Mastertop 1230 Plus PDF

Mastertop 1230 Plus PDF

Uploaded by

Francois-Copyright:

Available Formats

Mastertop 1230 Plus PDF

Mastertop 1230 Plus PDF

Uploaded by

Francois-Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Mastertop 1230 Plus PDF

Mastertop 1230 Plus PDF

Uploaded by

Francois-Copyright:

Available Formats

Mastertop®1230Plus

Self smoothing solvent free, epoxy overlay system for concrete floors

• Beverage production - including soft drink

Description manufacturing

Mastertop®1230Plus is a single-coloured, self • Pharmaceutical areas, laboratories, clean rooms

smoothing, solvent free, epoxy overlay system • Engineering workshops and assembly lines

designed to provide continuous protection for • Showrooms, demonstration areas

concrete floors at thicknesses of between 2.0- • Industrial and commercial cold kitchens

4.0mm. For greater thicknesses contact BASF • Retail

Construction Chemicals SA Technical department. • Schools, hospitals and hotels

The cured material produces a dense, colourful,

glossy surface. NB: This indicates examples only and does not

constitute a full and comprehensive list. For further

The product has also been successfully applied to information on application possibilities contact BASF

glazed and terrazzo tiles, steel and timber. For Construction Chemicals SA.

applications other than to concrete, please contact

your BASF Construction Chemicals SA Advantages

representative. • Excellent wear and abrasion resistance

• Easily applied

• Smooth high-gloss finish for hygienic applications

Primary uses

• Easily cleaned

Mastertop®1230Plus has excellent wear and

• Good general chemical resistance

abrasion resistance for floors subjected to high

• Colourful - improves the working environment

volume traffic.

Packaging

The smooth, ultra-dense and high gloss finish is

Mastertop®1230Plus is supplied as a 38kg multi

ideal for situations requiring a hygienic, easily

component pack (including colour pack).

cleaned surface.

Colours

The product offers good general resistance to a

Available in standard colours. Contact BASF

broad spectrum of chemical corrosives, but as in all

Construction Chemicals SA.

cases of chemical exposure a full analysis of

operating conditions is required, followed by

reference to chemical resistance data, to ensure

product suitability.

Mastertop®1230Plus may be applied in the following

industries:

• Food production and processing

Mastertop®1230Plus

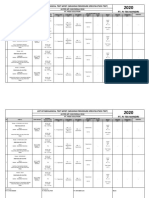

Typical physical properties∗

Laboratory tests carried out at 25°C • It is essential to seal the concrete surface prior

Pot Life 35 mins to the application of Mastertop®1230Plus, to

Cure Time 15 hours prevent air from the substrate rising through the

Compressive strength (ASTM C579-

Mastertop®1230Plus while it sets.

93) 1 day 35 N/mm²

3 days 60 N/mm² • Seal the concrete with Mastertop®1200Resin

14 days 75 N/mm² diluted with 0.5 litres Solvent No2 (if required or

Density of mixed material 1.79kg/m³ permissible).

Flexural strength (BS 6319 Part 3) 30 N/mm²

• Pour the base and reactor components into a

Tensile strength (BS 6319 Part 7) 17 N/mm²

∗ suitable mixing vessel, and add the Solvent No2.

Properties listed are only for guidance and are not a guarantee

of performance Using a slow speed drill and paddle, mix the

components for a minimum of 1 minute, or until

Hygiene all striations have disappeared.

Taint tests carried out on Mastertop®1230Plus at the • Apply the mixed sealer to the prepared dust free

Leatherhead Food Research Association under surface with a medium pile roller, at the rate of 6-

artificially severe conditions showed that the risks of 8m² per litre depending on the surface profile of

tainting foodstuffs are minimal during and after the concrete.

complete cure. • If the concrete is very absorbent, a single

application may not be sufficient and a second

Application procedure coat may be required to ensure the surface is

Surface preparation: completely sealed.

The preferred method for surface preparation of • Allow the sealer to become tack- free before

concrete is captive blasting, which gives a well applying the Mastertop®1230Plus.

prepared laitance free, vacuum cleaned surface.

Mixing

®

Prior to application Mastertop 1230Plus should be Pour the reactor into the base; add the colour pack

stored under cover in an air-conditioned environment and, using a suitable drill and paddle, mix the

and protected from extremes of temperature which components together until a uniform colour is

may cause inconsistent workability, finish and cure achieved. Mixing should be for a minimum of one

times for the mixed material. minute. Pour the mixed components into a suitable

mixing vessel of 30 litre capacity.

Sealing: With the mixer still running, slowly add the 1230Plus

Damaged or deeply pitted areas can be repaired and Aggregate and mix for 2 minutes or until the mixture

levelled using Mastertop®1230Plus filled out, if is smooth and free of lumps.

required, with additional aggregate. Always keep the mixing time the same for all

batches, to ensure a uniform colour when the

product is applied.

Mastertop®1230Plus

Laying

Pour the mixed material onto the primed and sealed Storage

surface and spread to the required thickness using a Store under cover, out of direct sunlight and protect

pin rake, notched trowel or steel float. As soon as from extremes of temperatures.

the material has been spread to the required level, Failure to comply with the recommended storage

the applied material should be rolled with a spiked conditions may result in premature deterioration of

roller to release entrapped air and remove trowel the product or packaging. For specific storage

marks. advice consult BASF Construction Chemicals SA’s

Rolling should be continued until all air is released Technical Services Department.

and a uniform colour is obtained.

The operator should always wear spiked shoes when Safety precautions

using the spiked roller so that he can walk in the wet As with all chemical products, care should be taken

material. during use and storage to avoid contact with eyes

Rolling should cease before the Mastertop®1230Plus mouth, skin and foodstuffs (which can also be

begins to gel. tainted with vapour until product is fully cured or

dried). Treat splashes to eyes and skin

Equipment immediately. If accidentally ingested, seek

Vacuum recovery shot blasting Scarifier immediate medical attention. Keep away from

machine (Errut/VonArx) children and animals. Reseal containers after use.

Masking tape/polythene sheets Grinder

Heaters for cold weather work Overalls

Note

Trowels Lighting

Slow speed drill with suitable paddle Spiked roller Field service, where provided, does not constitute

Brushes or short nap hair rollers Spiked shoes supervisory responsibility. For additional information

Industrial vacuum Pin rake contact your local BASF Construction Chemicals SA

representative. BASF Construction Chemicals SA.

Equipment care reserves the right to have the true cause of any

Remove Mastertop®1230Plus from tools and difficulty determined by accepted test methods

equipment whilst still wet using Solvent No2. Cured

resin will require mechanical removal. Quality and care

All products originating from BASF Construction

Yield Chemicals’ SA facility are manufactured under a

A 38kg unit of Mastertop®1230Plus will yield 21.19 management system independently certified to

litres of mixed material. conform to the requirements of the quality,

environmental and occupational health & safety

standards ISO 9001:2000.

Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or

implied with any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any

labour involved in the application are beyond our control.

As all BASF’s technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

BASF Construction Chemicals South Africa (Pty) Ltd

852 Sixteenth Road, Midrand

P.O. Box 420, Westonaria, 1780

PO Box 2801, Halfway House, 1685

11 Pullinger Street, Westonaria, 1779 Tel: +27 11 203 2405

Tel: +27 11 754 1343

Fax: +27 11 754 1105 Website : basf-cc.co.za

You might also like

- Method Statement - Masterseal 345 REV D PDFDocument17 pagesMethod Statement - Masterseal 345 REV D PDFFrancois-No ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocument2 pagesMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-No ratings yet

- Document Information For:: 5339157TST 5339157TSTDocument19 pagesDocument Information For:: 5339157TST 5339157TSTMkrtich AltunyanNo ratings yet

- Risk Assessment - Breaking ConcreteDocument2 pagesRisk Assessment - Breaking Concretednmule83% (6)

- Mastertop 1255: Decorative Aggregate-Based Resin Flooring SystemDocument3 pagesMastertop 1255: Decorative Aggregate-Based Resin Flooring SystemFrancois-No ratings yet

- Mastertop 1210 Plus PDFDocument3 pagesMastertop 1210 Plus PDFFrancois-No ratings yet

- Mastertop 1210 - TdsDocument3 pagesMastertop 1210 - TdstechnbksNo ratings yet

- Mastertop 1221 A PDFDocument3 pagesMastertop 1221 A PDFFrancois-No ratings yet

- Mastertop 1240 Tds PDFDocument3 pagesMastertop 1240 Tds PDFSolomon AhimbisibweNo ratings yet

- Mastertop 1240 Plus PDFDocument4 pagesMastertop 1240 Plus PDFFrancois-No ratings yet

- Mastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingFrancois-No ratings yet

- Mastertop 530 12-04Document3 pagesMastertop 530 12-04djrote4No ratings yet

- Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentDocument3 pagesMastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentFrancois-No ratings yet

- Mastertop DAF PDFDocument4 pagesMastertop DAF PDFFrancois-No ratings yet

- Mastertop 1205 TdsDocument3 pagesMastertop 1205 Tdskhalidraafat20No ratings yet

- Mastertop Primer 2 PDFDocument2 pagesMastertop Primer 2 PDFFrancois-No ratings yet

- BASF MasterTop 1205 Data SheetDocument3 pagesBASF MasterTop 1205 Data SheetAhmed AssafNo ratings yet

- Mfill 300Document2 pagesMfill 300Doby YuniardiNo ratings yet

- Mastertop 564Document2 pagesMastertop 564Doby YuniardiNo ratings yet

- Mastertop 1740m 12-04Document3 pagesMastertop 1740m 12-04djrote4No ratings yet

- Mastertop 1240 TdsDocument3 pagesMastertop 1240 Tdsdilshad khanNo ratings yet

- TDS - Basf Mastertop 566Document2 pagesTDS - Basf Mastertop 566Cloudy DayNo ratings yet

- DBASF Mastertile30Document3 pagesDBASF Mastertile30bassem muhannaNo ratings yet

- MasterTile 30Document3 pagesMasterTile 30Anamika KadamNo ratings yet

- Mastertop 1324: Seamless, Self-Smoothing Heavy Duty Polyurethane Based Flooring SystemDocument4 pagesMastertop 1324: Seamless, Self-Smoothing Heavy Duty Polyurethane Based Flooring SystemFrancois-No ratings yet

- MasterEmaco N 301-190315Document2 pagesMasterEmaco N 301-190315Irshad Ali DurraniNo ratings yet

- Mastertop DAP PDFDocument3 pagesMastertop DAP PDFFrancois-No ratings yet

- Mastertop 1207 TdsDocument3 pagesMastertop 1207 TdsAhmed IbrahimNo ratings yet

- TDS - Mastertop 1240 PlusDocument3 pagesTDS - Mastertop 1240 PlusVenkata RaoNo ratings yet

- 09 - TDS - Mastertop 1205Document3 pages09 - TDS - Mastertop 1205aahtagoNo ratings yet

- Mastertop 1110 T PDFDocument4 pagesMastertop 1110 T PDFFrancois-No ratings yet

- Mastertop 1230i M 12-04Document3 pagesMastertop 1230i M 12-04djrote4No ratings yet

- Mastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayDocument3 pagesMastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayAbi SomutNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDocument2 pagesMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiNo ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- Mastertop 1110 TdsDocument3 pagesMastertop 1110 Tdssr2011glassNo ratings yet

- Mastertop 1210i M 12-04Document3 pagesMastertop 1210i M 12-04djrote4No ratings yet

- Mastertop 1120tDocument3 pagesMastertop 1120themajsuryaNo ratings yet

- TDS MasterSeal-540Document2 pagesTDS MasterSeal-540Taposh PaulNo ratings yet

- MasterTop 430Document32 pagesMasterTop 430Ahmad ElghazolyNo ratings yet

- Mastertop 1210 TdsDocument2 pagesMastertop 1210 TdsAhmed AssafNo ratings yet

- Mastertop 1110 TDocument4 pagesMastertop 1110 THaresh BhavnaniNo ratings yet

- TDS - Mastertop 1730Document2 pagesTDS - Mastertop 1730Venkata RaoNo ratings yet

- Renovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationsDocument1 pageRenovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationswassimmahfouzNo ratings yet

- Masterbrace® Lam (Formerly Known As Mbrace® Laminate)Document2 pagesMasterbrace® Lam (Formerly Known As Mbrace® Laminate)KY PengNo ratings yet

- TDS - Mastertop 1210 PlusDocument2 pagesTDS - Mastertop 1210 PlusVenkata RaoNo ratings yet

- MasterSeal M800 IN V5-077820bilsDocument2 pagesMasterSeal M800 IN V5-077820bilskiranmisale19No ratings yet

- Mastertop 1175 12-04Document3 pagesMastertop 1175 12-04djrote4No ratings yet

- Masterseal 480 Asean 0709Document2 pagesMasterseal 480 Asean 0709jessicaNo ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- FIXHSNE-EN NovolacDocument2 pagesFIXHSNE-EN NovolacDepartamento SeguridadNo ratings yet

- TDS - Mastertop 1105Document3 pagesTDS - Mastertop 1105Venkata Rao100% (1)

- Basf Masterseal m808 TdsDocument8 pagesBasf Masterseal m808 TdsOkan KalendarNo ratings yet

- Technical Datasheets Masteremaco P 158Document2 pagesTechnical Datasheets Masteremaco P 158sumitha_kumarageNo ratings yet

- Europlast Expo SDocument2 pagesEuroplast Expo StechnicalsajaNo ratings yet

- BASF MasterEmaco S488Document2 pagesBASF MasterEmaco S488HJNo ratings yet

- Mastertop Bc338 AseanDocument2 pagesMastertop Bc338 AseanDoby YuniardiNo ratings yet

- Basf Mastertop 1205 Tds PDFDocument3 pagesBasf Mastertop 1205 Tds PDFEn CivilNo ratings yet

- Master EmacoDocument3 pagesMaster EmacoSmookers HeavenNo ratings yet

- MasterTop 1200Document2 pagesMasterTop 1200Ahmed aalatbeeyNo ratings yet

- Mastertop TC 458 PDFDocument3 pagesMastertop TC 458 PDFFrancois-No ratings yet

- Masterflow 410 PCDocument3 pagesMasterflow 410 PCFrancois-No ratings yet

- Effectiveness Analysis of Waterfall and Agile Project Management Methodologies - A Case Study From Macau's Construction InduDocument16 pagesEffectiveness Analysis of Waterfall and Agile Project Management Methodologies - A Case Study From Macau's Construction InduFrancois-No ratings yet

- Standard Grout PDFDocument3 pagesStandard Grout PDFFrancois-No ratings yet

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 pagesSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-No ratings yet

- MEYCO MP 367 Foam PDFDocument2 pagesMEYCO MP 367 Foam PDFFrancois-No ratings yet

- Ferroflow 939: Iron Fortified Shrinkage Compensated GroutDocument2 pagesFerroflow 939: Iron Fortified Shrinkage Compensated GroutFrancois-No ratings yet

- FlowcableDocument4 pagesFlowcableFrancois-No ratings yet

- Ferromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationDocument2 pagesFerromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationFrancois-No ratings yet

- Meyco MP308 PDFDocument3 pagesMeyco MP308 PDFFrancois-No ratings yet

- MEYCO MP320 Questions & Answers PDFDocument12 pagesMEYCO MP320 Questions & Answers PDFFrancois-No ratings yet

- Meyco MP 357 GS PDFDocument2 pagesMeyco MP 357 GS PDFFrancois-No ratings yet

- Primer SC PDFDocument3 pagesPrimer SC PDFFrancois-No ratings yet

- Meyco MP302 PDFDocument3 pagesMeyco MP302 PDFFrancois-No ratings yet

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocument3 pagesPozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-No ratings yet

- Meyco FIB 500 PDFDocument2 pagesMeyco FIB 500 PDFFrancois-No ratings yet

- MEYCO MP 364 Flex PDFDocument2 pagesMEYCO MP 364 Flex PDFFrancois-No ratings yet

- Meyco Fix Lube 1 PDFDocument2 pagesMeyco Fix Lube 1 PDFFrancois-No ratings yet

- Meyco FIB 600 PDFDocument2 pagesMeyco FIB 600 PDFFrancois-No ratings yet

- Meyco MP 301 PDFDocument2 pagesMeyco MP 301 PDFFrancois-No ratings yet

- Rheocrete 222+: Organic Corrosion Inhibiting AdmixtureDocument3 pagesRheocrete 222+: Organic Corrosion Inhibiting AdmixtureFrancois-No ratings yet

- Meyco MP355 1K - TDS - 07 - PDFDocument2 pagesMeyco MP355 1K - TDS - 07 - PDFFrancois-No ratings yet

- Primer TC PDFDocument3 pagesPrimer TC PDFFrancois-No ratings yet

- Pozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteDocument2 pagesPozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteFrancois-No ratings yet

- Protectosil CIT PDFDocument3 pagesProtectosil CIT PDFFrancois-No ratings yet

- RheoFIT 761 PDFDocument2 pagesRheoFIT 761 PDFFrancois-No ratings yet

- Rheofinish 303: High Performance Chemical and Physical Mould Release Agents DescriptionDocument1 pageRheofinish 303: High Performance Chemical and Physical Mould Release Agents DescriptionFrancois-No ratings yet

- Pozzolith 600R PDFDocument2 pagesPozzolith 600R PDFFrancois-No ratings yet

- Pozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteDocument2 pagesPozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteFrancois-No ratings yet

- List Mechanical Procedure Qualification Test (API 1104) 2018 (CEPU)Document5 pagesList Mechanical Procedure Qualification Test (API 1104) 2018 (CEPU)Muhammad Iqbal SpNo ratings yet

- Law Relating To Municipal EmployeesDocument100 pagesLaw Relating To Municipal Employeesdarimadugu100% (1)

- 670d584218529aef1556740a - The BlueprintDocument30 pages670d584218529aef1556740a - The BlueprinttobehevenNo ratings yet

- EET308 Chapter 4 Lecture 1 - Updated 13 March 2016 - 0Document30 pagesEET308 Chapter 4 Lecture 1 - Updated 13 March 2016 - 0Mustafa AlfahadNo ratings yet

- 1975 1980 PDFDocument19 pages1975 1980 PDFJoe Reiter100% (1)

- Chemical Reactions and Equations Worksheet PDFDocument4 pagesChemical Reactions and Equations Worksheet PDFVrushab MNo ratings yet

- 9th Physics Full Book UNsolved MCQS Full Syllabus From Past PapersDocument7 pages9th Physics Full Book UNsolved MCQS Full Syllabus From Past PapersSohail Afzal100% (1)

- Vitrectomy Combined With Posterior-Segment Ahmed Valve Implant: A Case Series StudyDocument9 pagesVitrectomy Combined With Posterior-Segment Ahmed Valve Implant: A Case Series StudyVlady BordaNo ratings yet

- 1851968974biology Class X For Sa-I 2015-16Document99 pages1851968974biology Class X For Sa-I 2015-16Afandi AmkajaNo ratings yet

- Tle Agriculture 9 - 2Q Test QuestionnaireDocument4 pagesTle Agriculture 9 - 2Q Test QuestionnaireFe DelgadoNo ratings yet

- Section A-A: Roof Plan Ground Floor PlanDocument1 pageSection A-A: Roof Plan Ground Floor Plansyed saleemNo ratings yet

- Homeroom Guidance: Quarter 4 - Module 17: I in The CommunityDocument14 pagesHomeroom Guidance: Quarter 4 - Module 17: I in The CommunityYOUR GUIDANCE COUNSELOR79% (14)

- RCF ProductsDocument50 pagesRCF ProductsArun Victor Paulraj100% (1)

- Civil Soc 1Document19 pagesCivil Soc 1DendenGalitNo ratings yet

- Translation ExposureDocument12 pagesTranslation Exposureirfan7867809No ratings yet

- Omega Construction ENDocument6 pagesOmega Construction ENFraz AhmadNo ratings yet

- Cartidge FilterDocument9 pagesCartidge Filterrojolele2018 beras premiumNo ratings yet

- Drama ScriptDocument12 pagesDrama ScriptFrancessca Joan100% (1)

- Smoke Detector InstallationDocument6 pagesSmoke Detector Installationsatria baraNo ratings yet

- Pharm ReviewDocument5 pagesPharm ReviewChelsea ChanceNo ratings yet

- Sphygmomanometer RepairDocument5 pagesSphygmomanometer Repairver_at_workNo ratings yet

- Abera Hailu Seminar Paper, 2013 Ju EthiopiaDocument30 pagesAbera Hailu Seminar Paper, 2013 Ju EthiopiaChad Newman100% (6)

- Press Dossier English - TelePizzaDocument5 pagesPress Dossier English - TelePizzaDich PhongNo ratings yet

- 22.02.23.01 Price List From Gaode EquipmentDocument1 page22.02.23.01 Price List From Gaode EquipmentKiel CorpuzNo ratings yet

- WEEk 6 - Topic Sentence, Supporting Sentence, Concluding SentenceDocument12 pagesWEEk 6 - Topic Sentence, Supporting Sentence, Concluding SentenceAZKIA FIL HIDAYAH100% (1)

- Circulatory System WorksheetDocument11 pagesCirculatory System WorksheetHalil OralNo ratings yet

- Mapeh 8 - Q1 PeDocument11 pagesMapeh 8 - Q1 PeJarvis RazonNo ratings yet

- Marketing ProjectDocument113 pagesMarketing Projectmanthanjadav7828No ratings yet