MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733

MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733

Uploaded by

ManekGorisCopyright:

Available Formats

MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733

MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733

Uploaded by

ManekGorisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733

MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733

Uploaded by

ManekGorisCopyright:

Available Formats

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

Cast iron monobloc centrifugal pumps conforming to en 733.

APPLICATIONS

• Handling of clean water for civil, agricultural, industrial uses and for

pressurisation units, heating plants and air conditioning plants

• Irrigation in farming companies

• Sports facilities

• Washing plants

TECHNICAL DETAILS

• Available with various special sealing systems

PUMP TECHNICAL DATA

• Temperature of the liquid:

-5°C ÷ +90°C (MD)

-5°C ÷ +110°C (MD version H-HS-HW-HSW)

-5°C ÷ +120°C (MD version E)

-10°C ÷ +90°C (MMD)

• Maximum working pressure: 10 bar

• MEI > 0.4

For further information please see our Data Book on the web site

www.ebaraeurope.com

MOTOR TECHNICAL DATA

• IE3 high energy-efficiency motors starting from 5.5kW (MD)

• IE2 high energy-efficiency motors starting from 0.75kW and IE3

starting from 7.5kW (MMD)

• Self-ventilated 2-pole and 4-pole asynchronous motors

• Insulation class F

• IP55 protection degree

• 230/400V ±10% 50Hz three phase voltage up to 4 kW included,

400/690V ±10% (from 5.5 kW and above) three phase voltage, 50 Hz

MD IDENTIFICATION CODE

• Permanent capacitor inserted and thermo-amperometric

MD H 32 - 250 / 7.5 protection with automatic rearm incorporated for the single phase

motor

• Protection under user’s responsibility for the three phase version

Motor power in kW

MATERIALS

Impeller diameter • Cast iron pump body and support

• AISI 304 shaft - part in contact with the liquid (MD),

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Discharge in AISI 420 (MMD)

32 40 50

• Mechanical seal in:

- Carbon/Ceramic/NBR (MD)

H

- Silicon Carbide/Silicon Carbide/NBR (MMD)

HS • Impeller in:

Optional version

HW - AISI 304 (MD)

HSW - cast iron (MMD)

Model

E

ACCESSORIES (On request)

• Galvanised counterflanges

MMD IDENTIFICATION CODE

MMD 80 - 160 / 11 R

Reduced impeller

Motor power in kW

Impeller diameter

Discharge 160 200 250

65 80 100

Model

Japanese Technology since 1912 197 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MD PERFORMANCE CHART 2 Poles

at 2900 min–1 (according to ISO 9906 Attachment A)

MMD PERFORMANCE CHART 2 Poles MMD PERFORMANCE CHART 4 Poles

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

at 2900 min–1 (according to ISO 9906 Attachment A) at 1400 min–1 (according to ISO 9906 Attachment A)

Japanese Technology since 1912 198 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

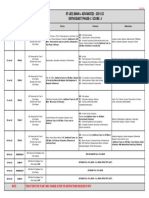

MD PERFORMANCE CHART 2 Poles

Model P 2 Q = Flow Rate

l/min 100 200 250 280 320 400 550 600 667 700 800 1000 1100 1150 1200 1300

[HP] [kW] m3/h 6 12 15 17 19 24 33 36 40 42 48 60 66 69 72 78

H=Head [m]

MD 32-250/5.5 7.5 5.5 56.5 53.0 50.4 48.6 45.7 38.0 - - - - - - - - - -

MD 32-250/7.5 10 7.5 70.0 67.1 64.5 62.7 60.0 53.0 - - - - - - - - - -

MD 32-250/9.2 12.5 9.2 81.2 78.2 75.8 74.0 71.4 65.0 - - - - - - - - - -

MD 32-250/11 15 11 89.0 86.0 84.0 82.0 79.0 73.0 - - - - - - - - - -

MD 40-250/11 15 11 - 74.0 73.0 72.2 71.0 68.2 60.1 56.3 49.8 46.0 - - - - - -

MD 40-250/15 20 15 - 92.7 92.1 91.7 90.8 88.1 81.2 78.0 72.9 70.0 - - - - - -

MD 50-250/15 20 15 - - - - - 71.2 69.2 68.2 66.6 65.7 62.6 54.2 49.0 46.1 43.0 -

MD 50-250/18.5 25 18.5 - - - - - 81.5 79.5 78.5 77.0 76.1 73.2 66.0 61.4 58.9 56.1 50.0

MD 50-250/22 30 22 - - - - - 91.6 89.7 88.9 87.6 86.9 84.3 77.4 73.0 70.4 67.7 61.5

MMD PERFORMANCE CHART 2 Poles

Model P 2 Q = Flow Rate

l/min 800 1000 1250 1500 1750 2000 2250 2500 2750 3000 3500 4000 4500

[HP] [kW] m3/h 48 60 75 90 105 120 135 150 165 180 210 240 270

H=Head [m]

MMD 65-250/22 30 22 64.0 63.0 61.0 57.0 53.0 - - - - - - - -

MMD 65-250/30 40 30 77.0 76.0 74.0 70.0 66.0 60.0 53.0 - - - - - -

MMD 65-250/37 55 37 86.0 85.0 83.0 79.0 75.0 70.0 64.0 - - - - - -

MMD 80-160/11 15 11 - 24.0 23.0 22.0 21.0 19.5 18.0 16.5 15.0 - - - -

MMD 80-160/15R 20 15 - 28.5 28.0 27.0 26.0 24.5 23.0 21.5 20.0 18.5 - - -

MMD 80-160/15 20 15 - 34.0 33.3 32.5 31.8 31.0 29.0 27.5 26.0 24.3 - - -

MMD 80-200/18.5 25 18.5 - 42.0 41.0 40.0 38.5 37.0 35.0 33.0 30.5 28.0 - - -

MMD 80-200/22 30 22 - 47.0 46.5 45.5 44.5 43.0 41.0 39.0 37.0 34.0 - - -

MMD 80-200/30 40 30 - 55.0 54.0 53.0 52.0 51.0 49.0 47.0 45.0 43.0 37.0 - -

MMD 80-200/37 55 37 - 57.0 57.0 56.5 56.0 55.0 54.0 52.5 51.0 48.0 42.0 - -

MMD 80-250/37 55 37 - - 67.5 67.0 66.2 65.0 63.3 61.0 58.3 55.0 47.0 - -

MMD 100-200/22 30 22 - - - 38.5 38.0 37.0 36.0 34.5 33.0 31.5 28.0 24.0 -

MMD 100-200/30 40 30 - - - 47.0 46.3 45.6 44.8 43.7 42.4 41.0 38.0 34.6 30.0

MMD 100-200/37 55 37 - - - 53.5 53.5 53.0 52.0 51.0 50.0 49.0 46.0 43.0 38.0

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 199 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MMD4 PERFORMANCE CHART 4 Poles

Model P

2 Q = Flow Rate

l/min 75 100 125 150 175 200 225 250 275 300 350 400 450 500 550 600 650 700

[HP] [kW] m3/h 5 6 8 9 11 12 14 15 17 18 21 24 27 30 33 36 39 42

H=Head [m]

MMD4 32-250/1.1 1.5 1.1 18.5 18.0 17.5 17.0 15.9 14.5 12.8 11.0 - - - - - - - - - -

MMD4 32-250/1.5 2 1.5 22.0 21.6 21.2 20.5 19.4 18.0 16.5 15.0 13.0 - - - - - - - - -

MMD4 40-250/1.5 2 1.5 - 18.3 18.0 17.7 17.4 17.0 16.7 16.2 15.6 15.0 13.7 12.0 - - - - - -

MMD4 40-250/2.2 3 2.2 - 22.5 22.3 22.0 21.7 21.4 21.2 20.5 20.2 19.5 18.5 17.0 - - - - - -

MMD4 50-250/2.2 3 2.2 - - - - - 18.5 18.3 18.1 17.8 17.5 17.0 16.2 15.5 14.5 13.5 12.5 11.3 10.0

MMD4 50-250/3 4 3 - - - - - 22.5 22.4 22.3 22.2 22.0 21.5 20.9 20.2 19.4 18.5 17.5 16.3 14.7

Model P 2 Q = Flow Rate

l/min 500 550 600 650 700 800 900 1000 1100 1200 1300 1400 1500 1750 2000 2250

[HP] [kW] m3/h 30 33 36 39 42 48 54 60 66 72 78 84 90 105 120 135

H=Head [m]

MMD4 65-250/4 5.5 4 19.5 19.3 19.1 18.8 18.5 17.5 16.5 15.5 14.0 12.5 10.4 - - - - -

MMD4 65-250/5.5 7.5 5.5 23.0 22.8 22.6 22.4 22.2 21.4 20.6 19.7 18.7 17.3 15.7 14.0 - - - -

MMD4 80-160/1.5 2 1.5 - - 7.7 7.6 7.5 7.3 7.0 6.7 6.4 6.1 5.7 5.4 5.0 - - -

MMD4 80-160/2.2 3 2.2 - - 9.7 9.6 9.5 9.3 9.0 8.8 8.5 8.2 7.9 7.5 7.1 6.0 - -

MMD4 80-200/3 4 3 - - 12.0 11.9 11.7 11.5 11.3 11.0 10.5 10.0 9.5 9.0 8.5 7.0 - -

MMD4 80-200/4 5.5 4 - - 14.4 14.3 14.2 14.0 13.8 13.5 13.1 12.6 12.2 11.6 11.0 9.0 6.5 -

MMD4 80-250/5.5 7.5 5.5 - - - - - 19.2 18.9 18.5 18.0 17.6 17.1 16.5 16.0 14.0 12.0 -

MMD4 80-250/7.5 10 7.5 - - - - - 22.3 22.1 21.9 21.7 21.3 21.0 20.5 20.0 18.5 16.9 14.5

Model P 2 Q = Flow Rate

l/min 900 1000 1200 1500 1750 2000 2250 2500 2750 3000 3500 3700 4000 4500 5000 5500 6500 7000 8500 9000 9500 10000

[HP] [kW] m /h 54 60 72 90 105 120 135 150 165 180 210 222

3

240 270 300 330 390 420 510 540 570 60

H=Head [m]

MMD4 100-200/4 5.5 4 12.3 12.2 11.8 11.2 10.3 9.3 8.0 6.6 4.8 - - - - - - - - - - - - -

MMD4 100-200/5.5 7.5 5.5 14.5 14.4 14.0 13.4 12.8 12.0 11.0 9.8 8.5 - - - - - - - - - - - - -

MMD4 100-250/7.5 10 7.5 - 19.5 19.1 18.5 17.5 16.5 15.2 14.0 12.0 - - - - - - - - - - - - -

MMD4 100-250/11 15 11 - 22.0 21.8 21.5 20.5 19.5 18.5 17.0 15.0 12.8 - - - - - - - - - - - -

MMD4 125-200/5.5 7.5 5.5 - - - 10.5 10.3 9.9 9.5 9.1 8.5 7.9 6.4 5.7 - - - - - - - - - -

MMD4 125-200/7.5R 10 7.5 - - - 11.8 11.6 11.3 11.0 10.6 10.2 9.6 8.3 7.7 6.7 - - - - - - - - -

MMD4 125-200/7.5 10 7.5 - - - - 12.9 12.7 12.4 12.1 11.7 11.2 10.1 9.6 8.7 7.1 - - - - - - - -

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

MMD4 125-200/11 15 11 - - - - 14.3 14.1 13.8 13.6 13.2 12.8 11.8 11.3 10.6 9.2 7.6 - - - - - - -

MMD4 125-250/11 15 11 - - - - 17.2 16.7 16.2 15.5 14.8 13.9 12.0 11.3 10.0 - - - - - - - - -

MMD4 125-250/15 20 15 - - - - 21.0 20.5 20.1 19.5 18.9 18.2 16.6 16.0 14.8 12.8 - - - - - - - -

MMD4 150-200/7.5 10 7.5 - - - - - 11.0 10.7 10.4 10.1 9.7 8.8 8.4 7.8 6.6 5.3 - - - - - - -

MMD4 150-200/11R 15 11 - - - - - 12.0 11.8 11.6 11.2 10.9 10.2 9.8 9.2 8.0 6.8 5.6 - - - - - -

MMD4 150-200/11 15 11 - - - - - - - 13.7 13.5 13.2 12.5 12.2 11.7 10.8 9.8 8.7 6.1 - - - - -

MMD4 150-200/15 20 15 - - - - - - - 15.2 14.9 14.7 14.2 13.8 13.4 12.5 11.6 10.5 8.2 6.8 - - - -

MMD4 200-250/18.5R 25 18.5 - - - - - - - - - 14.9 14.5 14.3 14.1 13.6 13.0 12.3 11.0 10.3 7.8 - - -

MMD4 200-250/18.5 25 18.5 - - - - - - - - - 15.9 15.5 15.3 15.2 14.7 14.2 13.6 12.3 11.6 9.1 8.2 - -

MMD4 200-250/22R 30 22 - - - - - - - - - - 18.0 17.8 17.6 17.1 16.6 16.0 14.7 13.9 11.2 10.1 9.0 -

MMD4 200-250/22 30 22 - - - - - - - - - - 19.1 18.9 18.8 18.3 17.8 17.3 16.0 15.3 12.7 11.7 10.7 9.6

Japanese Technology since 1912 200 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

PERFORMANCE CURVES MD 32-250 series 2 Poles PERFORMANCE CURVES MD 40-250 series 2 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

PERFORMANCE CURVES MD 50-250 series 2 Poles PERFORMANCE CURVES MD 65-250 series 2 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 201 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

PERFORMANCE CURVES MMD 80-160 series 2 Poles PERFORMANCE CURVES MMD 80-200 series 2 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

PERFORMANCE CURVES MMD 80-250 series 2 Poles PERFORMANCE CURVES MMD 100-200 series 2 Poles

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

Japanese Technology since 1912 202 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

PERFORMANCE CURVES MMD4 32-250 SERIES 4 Poles PERFORMANCE CURVES MMD4 40-250 SERIES 4 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

PERFORMANCE CURVES MMD4 50-250 SERIES 4 Poles PERFORMANCE CURVES MMD4 65-250 SERIES 4 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 203 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

PERFORMANCE CURVES MMD4 80-160 SERIES 4 Poles PERFORMANCE CURVES MMD4 80-200 SERIES 4 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

PERFORMANCE CURVES MMD4 80-250 SERIES 4 Poles

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

(according to ISO 9906 Attachment A)

Japanese Technology since 1912 204 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

PERFORMANCE CURVES MMD4 100-200 SERIES 4 Poles PERFORMANCE CURVES MMD4 100-250 SERIES 4 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

PERFORMANCE CURVES MMD4 125-200 SERIES 4 Poles PERFORMANCE CURVES MMD4 125-250 SERIES 4 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 205 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

PERFORMANCE CURVES MMD4 150-200 SERIES 4 Poles PERFORMANCE CURVES MMD4 200-250 SERIES 4 Poles

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 206 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

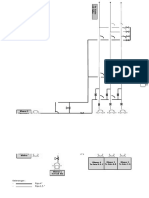

MD DIMENSIONS - up to 11 kW 2 Poles

DIMENSIONAL TABLE

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Modello Dimensioni [mm] Peso

DN1 P1 K1 D1 S1 DN2 P2 K2 D2 S2 H H1 H2 H3 R W M M1 N1 N2 A1 A2 B C F V1 V2 [kg]

Ø Ø Ø Ø Ø Ø Ø Ø

MD 32-250/5.5 50 102 125 165 20 32 78 100 140 18 405 180 225 150 100 95 125 65 250 320 176 176 539 275 15 PG 13,5 PG 16 74,2

MD 32-250/7.5 50 102 125 165 20 32 78 100 140 18 405 180 225 150 100 95 125 65 250 320 176 176 557 275 15 PG 13,5 PG 16 77,7

MD 32-250/9.2 50 102 125 165 20 32 78 100 140 18 405 180 225 178 100 95 125 65 250 320 176 176 589 354 15 PG 13,5 PG 21 94,5

MD 32-250/11 50 102 125 165 20 32 78 100 140 18 405 180 225 178 100 95 125 65 250 320 176 176 589 354 15 PG 13,5 PG 21 97,4

MD 40-250/11 65 122 145 185 20 40 88 110 150 18 405 180 225 178 100 95 125 65 250 320 176 176 589 354 15 PG 13,5 PG 21 100,4

Japanese Technology since 1912 207 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MD DIMENSIONS - starting from 15 kW and over 2 Poles

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

DIMENSIONAL TABLE

Model Dimensions [mm] Weight

DN1 P1 K1 D1 S1 DN2 P2 K2 D2 S2 H H1 H2 N1 N2 A1 A2 [kg]

Ø Ø Ø Ø Ø Ø Ø Ø

MD 40-250/15 65 122 145 185 20 40 88 110 150 18 405 180 225 250 320 176 176 105.1

MD 50-250/15 65 122 145 185 20 50 102 125 165 20 405 180 225 250 320 176 176 106.1

MD 50-250/18.5 65 122 145 185 20 50 102 125 165 20 405 180 225 250 320 176 176 136.3

MD 50-250/22 65 122 145 185 20 50 102 125 165 20 405 180 225 250 320 176 176 161.1

Japanese Technology since 1912 208 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MMD DIMENSIONS 2 Poles

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

DIMENSIONAL TABLE

Model Dimensions [mm] Weight

Fig. DNA n1 f1 P1 K1 D1 DNM n2 f2 P2 K2 D2 H H1 H2 H3 R W N1 M N2 M1 F A B C D [kg]

MMD 65-250/22 B 80 8 18 138 160 200 65 4 18 122 145 185 430 180 250 238 100 280 254 420 320 60 20 365 814 370 14 141.0

MMD 65-250/30 B 80 8 18 138 160 200 65 4 18 122 145 185 450 200 250 330 100 325 318 345 380 60 24 365 952 305 18 264.0

MMD 65-250/37 B 80 8 18 138 160 200 65 4 18 122 145 185 450 200 250 330 100 325 318 345 380 60 24 365 952 305 18 297.0

MMD 80-160/11 A 100 8 18 158 180 220 80 8 18 138 160 200 405 180 225 194 125 95 250 125 320 65 14 315 679 - 14 87.0

MMD 80-160/15R A 100 8 18 158 180 220 80 8 18 138 160 200 405 180 225 194 125 95 250 125 320 65 14 315 730 - 14 90.0

MMD 80-160/15 A 100 8 18 158 180 220 80 8 18 138 160 200 405 180 225 194 125 95 250 125 320 65 14 315 730 - 14 90.0

MMD 80-200/18.5 B 100 8 18 158 180 220 80 8 18 138 160 200 430 180 250 238 125 280 254 420 320 60 20 360 839 370 14 137.0

MMD 80-200/22 B 100 8 18 158 180 220 80 8 18 138 160 200 430 180 250 238 125 280 254 420 320 60 20 360 839 370 14 147.0

MMD 80-200/30 B 100 8 18 158 180 220 80 8 18 138 160 200 450 200 250 330 125 325 318 345 380 60 24 400 977 305 18 284.0

MMD 80-200/37 B 100 8 18 158 180 220 80 8 18 138 160 200 450 200 250 330 125 325 318 345 380 60 24 400 977 305 18 317.0

MMD 80-250/37 B 100 8 18 158 180 220 80 8 18 138 160 200 480 200 280 330 125 325 318 345 380 60 24 400 977 305 18 320.0

MMD 100-200/22 B 125 8 18 188 210 250 100 8 18 158 180 220 460 180 280 238 125 280 254 420 320 60 20 380 839 370 14 157.0

MMD 100-200/30 B 125 8 18 188 210 250 100 8 18 158 180 220 480 200 280 330 125 325 318 345 380 60 24 400 977 305 18 294.0

MMD 100-200/37 B 125 8 18 188 210 250 100 8 18 158 180 220 480 200 280 330 125 325 318 345 380 60 24 400 977 305 18 327.0

Japanese Technology since 1912 209 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MMD4 DIMENSIONS - up to 65 4 Poles

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

DIMENSIONAL TABLE

Model Dimensions [mm] Weight

DNA n1 f1 P1 K1 D1 DNM n2 f2 P2 K2 D2 H H1 H2 H3 R W N1 M N2 M1 F A B D [kg]

MMD4 32-250/1.1 50 4 18 102 125 165 32 4 14 78 100 140 405 180 225 138 100 95 250 125 320 65 12 320 476 14 50.0

MMD4 32-250/1.5 50 4 18 102 125 165 32 4 14 78 100 140 405 180 225 138 100 95 250 125 320 65 12 320 476 14 51.0

MMD4 40-250/1.5 65 4 18 122 145 185 40 4 18 88 110 150 405 180 225 138 100 95 250 125 320 65 12 325 476 14 49.0

MMD4 40-250/2.2 65 4 18 122 145 185 40 4 18 88 110 150 405 180 225 145 100 95 250 125 320 65 12 325 515 14 55.0

MMD4 50-250/2.2 65 4 18 122 145 185 50 4 18 102 125 165 405 180 225 145 100 95 250 125 320 65 14 333 515 14 58.0

MMD4 50-250/3 65 4 18 122 145 185 50 4 18 102 125 165 405 180 225 145 100 95 250 125 320 65 14 333 549 14 65.0

MMD4 65-250/4 80 8 18 138 160 200 65 4 18 122 145 185 450 200 250 160 100 120 280 160 360 80 14 365 549 14 79.0

MMD4 65-250/5.5 80 8 18 138 160 200 65 4 18 122 145 185 450 200 250 194 100 120 280 160 360 80 14 365 606 14 103.0

Japanese Technology since 1912 210 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MMD4 DIMENSIONS - from 80 to 200 4 Poles

DIMENSIONAL TABLE

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Model Dimensions [mm] Weight

DNA n1 f1 P1 K1 D1 DNM n2 f2 P2 K2 D2 H H1 H2 H3 R W N1 M N2 M1 F A B D [kg]

MMD4 80-160/1.5 100 8 18 158 180 220 80 8 18 138 160 200 405 180 225 138 125 95 250 125 320 65 14 330 501 14 46.0

MMD4 80-160/2.2 100 8 18 158 180 220 80 8 18 138 160 200 405 180 225 145 125 95 250 125 320 65 14 330 540 14 52.0

MMD4 80-200/3 100 8 18 158 180 220 80 8 18 138 160 200 430 180 250 145 125 95 280 125 345 65 12 355 586 14 68.0

MMD4 80-200/4 100 8 18 158 180 220 80 8 18 138 160 200 430 180 250 160 125 95 280 125 345 65 12 355 574 14 72.0

MMD4 80-250/5.5 100 8 18 158 180 220 80 8 18 138 160 200 480 200 280 194 125 120 315 160 400 80 14 400 631 18 109.0

MMD4 80-250/7.5 100 8 18 158 180 220 80 8 18 138 160 200 480 200 280 194 125 120 315 160 400 80 14 400 671 18 119.0

MMD4 100-200/4 125 8 18 188 210 250 100 8 18 158 180 220 480 200 280 160 125 120 280 160 360 80 14 385 574 18 77.0

MMD4 100-200/5.5 125 8 18 188 210 250 100 8 18 158 180 220 480 200 280 194 125 120 280 160 360 80 14 385 631 18 103.0

MMD4 100-250/7.5 125 8 18 188 210 250 100 8 18 158 180 220 505 225 280 194 140 120 315 160 400 80 14 420 686 18 125.0

MMD4 100-250/11 125 8 18 188 210 250 100 8 18 158 180 220 505 225 280 238 140 120 315 160 400 80 14 420 779 18 168.0

MMD4 125-200/5.5 150 8 22 212 240 285 125 8 18 188 210 250 565 250 280 194 140 120 315 160 400 80 14 470 657 18 137.0

MMD4 125-200/7.5R 150 8 22 212 240 285 125 8 18 188 210 250 565 250 315 194 140 120 315 160 400 80 14 470 697 18 147.0

MMD4 125-200/7.5 150 8 22 212 240 285 125 8 18 188 210 250 565 250 315 194 140 120 315 160 400 80 14 470 697 18 147.0

MMD4 125-200/11 150 8 22 212 240 285 125 8 18 188 210 250 565 250 315 238 140 120 315 160 400 80 14 470 790 18 190.0

MMD4 125-250/11 150 8 22 212 240 285 125 8 18 188 210 250 605 250 355 238 140 120 315 160 400 80 16 470 790 18 196.0

MMD4 125-250/15 150 8 22 212 240 285 125 8 18 188 210 250 605 250 355 238 140 120 315 160 400 80 16 470 854 18 216.0

MMD4 150-200/7.5 200 12 22 268 295 340 150 8 22 212 240 285 680 280 400 194 160 155 450 200 550 100 22 550 717 24 180.0

MMD4 150-200/11R 200 12 22 268 295 340 150 8 22 212 240 285 680 280 400 238 160 155 450 200 550 100 22 550 810 24 223.0

MMD4 150-200/11 200 12 22 268 295 340 150 8 22 212 240 285 680 280 400 238 160 155 450 200 550 100 22 550 810 24 223.0

MMD4 150-200/15 200 12 22 268 295 340 150 8 22 212 240 285 680 280 400 238 160 155 450 200 550 100 22 550 874 24 229.0

MMD4 200-250/18.5R 250 12 25 320 355 405 200 12 22 268 295 340 765 315 450 238 200 155 450 200 550 100 22 630 962 24 368.0

MMD4 200-250/18.5 250 12 25 320 355 405 200 12 22 268 295 340 765 315 450 238 200 155 450 200 550 100 22 630 962 24 368.0

MMD4 200-250/22R 250 12 25 320 355 405 200 12 22 268 295 340 765 315 450 238 200 155 450 200 550 100 22 630 1002 24 383.0

MMD4 200-250/22 250 12 25 320 355 405 200 12 22 268 295 340 765 315 450 238 200 155 450 200 550 100 22 630 1002 24 383.0

Japanese Technology since 1912 211 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

SECTIONAL VIEW MD up to 11 kW SECTIONAL VIEW MD from 15 kW and over

MATERIALS TABLE

Ref. Name Materials Ref. Name Materials

1 Pump casing Cast iron EN-GJL-200-EN 1561 24 Plug Brass

3 Motor bracket Cast iron EN-GJL-200-EN 1561 25 Plug Brass

6 Shaft AISI 304 (part in contact with the liquid) 26 O-Ring NBR [1]

7 Impeller AISI 304 30 Spacer AISI 304

11 Mechanical seal Carbon/Ceramic/NBR 32 Key AISI 316

12 Motor frame - 34 Impeller nut AISI 304

13 Motor cover Aluminium 42 Motor support Fe P04

14 Fan PP 56 Terminal box cover gasket NBR

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

15 Fan cover Galvanised steel Fe P04 58 Cable gland -

16 Terminal Box - 75 Washer Aluminium

17 Terminal Box cover Aluminium 76 Washer Aluminium

18 Splash washer NBR 92 Seal ring -

19 Bearing (pump side) - 93 Seal ring -

20 Bearing (motor side) - 101 Seeger ring (only for 9.2 and 11kW) Carbon steel TC 80

21 Adjustment ring Stainless steel C70 200 Screw Galvanised steel

22 Tie-rod Galvanised Fe 42 (up to 11kW) 260 Screw Galvanised steel (from 15kW and over)

Galvanised steel (from 15kW and over)

[1]= FKM for H-HS-HW-HSW versions; EPDM for E version

Japanese Technology since 1912 212 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

SECTIONAL VIEW MMD-MMD4 up to MEC 132 SECTIONAL VIEW MMD-MMD4 from MEC 160 and over

MATERIALS TABLE

Ref. Name Materials Ref. Name Materials

1 Pump casing Cast iron EN-GJL-200-EN 1561 30 Spacer Stainless steel

3 Motor bracket Cast iron EN-GJL-200-EN 1561 32 Key Stainless steel

7 Impeller Cast iron EN-GJL-200-EN 1561 34 Impeller nut Stainless steel

11 Mechanical seal Silicon Carbide/Silicon Carbide/NBR 200 Screw (pump body) Stainless steel

24 Plug Stainless steel Aluminum (up to MEC 160)

800 Motor Cast iron (from MEC 180 and over)

25 Plug Stainless steel

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 213 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

MD MECHCANICAL SEAL standard MATERIALS TABLE

Ref. Name Materials

1 Spring AISI 316

2 O-Ring NBR

3 Structure/frame AISI 304

4 O-Ring NBR

5 Rotating part Ceramic

6 Fixed part Carbon

37**

7 O-Ring NBR

22*

* Ø30 from 9.2kW and over

** Ø45 from 9.2kW and over

*** 42.5mm from 9.2kW and over

37,5***

MD SPECIAL MECHANICAL SEALS (on request)

Name Materials

H Version HS Version HW Version HSW Version E Version

Spring AISI 316 AISI 316 AISI 316 AISI 316 AISI 316

O-Ring FKM FKM FKM FKM EPDM

Structure/frame AISI 304 / AISI 316* AISI 316 AISI 316 AISI 316 AISI 304

O-Ring FKM FKM FKM FKM EDPM

Rotating part Ceramic Silicon Carbide Tungsten Carbide Silicon Carbide Ceramic

Fixed part Carbon Silicon Carbide Tungsten Carbide Tungsten Carbide Carbon

O-Ring FKM FKM FKM FKM EPDM

* Only for Ø30

MMD-MMD4 MECHANICAL SEAL MATERIALS TABLE

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Ref. Name Materials

1 Spring AISI 316

2 O-Ring NBR

3 Structure/frame AISI 316

4 O-Ring NBR

5 Rotating part Silicon Carbide

6 Fixed part Silicon Carbide

7 O-Ring NBR

Japanese Technology since 1912 214 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

ELECTRIC DATA TABLE MD 2 Poles

Model P 2 Efficiency Efficiency (%) P 1 Absorbed Current

Three phase [A]

Three phase [HP] [kW] Three phase η% Three phase Three phase

50% 75% 100% [kW] 400V 690V

MD 32-250/5.5 7,5 5,5 IE3 89,2 90,6 90,4 6,09 10,6 6,1

MD 32-250/7,5 10 7,5 IE3 89,0 90,7 90,8 8,26 13,6 7,9

MD 32-250/9,2 12,5 9,2 IE3 90,1 90,8 90,9 10,12 17,2 10,0

MD 32-250/11 15 11 IE3 90,4 91,2 91,8 11,98 21,3 12,3

MD 40-250/11 15 11 IE3 90,4 91,2 91,8 11,98 21,3 12,3

MD 40-250/15 20 15 IE3 91,2 92,0 91,9 16,32 27,7 17,3

MD 50-250/15 20 15 IE3 91,2 92,0 91,9 16,32 27,7 17,3

MD 50-250/18,5 25 18,5 IE3 91,6 93,0 92,6 19,98 35,0 20,3

MD 50-225/22 30 22 IE3 92,0 93,1 93,2 23,58 39,7 23,6

MD 50-225/22 30 22 IE3 92.0 93.1 93.2 23.58 39.7 23.6

ELECTRIC DATA TABLE MMD 2 Poles

Model P 2 Efficiency Efficiency (%) P 1 Absorbed Current

Three phase Three phase [A]

[HP] [kW] Three phase η% Three phase Three phase

50% 75% 100% [kW] 400V 690V

MMD 65-250/22 30 22 IE3 92,2 93,7 92,7 23,75 39,4 22,5

MMD 65-250/30 40 30 IE3 91,4 93,3 93,3 32,12 52,1 30,0

MMD 65-250/37 50 37 IE3 91,8 93,7 93,7 39,47 62,6 36,0

MMD 80-160/11 15 11 IE3 90,0 90,8 91,2 12,27 19,9 11,5

MMD 80-160/15R 20 15 IE3 91,0 92,2 91,9 16,33 26,8 15,5

MMD 80-160/15 20 15 IE3 91,0 92,2 91,9 16,33 26,8 15,5

MMD 80-200/18,5 25 18,5 IE3 91,6 92,8 92,4 20,12 33,0 19,0

MMD 80-200/22 30 22 IE3 92,2 93,7 92,7 23,75 39,4 22,5

MMD 80-200/30 40 30 IE3 91,4 93,3 93,3 32,12 52,1 30,0

MMD 80-200/37 50 37 IE3 91,8 93,7 93,7 39,47 62,6 36,0

MMD 80-250/37 50 37 IE3 91,8 93,7 93,7 39,47 62,6 36,0

MMD 100-200/22 30 22 IE3 92,2 93,7 92,7 23,75 39,4 22,5

MMD 100-200/30 40 30 IE3 91,4 93,3 93,3 32,12 52,1 30,0

MMD 100-200/37 50 37 IE3 91,8 93,7 93,7 39,47 62,6 36,0

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

Japanese Technology since 1912 215 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

ELECTRIC DATA TABLE MMD4 4 Poles

Model P 2 Efficiency Efficiency (%) P1 Absorbed Current

Three phase Three phase [A]

[HP] [kW] Three phase η% Three phase Three phase

50% 75% 100% [kW] 230V 400V 690V

MMD4 32-250/1,1 1,5 1,1 IE3 83,3 84,8 84,2 1,33 4,2 2,4 -

MMD4 32-250/1,5 2 1,5 IE3 84,3 85,9 85,4 1,81 5,6 3,2 -

MMD4 40-250/1,5 2 1,5 IE3 84,3 85,9 85,4 1,81 5,6 3,2 -

MMD4 40-250/2,2 3 2,2 IE3 86,1 86,8 86,7 2,61 8,3 4,8 -

MMD4 50-250/2,2 3 2,2 IE3 86,1 86,8 86,7 2,61 8,3 4,8 -

MMD4 50-250/3 4 3 IE3 85,1 87,1 87,7 3,47 11,8 6,8 -

MMD4 65-250/4 5,5 4 IE3 87,2 88,3 88,6 4,59 14,2 8,2 -

MMD4 65-250/5,5 7,5 5,5 IE3 89,8 90,2 89,6 6,16 - 10,6 6,1

MMD4 80-160/1,5 2 1,5 IE3 84,3 85,9 85,4 1,81 5,6 3,2 -

MMD4 80-160/2,2 3 2,2 IE3 86,1 86,8 86,7 2,61 8,3 4,8 -

MMD4 80-200/3 4 3 IE3 85,1 87,1 87,7 3,47 11,8 6,8 -

MMD4 80-200/4 5,5 4 IE3 87,2 88,3 88,6 4,59 14,2 8,2 -

MMD4 80-250/5,5 7,5 5,5 IE3 89,8 90,2 89,6 6,16 - 10,6 6,1

MMD4 80-250/7,5 10 7,5 IE3 88,5 89,4 89,2 8,41 - 16,4 9,5

MMD4 100-200/4 5,5 4 IE3 87,2 88,3 88,6 4,59 14,2 8,2 -

MMD4 100-200/5,5 7,5 5,5 IE3 89,8 90,2 89,6 6,16 - 10,6 6,1

MMD4 100-250/7,5 10 7,5 IE3 88,5 89,4 89,2 8,41 - 16,4 9,5

MMD4 100-250/11 15 11 IE3 89,4 90,3 90,1 12,49 - 22,0 12,7

MMD4 125-200/5,5 7,5 5,5 IE3 89,8 90,2 89,6 6,16 - 10,6 6,1

MMD4 125-200/7,5R 10 7,5 IE3 88,5 89,4 89,2 8,41 - 16,4 9,5

MMD4 125-200/7,5 10 7,5 IE3 88,5 89,4 89,2 8,41 - 16,4 9,5

MMD4 125-200/11R 15 11 IE3 89,4 90,3 90,1 12,49 - 22,0 12,7

MMD4 125-250/11 15 11 IE3 89,4 90,3 90,1 12,49 - 22,0 12,7

MMD4 125-250/15 20 15 IE3 90,6 91,2 91,0 16,87 - 29,0 16,7

MMD4 150-200/7,5 10 7,5 IE3 88,5 89,4 89,2 8,41 - 16,4 9,5

MMD4 150-200/11R 15 11 IE3 89,4 90,3 90,1 12,49 - 22,0 12,7

MMD4 150-200/11 15 11 IE3 89,4 90,3 90,1 12,49 - 22,0 12,7

MMD4 150-200/15 20 15 IE3 90,6 91,2 91,0 16,87 - 29,0 16,7

MMD4 200-250/18,5R 22 18,5 IE3 90,7 92,6 92,6 19,96 - 34,3 19,8

MMD4 200-250/18,5 22 18,5 IE3 90,7 92,6 92,6 19,96 - 34,3 19,8

MMD4 200-250/22R 30 22 IE3 91,1 93,0 93,0 23,67 - 40,2 23,2

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

MMD4 200-250/22 30 22 IE3 91,1 93,0 93,0 23,67 - 40,2 23,2

Japanese Technology since 1912 216 Commercial

MD - MMD

MONOBLOC CENTRIFUGAL ELECTRIC PUMP IN COMPLIANCE WITH EN 733

in cast iron

NOISE DATA TABLE MD 2 Poles

Model P 2 L - dB(A)*

pA

Three phase

[HP] [kW]

MD 32-250/5.5 7.5 5.5

MD 32-250/7.5 10 7.5 75

MD 32-250/9.2 12.5 9.2 80

MD 32-250/11 15 11

MD 40-250/11 15 11 80

MD 40-250/15 20 15 83-82

MD 50-250/15 20 15

MD 50-250/18.5 25 18.5 83-82

MD 50-250/22 30 22

* Mean value of several measurements at 1 m distance around the pump.

Tolerance ± 2.5 dB.

NOISE DATA TABLE MMD 2 Poles NOISE DATA TABLE MMD4 4 Poles

Model P 2 L - dB(A)*

pA Model P 2 L - dB(A)*

pA

Three phase Three phase

[HP] [kW] [HP] [kW]

MMD 65-250/22 30 22 81 MMD4 32-250/1.1 1.5 1.1

MMD 65-250/30 40 30 83 MMD4 32-250/1.5 2 1.5

MMD 65-250/37 50 37 MMD4 40-250/1.5 2 1.5 <70

MMD 80-160/11 15 11 MMD4 40-250/2.2 3 2.2

MMD 80-160/15R 20 15 80 MMD4 50-250/2.2 3 2.2

MMD 80-160/15 20 15 MMD4 50-250/3.0 4 3 72

MMD 80-200/18.5 25 18.5 MMD4 65-250/4.0 5.5 4

81 MMD4 65-250/5.5 7.5 5.5 78

MMD 80-200/22 30 22

MMD 80-200/30 40 30 MMD4 80-160/1.5 2 1.5

MMD 80-200/37 50 37 83 MMD4 80-160/2.2 3 2.2 <70

MMD 80-250/37 50 37 MMD4 80-200/3 4 3 72

MMD 100-200/22 30 22 81 MMD4 80-200/4 5.5 4

MMD 100-200/30 40 30 78

83 MMD4 80-250/5.5 7.5 5.5

MMD 100-200/37 50 37 MMD4 80-250/7.5 10 7.5 80

* Mean value of several measurements at 1 m distance around the pump. MMD4 100-200/4 5.5 4

Tolerance ± 2.5 dB. MMD4 100-200/5.5 7.5 5.5 78

MMD4 100-250/7.5 10 7.5 80

MMD4 100-250/11 15 11

MMD4 125-200/5.5 7.5 5.5 78

MMD4 125-200/7.5R 10 7.5

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

MMD4 125-200/7.5 10 7.5

MMD4 125-200/11R 15 11

MMD4 125-250/11 15 11

MMD4 125-250/15 20 15 80

MMD4 150-200/7.5 10 7.5

MMD4 150-200/11R 15 11

MMD4 150-200/11 15 11

MMD4 150-200/15 20 15

MMD4 200-250/18.5R 22 18.5

MMD4 200-250/18.5 22 18.5

MMD4 200-250/22R 30 22 81

MMD4 200-250/22 30 22

* Mean value of several measurements at 1 m distance around the pump.

Tolerance ± 2.5 dB.

Japanese Technology since 1912 217 Commercial

You might also like

- Biophysical Techniques in Photosynthesis PDFDocument424 pagesBiophysical Techniques in Photosynthesis PDFAbdelhakim HarchaouiNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ebara 3DDocument62 pagesEbara 3Dkikokiko KarimNo ratings yet

- Ebara 3M IE3 UKDocument19 pagesEbara 3M IE3 UKAfraz ShaikhNo ratings yet

- Ebara Monoblock Centrifugal Pump - Close Coupled - 3D SeriesDocument66 pagesEbara Monoblock Centrifugal Pump - Close Coupled - 3D SeriesYudha Trias RusmanaNo ratings yet

- CDX PDFDocument5 pagesCDX PDFThanhnam PhanNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3D Series: Centrifugal Pumps Close Coupled and Standardized en 733Document4 pages3D Series: Centrifugal Pumps Close Coupled and Standardized en 733نبيل عبد المجيدNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3 3LS Cat 50hz 2 Poles PDFDocument88 pages3 3LS Cat 50hz 2 Poles PDFkikokiko KarimNo ratings yet

- 3 LPF 65 PDFDocument4 pages3 LPF 65 PDFSherif AdelNo ratings yet

- Catalogo 2CDX-CDXDocument14 pagesCatalogo 2CDX-CDXEddie GuillénNo ratings yet

- MD-MMD - en - 1 - Catalogue EbaraDocument16 pagesMD-MMD - en - 1 - Catalogue EbaraNgọc Vương HồngNo ratings yet

- MD-MMD en 1Document24 pagesMD-MMD en 1Docu CenterNo ratings yet

- DWO 60 HZ: Open Impeller Centrifugal Electric PumpsDocument8 pagesDWO 60 HZ: Open Impeller Centrifugal Electric PumpsEddie GuillénNo ratings yet

- Catalogo 3DDocument36 pagesCatalogo 3DEddie GuillénNo ratings yet

- Ebara Vertical Inline Evm - EngDocument35 pagesEbara Vertical Inline Evm - EngAseem Vivek MasihNo ratings yet

- Vertical Multistage Electric Pumps: in Cast Iron, AISI 304, AISI 316Document36 pagesVertical Multistage Electric Pumps: in Cast Iron, AISI 304, AISI 316Daniel Cano BernalNo ratings yet

- 150122170134righteng1 15Document3 pages150122170134righteng1 15Docu CenterNo ratings yet

- Pompa EbaraDocument24 pagesPompa Ebaraahsan sunartoNo ratings yet

- Three-Phase Motors With Squirrel-Cage Rotor For Sea-Going VesselsDocument23 pagesThree-Phase Motors With Squirrel-Cage Rotor For Sea-Going VesselsmamontNo ratings yet

- GINO AKA Liquid Resistance Starters - ENDocument8 pagesGINO AKA Liquid Resistance Starters - ENJhonVanDiselManikNo ratings yet

- Ficha Tecnica Piloteadora Soilmec Sr-30Document8 pagesFicha Tecnica Piloteadora Soilmec Sr-30edwan lancherosNo ratings yet

- Scotch Yoke Design: Eha / Ehas High Pressure Electro-Hydraulic ActuatorsDocument24 pagesScotch Yoke Design: Eha / Ehas High Pressure Electro-Hydraulic ActuatorsfabioNo ratings yet

- T394X Doosan - TideDocument7 pagesT394X Doosan - Tideegc solutions ltda Jose ParraNo ratings yet

- 165LSDocument7 pages165LSsarokihNo ratings yet

- Se14 HC Ec 2022enDocument7 pagesSe14 HC Ec 2022engopinathdxb5No ratings yet

- Column Pumps - LowaraDocument100 pagesColumn Pumps - LowarayutNo ratings yet

- BCH-Motor-catalogue-2021Document16 pagesBCH-Motor-catalogue-2021vineetdhawan51No ratings yet

- Kh550-Apm403 enDocument4 pagesKh550-Apm403 enkunkzNo ratings yet

- SS 9022056 18330406 000Document7 pagesSS 9022056 18330406 000Shahid Raza SayedNo ratings yet

- 40 - 50 - 63kVA Spec SheetDocument4 pages40 - 50 - 63kVA Spec SheetDharmendra SharmaNo ratings yet

- AI Power: Diesel Generator Data SheetDocument4 pagesAI Power: Diesel Generator Data SheetAlbertoNo ratings yet

- EM-PME375-T200: Electric Machine, Permanent Magnet ExternalDocument5 pagesEM-PME375-T200: Electric Machine, Permanent Magnet ExternalÖzgür AkayNo ratings yet

- BG Selfpriming PumpDocument16 pagesBG Selfpriming PumpPremjith SudhakaranNo ratings yet

- Wilo Sub TWI Borehole Data SheetDocument8 pagesWilo Sub TWI Borehole Data Sheetniqo hamamNo ratings yet

- WEG Explosion Proof Motors Usep1027 Brochure English DC PDFDocument4 pagesWEG Explosion Proof Motors Usep1027 Brochure English DC PDFWilliam ChangNo ratings yet

- AdorDocument28 pagesAdorAnupamNo ratings yet

- 5.0 - en-US - 2019-01 - TS - Flygt 3202Document60 pages5.0 - en-US - 2019-01 - TS - Flygt 3202FedeNo ratings yet

- Diesel Generator Data Sheet: Power by Cummins Model: AC45Document4 pagesDiesel Generator Data Sheet: Power by Cummins Model: AC45serge misseyNo ratings yet

- Pipeliner Mps 4000Document4 pagesPipeliner Mps 4000COOKEY ABINYE EUGENENo ratings yet

- Standby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetDocument6 pagesStandby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetRainier AyapNo ratings yet

- Specifications: SS-8427703-18321430-000 SS Page 1 of 8Document8 pagesSpecifications: SS-8427703-18321430-000 SS Page 1 of 8أكرم المشايNo ratings yet

- SS 8428241 18321430 000Document8 pagesSS 8428241 18321430 000Văn AnNo ratings yet

- SS-8003897-1000006023-001 SS Page 1 of 6Document6 pagesSS-8003897-1000006023-001 SS Page 1 of 6Emanuel CondeNo ratings yet

- Booster Pump Unit Epower: Centrifugal Electric Pumps Standardised in Compliance With en 733 (EX DIN 24255)Document1 pageBooster Pump Unit Epower: Centrifugal Electric Pumps Standardised in Compliance With en 733 (EX DIN 24255)Vu DangNo ratings yet

- Cat 3406Document8 pagesCat 3406Dir Sales100% (1)

- 40 - 50 - 63kVA Spec SheetDocument4 pages40 - 50 - 63kVA Spec SheetMaynard Joshua CorpuzNo ratings yet

- Att at&CT CatalogueDocument11 pagesAtt at&CT CatalogueJohn Renzel Rivera IIINo ratings yet

- + BARTH GMBH GINO Liquid Motor StartersDocument2 pages+ BARTH GMBH GINO Liquid Motor StartersRandy FajardoNo ratings yet

- 6.0 - en-US - 2019-01 - TS - Flygt 3171Document48 pages6.0 - en-US - 2019-01 - TS - Flygt 3171FedeNo ratings yet

- AI Power: Diesel Generator Data SheetDocument4 pagesAI Power: Diesel Generator Data Sheetnacho100% (1)

- Electrical MotorsDocument108 pagesElectrical MotorsRoy Vergara100% (1)

- Ficha Tecnica Maquina Soldar Miller Big Blue 700 Duo Pro CoDocument8 pagesFicha Tecnica Maquina Soldar Miller Big Blue 700 Duo Pro CoGomez Arturo JorgeNo ratings yet

- CP-Series 10-12Document2 pagesCP-Series 10-12Diego Alejandro Villarejo EscobarNo ratings yet

- Ebara EvmDocument29 pagesEbara EvmnorsahiramaslazimNo ratings yet

- Bomba Evm Catalogos PDFDocument4 pagesBomba Evm Catalogos PDFdamc321No ratings yet

- Bomba Evm Catalogos PDFDocument4 pagesBomba Evm Catalogos PDFdamc321No ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Bulan Downtime Durasi TanggalDocument1 pageBulan Downtime Durasi TanggalManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Spesifikasi Pompa Pond & WWTPDocument4 pagesSpesifikasi Pompa Pond & WWTPManekGorisNo ratings yet

- Micro Schedule 2010.rev3Document5 pagesMicro Schedule 2010.rev3ManekGoris100% (1)

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Compile ScheduleDocument68 pagesCompile ScheduleManekGorisNo ratings yet

- Plan Bricking 2010 New Rev.2Document14 pagesPlan Bricking 2010 New Rev.2ManekGoris100% (1)

- Kebutuhan Flow MeterDocument2 pagesKebutuhan Flow MeterManekGorisNo ratings yet

- Cement MIll Flow SheetDocument2 pagesCement MIll Flow SheetManekGorisNo ratings yet

- Diameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SDocument1 pageDiameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SManekGorisNo ratings yet

- Max. Condensing Operating Condition in SummerDocument1 pageMax. Condensing Operating Condition in SummerManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- (Qfxxnknhfynts 5M XNHFQ 5wtujwynjxDocument1 page(Qfxxnknhfynts 5M XNHFQ 5wtujwynjxManekGorisNo ratings yet

- Grate Plate Cooler101215Document4 pagesGrate Plate Cooler101215ManekGorisNo ratings yet

- Manufacturing Workforce Training Production: Operation Area(s) : Category: Module/Sub-Module: Presentation Name: DateDocument28 pagesManufacturing Workforce Training Production: Operation Area(s) : Category: Module/Sub-Module: Presentation Name: DateManekGorisNo ratings yet

- Kebutuhan Panas Cement Mill (1) 1Document3 pagesKebutuhan Panas Cement Mill (1) 1ManekGorisNo ratings yet

- 15, Health, Safety & SecurityDocument25 pages15, Health, Safety & SecurityManekGorisNo ratings yet

- Trend Operasi & Foto Kondisi Grinding Ball Chamber 1 Cement MillDocument2 pagesTrend Operasi & Foto Kondisi Grinding Ball Chamber 1 Cement MillManekGorisNo ratings yet

- Hole Point Measurement DuctDocument1 pageHole Point Measurement DuctManekGorisNo ratings yet

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDocument23 pagesPhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Cement Plant InvestmentDocument12 pagesCement Plant InvestmentManekGorisNo ratings yet

- Skema CF SiloDocument4 pagesSkema CF SiloManekGorisNo ratings yet

- 2 High Alumina BricksDocument25 pages2 High Alumina BricksManekGoris0% (1)

- The Siam Refractory Industry Co., LTDDocument4 pagesThe Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Vignan'S Institute of Information Technology:: Visakhapatnam Department of Electronics & Communication EngineeringDocument94 pagesVignan'S Institute of Information Technology:: Visakhapatnam Department of Electronics & Communication Engineeringsonyprasanna416No ratings yet

- Solucionario Fisica Universitaria Volumen 2 Sears 11 Ed PDFDocument448 pagesSolucionario Fisica Universitaria Volumen 2 Sears 11 Ed PDFAlison Dayana RubioNo ratings yet

- Module 3 - 1Document26 pagesModule 3 - 1Biswajit LME016100% (1)

- H-1000 Fuel Cell Stack: User ManualDocument35 pagesH-1000 Fuel Cell Stack: User Manualabraham_dqhausNo ratings yet

- Chapter 2Document28 pagesChapter 2Keantai RinaNo ratings yet

- Worksheet (1) : Scholastic Year: 2021/ 2022 Subject: PhysicsDocument5 pagesWorksheet (1) : Scholastic Year: 2021/ 2022 Subject: PhysicsZuhair GamingNo ratings yet

- Aa 324-EnDocument3 pagesAa 324-EnManiNo ratings yet

- Homogenous Coordinate System: Unit 1Document52 pagesHomogenous Coordinate System: Unit 1Sanand MishraNo ratings yet

- Shemsedin Abdella 1471-14 Dynamics IndividualDocument13 pagesShemsedin Abdella 1471-14 Dynamics IndividualmacNo ratings yet

- IL300 AppNoteDocument21 pagesIL300 AppNoteVarun RajaranganNo ratings yet

- Fluid Properties - Density & Surface TensionDocument14 pagesFluid Properties - Density & Surface TensionStephen Mirdo100% (2)

- S&P+Safe Worksheet PDFDocument4 pagesS&P+Safe Worksheet PDFroxaskullNo ratings yet

- Classproblem2 PDFDocument2 pagesClassproblem2 PDFankiosaNo ratings yet

- Week 8 Momentum, Impulse, and CollisionsDocument19 pagesWeek 8 Momentum, Impulse, and Collisionsllanosangela094No ratings yet

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocument4 pagesNcma Tek: Segmental Retaining Wall Units TEK 2-4BjerryNo ratings yet

- Wind Energy: Wilson P. Oro Jasper Llaneta Royce Vince NazDocument16 pagesWind Energy: Wilson P. Oro Jasper Llaneta Royce Vince Nazyeah yeahNo ratings yet

- A Formula For Resistance of Substation GDocument8 pagesA Formula For Resistance of Substation GJoseph CeaNo ratings yet

- 3101 Mathematics Paper With Answer EveningDocument5 pages3101 Mathematics Paper With Answer EveningSaurabh ChatterjeeNo ratings yet

- Response Spectrum Analysis of Structures Subjected To Seismic ActionsDocument19 pagesResponse Spectrum Analysis of Structures Subjected To Seismic ActionsRamanathan GnanasambandamNo ratings yet

- Zinc and Copper SulphateDocument1 pageZinc and Copper Sulphatenewacademy234100% (2)

- Rayleigh-Lamb PDF Rev2Document6 pagesRayleigh-Lamb PDF Rev2Ben DanielsNo ratings yet

- Composite Materials Manufacturing CostsDocument90 pagesComposite Materials Manufacturing CostsÁlvaro MejíaNo ratings yet

- Enthusiast Score-I 2021-22Document1 pageEnthusiast Score-I 2021-22Roshan MNo ratings yet

- Materials System SpecificationDocument22 pagesMaterials System SpecificationMudabbir HussainNo ratings yet

- 202me472 Oh 6Document63 pages202me472 Oh 6Hussain Al-DawoodNo ratings yet

- Unit 2 Riveted JointDocument21 pagesUnit 2 Riveted Jointaditya.1540011No ratings yet

- Annealing FundamentalsDocument41 pagesAnnealing FundamentalsSuvro ChakrabortyNo ratings yet

- Waves Virtual Lab en Ingles PDF Waves WavelengthDocument1 pageWaves Virtual Lab en Ingles PDF Waves WavelengthidrispinchonNo ratings yet

- Yoon 2015Document13 pagesYoon 2015ashish mishraNo ratings yet