNo ratings yet

- 1100kw Gqma CumminsDocument4 pages1100kw Gqma Cumminserick_fer_bNo ratings yet

- SnerDocument2 pagesSnerDwarffyNo ratings yet

- Biological Diversity Act IIDocument18 pagesBiological Diversity Act IISameer YeoleNo ratings yet

- Thermofluid Lab 2-Part ADocument19 pagesThermofluid Lab 2-Part ABennAbdullah0% (1)

- Hyperbolic Method For Prediction of Ultimate Primary Settlement of Clays Treated With Vertical DrainsDocument2 pagesHyperbolic Method For Prediction of Ultimate Primary Settlement of Clays Treated With Vertical DrainsSingDollarNo ratings yet

- Occupant Load CalculatorDocument2 pagesOccupant Load CalculatorDaryl Gomez TimatimNo ratings yet

- Shower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZDocument11 pagesShower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZNoman KhanNo ratings yet

- AccushieldDocument1 pageAccushieldkylegazeNo ratings yet

- Adobe Photoshop Lightroom 2.0 Keyboard Shortcuts (Windows) : Library Module View Menu File MenuDocument4 pagesAdobe Photoshop Lightroom 2.0 Keyboard Shortcuts (Windows) : Library Module View Menu File MenuLuvjoy ChokerNo ratings yet

- Review Article: Biomedical Applications of Shape Memory AlloysDocument16 pagesReview Article: Biomedical Applications of Shape Memory AlloysAntonela-Georgiana MateiNo ratings yet

- Ele454ch1 PDFDocument24 pagesEle454ch1 PDFhamza malikNo ratings yet

- MeanDocument3 pagesMeanPaulo SilvNo ratings yet

- 05BII Dike ProtectionDocument19 pages05BII Dike ProtectionAbd El-RaoufNo ratings yet

- Welcome To::: Class 12Document14 pagesWelcome To::: Class 12Amarnath K VNo ratings yet

- Jijesh K.PDocument2 pagesJijesh K.PnithinNo ratings yet

- Assignment No. 8Document3 pagesAssignment No. 8JC Dela CruzNo ratings yet

- Annual Tool Box Meeting PlanDocument3 pagesAnnual Tool Box Meeting Plantoxicity23No ratings yet

- NOT Handout PDFDocument91 pagesNOT Handout PDFRakesh KumarNo ratings yet