Ncma Tek: Segmental Retaining Wall Units TEK 2-4B

Ncma Tek: Segmental Retaining Wall Units TEK 2-4B

Uploaded by

jerryCopyright:

Available Formats

Ncma Tek: Segmental Retaining Wall Units TEK 2-4B

Ncma Tek: Segmental Retaining Wall Units TEK 2-4B

Uploaded by

jerryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ncma Tek: Segmental Retaining Wall Units TEK 2-4B

Ncma Tek: Segmental Retaining Wall Units TEK 2-4B

Uploaded by

jerryCopyright:

Available Formats

NCMA TEK

National Concrete Masonry Association

an information series from the national authority on concrete masonry technology

SEGMENTAL RETAINING WALL UNITS TEK 2-4B

Unit Properties (2008)

Keywords: absorption, architectural units, compressive

strength, coupon testing, dimensions, durability, erosion

control, retaining wall, segmental retaining wall, specifica-

tions, testing

INTRODUCTION

Mortarless segmental retaining walls are a natural enhance- A variety of surface textures and features are available,

ment to a variety of landscape projects. Applications range from including split faced, stone faced, and molded face units, any

8 in. (204 mm) high terraces for erosion control to retaining one of which may be scored, ribbed, or colored to fit any project

walls 20 ft (6.1 m) or more in height. The individual concrete application. Construction of segmental retaining walls does not

units can be installed to virtually any straight or curved plan require heavy equipment access, nor does the system require

imaginable. special construction skills to erect. Manufactured concrete

Segmental retaining walls are used to stabilize cuts and fills retaining wall units weigh approximately 30 to 100 lb (14 to

adjacent to highways, driveways, buildings, patios and parking 45 kg) each and are placed by hand on a level or sloped gravel

lots, and numerous other applications. Segmental retaining bed. Successive courses are stacked dry on the course below

walls replace treated wood, cast-in-place concrete, steel, and in the architectural pattern desired. Mechanical interlocking

other retaining wall systems because they are durable, easier and/or frictional shear strength between courses resists lateral

and quicker to install, and blend naturally with the surrounding soil pressure. In low-height walls, overturning forces due to

environment. Concrete units resist deterioration when exposed soil pressure are resisted by the weight of the units, sometimes

to the elements without addition of toxic additives which can aided by an incline toward the retained soil. Higher walls resist

threaten the environment. lateral soil pressures by inclining the wall toward the retained

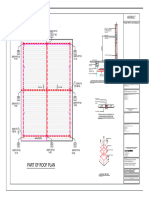

Shoreline erosion control Terracing

Figure 1—Examples of Segmental Retaining Wall Installations

TEK 2-4B © 2008 National Concrete Masonry Association (replaces TEK 2-4A)

earth, or by other methods such as anchoring to geosynthetic during transportation, the weight of the units above them in the

reinforcement embedded in the soil. Further information on wall, nonuniform distribution of loads between units, and the

the design of segmental retaining walls can be found in Design tensile stresses imposed as a result of typical wall settlement.

Manual for Segmental Retaining Walls (ref. 1) and Segmental Segmental retaining wall units will not fail in service due to

Retaining Wall Drainage Manual (ref. 2). compressive forces since axial loads are only a result of self-

Segmental retaining wall units are factory manufactured weight. Due to the direct relationship between compressive

to quality standards in accordance with ASTM C 1372, Stan- strength and tensile strength, this minimum requirement is

dard Specification for Segmental Retaining Wall Units (ref. 3). used to ensure overall performance.

These requirements are intended to assure lasting performance, Compressive strength testing of full size units is impractical

little or no maintenance, structural integrity, and continued due to the large size and/or unusual shape of some segmental

aesthetic value. retaining wall units. Therefore, compressive strength of these

Segmental retaining wall units complying with the re- units is determined from testing coupons cut from the units.

quirements of ASTM C 1372 have been successfully used The results of tests on these smaller coupons will typically

and have demonstrated good field performance. Segmental yield lower strengths than if the larger, full-size specimen were

retaining wall units currently being supplied to the market tested. The reason for the difference is size and aspect ratio.

should be produced in accordance with this standard so that However, it is important to keep in mind that the compression

both the purchaser and the supplier have the assurance and test is not intended to determine the load carrying capacity of

understanding of the expected level of performance of the the unit, since segmental retaining walls are not designed to

product. carry vertical structural loads. Compressive strength is used

ASTM C 1372 covers both solid and hollow units which solely to determine the quality of the concrete.

are to be installed without mortar (dry-stacked). Units are Because tested strengths are affected by size and shape

designed to interlock between courses or to use mechanical of the specimen tested, it is important that all retaining wall

devices to resist sliding due to lateral soil pressure. If particular units be tested using a similar size and shape. ASTM C 140,

features are desired, such as a specific weight classification, Standard Method of Sampling and Testing Concrete Masonry

higher compressive strength, surface texture, finish, color, or Units (ref. 5) requires that specimens cut from full-size units

other special features, they should be specified separately by for compression testing shall be a coupon with a height to

the purchaser. However, local suppliers should be consulted as thickness ratio of 2 to 1 before capping and a length to thick-

to the availability of units with such features before specifying ness ratio of 4 to 1. The coupon width is to be as close to

them. 2 in. (51 mm) as possible based on the configuration of the

unit and the capacity of the testing machine, but not less than

Materials 1.5 in. (38 mm). The preferred size is 2 x 4 x 8 in. (51 x 102

ASTM C 1372 includes requirements that define accept- x 203 mm) (width x height x length). The coupon height is

able cementitious materials, aggregates, and other constituents measured in the same direction as the unit height dimension.

used in the manufacture of concrete segmental retaining wall If these procedures are followed, the compressive strength

units. These requirements are similar to those included in of the coupon is considered to be the strength of the whole

ASTM C 90, Standard Specification for Loadbearing Concrete unit.

Masonry Units (ref. 4). Alignment of the specimen in the compression machine is

critical. Care should be taken in capping the test specimen to

Compressive Strength assure that capping surfaces are perpendicular to the vertical

Minimum compressive strength requirements for segmen- axis of the specimen.

tal retaining wall units are included in Table 1. Units meeting Saw-cutting is the required method of extracting a test

or exceeding these strengths have demonstrated the integrity specimen from a full size unit. Proper equipment and proce-

needed to resist the structural demands placed on them in dures are essential to prevent damaging the test specimen as

normal usage. These demands include impact and vibration a result of saw-cutting. Water-cooled, diamond-tipped blades

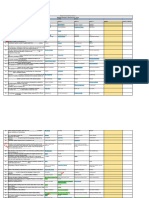

Table 1—Strength and Absorption Requirements (ref. 3)

Maximum water absorption requirements

Minimum required net lb/ft3 (kg/m3)

area compressive strength Weight classification—oven dry density of concrete

psi (MPa) lb/ft3 (kg/m3)

Lightweight Medium weight Normal weight

Average of Individual less than 105 (1680) to 125 (2000)

three units unit 105 (1680) less than 125 (2000) or more

3,000 (20.68) 2,500 (17.24) 18 (288) 15 (240) 13 (208)

on a masonry table saw are recommended. The blade should maintain vertical alignment and level of the wall. For this

have a diameter sufficient enough to make all cuts in a single reason permissible variation in dimensions is limited to not

pass. Manufacturers of the unit (or licensors of proprietary more than + 1/8 in. (3.2 mm) from the specified standard dimen-

shapes) should be consulted about recommended locations sions. Regarding dimensions, “width” refers to the horizontal

for obtaining the compression specimen. dimension of the unit measured perpendicular to the face of

the wall. “Height” refers to the vertical dimension of the

Weight Classification unit as placed in the wall. “Length” refers to the horizontal

Weight classifications for segmental retaining wall units dimension of the unit measured parallel to the running length

are defined in Table 1. The three classifications, lightweight, of the wall.

medium weight, and normal weight, are a function of the oven Dimensional tolerance requirements for width are waived

dry density of the concrete. Most segmental retaining wall for split faced and other architectural surfaces. The surface

units fall into the normal weight category. is intended to be rough to satisfy the architectural features

desired and can not be held to a specific tolerance.

Absorption

Absorption requirements are also included in Table 1. This Finish and Appearance

value is used to represent the volume of voids in a concrete Finish and appearance requirements are virtually the same

masonry unit, including voids inside the aggregate itself. The as those in ASTM C 90 for loadbearing concrete masonry

void space is measured by determining the volume of water units. Minor cracks incidental to the usual method of manu-

that can be forced into the unit under the nominal head pres- facture or minor chipping resulting from customary methods

sure that results from immersion in a tank of water. of handling in shipment and delivery, are not grounds for

Lightweight aggregates used in the production of light- rejection. Units used in exposed wall construction are not to

weight and medium weight units contain voids within the show chips or cracks or other imperfections in the exposed

aggregate itself that also fill with water during the immersion face when viewed from a distance of not less that 20 ft (6.1

test. While reduced voids indicate a desired tightly compacted m) under diffused lighting. In addition, up to five percent

unit, tightly compacted lightweight and medium weight units of a shipment are permitted to contain chips not larger than

will still have higher absorption due to the voids in the ag- 1 in. (25.4 mm) in any dimension, or cracks not wider than

gregates. For this reason the maximum allowable absorption 0.02 inches (0.5 mm) and not longer than 25% of the nominal

requirements vary according to weight classification. height of the unit.

Similar to compression testing, it generally is not practical

to test full-size retaining wall units in absorption tests due to Freeze-Thaw Durability

their size and weight. Therefore, ASTM C 140 permits the Segmental retaining wall units may be used in aggressive

testing of segments saw-cut from full-size units to determine freezing and thawing environments. However, freeze-thaw

absorption and density. Sampling location typically has little damage can occur when units are saturated with water and then

effect on tested results. undergo temperature cycles that range from above to below

Absorption limits are typically expressed as mass (weight) the freezing point of water. Freezing and thawing cycles and a

of water absorbed per concrete unit volume. This is preferred constant source of moisture must both be present for potential

to expressing by percentage which permits a denser unit to damage to occur.

absorb more water than a lighter weight unit. As previously Many variations can exist in exposure conditions, any

discussed, this relationship is opposite of the absorption char- of which may affect the freeze-thaw durability performance

acteristics of the material. of the units. Such variations include: maximum and mini-

Testing larger specimens requires particular attention to mum temperatures, rate of temperature change, duration of

drying times, because it takes a greater length of time to re- temperatures, sunlight exposure, directional facing, source

move all moisture from larger masses. ASTM C 140 requires and amount of moisture, chemical exposure, deicing material

that specimens be dried for a period of not less than 24 hours exposure, and others.

at a temperature of at least 212 °F (100 °C). The 24-hour ASTM C 1372 includes three different methods of satisfy-

time period does not start until the oven reaches the specified ing freeze-thaw durability requirements:

temperature. When placing larger specimens in an oven, it 1. proven field performance,

may take several hours for the oven to reach the prescribed 2. five specimens shall each have less than 1% weight loss

temperature. ASTM C 140 then requires that specimen weights after 100 cycles in water using ASTM C 1262 (ref. 6), or

be determined every two hours to make sure that the unit is not 3. four of five specimens shall have less than 1.5% weight

still losing water weight (maximum weight loss in two hours loss after 150 cycles in water using ASTM C 1262.

must be less than 0.2% of the previous specimen weight). Segmental retaining wall units in many areas of the country

This will require 48 hours or more for some specimens. If are not exposed to severe exposures. Therefore, the require-

not dried adequately, reported absorptions will be lower than ments above apply only to “areas where repeated freezing and

the actual value. thawing under saturated conditions occur.”

Freeze-thaw durability tests can be conducted in accor-

Permissible Variations in Dimensions dance with ASTM C 1262 using water or saline as the media.

Mortarless systems require consistent unit heights to For most applications, tests in water are considered sufficient.

If the units are to be exposed to deicing salts on a regular lot being sampled are accepted for use in the project. If the

basis, consideration should be given to performing the tests second sample fails, however, the entire lot represented by the

in saline. However, no pass/fail criteria has been adopted by sample is rejected.

ASTM for saline testing. The specification also provides guidance on responsibil-

ity for payment of the tests. Unless otherwise provided for

Compliance in the contract, the purchaser typically pays for the testing if

Guidance regarding compliance is also provided in the units pass the test. However, if the units fail the test, the

ASTM C 1372. If a sample fails, the manufacturer can then seller bears the cost of the testing. See TEK 18-10 Sampling

remove or cull units from the shipment. Then, a new sample and Testing Segmental Retaining Wall Units (ref. 7) for more

is selected by the purchaser from the remaining units of the detailed information on SRW unit sampling, testing, and ac-

shipment and tested, which is paid for by the manufacturer. ceptance.

If the second sample passes then the remaining units of the

REFERENCES

1. Design Manual for Segmental Retaining Walls, 2nd edition. National Concrete Masonry Association, 2002.

2. Segmental Retaining Wall Drainage Manual. National Concrete Masonry Association, 2002.

3. Standard Specification for Dry-Cast Segmental Retaining Wall Units, ASTM C 1372-04e2. ASTM International, 2004.

4. Standard Specification for Loadbearing Concrete Masonry Units, ASTM C 90-03. ASTM International, 2003.

5. Standard Methods of Sampling and Testing Concrete Masonry Units and Related Units, ASTM C 140-03. ASTM International,

2003.

6. Standard Test Method for Evaluating the Freeze-Thaw Durability of Manufactured Concrete Masonry Units and Related

Concrete Units, ASTM C 1262-07. ASTM International, 2007.

7. Sampling and Testing Segmental Retaining Wall Units, TEK 18-10. National Concrete Masonry Association, 2005.

Provided by:

Disclaimer: Although care has been taken to ensure the enclosed information is as accurate and complete as possible, NCMA

does not assume responsibility for errors or omissions resulting from the use of this TEK.

NATIONAL CONCRETE MASONRY ASSOCIATION To order a complete TEK Manual or TEK Index,

13750 Sunrise Valley Drive, Herndon, Virginia 20171 contact NCMA Publications (703) 713-1900

www.ncma.org

You might also like

- 2012 Standard Plans For Public Work ConstructionDocument502 pages2012 Standard Plans For Public Work ConstructionNicole Torres100% (1)

- Astm E564Document5 pagesAstm E564Julio Cesar ValdiviesoNo ratings yet

- Dry Stack Manual & Reference Tek 14-22Document6 pagesDry Stack Manual & Reference Tek 14-22rickbmayNo ratings yet

- ACI 318-56 Building Code Requirements For Reinforced ConcreteDocument39 pagesACI 318-56 Building Code Requirements For Reinforced ConcretejerryNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- ASHRAE - SystemPerformanceEvaluationDocument140 pagesASHRAE - SystemPerformanceEvaluation2742481No ratings yet

- Masonry ManualDocument114 pagesMasonry Manualdpdqh0No ratings yet

- Advantages of Steel Fibre Reinforced Con PDFDocument5 pagesAdvantages of Steel Fibre Reinforced Con PDFAce NovoNo ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemShanmuga SundaramNo ratings yet

- Textile Reinforced ConcreteDocument6 pagesTextile Reinforced ConcreteHiệpNo ratings yet

- Diaphragm Design of Metal Clad Post Framed BuildingsDocument11 pagesDiaphragm Design of Metal Clad Post Framed BuildingsjimgregsonNo ratings yet

- Ncma Tek: Density-Related Properties of Concrete Masonry Assemblies TEK 2-6Document5 pagesNcma Tek: Density-Related Properties of Concrete Masonry Assemblies TEK 2-6jerryNo ratings yet

- NCMA Astm c140 PDFDocument4 pagesNCMA Astm c140 PDFHaniAminNo ratings yet

- Studies On The Behavior of Glass Fiber Reinforced PDFDocument10 pagesStudies On The Behavior of Glass Fiber Reinforced PDFadadadadadaNo ratings yet

- Tek 10-03Document4 pagesTek 10-03Thai DamNo ratings yet

- PapeerDocument23 pagesPapeerEMANUEL 07No ratings yet

- Tek 07-01DDocument18 pagesTek 07-01DMd Rafat ArefinNo ratings yet

- Tek 07-01DDocument18 pagesTek 07-01DLionel LapuzNo ratings yet

- Uniform Section US1000 - PET Specification (IU) - 5 20 15Document11 pagesUniform Section US1000 - PET Specification (IU) - 5 20 15Felipe Strafite CusterNo ratings yet

- Beam DesignDocument33 pagesBeam DesignstructuresNo ratings yet

- Tek 07-01DDocument18 pagesTek 07-01DCarlos AlvaNo ratings yet

- Studies On The Behavior of Glass Fiber ReinforcedDocument10 pagesStudies On The Behavior of Glass Fiber ReinforcedSunidhi VermaNo ratings yet

- Chapter 1strength and Elastic Properties of ConcreteDocument40 pagesChapter 1strength and Elastic Properties of Concretesurafel shiferawNo ratings yet

- Static Load Test For Shear Resistance of Framed Walls For BuildingsDocument5 pagesStatic Load Test For Shear Resistance of Framed Walls For Buildingsmati.khan.wahidiNo ratings yet

- Buyukkaragoz20 Shear Be of Aerated Concret and Hollow Brick Walls With SFRC PanelsDocument10 pagesBuyukkaragoz20 Shear Be of Aerated Concret and Hollow Brick Walls With SFRC PanelsDaniel BarónNo ratings yet

- Ncma Tek: Empirical Design of Concrete Masonry Walls TEK 14-8ADocument6 pagesNcma Tek: Empirical Design of Concrete Masonry Walls TEK 14-8Ashamimzubery1969No ratings yet

- Concrete Ass1Document5 pagesConcrete Ass1MuhammedNo ratings yet

- Tek 14-08BDocument14 pagesTek 14-08BRaquelNo ratings yet

- Tek 10-03 PDFDocument8 pagesTek 10-03 PDFJUAN JOSE LariosNo ratings yet

- PROMATECT® H Double Layer Steel Stud PartitionsDocument14 pagesPROMATECT® H Double Layer Steel Stud PartitionsjeffNo ratings yet

- PTH Internal Partition PDFDocument17 pagesPTH Internal Partition PDFMartin KwanNo ratings yet

- Design Loadbearing Masonry StructuresDocument9 pagesDesign Loadbearing Masonry StructuresthushtikaNo ratings yet

- CMT 223 Finals Plate 1Document3 pagesCMT 223 Finals Plate 1Jhadhz Clarence DavidNo ratings yet

- C901 10Document3 pagesC901 10Lorena JimenezNo ratings yet

- Uniform Section US2000 - PET Specification (IU) - 5 20 15Document11 pagesUniform Section US2000 - PET Specification (IU) - 5 20 15Felipe Strafite CusterNo ratings yet

- Compression of GFRP Stiffened PanelsDocument7 pagesCompression of GFRP Stiffened PanelsGanesh MahidharNo ratings yet

- Promat Wall SystemDocument12 pagesPromat Wall SystemBaljit SinghNo ratings yet

- ETABS Design ProcedureDocument10 pagesETABS Design Procedureer_rahmansNo ratings yet

- PRS ReviewerDocument9 pagesPRS ReviewerRose Diana DecenaNo ratings yet

- Tek 16-04aDocument4 pagesTek 16-04akip2001No ratings yet

- Tek 14-08BDocument14 pagesTek 14-08BMuhammad ImranNo ratings yet

- Cantilever Retaining WallDocument19 pagesCantilever Retaining WallOdu Erikole50% (2)

- TEK 10-03Document8 pagesTEK 10-03Noorul RahmanNo ratings yet

- Tek 10-03Document8 pagesTek 10-03dbrown708No ratings yet

- Sismico MurosDocument8 pagesSismico MurosPauloAndresSepulvedaNo ratings yet

- Experimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)Document12 pagesExperimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)emad mohamedNo ratings yet

- Flexural Strength of Joint Reinforced Block Masonry WallsDocument12 pagesFlexural Strength of Joint Reinforced Block Masonry Wallsneve08No ratings yet

- Ncma Tek: Design of Concrete Masonry Noncomposite (Cavity) Walls TEK 16-4ADocument4 pagesNcma Tek: Design of Concrete Masonry Noncomposite (Cavity) Walls TEK 16-4AmurdicksNo ratings yet

- Ijaret 10 02 002Document8 pagesIjaret 10 02 002engahmedalemadNo ratings yet

- Retrofitting of Reinforced Concrete Column by Steel JacketingDocument5 pagesRetrofitting of Reinforced Concrete Column by Steel JacketingAhsan RafiqNo ratings yet

- Hemanth PPT NewDocument59 pagesHemanth PPT NewhemrajbmsNo ratings yet

- Tek 18-01B5 PDFDocument8 pagesTek 18-01B5 PDFMohamed HNo ratings yet

- Compresssive Strength Test Concrete Hollow Block PDFDocument8 pagesCompresssive Strength Test Concrete Hollow Block PDFMohammad Tarequl AlamNo ratings yet

- HiRib Design PrincipleDocument9 pagesHiRib Design PrinciplesanilNo ratings yet

- UniplanxDocument12 pagesUniplanxbiik0076153No ratings yet

- Behaviorand Strengthof Bearing WallDocument7 pagesBehaviorand Strengthof Bearing WallHussain AbbasNo ratings yet

- Ncma Tek: Concrete Masonry Bond Patterns TEK 14-6Document4 pagesNcma Tek: Concrete Masonry Bond Patterns TEK 14-6MarioleRouxNo ratings yet

- Hybrid Structural System (#97445) - 83516 PDFDocument15 pagesHybrid Structural System (#97445) - 83516 PDFakshaya bNo ratings yet

- Prestressed Concrete TerminologiesDocument11 pagesPrestressed Concrete Terminologieselainesiapno82No ratings yet

- Shrinkage CrackDocument9 pagesShrinkage CrackRiyaz SiddiqueNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Ncma Tek: TEK 3-1C All-Weather Concrete Masonry ConstructionDocument4 pagesNcma Tek: TEK 3-1C All-Weather Concrete Masonry ConstructionjerryNo ratings yet

- Considerations For Using Specialty Concrete Masonry Units: TEK 2-2BDocument4 pagesConsiderations For Using Specialty Concrete Masonry Units: TEK 2-2BjerryNo ratings yet

- Ncma Tek: Surface Bonded Concrete Masonry Construction TEK 3-5ADocument4 pagesNcma Tek: Surface Bonded Concrete Masonry Construction TEK 3-5AjerryNo ratings yet

- Ncma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BDocument6 pagesNcma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BjerryNo ratings yet

- Ncma Tek: Typical Sizes and Shapes of Concrete Masonry Units TEK 2-1ADocument4 pagesNcma Tek: Typical Sizes and Shapes of Concrete Masonry Units TEK 2-1AjerryNo ratings yet

- TEK 03-2A Grouting Concrete Masonry WallsDocument6 pagesTEK 03-2A Grouting Concrete Masonry WallsjerryNo ratings yet

- Ncma Tek: Architectural Concrete Masonry Units Tek 2-3ADocument4 pagesNcma Tek: Architectural Concrete Masonry Units Tek 2-3AjerryNo ratings yet

- Ncma Tek: Glossary of Concrete Masonry Terms TEK 1-4Document6 pagesNcma Tek: Glossary of Concrete Masonry Terms TEK 1-4jerryNo ratings yet

- Specification For Masonry Structures: TEK 1-2CDocument4 pagesSpecification For Masonry Structures: TEK 1-2CjerryNo ratings yet

- Astm Specifications For Concrete Masonry Units: TEK 1-1FDocument4 pagesAstm Specifications For Concrete Masonry Units: TEK 1-1FjerryNo ratings yet

- Building Code Requirements For Concrete Masonry: TEK 1-3DDocument4 pagesBuilding Code Requirements For Concrete Masonry: TEK 1-3DjerryNo ratings yet

- AISI S100-07 CommentaryDocument216 pagesAISI S100-07 CommentaryjerryNo ratings yet

- AISI S211-07 Errata PDFDocument2 pagesAISI S211-07 Errata PDFjerryNo ratings yet

- MSC Steel Interchange - Overstrength Requirement For Seismic Design of DiaphragmsDocument1 pageMSC Steel Interchange - Overstrength Requirement For Seismic Design of DiaphragmsjerryNo ratings yet

- Aci 548.3R-03Document40 pagesAci 548.3R-03jerryNo ratings yet

- Guide For Evaluation of Concrete Structures Prior To RehabilitationDocument22 pagesGuide For Evaluation of Concrete Structures Prior To RehabilitationjerryNo ratings yet

- MCQs - Question Bank - Third Year - Term I - Building Services III - 2020-21 - For Students1Document4 pagesMCQs - Question Bank - Third Year - Term I - Building Services III - 2020-21 - For Students164 MNo ratings yet

- DCC3113 - Chapter 5 PDFDocument24 pagesDCC3113 - Chapter 5 PDFXkarr Rasta100% (1)

- Fire Pump For Combined SystemDocument6 pagesFire Pump For Combined Systemgrincheu70No ratings yet

- Form Active StructureDocument8 pagesForm Active StructureShruti KhopkarNo ratings yet

- The Effective Ways of Utilization of Rice-Husk-Ash in Hot Mix AsphaltDocument6 pagesThe Effective Ways of Utilization of Rice-Husk-Ash in Hot Mix AsphaltDipendra AwasthiNo ratings yet

- Foundation Investigation ReportDocument20 pagesFoundation Investigation ReportStephen A. CuizonNo ratings yet

- FileserveDocument9 pagesFileserveThiri AungNo ratings yet

- Code Enforcement Division's: Registered ContractorsDocument44 pagesCode Enforcement Division's: Registered ContractorsMahmoud Abu Ne'maNo ratings yet

- Guide To Attic TrussesDocument4 pagesGuide To Attic Trusseschris_m_germainNo ratings yet

- Baguio Structural Estimate - Ok1Document20 pagesBaguio Structural Estimate - Ok1Jason HallNo ratings yet

- Quotation-3000 - Ethiopia Warehouse-Xgz Group-Mar.3, 2023 PDFDocument4 pagesQuotation-3000 - Ethiopia Warehouse-Xgz Group-Mar.3, 2023 PDFJohn TesfamariamNo ratings yet

- StrucTemp Brochure PDFDocument23 pagesStrucTemp Brochure PDFMinh HoangNo ratings yet

- Stairs Definition and TypesDocument2 pagesStairs Definition and TypesCj De las AlasNo ratings yet

- Rehabilitation of Damaged Concrete Structures: Peter BarlowDocument43 pagesRehabilitation of Damaged Concrete Structures: Peter Barlowdnavarrete01No ratings yet

- Viga de Concreto ACI 318-11Document144 pagesViga de Concreto ACI 318-11Luis López RodriguezNo ratings yet

- 10 Basic Exterior Design PrinciplesDocument2 pages10 Basic Exterior Design PrinciplesBintang PutraNo ratings yet

- S-002 Typ Renif DetailDocument1 pageS-002 Typ Renif DetailVirendra ChavdaNo ratings yet

- Cellular Lightweight Concrete ThesisDocument8 pagesCellular Lightweight Concrete Thesisafcmrdbef100% (2)

- Eco-Niwas Samhita (ENS) : Part 1: Building EnvelopeDocument1 pageEco-Niwas Samhita (ENS) : Part 1: Building EnvelopeJulfikar KhanNo ratings yet

- Beyond The Mud Hut - The Return of Raw-Earth Architecture - Financial Times PDFDocument7 pagesBeyond The Mud Hut - The Return of Raw-Earth Architecture - Financial Times PDFJohn SmithNo ratings yet

- HSC HPC RPC SCCDocument28 pagesHSC HPC RPC SCCapi-376659350% (2)

- FS 2017 Papers List 1Document2 pagesFS 2017 Papers List 1chetan.mundhe.jNo ratings yet

- Eternia BrochureDocument9 pagesEternia BrochureanadinathNo ratings yet

- Lightning Protection System Rolling Sphere Plan 1 - As BuiltDocument1 pageLightning Protection System Rolling Sphere Plan 1 - As BuiltravensarcillaNo ratings yet

- Beams, Design of Flanged Beams For Shear, Design For Combined and Torsion As Per IS - 456. 10 Hours L and L (Revised Bloom's Taxonomy, RBT Level)Document71 pagesBeams, Design of Flanged Beams For Shear, Design For Combined and Torsion As Per IS - 456. 10 Hours L and L (Revised Bloom's Taxonomy, RBT Level)Viji NpNo ratings yet

- Local Media8732017145129449152Document3 pagesLocal Media8732017145129449152Kent Aldwin MangalinoNo ratings yet

- Estimate 1 FinalDocument24 pagesEstimate 1 Finalselvakumar subbuNo ratings yet

- Aircraft Materials and ProcesesDocument36 pagesAircraft Materials and ProcesesWilson Mar VirayNo ratings yet